Leaderboard

Popular Content

Showing content with the highest reputation on 04/28/20 in all areas

-

3 points

-

What do you think. Being delivered in 2 weeks. Sent from my iPhone using Tapatalk Pro2 points

-

Been 'playing' with two today......... Firstly this 'Limit' 25 jewel automatic, that I initially bought just for the AS1903 movement to swap into a Camy with a cannon pinion problem...Cleaned up the case and polished the crystal and with a replacement croc strap, decided that it is far too nice to use as a parts watch, so the collection has a new member... Secondly the Avia Swissonic arrived and after a quick clean and crystal polish......... This watch appears to have the original stainless bracelet, as I have seen an identical watch and bracelet combo before, and no it is not the same watch as the other one is still in the possession of it's owner. What was strange though was, even though I have not got a small wrist, I had to take three complete links out of it to get it to fit, it appeared to have been sized to fit a gorilla! . Still got some to do to it, I want to refinish the case and the bracelet and the crystal needs a little work....2 points

-

Totally, it's a night and day difference.2 points

-

First of all my apologies for not having documented the disassembling, but the watch arrived in a terrible condition and I stripped it down right away to get rid of all that dirt. If you have worked on some watches yet and think about entering the chronograph world with a 7734 let me give you 3 advices: Do it! The 7734 is a solid construction and not too complicated. Take your time and watch all the 6 parts of Mark's Venus 175-service on youtube. Of course the Venus is a column wheel system, but the basic movement is very similar and also on the chrono layer you can learn a lot especially about lubrication: https://www.youtube.com/watch?v=EI3T-IR3AgM Download the 7734 service manual. A lot of information here: https://strela-watch.de/valjoux-7734-7733-7736-technical-documentation/ Here we go. Some 8200 for the barrel and the new mainspring goes in (got it from cousins - what I'm gonna do after Brexit? ). The complete barrel. Some D5 for the arbor. Putting in the wheels and the bridges. Lubrication: 9010 for the escape wheel and the second wheel, D5 for all others. The keyless works. 9501 for the stem and the gears. D5 for the wheels and the lever axis, 9501 for the contact points of levers and springs. The click spring. D5 for the click and the crown wheel, 9501 for the contact point of click and its spring. Finally the ratchet wheel goes in. The pallets go back in, no lubrication for the pivots. Lubricating the balance jewels with 9010. The balance back in. The escape wheel and the pallets got epilame so I let run the movement with dry pallets for some minutes. After that 941 for the pallets (work from the dial side through the window). Now I start with the chronograph. First the bridge and the spring for the levers go in. Fly back lever goes in with some D5. Operating lever, again D5 for the axis. A little bit tricky, you must upline the integrated spring with the upper lever first (9501 for the contact area). The second pictures shows the final layering. The sliding gear goes in, D5 for the lever axis, no lubrication for the wheel! At this point I forgot to put in the minute recorder runner (no lubrication). You should install it here, later its going to be more difficult. The blocking lever (D5) returns. Some 9501 for the contact area to the sliding gear. The blocking lever spring. Be very careful, this one isn't just a flyer, its a damned Lockheed SR-71 Blackbird. The friction spring (gets a drop of 9010). The chronograph runner and its bridge (9010 for the long pivot and the jewel in the bridge). The minute recorder jumper, no lubrication. The hammer. D5 for the axis, 9010 for the lever ends that hit the hearts, 9501 for the contact areas to the sliding gear, fly back lever, operating lever, jumper. The hammer cam jumper. Before installing the clutch give 9010 to the pivots of the coupling wheel. D5 to the lever axis. The spring. 9501 for the contact point. Finally line up the driving wheel with the coupling wheel and the chrono layer is complete again! The dial side. Some 9501 and the cannon pinion goes in. Hour wheel with D5. The dial rest with its 3 screws. The date indicator. The date indicator driving wheel with some D5. The jumper with D5 to its axis. As there was no lubrication described in the manual between disc/jumper or disc/wheel and the parts looked well polished I didn’t lubricate. It works - let’s see how long. The guard with 2 screws. Finally the spring. The dial comes back and is secured with its 2 screws from the side. While disassembling I put the little hands into seperate trays to prevent mixing them up. Now I turned the crown in the setting position exactly to the point when the date switches and put on the hour hand to 12. Positioning the chrono-hand exactly on zero was that tricky that I forgot to take a pic. New springs and gaskets for the pushers. Unfortunatly I’m not good in restoring cases. So just refreshing the brushing a bit and some cape cod work. The movement back in the case and secured with 2 screws. A new gasket for the caseback and here we are. Thank you for watching.1 point

-

Hi and welcome to the forum . The enclosed manual will show you how to remove the stem. Far easier than tyring to explain it to you Cheers 21-22-23-26-29 timex.pdf1 point

-

Hi As we are at some what of an impasse as far as diagnosing this problem , I would like to take a backward step here, Remove the balance and re check the pivots are sound. Then remove the pallet completely and if it helps strip the watch down to the main plate then re fit the balance on its own . withn everything else removed you will have a clear view of the situation. Now with just the balance in place does it swing clear and easy if not we will have to dig a bit deeper. By fitting the balance on its own we have eliminated any other elements .1 point

-

Hi Have a look at Ranfft Rego143 It looks like an exact match. for the second one.1 point

-

1 point

-

My 1970s Vulcain MSR Skeleton. I think every collection should have at least one skeleton. Vulcain is IMHO a brand that is under valued watch company. I haven't seen too many of these skeletons floating around and when I do, they are usually in a round case. I love the tourneau case of these examples. I think the vintage Perlon strap does well with the blue gray color on the dial.1 point

-

The Waltham is a 6/0 1942 model. Ronda staff No. 2577 DCN staff No. 1982 Balancestaffs.com has them and they are available on eBay.1 point

-

Yes, dials for 7S/4R/6R and their SII counterparts are all the same. Anyway you have too look for which crown position it has been made.1 point

-

Haha. Okay, I'm a late 40s dude with a military background and also a financial planners work history. I've been in financial services for 15 years and wanted to make a change given the circumstances in the world. I've been a mechanic since I was a pup and the last time enlisted in the army, I worked on Apache helicopters (D models). It's been a hell of a road over my life. I really wanted to immerse myself in a craft that is as precision as aircraft maintenance without the physical requirements, since I had some major surgery caused by my last enlistment. What I really want to accomplish one day is to create a watch from scratch and to make it a custom piece; I saw a watch that was made entirely from wood (except the mainspring and hairspring) and I just fell in love. I feel I have enough creativity and ingenuity to pull it off and most importantly, I love this kind of work! I look forward to my career in watchmaking.1 point

-

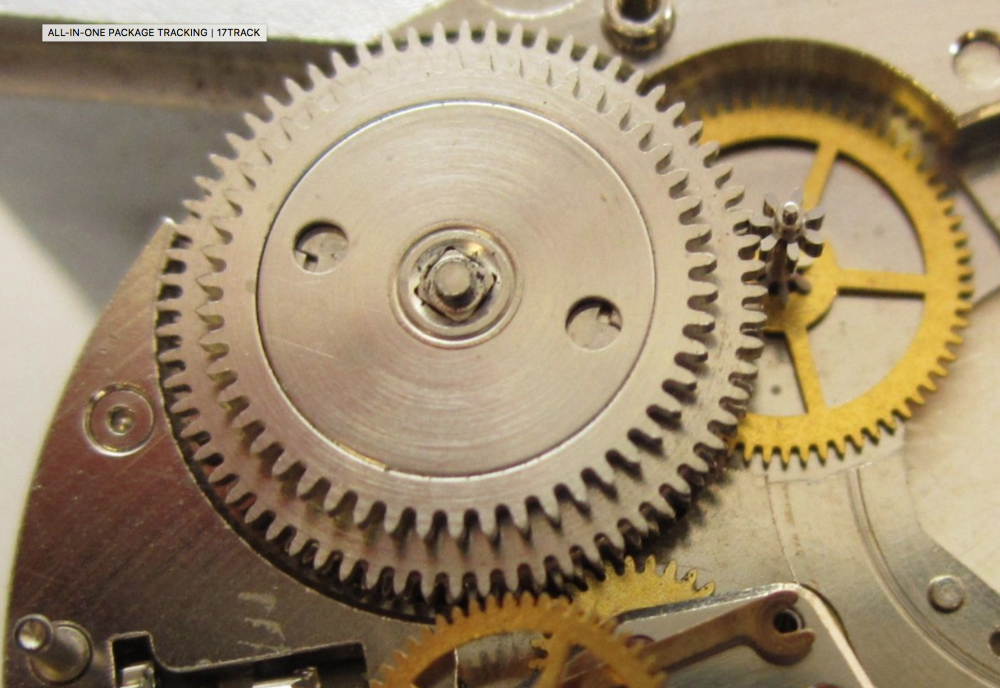

That's a great idea to investigate - the double-decker ratchet wheel. It has a slipping mechanism internal to it that allows the hand-winding to work independent of the autowind. I did not pull it apart to inspect the inner workings. I wonder if it is slipping and releasing the mainspring! Sorry about my original description, I was trying to describe my process of elimination. I started with a full movement reassembly and testing. Upon giving it a full, hand-wind (50 turns) I placed it in an autowinder to see if it would continue to go perpetually powered by the autowind mechanism. In this case, the mainspring unwound after approximately 4 hours. Because the oscillating weight had a bit of wobble (due to a worn axle I suspect) I thought perhaps this was causing a problem. I removed the oscillating weight, gave it a full, hand-wind (50 turns) and placed in autowinder. Same mainspring release after 4 hours. Replaced mainspring - same results. I'm trying to determine what would cause a mainspring to release after approximately 4 hours of working fine. For what it's worth I audibly hear the main spring release when it happens. I have had one instance of reassembling completely after installing the new mainspring that I fully wound it and left it sitting dial up. That was the one and only time it was held it's power reserve for 32 hrs.1 point

-

A very scruffy looking 1970s Lucern BG 866 based pin lever got a bit of a clean and polish today. This was actually purchased as a parts watch, but I guess I'll need to look for another parts movement, as I haven't the heart to consign it to the parts pile. It may be crusty, with its all aluminium case. It may also be somewhat jewel starved (just the one rock in this one), and it have a tick like a grandfather clock, but it has a certain pin lever charm about it. In to the 404 club it goes.1 point

-

Someone could have been trying to remove weight from the balance by shaving material off the screw. Not the right way to do this. If the opposite screw has the same amount of material removed, may not be an issue. After you stake the balance back on the shaft, poise it to make sure you do not have a heavy point. Sent from my iPhone using Tapatalk Pro1 point

-

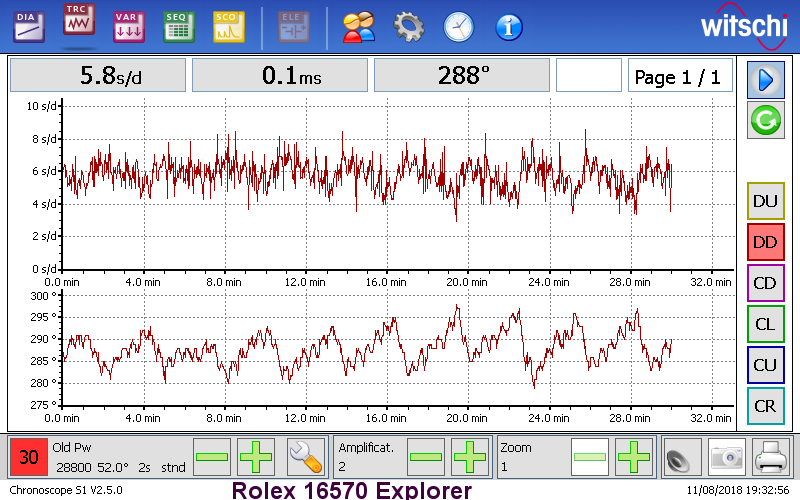

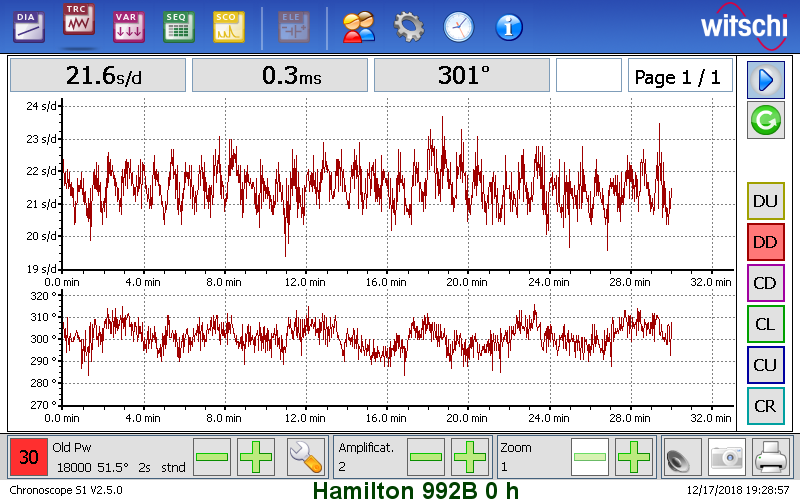

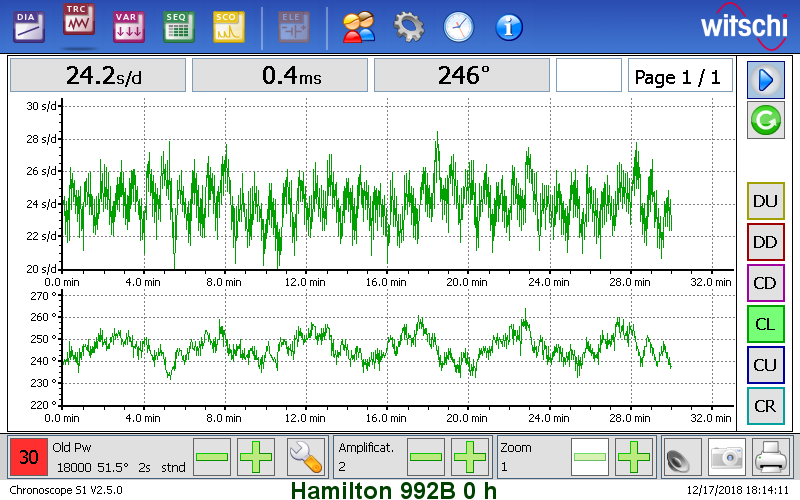

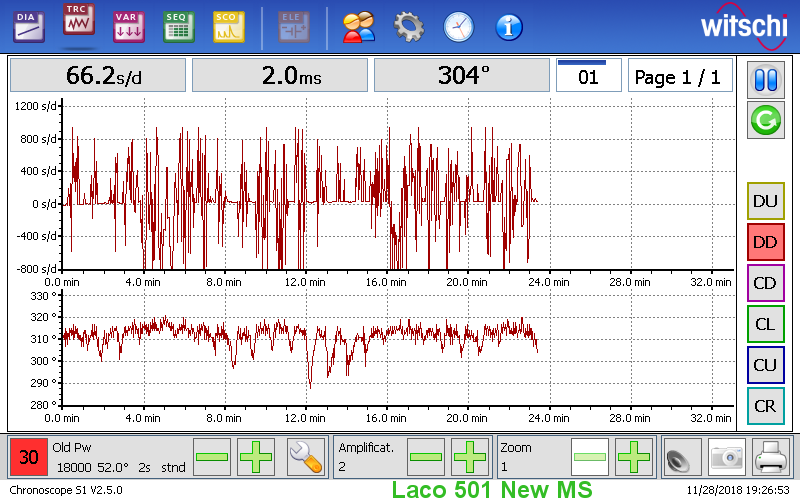

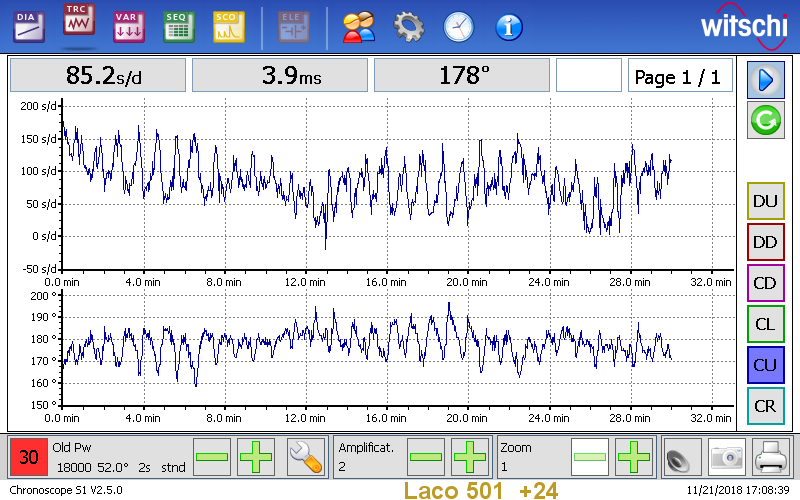

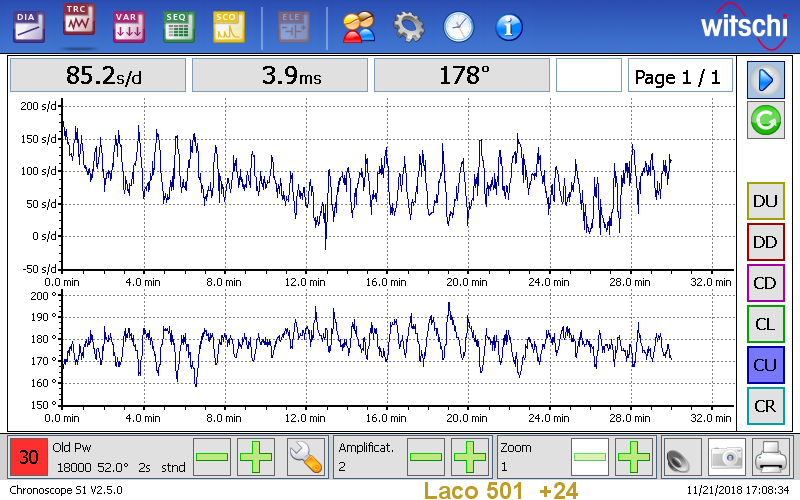

Only two times how sad? Not as bad is one of the questions this morning before I even got the answer half a dozen people answered so it got answered multiple of times except I did add something they didn't have. It's actually quite common here that questions will get answered multiple times basically the same thing for variety of reasons. Then I have more images but they're not labeled these all have text on them. You also have to be careful because the machine will do an auto ranging so things that look really bad if you look at the numbers might not really be bad.1 point

-

As @watchweasol says it's the rotor retainer, the worrying thing is that if it just fell out, then where is its screw? Likely as not it's rattling around inside the watch and is what caused the watch to stop, jamming in between other moving parts. I don't doubt that a replacement part can be found but the watch will need stripping to recover the screw. Don't try winding or adjusting the watch until it has been recovered as you may cause further damage.1 point

-

1 point

-

You can make a torque o meter of your own, solder a ratchet screw to a bar( hand) and some weights to hang on the bar. Surely there are proprietory tools made for manufacutrers, based on the same principle. Your watch is best tool itself, wind and make a record of how long it runs, to have a better graph repeat at half wind and fourth so on to get a graph of primery coils strength and thereon , in addition to power reserve you theoretically want a smooth curve for the torque throughout the length of mainspring. You agree why just replacing with a new one is the easiest and cheapest.1 point

-

So, an update to my repair. This watch has taught me a great deal about watch repair. In some respects, working on earlier movements has given me more of an understanding of the mechanics of a manual wind watch. The movements based on simplicity, without getting too complicated, and what a joy it was to do. In the end it was taken apart 3 or 4 times to overcome hurdles, aligning the bridge above the gear train to get them sitting perfectly in the jewels was quite an experience, thinking i've cracked it then then it would stop, only to find the hour and min hand colliding, then getting the click spring to catch perfectly through a plastic bag as i have a habit of making watch parts fly around my room. My biggest mistake was removing the front cap, slipping and colliding with the second hand which sheared off the top of the 4th wheel pin in which the second hand sits upon. A massive thank you to Rodabod who kindly sent me a matching Cal 59 movement the day after posting on this forum, which allowed me to replace the 4th wheel, then rebuild with the second hand now sitting correctly on the pin. And it works! I have it on my wrist and feel immensely proud. I am doing a shop for my dad this week and he doesn't know i've fixed it yet, i can't wait to see his face. Thank you to everyone who has given advice and helped me out on this post, I've learned a great deal from this and the watch bug has fully hit me. Once again, Rodabod, thank you. Keep safe all, Adrian1 point

-

When the chain is unable to move with your fingers that is telling you the chain is at the right tension. If the chain is slack around the barrel it will not wind on the fusee cone correctly. It is simply a trial and error. Just be very careful with the chain as you do not want it to twist and snap in bits.1 point

-

Good job! Setting the preload on those I feel is a lost skill. I've worked on a couple fusee's and had a heck of a time setting those correctly and still wondering if they were right. I think it may be an issue of feel that comes with experience and training on those specific movement types.1 point

-

A crediable repair job . I wonder where all these lost parts go, I lost a roller assy off a watch never to be seen again ?.1 point

-

The watch that started me down this crazy path of watch repair was a Rado Voyager. I was never a fan of mechanical watches until very recently. Quartz watches were more of my thing. When Seiko AGS and Citizen Eco-drive came out, I though, "Great! Now I'll never need to change another battery!" Haha. How wrong was I. I acquired this Rado Voyager when my Citizen Eco-drive was in the workshop. It ran great. Accurate to about 1 minute a week. But everytime it rains, then crystal would fog up. And it rains a lot in Singapore. I brought it to several watch repairers who said it wouldn't be worth the value of the watch. That irked me. So I got a sapphire crystal and a new gasket online and proceeded to repair it myself. When I pressed the setting lever to release the winding stem, the whole lever disappeared. I turned to Mark's videos on YouTube and was finally able to fix the keyless works. But not after suffering days of anguish. And that got me hooked. There was so much that I didn't know about that thing on my wrist. I have spent more on watch repair tools and materials than the total value of my watches. I have even bought a Seitz jewelling set, a staking set and a watchmaker's lathe. It's an addiction! BEWARE!1 point

-

I know the feeling! It started all for me after attending a yard sale and a woman was selling her father's items. She had a bag full of watches and a couple of watch boxes. At the time I didnt know anything about the value of the watches and neither did she for that matter so offered her $10 for the lot. They were all mechanical; some working and some not. I turned to YouTube and discovered that some of these can actually be worth money and moreover could be fixed. Inhad already owned an Omega Seamaster 300 that got roughly 14 years ago, so loved watches from the get go but now I have taken this to a whole new level! I had bought be a FireKing watch kit that contained a few cheaply made tools, devoured as much watch repair info as possible and here we are! This summer will be a year since this madness took over and in that time I have , acquired a few more watches and toys.1 point

.jpeg.ccca6ebee49a9675ad95c832ff5d5495.jpeg)