Leaderboard

Popular Content

Showing content with the highest reputation on 07/17/20 in Posts

-

the problem with getting a balance staff for a watch like this is? if you look at the link below you'll notice that this watch is been made from 1937-1970. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Landeron_48 then things get much more interesting when you go to the next link that I have. it looks like for balance staff you have 10 of them to choose from. Fortunately there descriptions as they should build a narrow it down considerably. Especially if you measure your old staff. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=LAN_482 points

-

Hi Sounds like it needs a dose of looking at for sure. There are several different flavours of the 6R15attached tech sheets for you 8693_Seiko 6R15C - Technical Guide (1).pdf 8955_pao024_14267_191030121314_1_6r15cd.pdf1 point

-

Hi The balance and spring are best dipped in a solution called "one Dip" especially for balances, Then left to dry no brushing it is sufficient unless it is really filthy then exercise great care . IPA dries clean no deposits 98%IPA. Clean other parts in small jars contaonong the appropriate fluid in the ultrasonic with water half way up the jar, Keep the lids on so water does not enter the jars.1 point

-

1 point

-

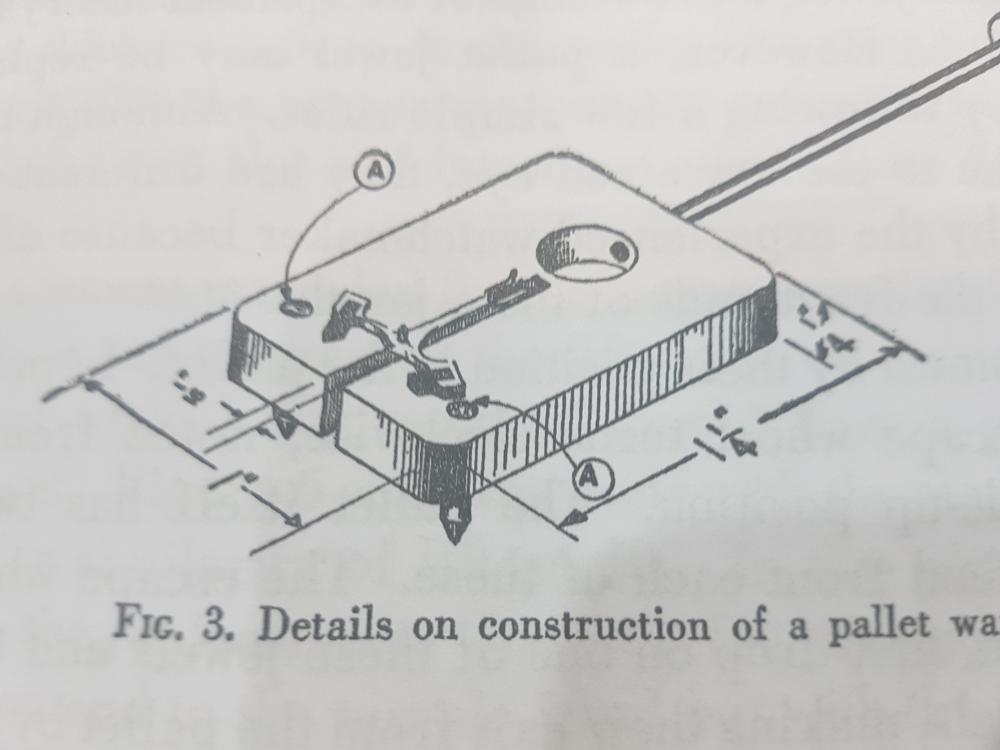

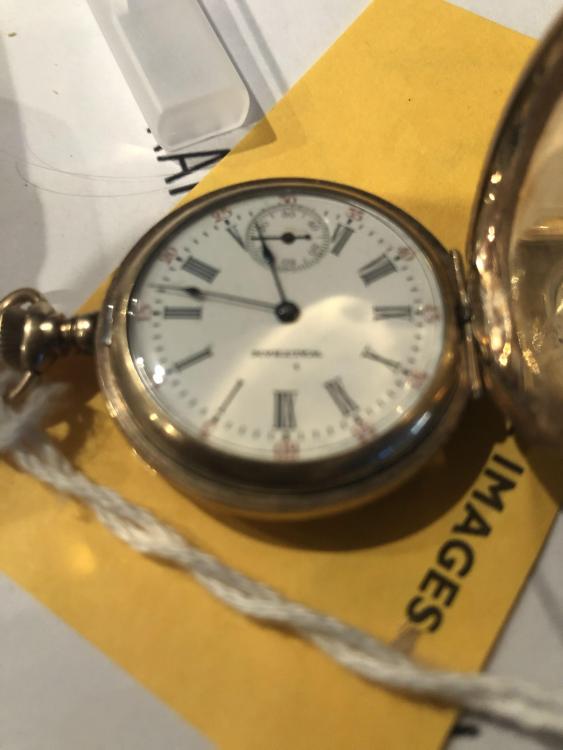

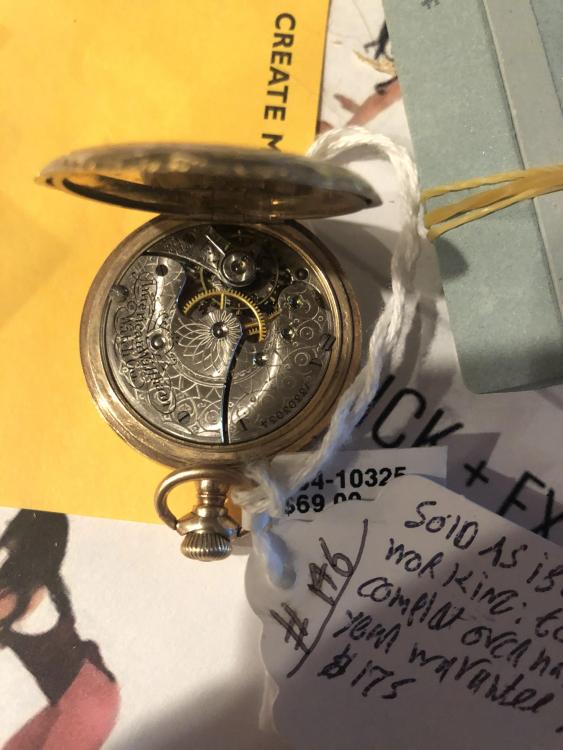

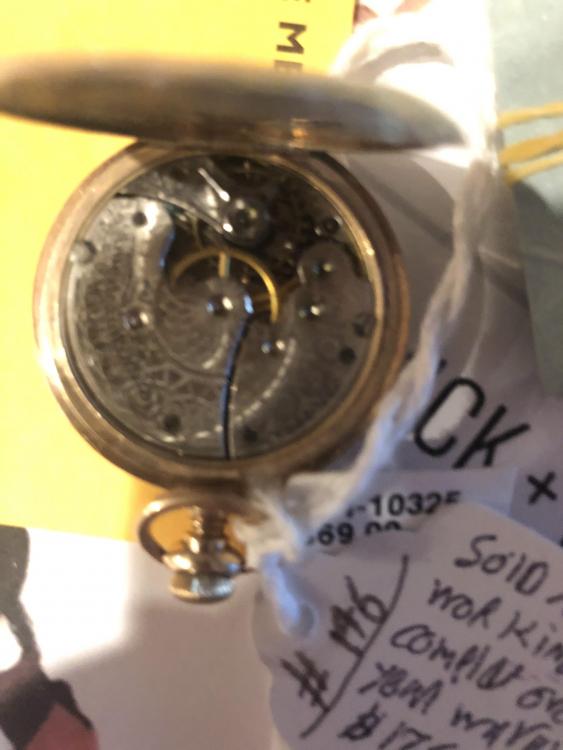

I have converted your images to something about the rest of us can look at. I've also looked up the serial number on the pocket watch database where we have a problem? notice there's a parts tab when you look up this watch but when you go there there are no parts listed? That's because if you look at the 1940 parts data book this watch is too old and its parts are not list. I would suggest for parts look on eBay find a another movement the same as yours purchase this for the parts. It also give you something to take apart and practice with before attempting this one less likely you will destroy your watch. then we can't even look up the mainspring for this watch so we'll have to take it out to see what it is because of its the original mainspring in satin has to be replaced anyway. The watch hasn't been serviced in a long time it needs to be serviced anyway and you change the mainspring when you service the watch. So can watch be serviced without going to professional and somehow it easily fixing the watch probably not. Not without a proper diagnosis which would put the watch at risk if you have no idea which are doing. Then the also have to determine whether it's a watch problem or a case problem. Sometimes the sleeve can move in the case Moves the position of the crown and stem that changes whether you can set the watch or even wind it. https://pocketwatchdatabase.com/search/result/waltham/133030341 point

-

1 point

-

1 point

-

Hello and welcome to the forum. As a Hobbyist cleaning watches best to use Naptha , Benzine . I use carburettor cleaner or brake cleaner, Both from automotive stores and rinse in IPA. Thigs to look out for is dont soak the pallets/Fork or the balance as they use shellac and the possibility of loosening pallet jewels and impulse pin. brush clean and rinse then dry. Lubrication information attached. Moebius Oil and Grease Application Chart - Leosics.co.uk.html Moebius Oil_Chart.pdf1 point

-

If a shot with a demagnetizer or line release box doesn't start a quartz watch the module is toast.1 point

-

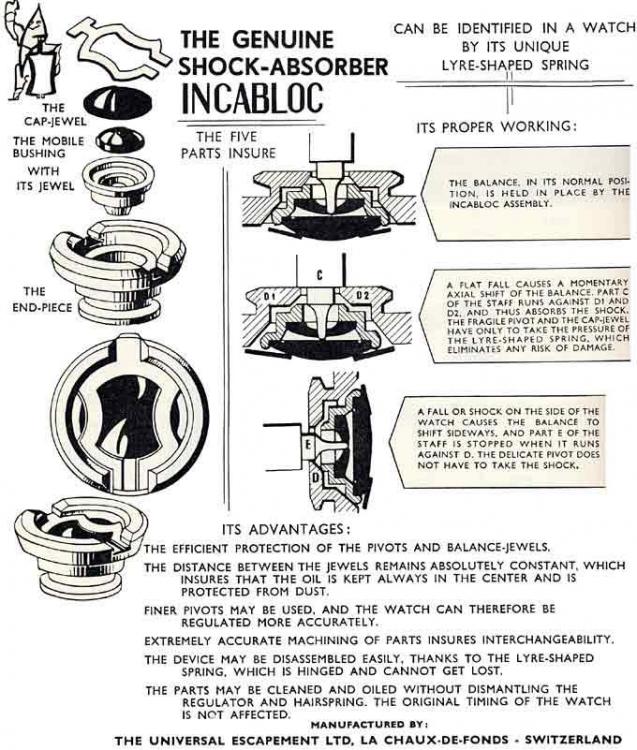

Did you check all the basics? -train freedom after cleaning and assembling, pallet fork out, does the escape wheel spin freely then reverse with a couple of clicks on the mainspring? -is the endshake for the fork correct? (well the rest of the train too) -endshake for balance is correct? -with the fork out, balance in, does it vibrate freely? dial up, dial down, and 4 vertical positions, it should stay in motion for some time with just a little puff from a blower -is the hairspring true? you mention it has an overcoil, but I haven't found an image of one with an overcoil. If the hairspring is out of flat it can be touching the balance arms. -is it incabloc or fixed jewels? regardless the balance jewels need to be spotless and oiled correctly. That it had so much amplitude in one of the flat positions with an oversize mainspring, but issues in other positions, tells me maybe someone in the past stuck in the bigger spring to try to get it going without fixing an underlying problem. You have two vertical positions with an enormous drop in amplitude. To me that points to a likely escapement issue. If you have excessive endshake on the balance that can exacerbate it. If the banking pins aren't straight you can have issues between dial up and dial down. If one is closed too much you can start touching the impulse jewel to the fork horns or guard pin to the safety roller, often seen in certain positions more than others. From your pendant positions my gut says the banking on the exit side might be too tight. But hard to say. Can you get some pics with your phone? I can see you have an Apple (haha, reflection on your timer), even if it's old it should be plenty good enough for some decent pics. Would be interesting to see the fork locked on both entry and exit side, and a view of the balance installed and the hairspring.1 point

-

Using boley I think I found the case code and a few stock part numbers. If the case number is right then you can easily plug those part numbers into ebay to see if you can find any nos parts Here’s a nos crystal. https://www.ebay.com/itm/124007604324 Sent from my iPhone using Tapatalk1 point

-

it really is my happy peaceful place. Is it too ironic that I lose time in there? or maybe 'forget' is a better word....1 point

-

Thanks for the kind words. My roll trench is about 6" from either end. I did it with a router and the sides were already in place when Tmuir mentioned the idea. I've looked at endless 3-D patterned cutting board made from end grain hardwoods on YouTube. Funny you should say, when I was making the drawers, I numbered the backs with a small and discreet number. The numbers were penciled in, and the thought did go through my mind that after I was gone, someone would surely see those numbers and wonder about the maker. You say "great experiment," Floyd says "Great Gig In The Sky."1 point

-

Ha i realized when I wrote that hair was a poor comparison- but still haha. Also, in case you want to work on tbis movement spare parts are nonexistent. The reason I have one on the bench is it needs a balance staff. It's only 1.6mm long so should be a piece of cake with so little metal to whittle off.1 point

-

one of the problems with the mystery of crystal fitting at least at the professional level is typically professional watchmaker's if they live the right part of the world do not fit crystals themselves. In the bigger cities at one time the material houses located near to the watch shops were if you needed a crystal you would just physically go the material house hand them a tray of cases come back later you'd have crystal fitted. Why should a professional watchmaker waste their time if there is somebody else could do it for you? but not everyone has access to a material house that means you're going to have to fit the crystal yourself as soon as you figure out what it is. I've attached the handout they help figure out what it might be GS Crystals.PDF1 point

-

I showed off a tool I made out of a dull nail clipper in a post to a forum member, he came out with an improved version of the tool in no time. Two screws were mounted on it to set the upper and lower limits it is suppose to pinch the canon pinion which gave you full control over tightening. Need tomorrow's sunlight to take pictures of my version and post, will search for picture of his version too.1 point

-

Fear not, Mike. The bench doesn't make the man. John Lennon can do things with playschool guitar that some guys can't with a $13,000 Fender Strat or Gibson Les Paul. Your tucked-away watch corner looks inviting and seems as though that's where the magic happens.1 point

-

Hi They are not the easiest of watches to put together being two plates there is quite a bit to do. The timex was designed as a throw away watch when they were returned for repair they just put a new movement in , but they can be fixed. We have a Guru on timex watches, JerseyMo who works on almost exclusive timex and knows then backwards. Next time you get one clean it out complete with Naptha, or ronsonol then a drop of oil. We have all cocked it up over the years I know I have.1 point

-

Take a look at the old Sternkreuz catalogues here https://www.cousinsuk.com/document/category/watch-glasses You need the ones marked R19, not G33. They have a lot more information in them about selecting and fitting crystals than the current catalogues have.1 point

-

Easy if you have the tool for it and a lot of experience. Even so, in this case, with such a minuscule cannon pinion, I'd be pretty nervous. I have Bergeon's cannon pinion tightener and the Seitz jewelling pushers and stake for lanterning cannon pinions but I doubt any of tools would work very well with this tiny thing. Perhaps you have some other technique or tool? Please share!1 point

-

I sorted my problem of the residue by changing my cleaning fluid and rinse. I now use 'Fine Clean' and 'Fine Rinse' by a company called 'Quadralene' https://quadralene.com/ They don't advertise it and you can't buy it directly from their website, you have to call them. The great thing is you get 5 litre containers, instead of 3.8 litres that L & R sell and it is a lot cheaper. I think it works out about £70 with delivery, whereas L & R fluids will cost over £100 and you get 20% less fluid. No brainer! It's non ammoniated, but works a dream1 point

-

1 point

-

Hi cannon pinion/hour wheel area loose/broken parts. Its a dial and hands off job.1 point

-

I'll see what is on Ebay. To speed it up, I'll probably end up making one from the 3mm piece if I can't find anything there for a reasonable price. If I find a thick piece of brass/copper I'd like to make one as per the picture bellow. The 'slot' and the hole are there to stop transferring heat from one side to another leaving the other side cool.1 point

-

Reflowing the shellac should work, but if you want to add some it's good to make a "shellac applicator"; heat a corner of shellac above your flame until it just goes liquid, then stick a toothpick in and pull away. You'll have a long strand, break this off a few mm away from the end of the toothpick and you can now apply it where and how you want.1 point

-

But in some cases one can make his own, below our Host Mark Lovic demonstrates1 point

-

1 point

-

Hi Find attached the tech sheet for the Landerton 48 Landeron 48 (1).pdf1 point

-

1 point

-

1 point

-

Nothing special, after planing I finsihed it with a random orbital sander up to 1000 grit and then applied an oil based marine varnish. This is my general work bench in my workshop, it is used for pretty much everything other than hammering and sawing, although usually its covered in parts of what ever I have disassembled in my workshop. I love that picture of the tree gent over by the wind. When you get out to the farming areas we have trees bent over and gnarled like that by the wind, but nothing as dramatic as that tree. I have a few Jarrah trees growing in my back yard, but they are a slow growing tree and because of this they are not 'farm grown' all Jarrah comes either from land clearing or old growth forest and so is becoming harder to find quality jarrah for reasonable prices. My house was built in the early 1980s and its 90% made of Jarrah, all beams are Jarrah, the outer cladding is jarrah as are the skirting boards and kitchen cupboards. The salvage value of the wood in my house in a few more years will be more than the house is worth.1 point

-

So it's time to take the watch into one piece. It seemed to be easy so I have started - hour hand, minute hand, zeroing chrono, minute recorder hand, hour recorder hand and the last sweep second chrono hand. I zeroed the chrono, attached position, pushed it down. I think great - it's done I started the chrono and after few seconds tried to zeroing. Pushed the reset button and .... what the heck? : -s Pusher was hard. I was affraid to broke any lever so decision could be only one - disassemble movement again: - | I took over chrono bridge and cleaned it with all reset chrono levers. Small amount of fresh oil and voila - works. : -! All that was left was to press bezel with crystal, put the new gold plated bracelet and have a enjoy of the watch. I know it's not pristine, have some drawbacks but I feel proud to back this one to life. I enjoyed some much during this project. I hope You too.There is still accurate tuning and amplitude measurement but it must wait until I buy a new microphone for timegrapher. I am sure I will inform You about the result. So stay tuned.1 point

-

good show, very good pic.s. the watch is a "raceing timer" ? vin1 point

-

Not the most easy watch to start with ? The broken post on the barrel bridge i have seen before. Common problem. You will have to find a new or used bridge. speedtimerkollektion had some before.1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point

.thumb.jpg.56e9071d12ee7dde7c16e3fddfc28658.jpg)