Leaderboard

Popular Content

Showing content with the highest reputation on 08/26/20 in all areas

-

It's time for me to give back.. these are not expensive items but it takes time to picture and ship, give with the sincere hope of helping, Offer is for old and new members worldwide, I reserve the right to not send to opportunists. Unless noted I will send one item per person Small countersunk screws, polished, Ø available 40, 45, 50, 55, 60, 65. Beginner's polishing compunds assortement. Includes one slice per type. More items to come as time permits.4 points

-

Supergluing a large steel nut to the caseback will give you much more to grab hold of. You can dissolve the superglue back off with acetone, but don't get that on the crystal as it will cause damage. Also the superglue will typically fail before the watch case gets damaged if you start to go full gorilla on it. Boiling a watch sounds like a good way to make watch soup, but a very bad way to start servicing it.3 points

-

Hi If all other avenues end up in a blind alley and the only recourse is to open the case your self I would suggest heating up the case back in order to soften the gasket. use either a hot air gun (as used for heat shrink) or a large soldering iron to keep the heat as local as possible (confined to the case back). This of course is a last resort. One might consider immersing the watch in a shallow dish of spirit, enough to reach the case back seal and allow the spirit to soften the gasket. It looks a beauty of a watch so be careful and no brute force whatsoever.3 points

-

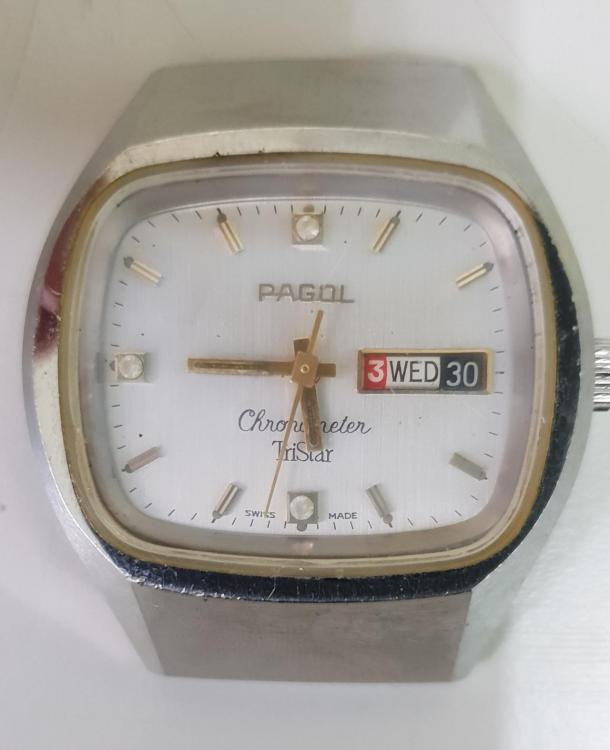

Here is a watch that belonged to my late father. It was never serviced before. The caseback was so tight that it broke the jaw of my mentor's bench mounted caseback opener. We sprayed WD40, we heated it with a microtorch, we dripped acetone into the threads, we superglued a nut to the back... We didn't just go full gorilla on it. We went all out King Kong! It still wouldn't budge. In the end, I used 5 ton epoxy and glued a really big nut to the caseback, mounted my caseback holder to my bench vise and used a 15" wrench on it. Finally it opened. Broke my caseback holder in the process.2 points

-

Given the right tool, it will open, no heat, no boiling .......2 points

-

What has happened is the case back gaskets has sort of disintegrated and turned into tar like substance. It holds the case back on really really tight. What you need is somebody who has a case back opener like the one below. What makes this holder interesting is you can hold the movement very securely in the vice. You change the jaws to the flat ones as you basically Have flat sides to grab. The lower it down and as the video shows you can move the or spin the locking ring which locks it in place. That means everything is Held really really secure and then you put a heck of a lot of pressure on the handles and if you're lucky the case back will start to rotate. As soon as it rotates a little bit then you twist the locking ring a little to release it and slowly can Remove the back. Sometimes though you might have to put a penetrating oil on the edge hoping that that might make things better. Others in the past in this group have suggested things like gluing or epoxy glue something I a really big not and using a suitable ranch. https://www.nielsmachines.com/en/precista-generic-bench-top-watch-case-opener.html2 points

-

I don't suppose we can get a picture of the back of the watch?2 points

-

While i certainly don't know everything... I've never heard of a deteriorated caseback gasket causing that much trouble, i struggle to imagine it could. Also never heard of the technique of 'boiling a watch case back off' that sounds kind of... completely insane. Not to challenge their expertise, this may just be a case of "make something up that sounds convincing" because the truth is either too complicated or awkward to explain. I don't know what to suggest than to keep looking around for other good repairers, I doubt this watch is impossible to open.2 points

-

Hi everyone, just a quick intro from me, I'm retired living on the Lincolnshire coast in the UK and with all this spare time on my hands have decided to try repairing some watches I've found in a drawer. Nothing vintage or classic and only basic repairs but you have to start somewhere!1 point

-

1 point

-

Just for the record, Chinese (Seagull) only make one true tourbillon caliber, it costs like $3,000 but nobody buys it. The others are "open heart" movement where the balance is visible from the dial side, not sure who these can actually impress.1 point

-

1 point

-

Thanks - yes, I let the power down and I can see the impulse jewel between the horns. I'll try the other steps and let you know the result. The NOS balance was packaged in some cotton wool so it's possible there is a hair stuck on there.1 point

-

1 point

-

1 point

-

Brass tweezers arrived today. As you all said, much easier to handle magnetic parts with. About 20 minutes later I have the train back under its bridge and working. Next challenge is to repeat the task! Going to try with a magnet under the watch to try and keep all the magnetic parts down.1 point

-

Did you release all power reserve to observe impulse pin in the fork horn? Mark the third wheel with ink, to observe if there is a pattern in the stoppage. Perhaps tiny hair rubbing on escape wheel or balabce rim. Bad escape teeth or pinion.1 point

-

That is a lot of money for servicing that kind of watch and not even being able to open it. Take it back and give it to someone else. BTW I am also of the party that uses the right die is possible at all. No problem applying a bit of heath all around with a 65W soldering iron.1 point

-

Superglue is probably safer than epoxy, but when things get really stuck, epoxy is an option. You may need to use a lot of heat on the caseback to remove epoxy though, or in some cases you can dissolve the epoxy with an aggressive solvent like MEK. Epoxy is not easily dissolved in the way that cyanoacrylate (superglue) is. Glue the nut on so that it is concentric with the case back. I've done this a number of times with a good rate of success. I have also encountered front loading cases with backs that appear to unscrew, but in fact do not. Check with a microsope to ensure there is actually a break between the front and the back, and that they are not actually case as one piece.1 point

-

Hi Check this out, Its about removing a glued in crystal, but the methodology may well be applied ti your problem with the "glued" on back. https://blog.esslinger.com/watch-crystal-3/ cheers1 point

-

Hi I would be surprised if a high end watchmaker repairer had not got access to the proper tools, So it may be it too much trouble. Be interested in the outcome. good luck with the problem. cheers1 point

-

I smell BS here, maybe he works on such high end watches and probably can't justify the time to work on a simple watch? Think about it, a service of a higher end watch (tourbillon) would be into four figures so this would be an hourly rate of close to 200USD? I would try another watchmaker. Anyway if you have a problem send it in to Mark, the owner of this forum..might be the subject of another video!. Anilv1 point

-

1 point

-

1 point

-

1 point

-

Today, a watch from my past. A Casio Ana-digi AQ-321 from some time after 1983. Back when the world was young, and so was I, I often repaired "stuff", which had hazardous voltages, and I was in the habit of taking off my watch and popping it in my tool kit, or jacket pocket or indeed anywhere that it wasn't likely to snag on something and get me zapped. This is a habit I still adhere to. Today I was out in the shed where my lawnmower lives, rummaging through a bunch of stuff looking for a screw driver, to take the air filter off the mower, when I came across a watch I thought I had lost years ago, most probably left at a customers site. It was sitting in the bottom of one of my old tool boxes. Naturally the battery was flat, but other than that and a few minor wear scratches, it has no issues. This watch has probably spent at least 15 years sitting in various sheds and out houses, with winter temperatures that can get pretty darned cold (-10C is not unheard of round here, and at least one winter in the last ten got down to -16C). The battery hadn't leaked and the LCD hadn't burst. There is no mould or other damage. I even remember buying the thing in a Jewellers shop in Falkirk. qw305.pdf1 point

-

I don’t find any questions ignorant I just assume everyone is on this site to learn just like me. There is nothing digital about these 70’s watches in the sense there would be some electronics working with some binary logics. The digital is just a play with words which refers to the fact it lac the ordinary hands to show the time. Instead the disks will in a snappy way show the time with the hour disk and the minutes disc. There were some versions with a second’s disc like the one in the picture which somehow took the digital illusion away in a sense since the seconds is “floating”. But these movements always are stamped with a D which indicates they are prepared for this disc style time visualization. The disc under the hood this is one I'm working on now. The caliber with a D added.1 point

-

hi guys ,here another early manuel http://www.bestoftimeswatch.com/uploads/1/0/9/3/109363525/l_r.pdf1 point

-

I have seem the issue where the outer edge of the spring slips against the barrel. It could be either the tails or the small dibble that catches the tail is worn. Either way this not an easy fix since it requires a full tear down and rebuild. So what to do about the required parts? Buy a lot of 'fixer uppers' or 'spares repairs' as they say across the pond. What happens as a result of this of course is now you will want to repair them all. BTW: The watch shown is a European model from what is commonly named the "Sports Series". This is distinguished by the use of Meters rather than Feet printed on the dial. Need a NOS mainspring and barrel? I have them but shipping cost more than the part.1 point

-

Hi just a thought you could try second user dealers such as speedtimerkollection (europe) obsoletewatchandclockparts.com, welwynwatchparts.co.uk there will be others have a google.1 point

-

Hi Nicola the best place would be Ebay or its continental equivalent as I guess new parts would be dificult because of its age.1 point

-

Hi As explained by JerseyMo what you are describing is either click or mainspring problems, either was its a dismantle job hence the advice to get a donor movement a taking apart and re assembling a timex is not a beginners task. I have attached the service manual to highlight whats required. 25 timex.pdf1 point

-

that looks like a Sprite model. the N44 is a factory number and has no bearing to this topic. is there a date ring? if so it would likely be a M25 no date ring than m24. still a guess without seeing the dial. aside from this, it sounds like the mainspring is the issue. But, that would have to be confirmed by more investigation. If your intention is to repair the watch you will be in for an interesting journey. Finding NOS replacement parts for vintage Timex is a challenge here in the US and I know it is even a greater challenge elsewhere. Best suggestion would be is to find a donor watch that has same movement and exchange them. Good Luck with the journey!1 point

-

well, to me it sounds more like a click issue. are you sure it is a M25? show a picture! this way we don't have to guess...:)1 point

-

Hi for all. I read almost of the posts and I only can congratulate for a nice job in the restoration of these machines. Just a comment, may be to help understanding the work of the motor. This kind of motor is called induction motor or inductive motor. The speed is a directly proportion to the frequency of the source that supply it. In this case, 50 Hz. The tension applied to it's terminals only give the power to turn. The number of the coils of the motor fix the speed and less coils more speed. Normally in this application the motor have two or four coils (two will turn faster than four). This kind of motor was used in vinil record players because as the source frequency is very stable, the speed of the turntable will be too. With a reostat in series with the motor supply you only change the power making the motor strong or weak. O course if you have some obstacles to fight like the fluid resistence of the cleanning liquid, reducing the power, indirectly you will reduce the speed. That's why when you turn it on outside the liquid the speed raise to the top limit. You can lower the speed outside the liquid using a reostat with high resistece value, and the motor will lower the speer against the atrit between the axis and the supports, that it is not perfect. However, if you do this, when the basket is inside the liquid, the reostat will only increase the speed at the end of his cursor, and the speed will have a fast icrease with a small turn of the reostat. One more tip. The energy that is not used by the motor (in the lower speed) will be burned by the reostat. So, when you adjust for lower speeds, it is normal to the reostat to heat. I hope this can be helpfull in future jobs.1 point

-

Hearing sad tales like this make me angry at businessmen who would do this to their clients. If such a technician wants to be in business to work on the kind of watches he agrees to repair, he should first learn as much as he can about them. And I think a situation like this (unassembled and unrepaired with missing and broken parts) warrants more than just an offer of money to cover future repair. He should have offered to replace the watch for you. Or offer to put a new movement in it. One should take responsibility for one's mistakes. He ruined your personal property. Saying it would take forever to fix is a poor excuse. I think he could have given more explanation and better compensation.0 points