Leaderboard

Popular Content

Showing content with the highest reputation on 02/04/20 in all areas

-

It has a Marvin 362 movement. https://www.vintagewatchstraps.com/movements.php3 points

-

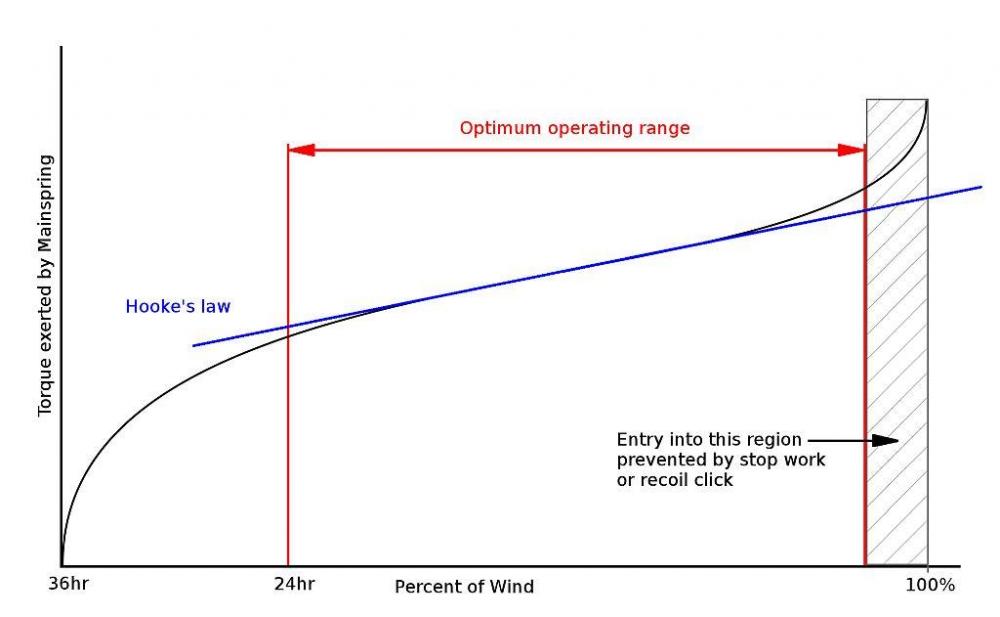

It was to use a more consistent power from the spring. In the pic (from Vintagewatchstraps - great site) you see a typical graph showing power from zero to full wind. The stopworks allow using just the "good" part. They do also help protect against broken springs, though that's not their purpose. Since there will always be a wrap of spring in the barrel wall at full wind the stress on the hook (whatever form it may be) is greatly reduced. This is an issue in old clocks in particular; I see some 250+ year old Neuchateloise clocks fairly regularly and they are always missing the stopworks. These old boys have tremendously powerful springs, but run a full 8-9 days on just 3.5 turns of spring. They invariably have simple hole end mainsprings, and after hundreds of cycles getting that hole stressed (with the stopworks missing), one day, maybe, BOOM. I always remake them when missing, even if the customer refuses, just out of respect for the clock. In the pic you can see it's a different type of stopworks, simpler than Maltese cross but very effective. The partial gear has a friction spring to maintain its position, where the Maltese uses the geometry of the cross to hold position.3 points

-

I picked up my latest project today, listed on Ebay yesterday as a Victorian Grandmother clock, The clock is certainly not Victorian it dates from 1924 this can be pinpointed quite accurately because it has a two train full Westminster strike movement utilising a locking differential gear although patent applied for in 1920 its first use by Gillett in a commercial clock was around 1924, this clock movement is stamped with the Gillett and Johnston trademark, some time in 1924 F.W Elliott purchased Gillett and subsequent production was stamped Elliott. I already own a couple of Gillett and Johnston two train Westminster clocks one a small spring driven platform escapement mantle clock and the other a twin fusee bracket clock, I have wanted one of the weight driven variety for a while but auction prices and dealer prices are too high for my pocket. I took a gamble on the clock because the ebay listing gave scant details and poor pictures and the elderly seller could only say that the clock had been inherited many years ago from her aunt because no one else in the family had wanted it, but a few things helped make up my mind that the clock was a Gillet and Johnston, although the ebay listing did not show the pendulum it did show the flat pendulum rod, this is a very distinct feature of later Gillett clocks from around 1920 onwards which used a patented Invar self temperature compensating pendulum as seen in the picture I have taken below, the pendulum bob is a lead antimony alloy. The other clue to its maker is in the unsigned engraved dial, in nearly all engraved Gillett dials the motif is a basket of flowers in the central portion of the dial this features on longcase and bracket clocks they made and is considered as a unofficial trademark amongst collectors very few Gillett and Johnston dials of this period are signed because most of their production wasn't sold directly to the public, but through retail jewellers and a plaque featured on the dial for the retailer to engrave their company name onto, and any dial actually signed Gillett and Johnston would be unusual. The Movement is typical of Gillett and Johnston production of the time being of high quality, with thick plates, deadbeat escapement, with beat adjustment on the crutch and maintaining power on the going train, the weights are of brass cased lead, the strike, chime weight is very heavy weighing 26 pounds, as with all two train Westminster they do require a lot of power to run. The clock is very dirty and I shall be cleaning it some time soon so shall post pictures of the cleaning and also explain how the two train striking system works.2 points

-

Sometimes I travel a few hours to repair or service a relatives or friends watch and I take all the gear I need. Instead of taking my normal ultrasonic I pack this little 12v 45khz unit, and it is fantastic it's only 185x59x98mm in size. That's a 20mm wide watch band inside. Holds 500ml of water. Oh yeah I have 8 grown kids and 14 grandchildren. So there's always 2 birthdays and someone's watch to fix2 points

-

It would've been better to have a picture of the balance wheel when it's not moving as it makes it hard to see things. It looks like you might be missing timing screws perhaps? You should have pairs of screws one on one side one of the opposite side and they should match. Sometimes one will fall out and that makes the watch run really fast. Then as these are early production watches you will have lots of variations with the quantity of timing screws the length of the hairspring etc. If you look at the link below you can see other examples of watches like yours. The reason you want to look at the pictures is this is a really early watch and it helps to see examples similar to yours. For instance unlike modern watches that are usually pinned really close to the end of the hairspring these were not. You'll notice quite a few of the watches in the pictures have quite a bit of hairspring stuck out. If you do decide to re-pin the hairspring you will have to put the watch back in beat. Then look really carefully as you want to make sure the hairspring is flat not touching the balance arms or the balance bridge. Then we really need a better picture so I found another link the second link below much better picture. Notice they hairspring is stuck out quite a ways. Then I believe this is a flat hairspring obsession with centering might be an issue. Notice there is very little terminal curve found on modern watches. Usually it's not a problem but if you get carried away with trying to center then the next coil over conceivably will bump into the other side of the regulator pins. Problems of American pocket watch mainsprings" Originally the Springs came in a variety of strengths for a given size of a manufacturer of a watch. This way a seven jewel watch could have a spring strong enough to run. A jeweled watch could get a weaker spring. But today they've reduce the quantity of Springs down. Then for the same thickness the modern white spring is usually always stronger than the original blued spring. https://pocketwatchdatabase.com/search/result/illinois/1106 https://commons.wikimedia.org/wiki/File:Vintage_Illinois_Springfield_Watch_Co._Pocket_Watch,_Currier_Model,_Hunter_Case,_Coin_Silver,_Key_Wind_%26_Set,_11_Jewels,_Size_18_(14714708570).jpg2 points

-

2 points

-

Put down your hammers and back away....Just kidding . Some members have stated thar's how they service Timex Watches . I picked up this Timex Electronic , back-set , front loader at the swap meet for $8 . It wasn't running and had an AG10 battery still installed , but with no visible damage to the movement . This one has the M87 movement with the date . This is a late 60's model called " The Blue Nebula " with a West German movement that was produced by the Laco watch company that Timex acquired when they bought Durowe-Laco at the end of 1958 to get into the electronic watch arena ..... http://electric-watches.co.uk/makers/laco/ I got home from the swap meet , opened the watch up and installed a new battery . The watch would only tun for a minute or less . I did some reading on this movement and started to disassemble it for a service . If you have ever tried to service a Timex you know why the hammers are used . I got as far as taking off the magnet and then the balance and then a voice from above said , " don't do it . Don't go any further "...so I didn't . What I did do was to clean and tighten any electrical contacts that I could reach , and put a light oil on any jewels and bushing in reach and assembled the watch again . At that point it would tun for an hour or two , and stop . I would shake it and get another couple of hour worth of run time . I left the watch under a light bulb for a while and it ran for approx. 24 hours . Back to the light bulb treatment that I may patent and the watch has been running for 5 days now and actually keeping very accurate time .....Honest . I had a watchband in my stash but have had to file some areas where the lug area of the watch was binding . I still have to smooth and buff those areas so it has a better finish .1 point

-

1 point

-

Yes to both above. Ideally you have a mainspring arbor holder (yes this is an actual tool and darn handy), basically a slide locking pinvise for distinct diameters. With this you can confidently coax the most stubborn arbors into the mainspring loop. I have a bunch of them but honestly most of the time I use sturdy nickel tweezers and the tilt-it-in technique. I also have a number of hours of barrel arbor floor searching under my belt.1 point

-

Could be hard if the mainspring is new and the arbor is larger then the loop . Try to lean it in from an angle . With the tab to the opening . You could use a pin vice to hold the arbor . Ones in it will correct itself when you first wind the movement .1 point

-

Hi Spiro once the mainspring is installed place the arbour in position and work the mainspring end round it with a stiff needle in a pin vice in a rotary fashion untill the spring end sits snug and attached to the arbour.1 point

-

Apologies JDM, it’s easy for the conversation to get derailed and for the scope to widen when chatting with intellectual like-minded folk on such a friendly helpful channel. [emoji53] Sent from my iPhone using Tapatalk1 point

-

blockquote widget That guard pin appears to be quite bent, (upward as per this pic) normally these would be straight and in between the horns when viewed from above. That in itself could cause a binding and dragging on the impulse jewel in one of the positions according to endshake and movement of the pallet fork and balance.1 point

-

He probably turned it down as experience told him even if charging double price it would be more time and effort than doing regular work, which if he's good he probably is overloaded with. I do "box jobs" every now and then, but they are expensive. They do take more time, and there are often surprises. With a higher price, often for a piece that isn't even valuable, the customer expectations go up. Then there is a back and forth and discussion and possibly an unhappy customer because their box job watch has terrible performance on their Chinese timing machine and then that's a voice that will holler out on review sites or forums or to other collectors. This is pretty much the primary reason any decent watchmaker will only ever do a full service, with a decent cushion in the estimate for potential parts- the possibility of a partial job or "friendly job" turning sour just isn't worth the risk of time and reputation.1 point

-

What did you want him to do? Make a working watch out of out of the three, or help you make a working watch out of the three? If the latter how much time do you think he would spend helping you? It likely would be more than if he did the work himself- which, when building one good watch out of three unknowns is already almost guaranteed to take more time than servicing one complete piece (i.e. more expensive). It's already tricky finding time to actually work at the bench for a watchmaker with a store front. Did you just want some advice? Honestly for an amateur it is really best to spend time on forums like this gaining skills; when you are decent at basic servicing then you can ask pertinent questions, and if you have built up a relationship as a customer the watchmaker quite likely will be happy to give some advice and tips.1 point

-

If you can remove the dial and take a photo of the movement from that side and give the measurement of the movement it is highly likely we can work out what it is, but my knowledge isn't good enough to id it from just the back.1 point

-

I understand where your coming from but the same can be said about the dippers as far as control and cleanliness , but obviously you have to use the right one for what your oiling . I taught myself how to get the exact amount without touching the jewel . I don't use them all the time about 30 percent . yor right about being hard to clean that's why I clean them out once a week when I use them. need to soak overnight in lighter fluid then into ultrasonic tub ,then rinse and rinse and rinse .However sometimes especially on ladies movements I can nail the oiling without any magnification . Is that good or what?1 point

-

1 point

-

1 point

-

In case someone is interested, a local (for me) auction house has a bunch of pocket watches, wrist watches and some bands and fobs. These end tonight and the link is here. https://lenhartauction.hibid.com/catalog/198914/joyce-guymon-estate-and-so-much-more-online-auction/1 point

-

1 point

-

Your problem isn't the mainspring. However, if you really want to increase the strength I would suggest going to 0.13 thick maximum. Going higher will almost certainly cause rebanking and you will lose power reserve and cause undue stress and wear on the gear train as well. I am fairly convinced that you do have one or more damaged teeth either in the chrono runner or the clutch wheel or both. More likely is the chrono runner. That your problem is consistently with the chrono runner at 12h; this is the position that the coupling clutch engages the chrono from zero and the most likely to exhibit wear or damage. The damage can be very very small, and function OK, until it finds a tooth on the clutch wheel it doesn't like and then bang you're stopped. Just a tiny burr will suffice.1 point

-

Reporting back. Here's what worked: Hand sanitizer. Decided to give it a try since none of the other conventional cleaners were touching it. Best thing ever - it dissolved the black goop immediately and it wiped away easily with bud swabs and Scott tissue. It works really well removing Sharpie marker and tape goo, guess gasket removal goes on the list, too.1 point

-

That's where the maltese cross would be mounted. It limits the number of turns you can wind up and also allows prearming the batrel1 point

-

OK, here are the bad boys. The curving ones I have go from 00 to 5, the lifting ones from 00 to 4. The example hairspring would be about right for a deck watch- very big, and the largest of both sets worked well. You can see in the 4th pic that the end of the lifting tweezers can be adjusted for the thickness of the spring (red circle) and how far it pushes (screw in blue circle). I just did a simple overcoil, there are many shapes, here the goal was to get the curve to follow one of the spirals more or less imagining in our imaginary watch that would be where the regulator lies.1 point

-

1 point

-

"Chat About Anything Here Talk about whatever you fancy within the forum rules, not just about watches." I found it useful information, probe things all the time and seldom look at the tools section. Anything here means that to me. Not JUST about watches does not preclude watches and tools. Perhaps there is a language barrier at work.0 points

-

they are "rounding plyers" avaible at the tool store. AND you bend a spring. probably not available in de Carles time. vin0 points

.thumb.jpg.c92db9549557b329738ed476ee05c255.jpg)