Leaderboard

Popular Content

Showing content with the highest reputation on 10/09/20 in Posts

-

2 points

-

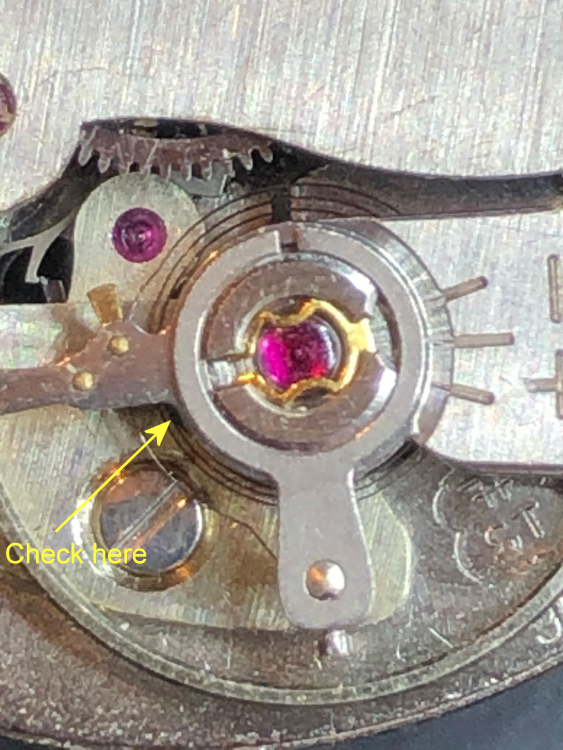

Ok, So the screwdrivers, tweezers ect arrived today. Could not wait to start! Have got a Fortis as first project, that seems to come from a lot of sparepart watches. It has the FHF 96ST movement. Looks brand new, and was sold as a non runner. It is missing the stem. And the dial looked loose. Pried up the case lid. And the movment fell out. So, I tried to wind the barrel a little with a screwdriver. No surplice there, It didn't run. After a little closer look. I saw the balance jewel is missing. Also looked like the pivot might be broken. Bit exited, I started with removing the hands. Had little trouble there. The houerhand was pried to dial face. But after a little more fiddling than expected. I got it off. For my life. I couldn't find the screws to the dial. Turns out it was glued on to the movement.. Even more intresting! But got that off too, with little "fiddling" Tried to get it running again. But noticed that the balance looked out of alignment. Time to bring out the new "chunky" Bergeon screwdrivers! (love them already) With a "some" intresting trying out different work positions, shifting between 4x and 10x loupe. Half scared to mess up the balance, possibly even more. Still exited. But with some fueling with the tweezers. Tha balance came out in one piece with the hair spring. Im not sure why its called hairspring. It sure is thinner than a hair.. After som try and tribulations with the loupe. I managed to notice that the lower pivot on the balance staff is ok. Had hard time to see if the upper pivot was existing. The hairspring is in the way. Im not sure how you guys do it? Im sure scared to mess up the hairspring! But eventually, I got a glimpse of it. Looked at the fork and timing wheel. It seemd to want to "tick". So I decided to remount the balance again. Well..That took some time. Again very fiddly! First time, I got the impulse jewel out of alignment. Took me a while to figure out. And even more time to reassemble with it in alignment. But got it there on the second try. Im not telling you about how long it took.. With everything back. I I tried to "kick" the balance. Veeerrry carefully. It wanted to go! With the missing to jewel in mind. I decided to give it "some" oil. Since it never has been up and running. It is probably very gummed up. So disassembly, cleaning and oiling have to be done anyway. So I thought it is the perfect first oiling effort, as I can clean upp my mess, anyway. Oiling. Jeez.. Those jewels is tiny!! Let say.. Comparing on what Ive seen on turitorials ect. My jewels isn't missing any lube.. But it started ticking!!! It definitely isn't strong ticking. But an houer later, writing this. It is still ticking! Mezmerasing! I call this evening a success! Some notes to self: 1. Im getting a bit shakier over the years. Loupes magnifies that too.. LOL! 2. Improve working position. Sitting on the floor isn't an option. So raising the office table some how, is needed. 3. I did like to use the loupe better without the head band. It was quicker to change between magnification. (have only 4x and 10x) 4. Amongst many other things. A microscope is now on the wishlist for the future wallet enlightener list. 4. When doing close up work. Don´t poke the nose with the screwdrivers.(unintentional, or not). The new Bergeon screwdrivers will be offended!! 5. Somehow, I need to find a correct jewel, spring ect. Find out if a jewel press is needed?. Hm. have to get a stem and crown too. 6. The only thing I got top quality tool to start with. Was the Bergeon screwdrivers. As the first set "stuff" needed. Didn't come cheap any way. But Im happy I got quality screwdrivers. So Im pondering if the wife get upset if I have them on the night table! Hm! 7. Today was a great day! lets make tomorrow even better! 8. Tomorrow is disassembly day. Remember to take maaany pictures!! 9. Get some sleep! /Johan1 point

-

I think you need to send watches to this guy. He is replacing the "compacitor" on a citizen eco drive watch. Sent from my GT-N5110 using Tapatalk1 point

-

1 point

-

I vibrate the balance completes I build , right inside the movement, Usually in two tries and despite no tg nor a vibrograph. Must be nice to have one of them vibrating tools1 point

-

Sorry, when I was writing my post the OP didn't say the make of the watch.1 point

-

technically you do not have the exact same problem because if you had the exact same problem you would have Rolex watch. It makes for a very confusing discussion if somebody posts a question that seems similar but is not it should really be in a separate question. So you have the exact same problem which is a broken balance staff and another balance that has a good hairspring so it be nice to have some pictures and let's swap those hairsprings. oh wait somebody appears to be negative? Maybe you don't have the exact same problem an unfortunate problem in modern watchmaking especially production watches are how they save money. For instance there is at least one Rolex watch that the only way you can remove the hairspring is by driving the balance staff out with special tools. As somebodies indicating Seiko has perhaps permanently attached the hairspring. Because? I know I'm being a naysayer and being negative but traditionally with the exception of American pocket watches and a few other watches hairsprings never came separate from the balance wheel. So in the case of modern manufacturing I could company like Seiko is a lot easier to make a permanent le made balance wheel than one made out of a whole bunch of little components that can be separated. although for the 7009 the balance staff is available separate which means they hairspring has to build come off it's not attached the balance arms or the balance wheel if it's a separate staff they hairspring has to come off. on the parts listing for the 6309 a is something peculiar it is listing a number for the staff but it says it's not available? Now that's not the same as where it's listed and it says it's unavailable or it's discontinued their implying that it is not available at all. That might suggest that on that watch that is an entirely and assembly of a balance complete which would make it problematic of swapping hairsprings. So were going to need pictures of your balance wheels to see what we can do to swap them.1 point

-

def. brass, looks as if it was plated and somebody tried removing it using a chemical process (acids) and tried to dry it with heat and accidentally overheated it, minerals and water can also have the same affect on brass, its highly unlikely but its the first thing that comes to mind due to the purple/blue discoloration, this is a very common problem when people try to clean empty shell casing in order re-case them and make their own ammunition. The brass is treated or heated improperly.1 point

-

1 point

-

So many possibilities! You can have hours of fun searching here: http://www.mikrolisk.de/show.php1 point

-

First of all remove the strap by retracting the small spring bars, they can be either double sprung or single check the ends, Then measure the distance between the case lugs 18mm,,,,20mm then select the type of strap required. Cousins uk do a good selection. Whether you can pick up a like for like is doubtful but you may be able to get a close match.1 point

-

Cousins also sells very small silicone-tipped devices that I now use to lift incablock circular springs (can't remember the name of them right now), and remove/replace the cap jewel from the chaton. They work very well, and are fairly inexpensive.1 point

-

Little bits of Rodico are great for handling the really small parts. Either by itself, or stuck on the end of a toothpick or other small stick of some sort.1 point

-

Well done! I got more than one Oris from eBay from India for a song. The dial was repainted, and that was the strongpoint. It, too was glued to the main plate. Yes, the parts are small, aren't they? ? It gets better when you disassemble, oil and try to put back together an incabloc assembly; the one held in place with the rotating spring. Once the spring is off, you develop an appreciation for how small things are. Once the cap jewel is removed from the ass'y, it has to be in the top 10 for smallest manual-wind movement part. If you're familiar with the game tiddly winks, that's what picking up that jewel is like. It's small to the point where one could place it in a zero from the date on an American dime, and if viewed from the side, it wouldn't protrude. I exaggerate, but that's small! You really did go big with the screwdrivers. Good luck getting that watch tip top.1 point

-

I understand ?, but this is not a beginners task. If you want real fun, wait till you have the skill, experince and tools. Else, no Rolex service center needed! It is an easy task for any watchmaker located near to you (who has a workshop!). Frank1 point

-

I think your clock would be late 20's early 30's in production Japy during that period were concentrating on making affordable clocks for the masses, there are thousand of the type of movement you have in your clock around in early 20th century French clocks, they were eventually killed off by the war and could not compete with other french manufacturers Jaz, Blangy and Duverdrey and Bloque who produced Bayard clocks.1 point

-

Considering its the same exact caliber and not a real old movement, it will vibrate, however, all I see in images google brought me are anulare wheels, that means you will need to remove material to poise and achieve the percision expected of Rolex. Overall, I wouldn't go for it.1 point

-

1 point

-

Hej och välkommen Johan! Kul med ytterligare en landsman! During my first service attempt some years ago I decided to invest in an inexpensive Chinese stereo microscope from eBay (you can read about it here) and I still consider it my most important tool alongside my tweezers, screwdrivers, and oilers. Using the scope I can see exactly what's going on, what I'm doing and the result of it and it's just invaluable. I just couldn't do without it.1 point

-

Thanks for the quick response, Mark! And yes, this was concerning Tapatalk. When I started using my Ipad for WRT this app seemed to be the best option but things change... Good to hear that the browser version works fine and will continue that way.1 point

-

Hey guys long time just wanted to share some finding with you, I have been searching for a way to clean vintage watch lume, particularly in Seiko's which seems to be one of the top brands where collectors look for clean original lume. Esp when it comes to the 6105's, re-lumes kill the value of these, an old moldy patina lume is better than a re-lume, but is obviously not as good as nice clean white lume. These pull in prices that go for about double the cost of an original moldy lumed one. SO i picked up an all original 72' 6105 very clean, except for dial it wasnt that bad really but one of the markers was a coffee color much darker than the other which where like a nice off white cream color, some tiny black mold spots. it was really getting on my nerves so as usual i did my research again and find out that every forum post and every person i spoke said the only thing you can do is re-lume? now i have seen pros like spencer klein clean up lume without reluming but he always skips that part in his videos, a master will never reveal his secrets....so i did something i wanted to do for a very long time but was always afraid to do.........I used bleach, YES BLEACH! Now, this will only work on water based lume, and it does NOT dissolve it any way......you must must be very careful to only get it on the lume and NOT on the dial. I have tried it on many scrap dials and what i found is it wont affect metal dials much but it will affect matte dials, black dials, and dials with any kind of paint. I used a tiny cotton swap used for car touch paint for chips and i soaked in 3/1 or even 2/1 water/bleach solution. i made sure to remove excess and then i would carefully dab the lume plots until i can see it has been absorbed. In some cases i put a tiny bead of the solution on top of the plot and leave it for about 30 min. then soak it back up. This will require more than one application depending on how dark the lume is. I also used a dry swab and gently wiped the top of the lume plot and this removed almost all of the black mold. I went from cream/coffee color to an off white....i am trying to post photos but i cant for some reason...i didnt have a before picture but i will be doing a few more soon on a 6309 dial i will post the before and afters.1 point

-

I was toying with the idea of using small concave glass lenses. Something like these. https://www.ebay.co.uk/sch/i.html?_from=R40&_trksid=p2334524.m570.l1313&_nkw=pcs+8mm+Glass+Optical+Lens+Double+Concave+Beam+Expander+for+532nm+Green+Lasers&_sacat=0&LH_TitleDesc=0&_sop=15&_osacat=0&_odkw=5pcs+8mm+Glass+Optical+Lens+Double+Concave+Beam+Expander+for+532nm+Green+Lasers1 point

-

Yes got a PACE MBT station. But the board is just too delicate to heat it up i am afraid it will bulge and also too close to the crystal. Just did low temp iron, wick and lots of patience. Apart from the IC all the other components are discreet components and they all tested fine. With the new boards that will arrive will be great to see it and I will also make some charts of the signals to share. Had some experiments with glass bead blasting at low PSI. looks really nice.1 point

-

I had to post this. Absolutely looks like it's out of Dr. Frankenstein's watch lab. https://www.ebay.com/itm/Vinetage-Watch-Case-Opeaner/293489561319?hash=item4455574ee7:g:WlAAAOSwnIZeUo4N1 point

-

1 point

-

The springs used to come in a pack of three. With the help of your book you will be able to get the right length of the spring and the blocks and the position of the fork for the pallets.1 point

-

1 point

-

I like that idea. I also discovered that EB8800 hands should fit the Ronda 1239-21 (the seconds may be a bit of a squeeze) so I might have some luck with that idea too.1 point

-

I ordered the one suggested by Cas-Ker. I didn't order it before because it had a tongue end and I needed a hole end. If you say it will work I'll try it. Thanks for every ones help.1 point

-

1 point

-

So, I've debated sharing the proof of concept picture below, as it's with an imperfect fordite dial slice and the fordite itself hadn't been polished. It's not even a particularly compelling cut of fordite; I'm going to be selecting the most visually appealing dial veneers I can. The failure rate of the section cuts is quite low (the material is really easy to work with, and stronger than it looks), so I can afford to be selective in my dials. This was one of my first attempts at a complete dial. The problem here is that I didn't start with a perfectly flat and even piece of fordite -- after gluing it to the brass dial, my total dial height ranged between 1.05 and 0.95mm. I ground this down by hand using 400 grit sandpaper, but inadvertently exposed brass on the dial underneath the fordite in doing so. Starting with a thinner, perfectly even disc of fordite will prevent this from happening in the future. The new larger saw blade should be arriving in a couple of days, and I'll do some more cutting ASAP. Here, I also glued the fordite with G-S Hypo jeweler's cement, which may have encouraged the thin parts of my fordite veneer to peel if the adhesive wasn't even in spots. My next attempts are going to use a very thin layer of 330 epoxy instead, which I've "thinned" by heating before mixing. So, this picture is not a good end product. As proof of concept and feasibility, however, I'm really proud of this picture. Total dial height here was 0.5mm, not the 0.4mm I'm shooting for. Despite that, the hands cleared everything quite well. I will say that the case I'm using does have a protruding tube -- the stock dial for this case has a very small notch cut out of it to accommodate the tube. The brass dial blanks I'm using *dont* have this cutout, so I'm going to need to file one in future attempts. It's going to take a lot more work to get everything to the point where I'm satisfied, but I'm confident that I can pull this off based on last night's progress. Also, I'm committed to sharing my techniques and process openly. So it's honest to show failures, even if they're embarrassing. Finally, I scanned another piece of fordite. I'm sharing it not because it's particularly interesting visually, but because it shows the colors embedded in the "Jeep / Dodge" fordite I'm using. I love the metallics!1 point

-

I've been able to get this spring back in place. The Bergeon Novodiac spring tools I mentioned above was very useful for this. This tool, and a sharpened bit of peg wood to press the spring into its seating slot make short work of these strange springs. Here's the tool itself: https://www.esslinger.com/bergeon-31081-novodiac-shock-spring-tool-for-eta-2801/ Here's a video from another watchmaker who deals with this kind of spring by creating his own tool from a q-tip: I've got a 2209 movement up and running now. Still more work to be done before it is finished, but making good progress considering it was built from parts taken from scrap movements.1 point

-

You might break all the rules as long as the outcome is alright. No pegwood neither any tool has a feel to it like your hand and fingers do. If you have surgical gloves to wear, then by all means do, if not fine. Hold the movement in your hand if you like, you might place two prongs in the groove and turn to get the third one in, hold the spring down by laying a safety razor blade on it or anything flat you feel comfortable to use, just get the shock spring in the groove however you can and messy it may sound or get, then rinse the mainplate with jewels and spring installed. use of a soft brush on the mainplate or the cock ( with jewel assembly installed) when submerged in lighter fluid is alright, blow dry with hairdryer, when you rinse after installing jewel assemblies , you have done a much neater job than the guy in the vid , then lube. As you get more confident by practicing and doing more movements, you find funny your words that you just can't do it. Good luck pal.1 point

-

As you're new to watch repair I will start off with the basics. The basics are people new to watch repair look for problems were they don't exist in other words it's usually the simple things it's usually the basic things but those are not the things you're ever going to see. Then changing components doesn't always have the desired effect of improving things. Unfortunately if you mutilate the balance wheel you have to change that. But changing components has consequences unless the watches super new were manufacturing skills are almost perfect and you can swap with usually zero problems. Soon always empty careful in changing components as you can introduce new problems. Then the mainspring yes the white springs can be stronger than the blue Springs but it usually isn't a consequence. It's a much bigger problem in American pocket watches where once you might have five different sizes and now you just have one and it's probably too strong but even there it usually isn't a problem most of the time.. I snipped out a section of the mainspring catalog to the sizes listed agree with the size the mainspring you put in? Where exactly did you purchase your new old stock balance wheel? Then unfortunately I don't have a cross reference to the number you have plus if it's a different size it's not the balance wheel for your watch. As the diameter is wrong I don't suppose the roller parts are wrong in size also? Like the safety roller the roller table the roller jewel are they physically different? Also it be really nice if you could get a close-up picture of the balance wheel in the watch for us preferably one looking straight down and one looking sideways. Along the lines of basic problems balance wheels fall under that category it is really easy to do things undesirable here and it is exceedingly hard to see those things by just about everyone on this group.. It's one place where you have to really really pay attention because there's a lot of faults that are very bad under very hard to see. If your balance wheels physically smaller is the hairspring physically smaller? Visually when you look at your balance wheel in the watch does they hairspring appear to be centered, is they hairspring going to the regulator pins is it flat is it touching anything it's not supposed to. If they hairspring is physically smaller you going to have issues with it being where it's supposed to be for the regulator pins you're going to have issues. One of the things nice to do with incoming watches is to attempt to determine why it's not running. As opposed to assuming that cleaning will fix all problems because many times there were pre-existing conditions as to why the watch wasn't running and cleaning doesn't necessarily fix those problems. Then a new updated picture of the timing machine where it's showing you nothing that's because the timing machine is trying to reach out and communicate with you unfortunately it does not have artificial intelligence to do that correctly. The same as your original pictures you need to visually verify that whatever the machine is telling you the watch appears to be doing the same thing.. So if the amplitude looks like it's super superhigh visually it should look like at superhigh. Occasionally it's more common problem with Chinese machines but it will happen to all timing machines if the amplitude is super low for instance it won't numerically look to be super high. This is where missing features from the Chinese machine would be helpful if we had such as the oscilloscope where you can look at the waveform and see where the timing machine is attempting to pick up the signal. Because oftentimes you'll find is looking at the wrong part of the waveform so if your timing machine says you're doing 300° that balance wheel better look like it's doing 300° otherwise you have a problem.. So the basics would be let the power off get us some photographs.. Visually verify the watches in beat. Look carefully at the hairspring if necessary look at another watch or look at several watches as I said it is really really hard to tell if they hairspring is flat and where it's supposed to Be. Then one little warning about stock? Typically and watch repair especially if you buy from eBay if the package has been opened there is no guarantee that at actually is new old stock despite what the seller might think.. It's a common practice of watch repair people to put the old part back into the package so any opened packages should always be suspected that they're not correct.. Unfortunately this also does not apply to watch repair there's been other things I purchased off of eBay that were listed as new old stock and they were definitely not because the seller wasn't paying attention in my case I wasn't paying attention to the photos either I took them at their word.1 point

-

Not some actual "hands on" progress on the movment today. But some more good info collected! Found this! It certainly clears a few things for me. So it is the same movment as the FHF 96. So I think I let it in this thread. For future rerference on this movment. Hopefully it helps some more ppl. (hope it is ok to share this) Another pleasant news. Is HSL has offered to donate a spare movment. Im humbled of his offer. I offered to pay something for it. But he galantly refuse! Thank you HSL. It will defenetly help my skills move forward!1 point

-

I see you might have been at Tradera and looked for treasures. That glue what looks like the Swedish specialty "Karlssons klister" might be tough to get off but a good rub with pure acetone on a cotton Topps would do it. Since the dial lacks feet you shouldn't glue it back on, I recommend you begin with dial feet stickers and take it from there, when you get a bit experienced swap them to dial feet’s. Unfortunately I don’t have that kind of cap jewels for the FHF (ST) 96 at home, if you don't find it I have a replacement movement which I can donate for free. Just pop me a PM.1 point

.thumb.jpg.34a18c413397c74bc35e1b8743539a58.jpg)

(Large).thumb.jpg.b068ca0747bf62ec1bf8d11c583fe836.jpg)