Leaderboard

Popular Content

Showing content with the highest reputation on 07/20/20 in all areas

-

Hi everyone, I put together this document after my experience with watch tools and oils as a hobbyist. This is my humble opinion based on my reading and experience. I understand some things (like the lubrication) may not be up to standards, but I tried to make this with the beginner/hobbyist on a budget in mind. All suggestions are welcome and please post your experience as well. I have attached it as a PDF for simplicity. I would also like to thank everyone in this forum and especially Mark Lovick for all your teachings and suggestions. best, Guido Tools for the Hobbyist.pdf4 points

-

we do not need to identify who or what made the watch if you want CGS of the hairspring. fortunately there is a procedure is relatively easy. Using the table I've attached below find an approximate hairspring it does not have to be the correct one. Then you vibrate they hairspring using the formula you can do the calculation the figure out the correct hairspring. then using a calculation and your new CGS number you vibrate that spring and verify it is correct. As I said easy except? The exception is to vibrate a hairspring you need a vibrating tool I haven't looked lately on eBay may be in the $500 range if your lucky. then also going to need hairspring collets and the pins. the biggest problem will be and I will referenced something here the horological journal a publication of the British horological Institute in August 2007 has a really nice article on hairsprings. They made a discovery oh dear there is a hairspring crisis? In the past hairsprings were made exactly as the table shows and they were available. simplistically the Swiss keep consolidating in their manufacturing slowly make what they actually need versus generic. This means rather than making all the hairsprings in the table hairspring companies only manufacturing now for the watch manufacturers. If your watch manufacturer you can order your specific spring vibrated yourself. Or supplier balance wheels to the hairspring manufacturer and they will vibrate the hairspring for you. This means there are no more new CGS hairsprings to purchase only new old stock if you can find it. then the skill set the vibrator hairspring is not exactly an easy skill set the learn. Plus this is a tiny watch makes things much more complicated. So can it be done yes could somebody do it for you may be there used to be people doing hairspring vibrating but they've slowly gone away. The thing to do is look at eBay the movements come up from time to time sometimes priced quite reasonable other times with really silly high prices. You wait long enough you should build get a movement and hopefully the hairspring will be in better condition than the one you have now. Then no you cannot take a hairspring off another balance wheel it's only relatively recently where they can make things precise enough with a floating regulator and the stud you can get away with that everything before that was vibrated specifically to that balance wheel slid hairspring is not available separately. Although if you have timing screws you can fudge a little bit and perhaps get away with a substitute hairspring but it's still going to be really really close. Then if it really is a chronometer that hairspring is a different grade than the generic watch but this is a really tiny little watch and would anyone really notice whether it's keeping chronometer timekeeping are not anyway?2 points

-

here is the tool I made for both removing and installing the stem crown on the older mode 21 and 22 US Time Timex movement. It is not more than an old dental pick. To remove the stem, you must lift the set lever up. and to reinstall you must lift , seat stem and than push set lever. it works every time!2 points

-

Hi plenty of advise so I will keep my nose out. Tech sheet for the 8110 attached. cheers Citizen 8100, 8110 (1).PDF2 points

-

2 points

-

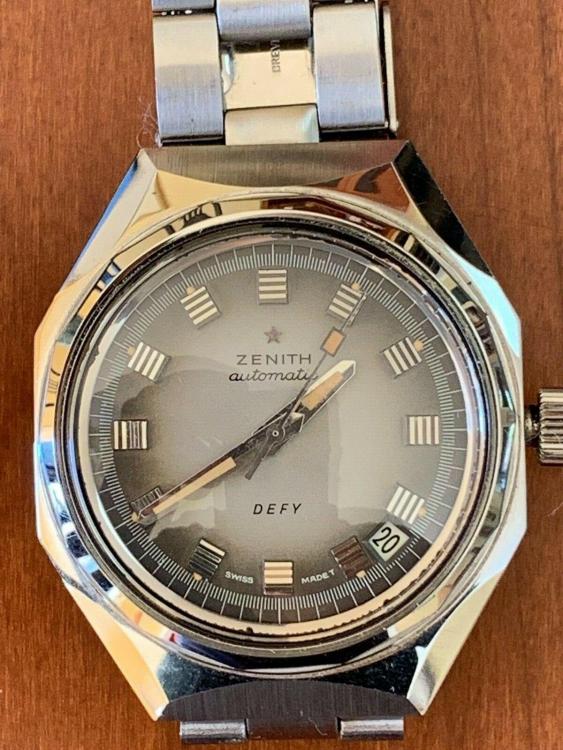

I have one more incoming watch that I'd like to share: A ~1972 Zenith Defy (A3642). I've been looking for a nice example of this watch for a few months, and have purchased and returned two examples because of undisclosed problems and generally not being as nice in person as they were pictured and described as being. This one, I hope, will be the keeper: It is completely original, not overpolished, and looks like it has been kept in a safe for years. It was purchased new in ~1972 by the father of the person who is selling it to me. Once I get it open, I'll be able to date it from its movement (which should be a 2552PC). It purportedly runs well, but the seller didn't offer any pictures of its movement. This is a watch that I'm definitely going to send out for an overhaul, either to the Zenith factory or to someone recommended to me. Normally I wouldn't send a watch back to the factory for repair, but I'm concerned that parts availability will be an issue with this model.1 point

-

...I measured them after I received them. The dimensions are for the Nivaflex version, the ones in the post. The table is a print screen from an excel file I made1 point

-

Hector - see the attached photo related to end shake on Timex electric such as the one you are working on. The loud sound is common to all of them. As you state it does at times depend on the angle the movement is in. If I wear one of my 'Electric' watches and leaving it on the night stand next to the bed, at some point it gets tossed to the carpeting on the floor so I can go back to sleep without hearing the 'ticking'.1 point

-

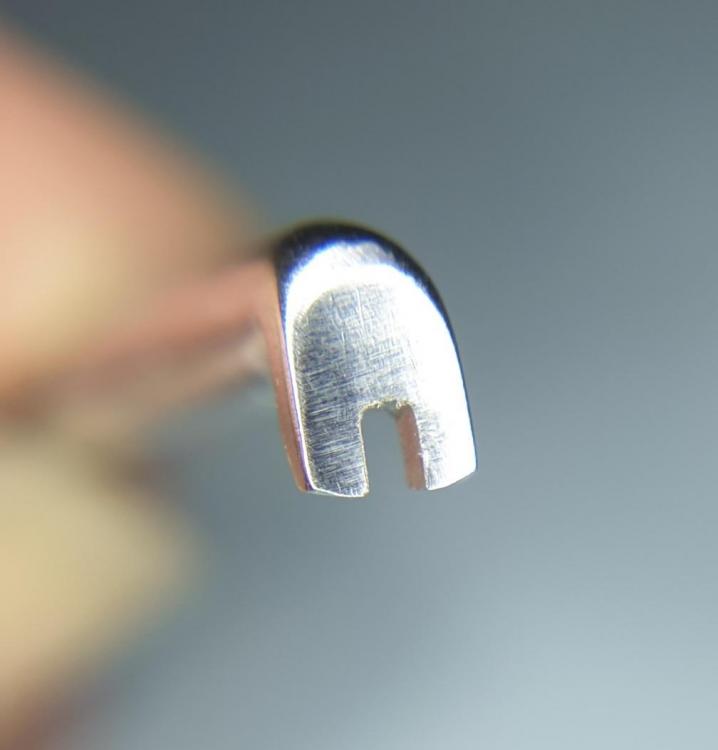

Is it just me or do any of you also experience difficulty making fine adjustments of the regulator arm and hairspring stud position arm. Some of these are so stiff that when you apply enough force to overcome the static friction, it moves more than intended. Recently I made 2 tools that are a tremendous help to me. The 1st one is made from an old screwdriver. The 2nd one is made from an old iron nail. I just put the regulator between the fork of the tool and torque it. I can look at the screen of the timegrapher while making adjustments, without fear of slipping and damaging the hairspring.1 point

-

And yet, you didn't bother answering my question...because you didn't know either. Instead, you advised me to head to the mall. Further, it WAS a matter of caution, as I didn't want to damage a screw-on back by trying to pry it off, had that been the case. Finally, and AGAIN, ability was never the issue. Despite your odd insistence. Capiche?1 point

-

If we can identify the family this belongs to, there is a chance to come up with the CGS of the hairspring, thence its balance can be vibrated( Hopefully we can work with Cduke to vibrate one) I am affraid just the name ulysse Nardin would hurt Cduke's wallet , where as generic hairsprings cost 6 to ten dollars for a dozen. Regards1 point

-

I just use a flat nose plier to unscrew the rotor screw. You might drop a piece of nylon on the screw head( like you do when removing hands), trying to avoid scratching parts there.1 point

-

I had an idea a couple of days ago. It was so simple that you can make it yourself. By putting a fulcrum on the inside jaws of a pair of tweezers and squeezing above this point, the jaws will open up. This will open up the retaining clip on the winding stem and allow the stem to be pulled out. 20200720_200542.mp41 point

-

Looks like it is based on an ETA movement, it looks like the escape and pallet been modified to achieve the chronometer standard. They probably done stuff with the balance too. Found an article about the watch but it doesn't reveal the movement caliber. http://www.vintage-watches-collection.com/watch/ulysse-nardin/ulysse-nardin-art-deco-tank-1947/1 point

-

A look at the other side of the movement is neccessary. Ulysse Nardin made high grade movements usually chrono grade which were put in chronograph watches, temperature as well as several positions adjusted. This square geometry point to Michelangelo collection in tonnou cases, go to chrono24, search for the said collection to match a dial that accomodates the complications of your movement. If this is a flat hairspring( pic a bit blurry), you may just vibrate a hairspring with balance wheel, since you have already lost the temperautre adjustment and are unlikely to get satisfactory adjustment in five positions. Good luck pal.1 point

-

Just because the case is UN or whatever doesn't mean the the mov't also is. Back then, and now as well, the mov't maker may remove or change any stamping for the customer. Your movement is an ETA 87x or 87x. You can do this kind of searches on ranfft.de1 point

-

Yeah I had issues with the screws, I set them aside on a bit of cardboard. There were way too many different types. I also found the calendar very complicated at the time and did not justify re-learning it. I just cleaned all the jewels and the mainplate and fitted everything back together. These are quite well built, arguably better than the venerable 6139. I found a simple service and re-assembly was enough to have it running well.1 point

-

Hi folks and thanks for the welcome. Yes, Mark L does use an ST36 Chinese clone of the ETA movement in the course. I bought one, hard for me to find, long delays in getting them in from China right now. What I got was new, someone had one in stock, it was almost exactly what Mark used in the course, but the train bridge was made in two parts, which should have made it easier. But it confused me, and the pivot on the escape wheel snapped somewhere along with me taking off the part of the bridge used solely for that wheel. Also, the shock jewel mount was not put in right when they built it, when I touched it to take it out, it went flying...I found it, but I could see why it was not put in right: The top of the balance wheel where it goes was too tight for the mount to fit. So I played with this watch, took it apart, put it back together as much as I could. Did not seem they oiled it either when they made it. My old working Elgin was much more fun. I am looking now for non-working pocket watches -- a little bigger for a beginner like me -- and many to choose from. And I won't ruin a working watch Check the photo, the top one is my old 'door prize' elgin, beat up case, but movement works pretty well after cleaning. The bottom two are recent purchases, the silver one is really nice, all three are regulated.1 point

-

This is a really great guide. The only thing I'd add is finger cots (sorry if it's there and I missed it).1 point

-

Anybody here got kids? Kids with watches? Ever wonder how a daughter could get mud (I really hope it was just mud) *inside* a Disney Princess watch?!?!? Rugged little thing, it still works! Oh well, last time it was a mishap with the honey. At least the honey didn't make it's way inside. It's kind of a "dad thing". If one of the four prettiest little girls in the world comes up to you with her most favorite cheap glitzy bling watch and says "Can you fix it daddy?", you of course treat it better than you would a Patek Philippe because her heart is with that watch. (For now anyway. I think other, more expensive, watches may come along. She has a magpie eye like her mom.)1 point

-

You must have been in business for many years and serviced thousands of watches for the odds of that happening. How do you sign your work? With a sharpie or a scribing tool? I've seen many watchmaker's scrawlings on the back cover of watches but I could never figure out what they mean.1 point

-

That chrono hand does look too high. Maybe the source of the reset to zero problem. As opposed to 7750 you do need to hold the reset in to install all 3 hands as all the hammers are actuated directly with the pushers and not spring loaded. Note that the chrono second hand is keyed to the post. It should stay put and reliably reset to zero as long as it doesn't back out. I have no experience with the Seiko so I do not know how it compares to that, But I do have extensive experience with 7750 and I would say this is magnitudes more complicated, difficult, and less enjoyable. Chief of which that annoys me is the difficulty in finding parts. Up until now I cannot find a fresh mainspring for mine, OEM or otherwise, which I would consider to be the most consumable part. There are also a crap ton of different screws to keep track of. I can now remember which kind of screw goes where but this frustrated me to no end when I first started working on this movement. It's heavy handed on the sub-assembly. The hammers, reset lever, buffer and spring, minute recorder brake, hour recorder brake lever, vertical clutch actuator etc all need to go in the underside of the top most plate in a specific order. On a 7750 you do all the work on the movement held securely by a movement holder. Here you're off to fiddle with sub assemblies wiggling around on an anvil. Very heavily integrated design too in that nothing works until the movement is mostly back together as opposed to 7750 which you can get running pretty early on in the assembly process. All in all take it slow and and take lots of pictures. Pay real close attention to where each type of screw goes. The smaller screws are easily confused with the naked eye, 2 of which are also ever so slightly elongated and don't get anywhere but the lever springs on the top side of the top plate.1 point

-

You might need a couple of spare C clips or circlips that hold chrono pushers in place. If you happen to need to remove levers in the chrono mech , record a video of the mechs, as you push the pushers that activates the chrono in. Saves time and the parts. Escape pivot have real tiny shock springs, so a couple of extra springs to place order for. A thin washer that resembles dial washer sits under the cam , which gets lost easy, some just ignor it and end up having issues. Balance staff has no end shake by design, but check jewel holes to the staff for excess wear which can eat amplitude. I take plenty of pictures during disassembly. Good luck.1 point

-

Gruens would have a 2 arm balance (with some exceptions maybe). From dead zero the balance arms will switch places at 90 degrees when the are above the pallet fork. 180 degrees is when the look like they are hitting their rest position. Wind the watch until they are there, it's easy to see, then set your machine so it reads 180 degrees. Now wind up fully and you know where you are. With 3 arm balances it's worth making magic marker marks at 90 degrees each side of the pallet center. Remove them after with pegwood and alcohol (works for permanent marker too).1 point

-

I would be curious as to what a typical American pocket watch is? I think you'll find the video at the link below interesting it shows a nice simple method how to figure out the lift angle. Of the pocket watches that I've done 36° is a bit on the low side. On my list 38° is the lowest and I guess a six size is not a pocket watch because I have a couple of those that were 62°. I would say on average closer to 45° would be a better average for American pocket watches. https://youtu.be/-Xgcck692js1 point

-

I think isn't particularly difficult to work on but since there are corrosion signs one should examine all parts really close hoping to not find more. And a perfect aesthetical restoration of all screws, wheels and bridges finishing is definitely above beginner's level.1 point

-

Hi Dan I found a little more Gruen Information for you. Gruen-Watchmaking-Lessons (4).pdf Gruen-Horological-Text (4).pdf1 point

-

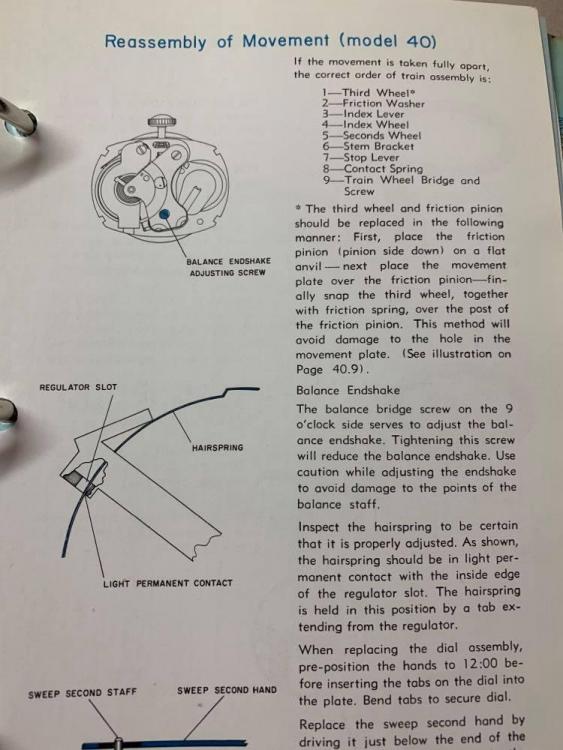

Hi Read throught the service guides Before attempting to dismantle the watch and familiarise yourself with the construction of the watch in question. The Highlighted areas are points of note and will be refered to within the manual.1 point

-

Thanks all. After much deliberation, I have decided to seek knowledge over tools. I’ve signed up for Mark’s Online courses. Tools will always come around. :)1 point

-

At this time Mark Lovick is not taking watches for service or repair. If you intend to learn how to work on mechanical watch I recommend that you start with practicing on something very cheap, because there are many aspect to learn which are are not paying money. Fortunately however the needed lubricants for a 6R15 and 99% of other watches are much, much less than C$300.1 point

-

I realize now that is an electric movement, sorry I don't know anything about these, pls ignore my posting above.1 point

-

Hello all. It’s been so long since I posted in here yesterday may as well re-introduce myself. My name is Mike and I am a watchaholic !! I am actually Mike from My Retro watches YouTube channel. I’m just an obsessed watch tinkerer to the point of living and breathing watches ... To many in the collection with too many more still to collect! Sent from my iPhone using Tapatalk1 point

-

The base is about 30mm, the opening of the basket is 50mm and height with cover is 50mm.1 point

-

I think my strangest find yet was underneath the dial of an old French watch, which I bought on ebay from a seller in France. The watch movement, an HP 81, dated from the 1940s. An inscription was found scratched into the underside of the dial in what looked like French. I was intrigued and asked a French colleague at work to attempt translating it. Both he and I were baffled and humoured by his translation. Some may find the translation offensive so I’ll add the photo and see what you make of it. Sent from my iPad using Tapatalk1 point

-

1 point