Leaderboard

Popular Content

Showing content with the highest reputation on 05/21/20 in Posts

-

I needed a Lorsa P75A for a custom build and I saw a little watch on eBay, quite ugly but with the right movement and a nice bracelet ... Bought it for €20 shipped ... The Lorsa ticks great at 5s/day so much better than I expected ... customer will be happy ... And the bracelet looks !!! great !!! on my Ingersoll Sealion ... Today is a happy day [emoji16] Envoyé de mon moto g(7) power en utilisant Tapatalk5 points

-

I’ve always been really impressed by the lapping machines that are used to achieve flat faces and crisp on cases. Although I don’t do enough case refinishing to warrant the price of a machine, I though maybe I could achieve a similar result with something home built. The impetus to try came when I bought an Omega Chronostop. The case came with a sunburst case finish that was long gone and would require precise brushing. I figured I could replicate the multi-axis adjustment by using a telescope head. Found one on eBay for $125. Then added a 3 jaw Chuck for $50. My only issue was that I needed to adapt the two together. Because the stress won’t be so high I figured I could just 3D print some adapters and it worked perfectly! The great thing about the resin printer is that the resolution allowed me to actually print the threading! Because the case is a top loader, there was no good way to hold it properly so I printed an adapter to screw on the back. All ready to go: I am really happy with the results! The case has some dings that I wish I could laser weld but alas I can’t built one of those on the cheap. Lol. My next step is to find a way to fasten everything down so I get more consistent engagement with the sander and recreate the angles consistently between checking my work. - Craig4 points

-

3 points

-

Arrived Sent from my iPhone using Tapatalk Pro2 points

-

Hi Max Like has been told to you put the watch back to the status quo and start again following the advice you have recieved. To assist you on your quest I have enclosed the tech sheet for the oris 292 hope it all helps. cheers Oris 291, 292.pdf2 points

-

2 points

-

first thing I would do is put the screws back in because if the watch really is fully wound up when you take it out of the case and those plates falloff all the mainspring energy is going to unwind really fast it's probably got break something. then from the link below you find out that the ratchet wheel is under the dial side. More than likely from your picture the move but probably comes out the front side.. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Oris_2922 points

-

We have had this discussion so many times but it still happens every time the word is mentioned. You are referring to benzene, that is a common mistake for English speakers. https://en.wikipedia.org/wiki/Benzene Not to be confused with Benzine.2 points

-

It has finally arrived. A Hamilton 992 in a clear back salesman skeleton case. But when i looked at it closely, the back would not screw don all the way as it was bottoming out on the two movement case screws. Here is the beautiful watch but with the screws removed and the back screwed on tight. Any insight on why these screws interfere with the case back closing. As well, would love some history on the Salesman Cases from Hamilton. Sent from my iPhone using Tapatalk Pro1 point

-

Nice JDM watch there, I suppose you realise that it will have an English/Kanji day wheel?. I don't have a blue faced 0923 QZ, only this silver faced GP 0923-8000..... And this 0922-8060 (date only) in stainless Out of about 40 examples of these early analogue quartz watches I don't have one with an '-8040' case... Nearest I have to that is a couple of 0903-8049's This 4633-8049..... This 0903-8089... And this 0903-8099...... Plenty of other blue faced 4004's (export version) though, mainly with 0903 movements though a couple with 4633 movements...1 point

-

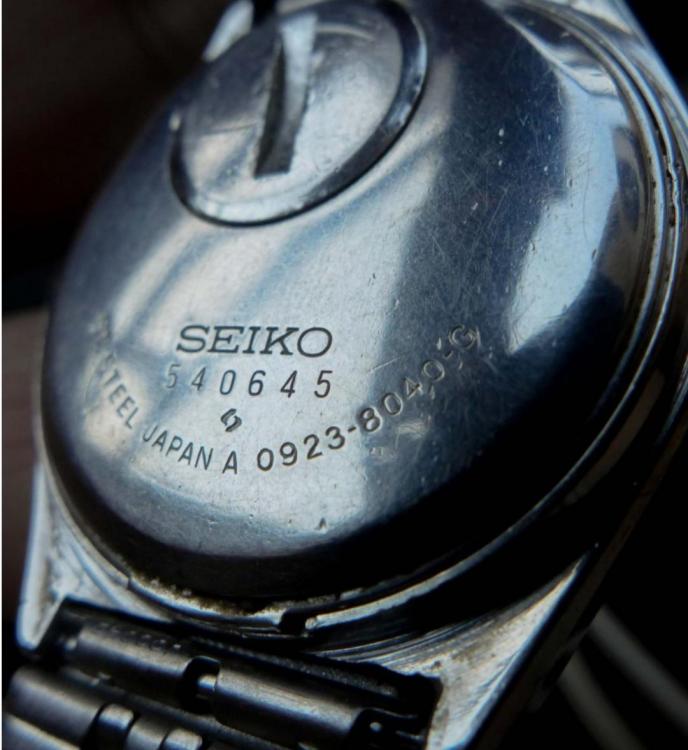

Have had my eye on a 70's Seiko with a quartz movement for quite some time. I picked up this green dial little honey this morning. It has a quartz heart oscillating at a steady 32,768 cycles a second! It's a model 0923-8040. The serial says it is of a 1975 vintage, exactly the time frame I was searching for. Pictures I've seen online of others, look fantastic, fingers crossed it's the same in person.@JohnD has several vintage quartz Seiko's with blue dials and I believe he has this exact same model with a blue dial, possibly with a different case. Will definitely share this when it arrives.1 point

-

Something a little bit different from the penny lots today (0.99p no other bidders). A 1976 Citizen Crystron early LCD. Sadly not in as good condition as this one -> here <-.. but then again it doesn't have the eye watering price tag to match either. I've picked up some nickel welding rods, to do some electroplating experiments with, so I may try to re-plate the case on this one, assuming I can get it running of course.1 point

-

1 point

-

The Salesman Case is actually from 2019 Classic Watch Case company and not a vintage case, however, no problem because it will be durable and I plan on keeping this for a very long time. I removed the case screws and the back now fits. I may just shave them down or modify the case in my lathe to accommodate the area needed for the screws. Open the crystal on your case and you will see “CWC Co “ on the top and a serial number on the bottom. Your case is also a remake of a vintage case I would bet. This company has one currently on sale for $180, so not cheap. Sent from my iPhone using Tapatalk Pro1 point

-

WOW !!! great job ... I've been "playing with dials" for some years now and I'm amazed how quickly you did that ... congrats !!! Now your oldie looks like a 4925 ... Envoyé de mon moto g(7) power en utilisant Tapatalk1 point

-

1 point

-

Hi again I have had ago at restoring the dial using spray paint and a ink jet printed numerals etc. I think I will have another go at it now that I have a better idea of what I’m doing but I think it looks ok for a first attempt. Also the completely knackered movement I repaired seems to be going well so overall I’m happy with my efforts for a £20 punt. Let me know what you think. Many thanks for all the help received.1 point

-

This might sound like a dumb question, but what is the practical difference, other than there being an additional jaw? A other much cheaper part which I would recommend is a jacob’s chuck. I have fantastic ones by Bergeon and Jacob’s USA and they are so quick and easy for drilling.1 point

-

1 point

-

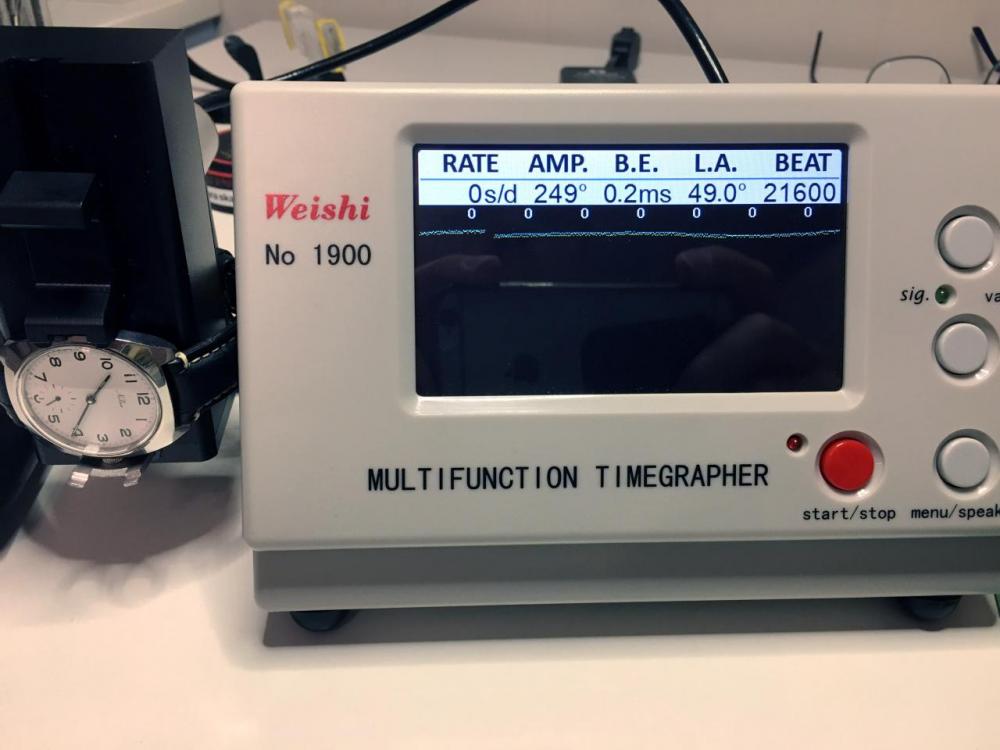

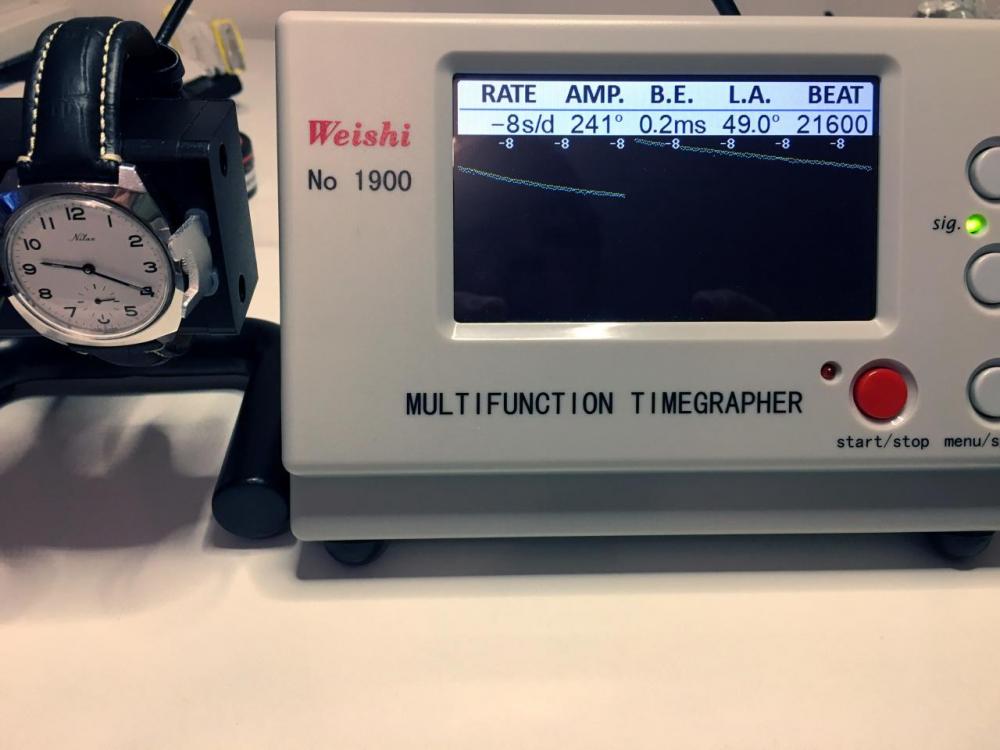

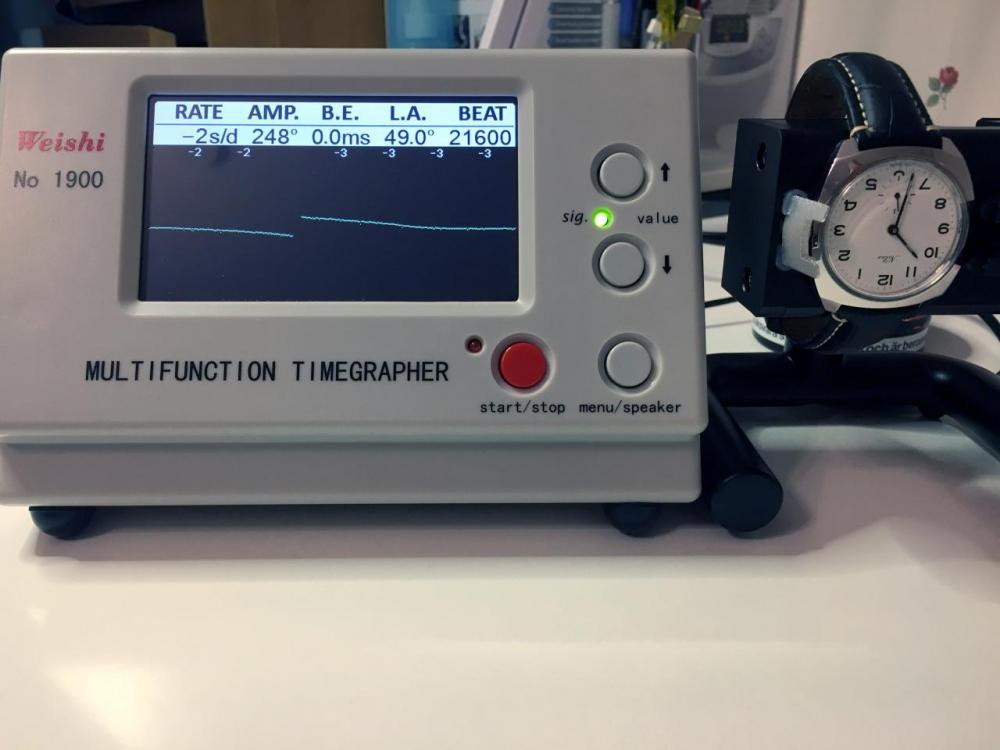

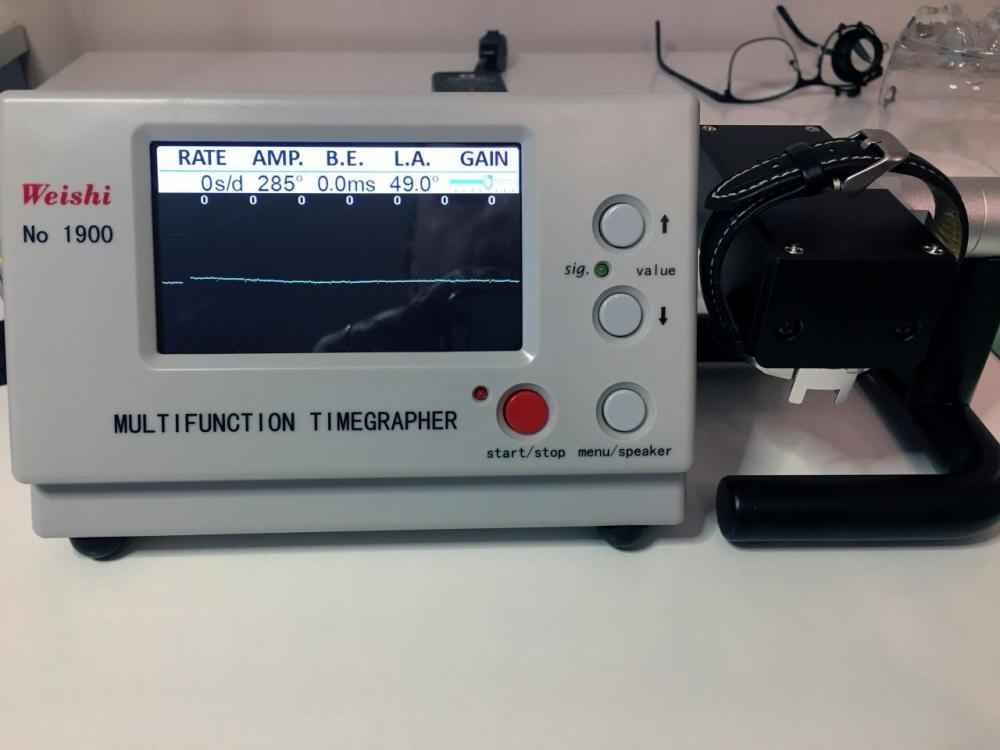

So, finally my very legible Unitas 6325 ”amplitude problem child” has been re-assembled. Timing machine images below. I started the reassembly weeks ago but as I was fitting the click spring it decided to launch for outer space, never to return. Anyway, CousinsUK had the click spring in stock and delivery to Sweden usually just takes a week. However, my local mail delivery “decided” not to inform me and not to deliver it after it had arrived. Instead, three weeks after my order, they informed me that they would send the package back to England if I did not pick it up. How very, very annoying! Anyway, when into watches there’s always something else to do meanwhile, like servicing an ORIENT movement and replacing an ETA cannon pinion with driving wheel, and… The current amplitude is maybe not perfect (not sure what is to be expected from this calibre) but it is now in the acceptable range, especially considering it started out at 200 degrees dial up/dial down. The graph is a bit wavy and I guess the reason could be that for some reason the power isn’t perfectly and evenly transferred to the escapement. Anyway, I think I can live with that, and as I said, not sure what should be expected from this calibre. Perhaps my copy is a bit of an odd one. My original plan was to try to locate the source of the low amplitude, but I ended up doing several adjustments before reassembling. This is what I did: Adjusted the hair spring with the help of @nickelsilver's excellent illustration. Again, thank you! Stripped it and ran in in my (ancient) ELMA cleaning machine. Meticulously pegged every bearing and jewel hole including the barrel. Then rinsed and brushed the parts in IPA to get rid of any peg wood residue, carefully inspecting everything to be spotless. Polished every single pivot. Replaced the mainspring with a brand new Generale Ressorts spring. Replaced the jewel for the third wheel in the main plate as it was slightly cracked. There was a super tiny groove on the pivot, but I decided to keep the wheel as this post by @rodabod made a lot of sense to me. Checked and adjusted the end shake of every train wheel individually. By doing it one wheel at the time I could use my stereo microscope to actually see and not just feel the end shake. To the best of my ability I adjusted the end shake of all wheels and the pallets to about two hundredths of a millimetre. That is, barely visible even at 40X magnification. I used my jewelling tool for this operation and with this in mind for inspiration. Applied Fixodrop on the pallet stones and lubricated with Dr. Tillwich 1-3. I think I’m beginning to prefer this oil over Moebius 9415. I have no evidence whatsoever that it is “better”, but it has worked well for me several times now, so I will probably stick with it Putting an end to this chapter I’d like to thank all of you for all suggestions, help and inspiration! A special thank you to @Endeavor who kept my spirits up when I was feeling lonely and lost!1 point

-

1 point

-

ah, I just reply to your intro post. i see you have opened the Sprite only to find the set lever and screw are missing. Easy enough to replace as is the stem crown. As for the question about interchanging of the m25 and m75 . Yes, they will exchange with all but one very important step. Which is the minute hand from the m25 is not going to fit to the m75. and I did also notice you are missing the movement retainer. I have all the parts but of course we are separated by an ocean. Which makes stopping by a bit of a challenge. I'd bet the movement just needs a basic "Timex" service.1 point

-

Yes, it makes sense to have fewer types of jewels. But ultimately putting in the sink is an added process and it you're makes 10s or 100s of thousands of movements that can be a cost factor. One other reason to have the sink is that the jewel hole length should be shorter than the pivot length. The sink shortens the hole length. To make the whole jewel short enough in height to be shorter than the pivot length makes it quite thin and fragile.1 point

-

A blue dialled EB8800 based 17 jewel "JWB Sur-a-Zal" is on test today. It was suffering from a serious dose of hairspring salad with a side order of mechanical neglect. Although it now runs, I'm not 100% happy with it. The beat error is still a little high, and the amplitude is too low for my liking. I'll see if it manages to limp through the next 24hrs. Hopefully the cleaning and oiling will encourage it to pick up a bit. If I can get it to settle down, then I'll replace its crystal, but in the meantime I've just given the original one a quick polish, which is why it looks a little hazy. The 19 jewel Sekonda on the other hand (literally) accompanied it today, and is still performing nicely.1 point

-

1 point

-

1 point

-

I think you have nailed it Rodabod. When I was looking for a spare AS1194 I did see that some were built with rubbed in jewels and non Incabloc on the balance wheel. It’s good to get this little niggling problem resolved at last. Regards Deggsie Sent from my iPhone using Tapatalk1 point

-

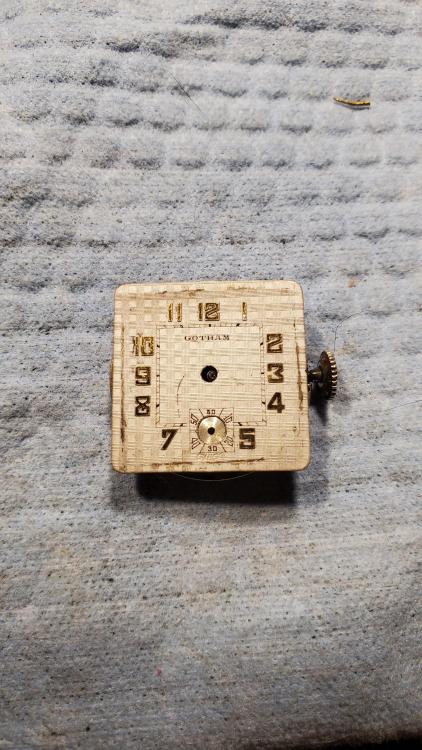

Today I'm finally able to wear my newly acquired Art Deco Gotham. It has an AS 340 beating inside. The case is amazing! I love the two tone gold and chrome scheme with enamel detailed engravings. I also love the swinging lugs. I've read these were called Driving watches. It was a bit of a challenge getting it to run consistently, but I think I have it sorted out. I'm not 100% sure what year it was made, but according to Ranfft the movement was produced from about 1920 to 1935...or there abouts. I'd guess about the mid 1920's for mine. If anyone knows how to date these older A. Schild movements, please let me know.1 point

-

1 point

-

This 19 jewel USSR era Raketa 2609HA based Sekonda turned out very smart. I didn't have a full high dome crystal for it, and had to settle for a more square profile one from my stash, but I can live with that. The watch itself looks hardly worn, despite the terrible condition it arrived in. None of the usual grime, and no apprentice marks round the case back or round the edges. A quick service, some delicate hand straightening work, a clean and it is as good as new. This is what I started with. Note the "interesting" shape of the second hand. My worry was that the impact that caused that damage might have done some serious destruction inside, but fortunately not. Naturally for a watch in that condition there wasn't much interest.1 point

-

1 point

-

1 point

-

1 point

-

Hey guys. I was killing my time and reading the technical sheet of 7s26. I found seiko suggest watchmaker to oil both two pallet fork pivots. Then I check other models as well, the results are the same. The technical sheets of 7s26,7s36,7009 all recommend watchmaker to oil the two pallet fork pivots with MobiusA( presumably 9010). I think this is not a very common practise. What do you think? What's the purpose of this?Will you oil it?1 point