Leaderboard

Popular Content

Showing content with the highest reputation on 05/28/20 in Posts

-

As we all know, our world has been deeply shaken. Lifestyles, routines and every partXa,a of our lives have been effected in some way. This is equally true for our children. Their academic and social life's have also been upended. As a father of 4 who range in age from 15 to 24 this new reality is all too acute. My youngest two are still in high school with one a freshman and one a sophomore. They have been pretty much on their own with getting their online classes up to date and completed. My daughter, who is also my youngest, has been on task the entire time, she had finished her work last week. My 17 year old son has procrastinated much of the entire time. 4 weeks ago he was in danger of flunking. So, as an incentive, I offered to get him his favorite watch which is a duplicate of mine if he finished with at least a C average in each class. In this case, it's a 1978 Timex Falcon Eye. Thankfully I had found one for an absolutely fantastic price, a steal to be honest. When it arrived, it was pristine! Tonight was his final night. The final assignments were due. He plugged away and by 9:45pm, he crossed the finish line! And as required, no class was below a C grade point average. In fact, only one was a C, the rest were comfortably within B and A averages. I'm very proud of him and it was a Thrill and an honor to present his watch to him. For fun, I had him put on his new watch but told him he was trying on my watch to see how victory feels. He was all smiles and kept saying how awesome the watch is. Then I held up mine on my wrist and put it next to his and said, yep, it's almost as cool as mine! He was like, What!? Is this mine? No way! He was so excited! Totally worth the wait. Here they are, two of the finest original 1978 Timex Falcon Eye's you'll likely ever see!3 points

-

A 6R15 will set you back $130 if branded as SII NE15, and even more if Seiko, now since a SII NH36 does practically the same for $100 less then is clear why the latter is the popular choice. Have a read of the many modders topic on WUS. There must be thousands of posting and pictures on the subject, and complete watches and parts are often listed.2 points

-

When you slowly turn the crown backwards in setting position, you are actually applying an opposite force to the train of wheels through the cannon pinion to take enough force from the mainspring power to stop the movement. It doesn't jam the works.2 points

-

Your other tool may still be or have been a combined pivot file and burnisher. It depends how it's been used in the past as to what it will be like now. One or both ends may be dressed as a burnisher - depending what sort of tool they presently appear to be, if one end is still a pivot file then you may wish to keep it as one.. a pivot file is useful so I'd keep it as one if it's in even partially worn condition. Basically to dress a burnisher you could use traditional techniques such as oilstone dust on a lap with a bit of oil, or nowadays you could use a modern abrasive of a similar grade. The process creates tiny grooves in the tool from the abrasive which do a combination of really fine cutting and burnishing the pivots you apply the tool to. The burnisher would be moved across the abrasive and rolled over part way through the stroke, starting with a large face then rolled onto the next smaller face. You will see that there should be 2 sharp edges and 2 rounded edges, that will indicate which edges are rolled over and which shouldn't. It will probably take a bit of time if there are any imperfections or surface rust, etc to remove - you may choose to work on a side at a time to flatten and remove imperfections before dressing it.2 points

-

Bezels? I suppose that depends on the environment. Too much sun/UV or a salty environment would cause fatigue for sure. I have some that are faded despite being solid colours2 points

-

I hear they get brittle as they age and don't do well with being popped off and on.2 points

-

She got a couple of those Pop Vinyl figures, a nose piercing and a dozen roses. The only thing she really wanted and had asked for was the nose piercing.2 points

-

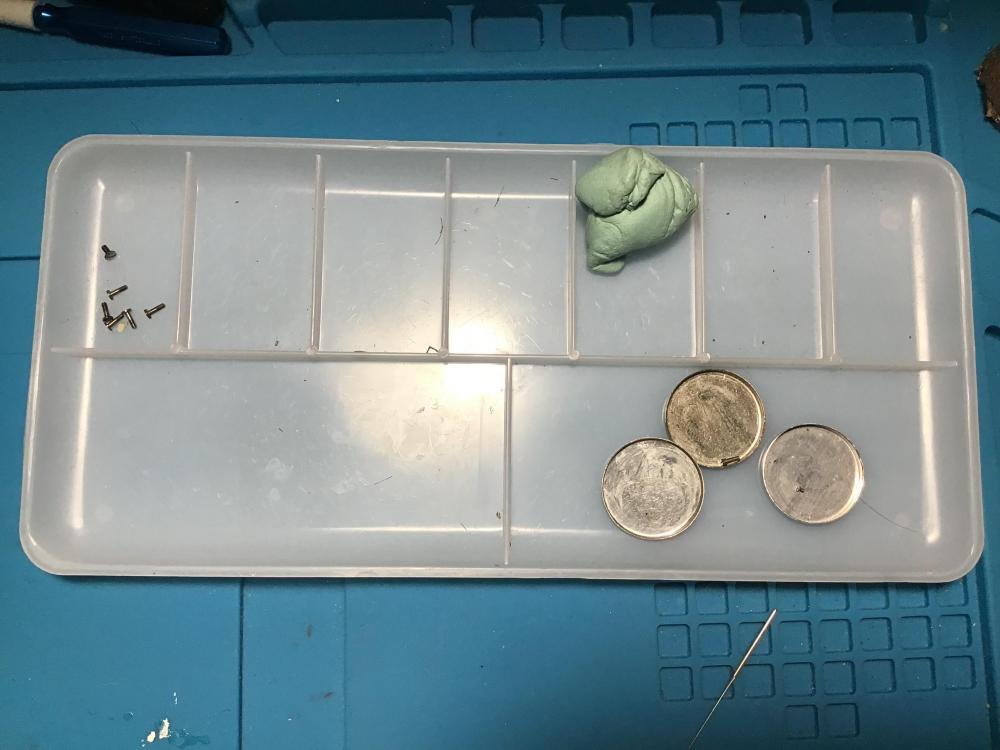

Pictures don’t always help so I always use these compartment trays, these I get from a hobby store in the paint section. But Esslinger sells nice ones with lids....each piece I remove goes into one compartment with its respective screws. Each compartment represents a step. When i reassemble I work backwards. As far as a bridge that uses different length screws you can always attach the bridge and look from the sides and tell where longer screws will go. Or by seeing where they screw in from under. Kinda hard to explain but just observe and you will get the picture.2 points

-

With me it was practice. Never took notes and never used a camera.2 points

-

Actually it was my second watch joke since the movement doesn't actually have "hacking" either so the use of the word hack was obviously a double entendre with the extend usage of hack (n) being "a tip or trick for an efficient method of doing something"1 point

-

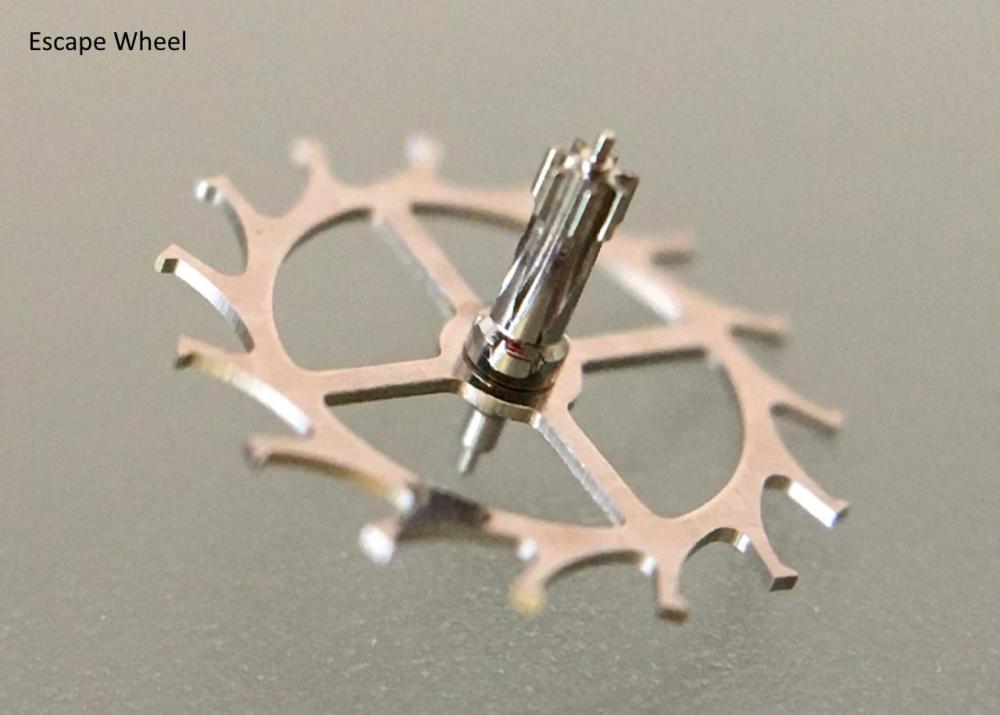

Hi Everyone! I have been practicing watch servicing these past months. So far I have successfully serviced a ST36 (ETA6497 clone), thanks to Mark's watch repair course which is awesome! I have also tried to service a NH25A, and messed up the hairpsring (replacement on the way), and a Miyota 8215. Everything was going well with the 8215 until I reassembled the train bridge and noticed that the escape wheel wobbles when I turn the wheels. My guess is that I accidentally broke off the upper pivot during cleaning. I was looking for a replacement escape wheel and found it at Cousin's, but they are out of stock. Anyone know any other place I could get one? Thanks. PS: Trying to keep a positive attitude after messing up two movements, but practice makes perfect. :)1 point

-

If this is your first movement, you can pretty much count on either breaking or losing something. Fortunately parts are fairly easy to get.1 point

-

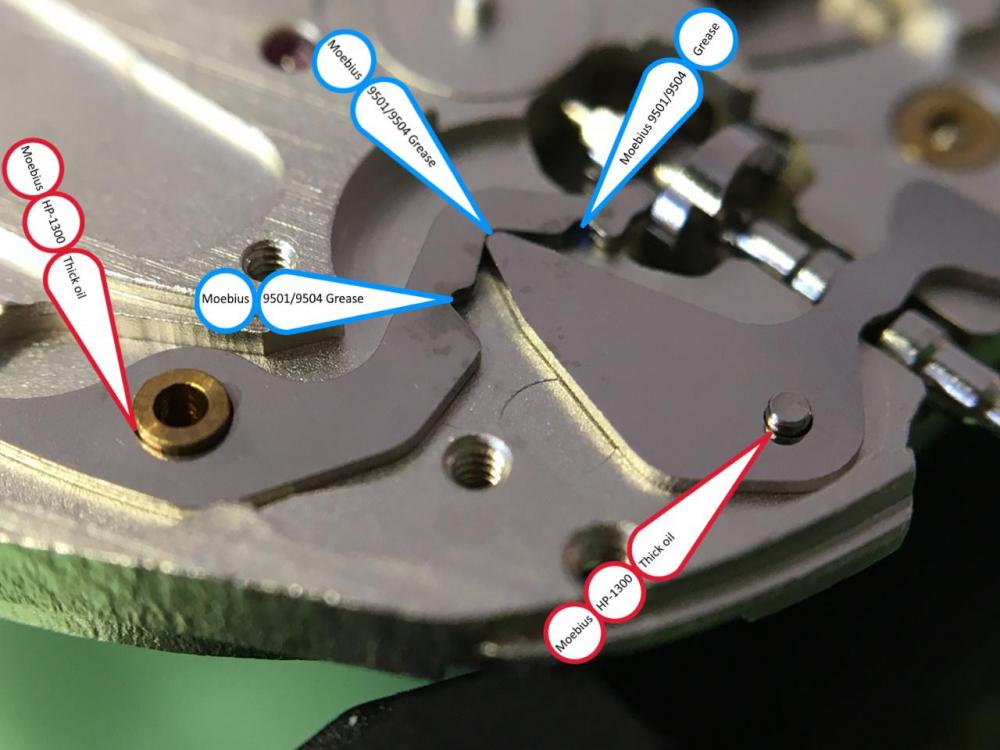

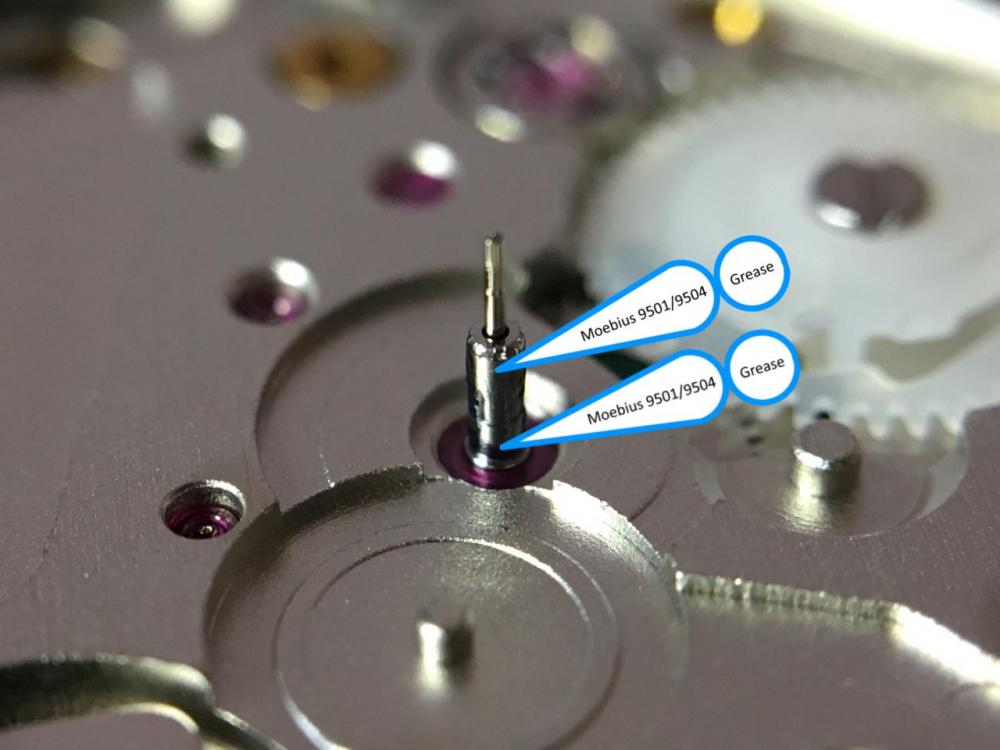

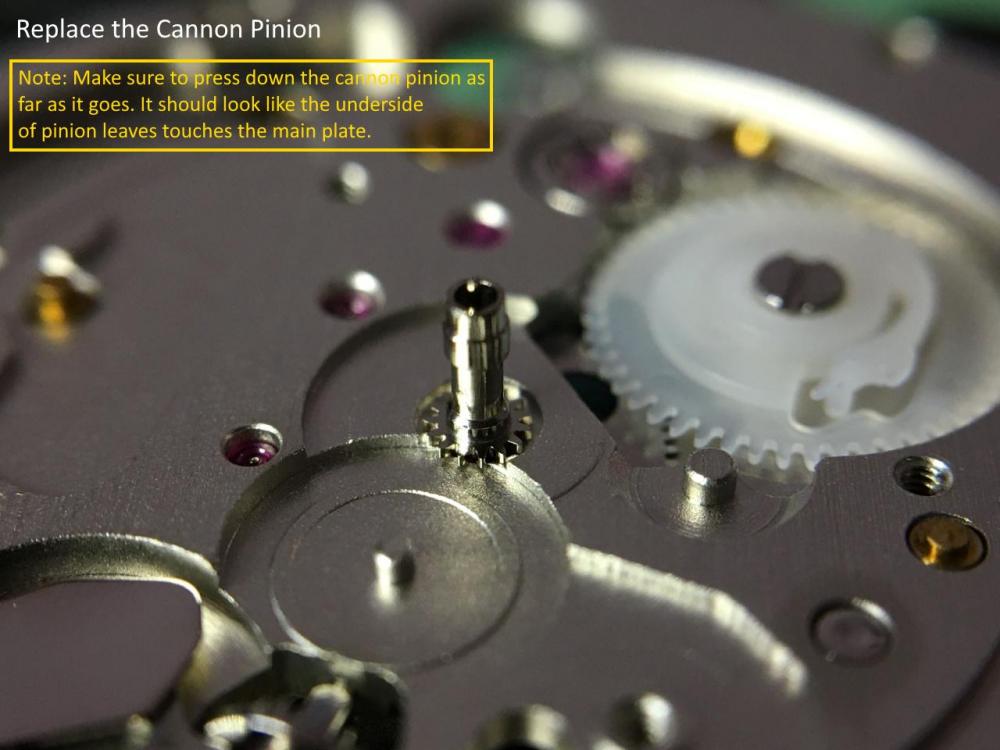

Canon pinion is too tight, if you did take apart, first oil the canon, refit and advance the hands couple of turns around the clock to spread the oil, it should loosen up, if it didn't you may have to broach the canon.1 point

-

There is no Seiko 5 "Malasyan model". All Seiko 5 are manufactured in factories outside Japan. If you want a Made in Japan Seiko you can get something like an SKX007J or a. SARB watch that are a mix of proveniences but can legally show that. For a brand new, fully Japan made piece you have to scale up further, perhaps not to Grand Seiko levels, but above $1,000 for sure. I recommend against you taking your new watch to tinyi parts but to read here instead about what is best for a beginner to learn on.1 point

-

Hello, New lanterns can occasionally be found but it is rare. More often these tools are sold with damage to the same parts. It is possible to make or repair the parts which are damaged with a combination of tools which will generally differ by whether they include a 90 degree double angle milling cutter or a tiny drill - for grooves or holes. Off the top of my head, the depth of grooves with a 90 degree cutter is a depth of 0.65 times the desired pivot diameter. I'm assuming the issue is with the disk with tiny holes in it.. it can be possible to anneal the damaged end and to turn most of it away, leaving a boss concentric with the outer diameter which fits through the tool. The end of the boss can be tapped for a retaining screw for the new part, or the new part can be glued/ bonded on the end - both parts will want to be a nice close fit so that the new part remains concentric if drilled before being mounted to the old arbor / part of the tool. The new disk can be steel or brass (they don't see a massive amount of wear but may have abrasives embed in them, and will wear out quicker than steel). In order to drill one you'll need a way of indexing so that you can use the tools existing divisions (the star shaped part and guide). It is possible that a new disk may be able to be drilled or center drilled in place on the tool with some creativity. I've also got a jocot tool with a damaged disk, shall repair it eventually but just use another for now.1 point

-

I'll defer to Jersey mo who owns one! Nice pepsi. If you get a second with bezel.and want to sell the bezel off this one let me know im always short of bezels lol1 point

-

200ft are not as rare as 200m/600ft which I believe we're actually commercially used dive watchesive also got a kelton diver which has a bigger screwdown caseback and is a tank!1 point

-

I had my eye out for either a 200 foot or 600 foot diver and I finally found a 1970 200 foot in my budget within a large Lot of Timex's. I snapped it up and was sorely disappointed when the seller had forgotten to ship it with the lot. Thankfully they sent it out when I pointed it out. Still waiting on a period correct Tropic rubber strap. Looks great though.1 point

-

Wow, great collections! I just have the one, that I got some while back. Non-running, the balance wheel has come loose from the balance staff, and with its design I'm not sure how to stake it so I'm just looking for another one instead. It's an M75 so should be fairly easy to pick one up from the bay, I just need to pull my finger out. And I've found the stem bridge assembly so fiddly! Give me a Japanese chrono to reassemble any day rather than another one of those!1 point

-

I just grabbed this 1971 vintage Seiko Lord-Matic. It was being sold as a non-runner, hopefully nothing is actually broken. I'd like to replace the Crystal, but it looks like there isn't a direct replacement currently available on the internet. At the very least the dial needs some attention with some kind of stain around the day window. Updates will follow as soon as it arrives.1 point

-

1 point

-

Hey, bit late to the party but I use the Elma 1:9 too. I have spent a lot of time trialing different strategies for cleaning parts. The best I have come up with is Elma 1:9 in an ultrasonic at about 40C for 4 minutes, then rinsing the parts basket in distilled water at 40-50C twice, the second time in the ultrasonic. For some but not all parts I use pure Isopropyl alcohol as a final rinse. I have a gallon of the Suprol rinse here doing nothing but posing a fire hazard. Because I hate the smell of it and also, no matter what I tried it would leave some residue on the parts after drying. I have an Elma S10, non heated ultrasonic cleaner, it works very well. I just run my tap to get the water temperature right, and considering the short cleaning times the water doesn't cool down much.1 point

-

1 point

-

Hi I have just test loaded the timezone PDFs both worked ok are you using Adobe reader1 point

-

Forgot to add when I clean the parts I use mesh compartment trays. But in the beginning I used mini glass vials filled with cleaning fluid and each one was numbered and I also numbered the compartments of the tray. So each tray section would correspond with the glass vial. I still use this method today when dealing with an unfamiliar movement. But if you have disassembled and reassembled enough movements you kinda start to just know where everything goes, kinda like when you move to a new town you don’t know where everything is, you use gps a few times get to know your area and grid, then you just know.1 point

-

1 point

-

1 point

-

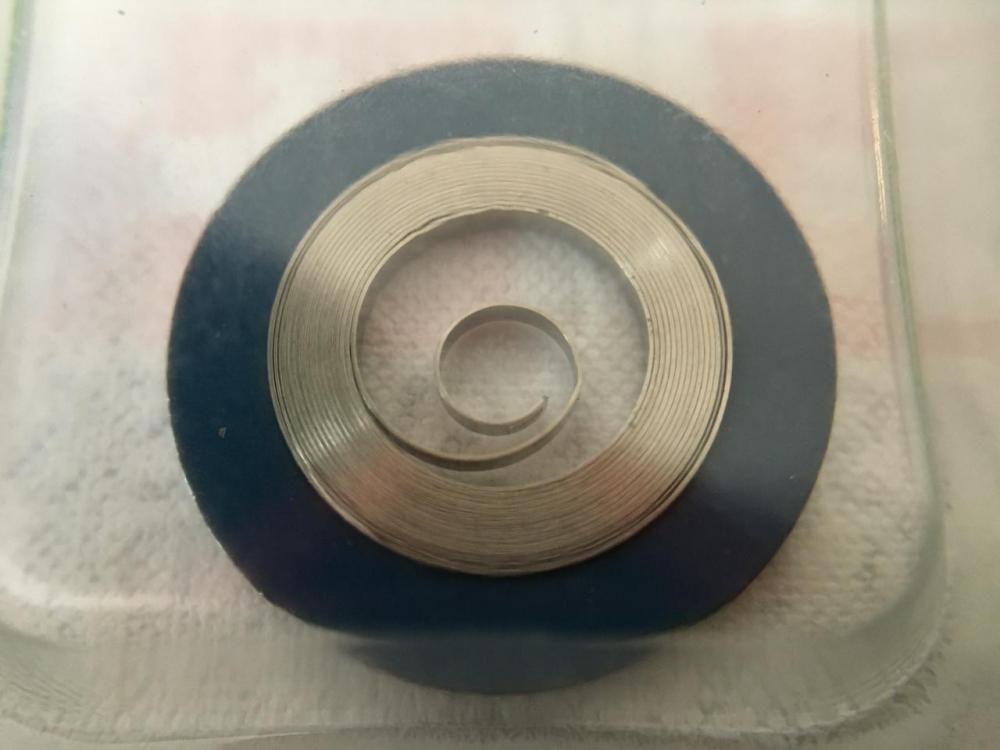

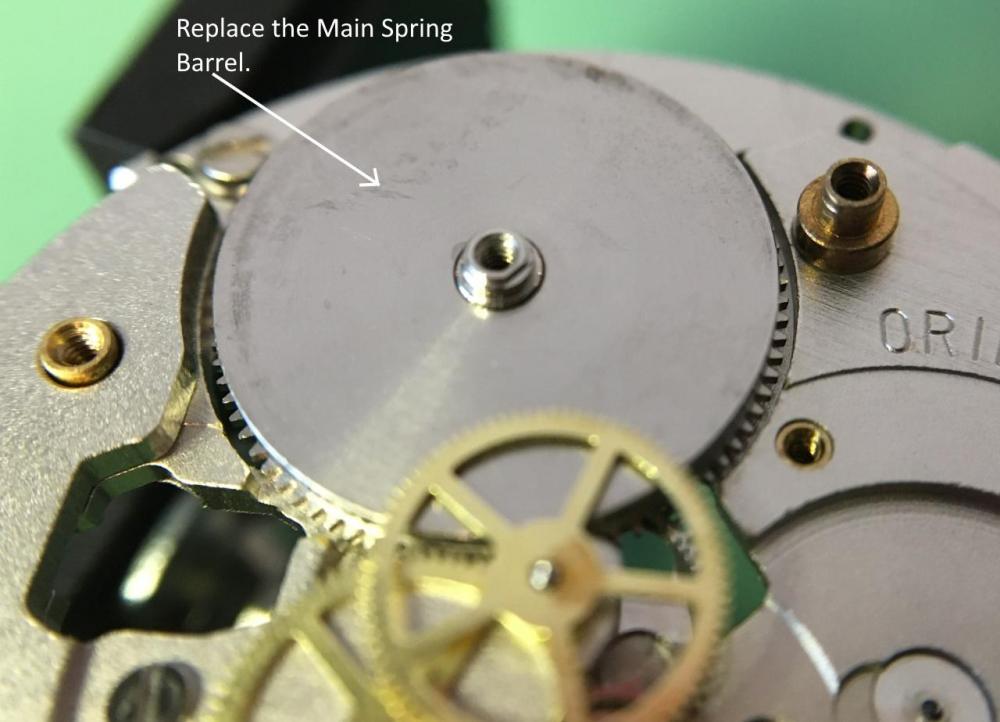

Main spring cleaning depends upon whose literature you're looking at. For instance Omega has a technical document on recycling mainspring barrels as they call it. They only wiped the mainspring down with a cloth no cleaners Or solvents. They're assuming that it Is a original mainsprings still has the dry somewhat invisible lubricant on its and that's why they just wipe it. At least that's what I'm assuming because there really really clear on no solvents were cleaners. If I'm doing a watch which is typically is a pocket watch and if I'm going to reuse the mainspring because it's an really beautiful nice condition then I just wipe it with a cloth with a solvent because it usually has sticky grease on it. So I typically never clean mainsprings in the ultrasonic. If the mainspring is an original blued steel spring Hulk still clean those with a cloth in a solvent but once their clean it put a thin coating of oil and/or grease on them. The Elgin watch company had a interesting document to why mainsprings break and they implied micro fractures due to rust. I tend to think poor manufacturing skills or not understanding things but steel mainsprings definitely do not like rust.1 point

-

I think memory is less important than understanding. If you understand what the part does, then you should be able to figure out where it goes. Having said that, taking notes and pictures will help, both with the understanding, as you learn, and with those situations where it is less than obvious what goes where. I recently took apart a Sekonda with date complication. I've taken apart and re-assembled several of these recently, and every time I do so, I can't for the life of me remember which way round one of the springs goes. I'm not sure what this proves, maybe Its an age thing, or maybe, and more likely, its because I don't actually remember every part of every movement, but actually figure most of it out based on experience. As it happens I also have pictures of that particular movement, and there are others on line, so the issue doesn't cause me any grief. If you have any doubt about a particular assembly or disassembly step. Stop and think.You will save yourself a lot of time in the long run, if you take the time to think. If you can't figure it out, ask. There are no daft questions, but there are many people too daft to ask questions.1 point

-

1 point

-

I also have a 6mm lathe although mine is a Lorch. I bought it second hand and seem to have been lucky as it works surprisingly well for what I use it for. However, the previous owner managed to make a repair to a very similar problem by putting a right angled piece of metal in and tapped holes in the casting to hold it together. It works well although it is very tight fitting now so it is a bit of a pain to take on and off. Fortunately I don't use the cross slide very much and prefer the hand held graver. I haven't cleaned everything yet but here is a picture of the repair: Failing that, cast materials will braze as long as you are careful with the temperature which is another possible way of repairing it. I haven't done much brazing, welding or silver soldering before so I don't know about the practicality of that idea.1 point

-

Hi there! Not yet tbh I don't see that dial style that often for sale on eBay... Least not under £100 lol1 point

-

Today I'm letting may father's US government issue GG-W-113 stretch it's legs. It has a genuine Hamilton 685 manual wind with hacking. I got this for him last year as a father's day gift. The date on the back of the case is June 1969, the year he was there, and exactly 50 years since he was there plus the month Father's day falls on. I can be thoughtful... No matter what my wife claims! It had random issues that I thought were minor, but then it flat quit on him. It has been on my bench since before Christmas waiting on me to troubleshoot it. Yesterday, I finally had some time to dig into it. Turns out the lower balance jewel Chaton had moved and just needed to be pressed back some. I had to guess as to how much to move it. Unfortunately I don't own a jewel press, very nerve wracking trying to push on the Chaton and not over do it. But it seems much better now, no stalling or anything. It's keeping excellent time. I gave the Crystal a better polish too. My first attempt was kinda half assed. So, I'll hang on to it and let it run down and sit for a week or so and wind it to see if it takes off. Fingers crossed.1 point

-

Indeed they are. I'm also working with a cheap table saw whose runners have a lot of slop. I'm going to make my own runners later today out of hardwood. The jig should give more repeatable results. The top 7 drawers are all 2 1/2" high. The bottom two will be larger, with the very bottom being 7" to accommodate my staking set box. I think I'll use thicker fingers on the bottom two, larger drawers. It will be a nice variation.1 point

-

All vintage Gents watches are collectable, specially the ones like yours with in-house movement, Oris made all the parts except stones. Not too pricy yet not a practice piece either.1 point

-

Cool watch! Use caution on this one, and good luck. I will await the service and seeing a video of it running. Regards1 point

-

Thanks for all your help so far guys, really, I am truly grateful for all your advice, comments and input. I've since refitted all the plate screws. I await delivery of a crystal lift which should arrive next week. I will keep you all updated.1 point

-

1 point

-

Hi Max Like has been told to you put the watch back to the status quo and start again following the advice you have recieved. To assist you on your quest I have enclosed the tech sheet for the oris 292 hope it all helps. cheers Oris 291, 292.pdf1 point

-

Movement comes out thru the front. And as suggested, replace the screw in the plates (apart from the ones around the rim) otherwise the whole thing may come apart! good luck Anilv1 point

-

first thing I would do is put the screws back in because if the watch really is fully wound up when you take it out of the case and those plates falloff all the mainspring energy is going to unwind really fast it's probably got break something. then from the link below you find out that the ratchet wheel is under the dial side. More than likely from your picture the move but probably comes out the front side.. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Oris_2921 point

-

1 point

-

1 point