Leaderboard

Popular Content

Showing content with the highest reputation on 07/29/20 in Posts

-

4 points

-

The technique might be useful in cases a better replacement is not available. The ash is to minmize availability of ambiant oxygen to the metal, therefore oxidation and subsequent rusting plus uniform distribution of the low temp heat imparted to the metal. Heat is the kenetic energy of the constituent parts, Intermoleculare distance increase with heat ( thermal expansion) , any temp increase is an excitation of the phase the metal was in, though not neccessarily pass a chemical threshold level, it would affect the crystaline structure of the steel that is the crystaline formation of molecules undergoes some alteration depending on the de-excitation process, if not quenched "a rapid tem decrease" some bonds go un-reformed, therefore less intermolecular bonds , which amounts to less the springness. This is a crudely reversed mimic of metalurgical methods used in steel production.3 points

-

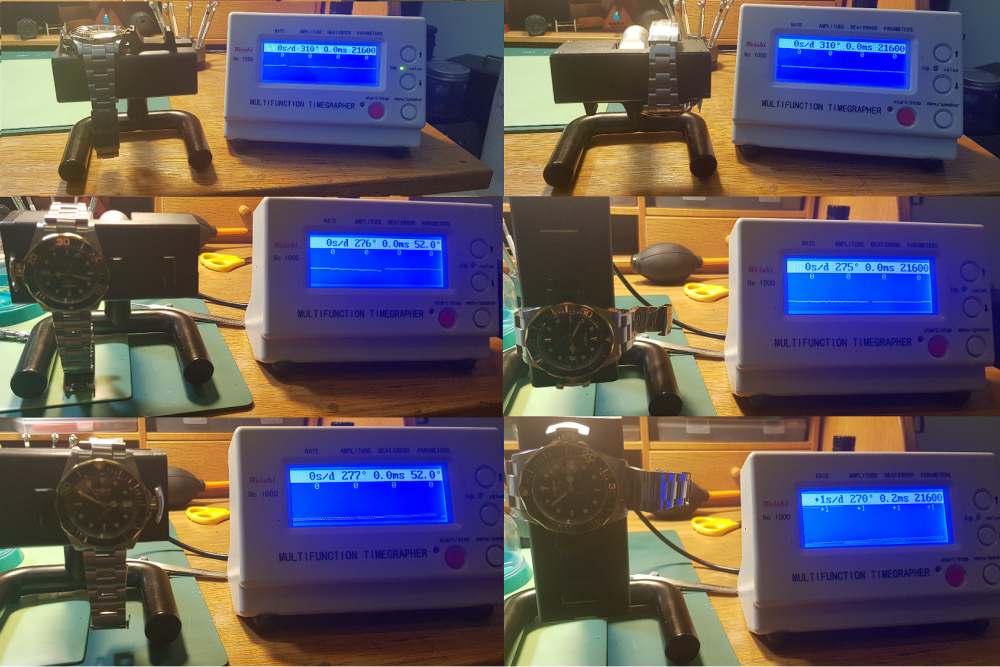

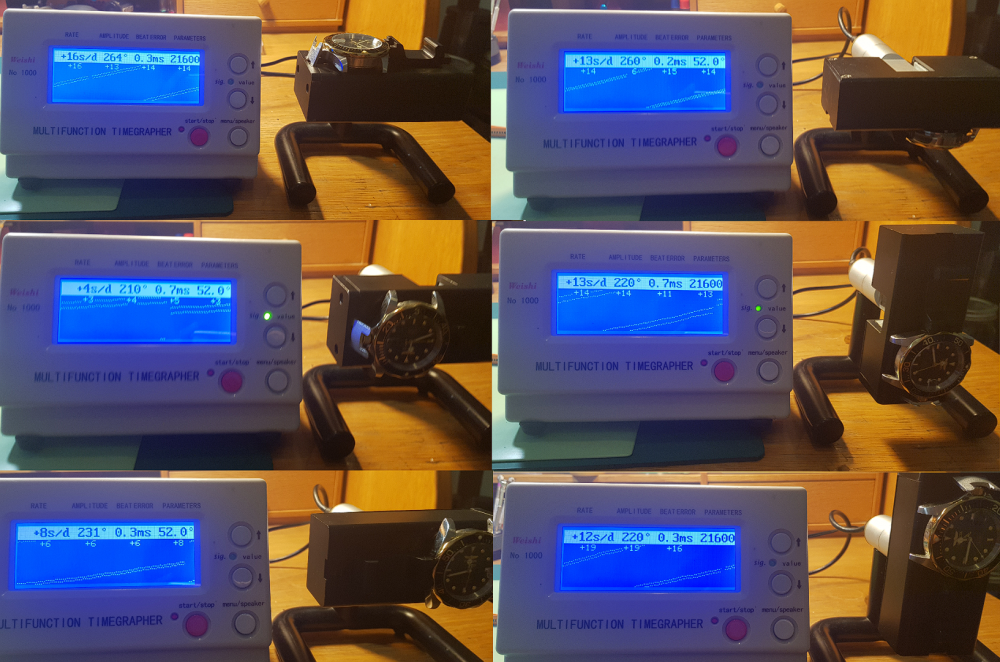

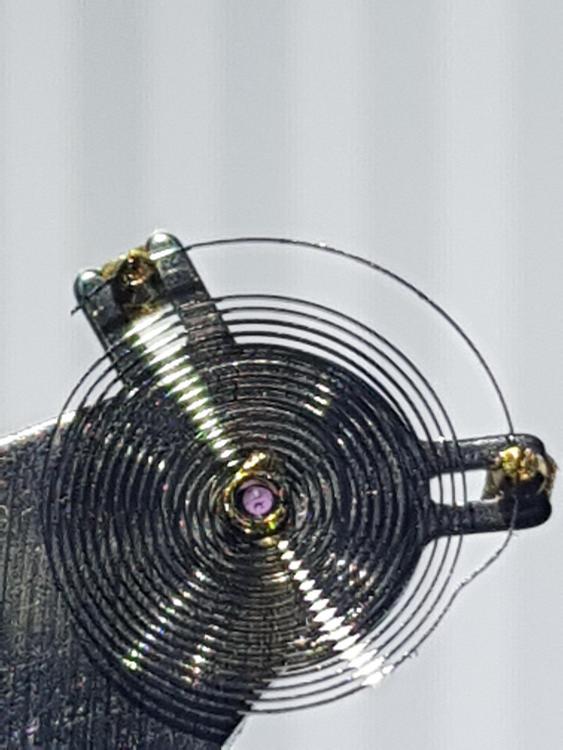

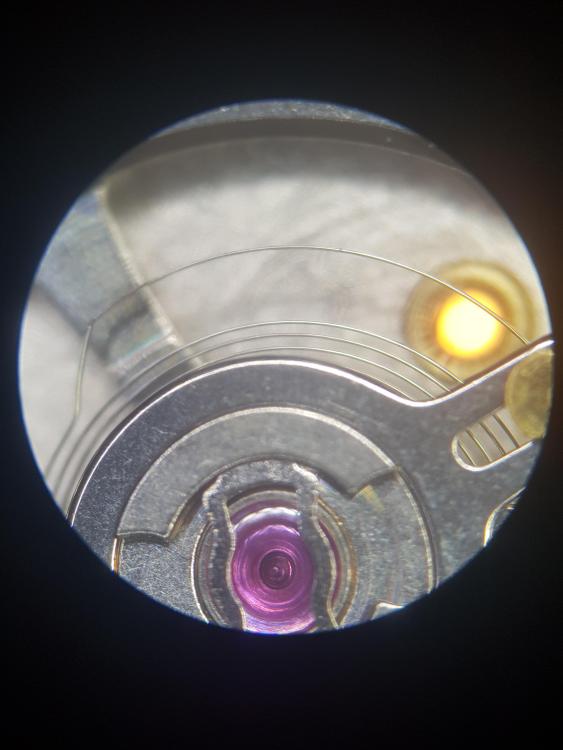

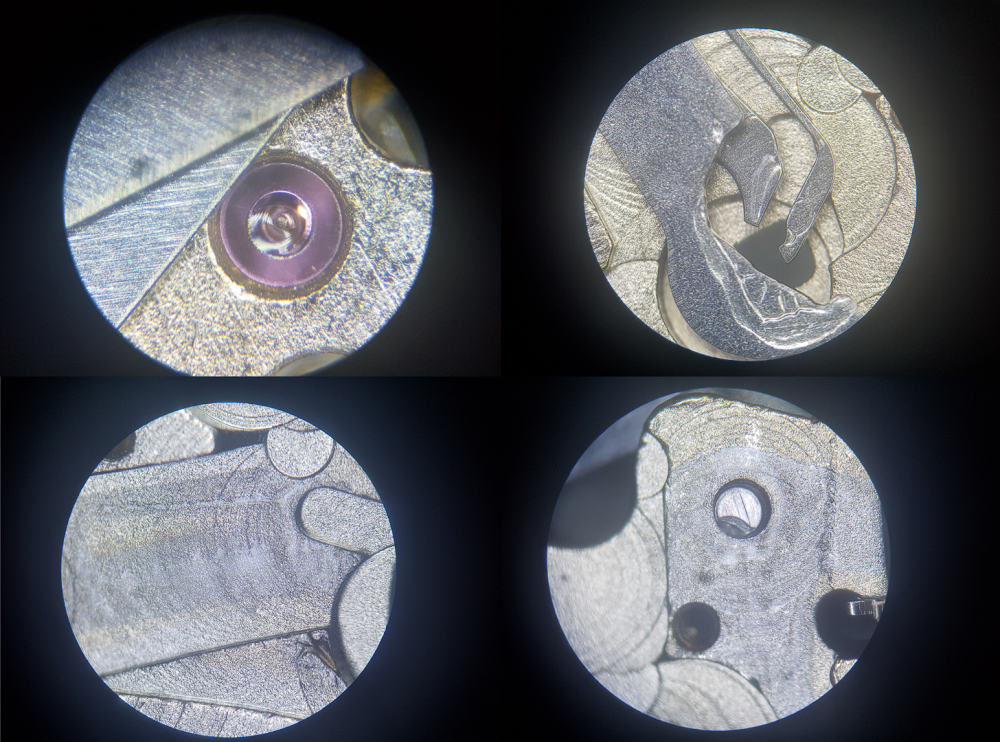

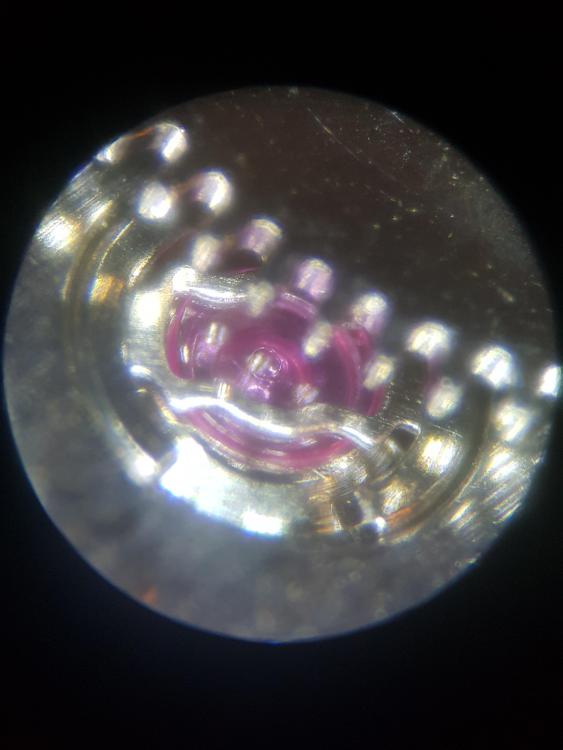

Today I show off what is probably the most accurate Seiko NH35 in existence. Let's see what this brand spankin' new Invicta does on the timegrapher: Oof. Ya hate ta see it. I know these numbers aren't anything to cry over for an 80 dollar automatic, but considering how these days microbrands stick this movement in watches costing hundreds more, and Seiko themselves with the equivalent 4R in watches costing even more, it's just not great. The rate itself to me is a trivial matter as nudging on the regulator is a trivial task. But what speaks to the quality of a movement in my eyes is the consistency of that rate in different positions. With 12 seconds per day difference across positions, middling amplitude, and fluctuating rate while static, albeit slight, is all just a bit "meh" to me. Let's crack it open and see what we can do. . Hairspring seems to be pulling towards stud. Hairspring removed from balance and mounted on cock and we can see the full extent of the malformity. That collet is a good ways off from the jewel. Few hours of sweat later: Much better! Regulator now runs the full length of the terminal curve without disturbance and collet is centered on jewel. Let's check out what else I saw: Some places are absolutely flooded. While others just barely got any. A good thing I intervened. This thing needed to be redone top to bottom. Stripped apart, ready to get rid of the crappy factory lube job, and get a real, proper lube job. All put together, lubed, and few rounds of dynamic poising later: Massive boost in amplitude, runs on rails and a measly 1 second difference across all positions. Wasn't lying when I said "probably the most accurate Seiko NH35 in existence." See for yourself. Isn't it at the moment a bit of a waste that this souped up NH35 is being trapped inside its Invicta skin? What do you think?2 points

-

Your braver than me. I would love to learn how to repair porcelain dials, but I think that is one skill I will have to admit defeat before I even start. If you repair any more make sure you post photos and let us know of your techniques. I have a book 'The Watchmakers' Hand-Book' by Claudius Saunier published in 1882 which goes into some detail on how to make a porcelain dial from scratch. At some point I will have to try and copy out that chapter and post it on the forum. It talks about hand painting all the numbers and markings in black enamel and then firing them to set them into the white enamel, you would have to have great skill to do that.2 points

-

If you hold it in your hand, the difference becomes even more obvious. The real thing feels like quality. The machined edges are perfect, the weight is good, the bracelet is far superior, the crystal is infinitely nicer. Everything about it is superior in every way to the fake. There are some pretty convincing fakes out there though (better than the example shown), so always do your research before parting with the cash. Or of course stick with the 404 club. At least you know where you stand with them. If they turn out to be a gem in the rough, you have 'won a watch' and nobody is going to go to the trouble of faking anything in that price range. Having said all that, I'm still trying to convince myself that I don't actually *need* a vintage Omega.. but one of these days, my less than steely resolve is going to buckle.2 points

-

I am thinking this type of movement has a sort of square drive socket that the stem engages that you push in to set.if so perhaps you can find a piece of square key stock of the appropriate size If you have an actual hardware store that hasn't been driven out of business. Winding could be accomplished with a proper screwdriver. As for a case,you might try those who ply the steampunk trade on ETSY.1 point

-

1 point

-

Crown depends on a few things.tap size or diameter of threaded portion of stem. Also tube diameter on case. You really need to know that, or your crown may or may not work with your intended case.if you just want a crown while the movement is uncased any one will do.just measure the threaded portion of the stem and order any crown you like .or if you have an old cheap quartz watch laying about you could unscrew the crown from it. Chances are about 50/50 it will screw on and work.1 point

-

The crown depends on both the case type, and the stem thread pitch. The thread pitch will be quoted by the seller of the crowns, and as @Nucejoe stated the case determines which style of crown suits. For example the two Poljot 2614-2h based watches here -> https://17jewels.info/movements/p/poljot/poljot-2614-2h/ <- have different crowns, but the thread pitch on the stems will be the same, since the same stem is generally (but not invariably) used for all watches with the same mechanism. Occasionally you will see different lengths of stem offered for the same mechanism. The stem is mechanism specific, the crown may fit many different types of watch, or may be specific to a few models.1 point

-

It's not watchmaking per se, but very adjacent. Might be of interest to this crowd. This article crossed my path this morning. https://www.nist.gov/news-events/news/2015/04/getting-better-all-time-jila-strontium-atomic-clock-sets-new-records This was in the news a few years back (and actually, I see the article is about that old). My best friend works at JILA, and he built at least part of the resonator used in this clock (his focus is ultra high frequency electronics). The resonator is the equivalent of an escapement. When he told me about it (either over beers or on a hike), he glossed over the coolest part. Warning, the following is beyond nerdy, and will break some people's brains. If you can follow, it's pretty seriously cool. I'll keep the math out of it. Back when this came out, it set a record, was in the news, and all the stories were about how it wouldn't lose a second over the entire age of the universe. That's cool, but it's not exactly tangible or relatable. As watchmakers, you all have a firmer grasp on what that means, but here's the really cool part: It is capable of measuring the difference within earth's gravity well over a distance of a mere 2 cm... According to physics, there is a floor to how small things can get. This smallest possible distance is called the Planck length. Imagine that the universe exists on a three dimensional lattice grid of Planck length cubes as a visual. This lattice of Planck length cubes is the fabric of spacetime. General Relativity (Einstein's theory of gravity) tells us that this Planck length is... wait for it... relative; it can be larger or smaller depending on various factors. The cubes can be expanded and stretched. One thing that alters the Planck length is gravity. More gravity stretches it out, while less allows it to contract and be smaller. If you're at sea level, the Planck length of the above mentioned lattice grid is larger, and the cubes are bigger. Up here at 7K' above sea level, my Planck length cubes are smaller. When your cubes are bigger, it takes longer for information to be transmitted across them and vice versa. "Information" here means energy, matter, change, what have you; it's kind of a broad technical term. The speed at which this information is able to travel is called Causality, and is the C in E=MC^2 (not the speed of light, as is commonly stated as a more easily explainable concept, thought they are also one and the same). What it means practically for this conversation, is that as the Planck length is stretched, time is slower relative to a space with a shorter Planck length. This slowing of time due to the stretching of spacetime (longer Planck length) is called time dilation. When that time dilation is due to gravity stretching spacetime, it's called gravitational time dilation. Practically speaking, those of you at sea level experience time more slowly than we do up here in the mountains. It's a very very small difference that we can't actually discern, but it's there and more gravity, or being closer to the source of the gravity means more slowing. On a larger planet, or a black hole as the classic example, as it represents the most extreme of extremes, this difference is far more pronounced. A practical example of time dilation is the time corrections used in satellites. There's some correction made for their speed, but they're also corrected for their position in (or out) of earth's gravity well. The accuracy of these corrections is what allows your favorite navigation app to know where you are in order to tell you when to turn, and increases in that accuracy over time is why those apps have gotten better at figuring out which lane you're in, as an example. It's difficult to express how tiny the effects of time dilation are on such a tiny scale as earth without getting into the math... Lot's-of-zeros-between-the-decimal-and-any-number-other-than-zeros of a second. For there to be time dilation on a scale that would be noticeable to a person without lots of expensive measuring tools (say, drop the rate of the passage of time by half), you would need a black hole with a mass at least a few times greater than the sun. Then you'd need to get real close to it.... Then you'd notice the universe around you starts to speed up relative to your own experience (and to the rest of the universe, it would look like you were moving in slow motion). Get too close though, and your Planck length gets stretched out so long that time just stops (at least according to an outside observer that's not in the black hole's gravity well with you)/the universe just suddenly ends in an instantaneous fast forward (blinks out, heat death, contraction, dragons, pick your theory)... But that's a different conversation. Back to the clock now... This puppy is so accurate, it can tell where you are to within 2 cm altitude... What that means, is that it is capable (indirectly) measuring the change in the stretching of spacetime due to a (relatively) tiny mass like the earth! We are talking tiny distances here, and even tinier stretching of those tiny distances. That is absolutely incredible! The technological possibilities with a clock this accurate are huge. It's 150X more accurate than that lame old "THE Atomic Clock". The mind boggles. An incredible feat of engineering, and a huge milestone in the science of horology. Hopefully that was an interesting read, and anyone finds it as interesting as I do. \nerding1 point

-

Nicely done! Chalk and cheese when it comes to the timegrapher readings as well. Getting towards COSC territory in the timing.1 point

-

There is a product MILIPUTTY which i have seen used for dial repair. I have some but not yet used it, may be worth a look it comes in various colours.1 point

-

In recent years, some companies have started producing resins in the shades of "Hollywood white". Probably in response to people wanting their teeth as white as their toilet bowls. I have never tried those.1 point

-

Hmmmm.how to get it apart in the gentlest manner. I am concerned that the dial may be stuck to the case. If it is an acrylic crystal as it does appear to be,maybe it would be best to remove the crystal first and clean enough to remove the movement/dial. Before proceeding with a more thorough cleaning.1 point

-

Hello all. I received an Elgin (grade 50) pocket watch yesterday that has a few "issues" but I'm not sure how to diagnose them because the watch has a bunch of different parts that I'm not used to. From what I can tell, there is an obvious issue with the stem - it keeps slipping when I try to wind the watch, this I can fix. However the weird thing is when I wind the watch backwards, it makes a different clicking sound and upon inspection of the movement, the circular piece up to the left of the pinion raises up and drops back down like it's disengaging or something. I don't know how else to describe it. I've back-wound it for a whole minute while the watch is running and it doesn't stop so it clearly isn't releasing tension from the mainspring. This piece is attached to what looks to be the barrel? Is this normal?1 point

-

First time for me placing my hands on a true watchmaker's lathe to repivot a central wheel (small seconds), under the guidance of my mentor master Lino. Work isn't complete and practically it never will be, because ase the pinion was picked from a box of spares that he accurately set aside. Lots of of technique details were passed to me, probably these are explained in most books, but the experience of learning first hand is priceless!1 point

-

There is sure to be some goo on back side of dial plate, which you can test different ideas on. I had a bellmatic dial with some stuff stuck on the face, some sort of sealant used on o-ring on back plate, whiped it off with tissue paper and acetone, turned out incredibly perfect. Acetone is friendly to the paint of bellmatic dial. Good luck, you need it in this case.1 point

-

it depends upon your balance wheel as to whether you can just swap a hairspring or not. If it was an American pocket watch for instance the answer would be yes. American pocket watches if you look in the parts book had hairspring is available separately. That's because the hairsprings are made to very exacting specifications with the over coil and it's too hard to vibrate and then bend that. Not that they didn't do it at some point in time it was easier to make the hairspring first. Then the balance wheel has timing screws which were also available. then typically with wristwatches at least up until now they hairspring is vibrated to each and every balance wheel. There was enough variation with the balance wheels and even just pinning the hairspring that they have to be vibrated together. which is why typically on the parts list it's a balance complete. then the quoted paragraph above another thing that helps today is having a floating stud and regulator. previously on watches your regulation range was limited and now you do have considerably more range. but for timing purposes everything really asked be really really close or you're going to be really often timing. So ideally to get this to work your balance wheel has to have screws unless you have enough hairsprings you can find one that's slow for the balance wheel then you can take weight off a screwless balance wheel.1 point

-

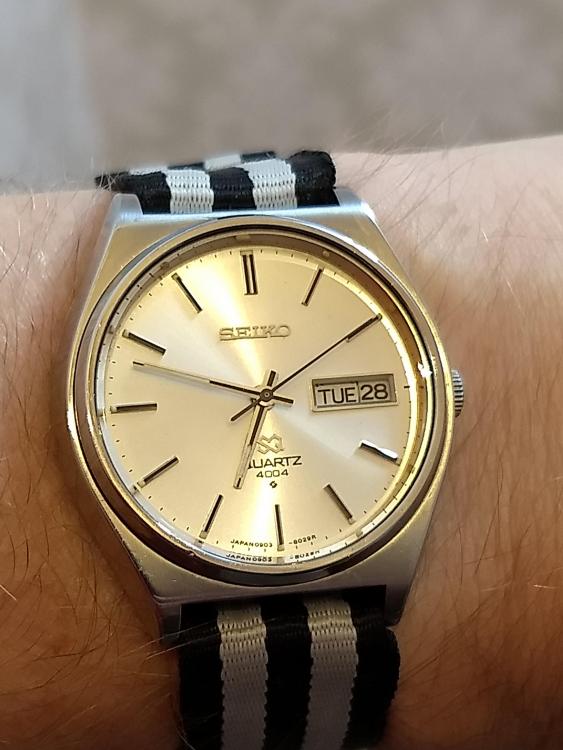

My watch of the day, just finished this as a present for my daughter's 16th this Friday. Seiko 4004 Quartz from mid 70s. The lengths I have gone to with this watch, I even had to find a case back for it as the one it came with was from another watch and stuck on with double sided tape. She will love the retro look.1 point

-

1 point

-

1 point

-

Hi In view of the damaged area you started with and the constraints You have done a creditable job. The art of dial refurbishment is a skill all on its own. Be proud of what you have achieved. well done1 point

-

I read a while ago that it was an aesthetic decision to increase symmetry of the dial. Quite interesting actually! https://www.hautehorlogerie.org/en/amphtml/encyclopaedia/glossary-of-watchmaking/s/roman-numeral-iiii-on-dials-1/ Sent from my iPhone using Tapatalk1 point

-

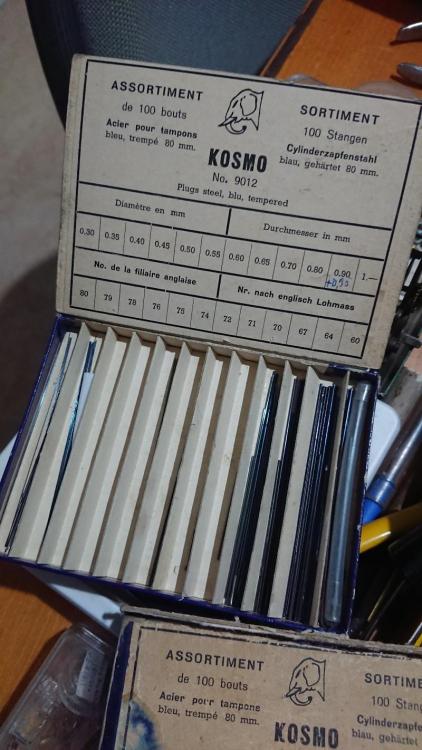

To anneal the pinion before drilling. I used an HSS bit from the vintage set below. It could have done with a carbide bit on the hardened part, but we didn't have any, and there is always the risk of breaking the bit. The hole was started with a center drill made from a broken bit, then I manually sharpened a long bit on a small stone. It drilled very well with short pressure on fast spinning, quick retreats and a droplet of oil. Now, the main disadvantage of annealing was that master wanted me to coat first with boric powder to avoid bluing the part, that required a good time to clean up the resulting scale. It would take take a long posting to tell his experience and achievements, and I want to do that as soon as possible. For now I'll just say that at 96 years young he's incredibly active and I am lucky to take precious lessons from him. I should explain. He saved some broken centre wheels, like snapped at the cannon pinion arbor section. First, a sketch of the pinion and all dimension is made, that would be very important in case the part is misplaced or lost. Then a suitable diameter steel wire is selected from an assortment like the below -that is a very vintage one, but such wires are still made today, it is cut of sufficient length. Within the same nominal size, the nearest one can be picked using a micrometer. There can be a difference of one or more cents of millimeter that will help reaching the best result with the less effort in the following steps. Then the pinion is drilled as above. It could have been repivoted on the broken side only, but for practice I drilled through and repovited both sides. The wire is fitted first within the lathe, then one can use the staking set, as the typical hole depth of a stake is perfect for the purpose. In my case it fitted tight and strong so not to require cement, and to improve friction one can roughen up the contact area rolling the relevant section of the wire between two diamond files, exercising strong pressure and very short travel. I did not made further progress today as we got caught with other contingencies.1 point

-

the company that makes your cleaning fluid is very unhelpful as there is no material safety sheets or chemical properties of their cleaning fluid other than vague terms. But it does comment that makes metals bright shiny which makes me suspicious there's probably ammonia in the cleaning fluid. Ammonia is really wonderful for cleaning watch parts it is the substance that makes the parts bright and shiny. But as spectre6000 and I have found out even using cleaning fluid specifically designed for cleaning watch parts a little cleaning is good a lot of cleaning is bad and throw in some heat that would be very bad. So even commercial watch cleaning fluids are very time-limited because at a certain point in time you go past cleaning and you have the possibilities of cleaning the metal right off the watch parts and putting it in solution.. ttps://www.carbusonic.co.uk/ULTRASONIC-CLEANING-FLUID-JEWELLERY-JEWELRY-WATCHES-TATTOO-DENTAL you have a unknown water-based solution and your cleaning wheels which are made out of brass and steel which definitely could form a undesirable electrolysis situation. the answer to his or something wrong with your cleaning fluid yes it's not designed to clean watch parts. But if you insist on using it try five minutes or find something to practice with it's disposable and see how long it go before bad things happen. then for the performance issue if your pivots are feeling rough that would be undesirable.1 point

-

I had a similar gaffe recently. I did 10 minutes X3 cycles (clean, rinse 1, rinse 2) and stripped the nickel plating off the majority of the main plate (but nothing else surprisingly). Shocked the hell out of me, because nickel on brass should definitely be hard enough to not have issues. For the most recent cleaning, I did 3 minutes for each cycle, and that seems to have been plenty. I'll try two next, then one to see where the curve falls. It definitely seems like more makes sense, and there's nothing really out there in the literature about how long to use an ultrasonic cleaner (at least not that I've seen). This forum is great for hammering out those little details...1 point

-

30 minutes in the ultrasonic sounds a bit too long. Ultrasonic cleaners can be very damaging. You can try an experiment. Just take a small piece of aluminum foil hold it with your fingers and just dip it in the bath and run it for 1 minute, try not to touch the sides or bottom of the tank. Now remove the foil and inspect it. It should be peppered with a lot of holes. This is how we test an ultrasonic bath to see if the transducers are working properly. And also to check for and "dead" spots where there is no ultrasonic energy. I normally put my parts in the solution and run it for a couple of minutes. Then let it soak for maybe 10 minutes and run it for another 2 minutes. This way, I minimize the cavitation damage to the surface of the parts.1 point

-

Welcome BrianR! IMO watchrepairlessons.com is one of the very best (and most affordable) ways to get started, but there are plenty of sources to learn from, WRT being one of them. It is not what it seems to be, trust me, and you'll know the first night you can't fall asleep because that amplitude of your newly serviced watch just won't reach 270 degrees, no matter what you do Good thing is that when you finally prevail you will feel like you own the world.1 point

-

I have a Star lathe & over the years I have gradually built a nice collection of collets & tools. All are used but work just fine. The hardest part when making parts using a watchmakers lathe is not the make of lathe but the skills required to use one. My brother in law purchased a Chinese lathe a few years ago & he produces excellent work from it.1 point

-

a milling machine is more important than the lathe, for general use. take your time to find a good one.1 point

-

BobM12, The biggest problem with most watchmaker lathes is that most of the companies that manufactured them are no longer in business. This means that finding quality accessories can be a bit of a problem. Eight millimeter collets are still manufactured but six millimeter collets are not. There are a number of used Wolf-Jahn and lorch 6mm lathes available for a reasonable price but finding collets for them can be a matter of blind luck. To the best of my knowledge the only companies who manufactured watchmaker lathes in the past that are still in business are LEVIN, DERBYSHIRE, STAR and DIXIE (marketed under the BERGEON name. I don't know how long the SINCERE brand has been out there but they currently make a high quality lathe. Both DERBYSHIRE and LEVIN have shifted over to a slightly larger instrument size lathe but the precision and quality of these machines is so fantastic (20-50 millionths of an inch spindle runout), they can certainly be used to make watch parts. As a matter of note both of these machines use ultra precision ball bearing headstocks while the Star, Dixie (Bergeon) and Sincere use the old fashioned cone bearings. While cone bearings are not as accurate as ABEC 7 OR ABEC 9 ball bearings, they have enough accuracy to make suitable watch parts. This brings the selection down to availability and affordability. Any of these five currently manufactured lathes can make suitable quality watch parts. Out of the five the Sincere lathe is the most affordable as are its accessories. As an example a Sincere milling attachment is less than $400.00 while a Bergeon milling attachment is around $7000.00. Both milling attachments are light duty accessories that lead to deflection problems under a cutter load. A 175 pound Harbor Freight (CENTRAL MACHINERY) bench top mini mill (once tweaked in and adjusted) will cut better than a watchmaker lathe milling attachment. The mini mill has more size, mass and power than the watchmaker lathe accessory, so the cutter is more likely to go where you want it to go. If I were to give a recommendation it would be to stay away from machines with aluminum beds. Aluminum headstocks are stable but aluminum beds can cause deflection and/or wear problems. This is true for lathes but especially true for milling machines. Aluminum is not as rigid as steel and tends to bend more easily under a load. Cone bearings are OK but you have to learn how to clean and adjust them. You also have to run them at lower speeds. Modern ball bearings are more accurate to several magnitudes and can run much faster than cone bearings. Just thought I would throw in my 2 cents worth. david1 point

-

Thank you Geo, as always a great answer. I'll check out the links right after this message.1 point

-

Hi Bob, Make sure that you buy a watchmakers and not a small modelmakers lathe. There are a few good makes to choose from, Boley, Lorch, Levin, Pultra and Rolls Royce of lathes Schaublin. Whatever you go for make sure that it is in excellent condition and with as many collets and attachments as possible. The reason I say this is to purchase the attachment separately will cost a lot of money. Lathes such as Unimat are excellent for modelmakers, but do not have such a comprehensive selection of collets and attachments that you will require for doing watch repairs. I have a Boley Lienen WW bed lathe and attachments. If you check out this http://lathes.co.uk/leinentradwatchmaker/ and http://www.lathes.co.uk/leinenmodern/ you will get some idea of the sort of things available. If you go to the homepage of the link, you will be able to look up information on just about any lathe, both large and small.1 point