Leaderboard

Popular Content

Showing content with the highest reputation on 12/21/16 in all areas

-

Yesterday we went to visit our old neighbours for tea & mince pies before Christmas. When we arrived they presented me with an old leather bound box, inside was a collection of vintage watches like a mini treasure chest, Swiss makes I've not heard of before plus others, one even working ! enough to keep me busy for a while.3 points

-

I've got a bag like that in my desk drawer too. My tried and true method: Dissolve about a half teaspoon in a shot glass of water (water will become a bit cloudy) Fill rice cooker with about 1 inch of water and set to warm Place plate (stripped of steel) in glass Set glass in center of rice cooker bath Check in 12 hours or so The steel you're attempting to extract should turn black and crumbly and you'll be able to work it out of the plate with a sharp bit of pegwood or an old oiler. It may take more than one bath in the Alum depending on the strength of the solution, temperature, and the surface area of the steel.2 points

-

Old hippy is referring to pre made bushings. Look at Cousins under bushings2 points

-

1 point

-

Yes, that's the part... circuit and coil combined... £3.75 from Cousins (plus postage and packing!)1 point

-

1 point

-

They certainly can cause a clock not to run. With worn bushes the wheel gears do not mesh correctly either too shallow or too deep. If not sure remove the barrel and just have the wheels installed and see if they spin freely. I follow this guy a lot. See how he re-bushes. You will not have the customised tools he has but he explains really well the techniques required to fit a bushing successfully.1 point

-

1 point

-

Before you go buy bushes or make them check the pivots to see if they are worn, if they are you will need to fix them first and them measure the diameter of the repaired pivots to make sure you don't end up with bushes that have a too large pivot hole.1 point

-

I'm enjoying your posts @IFELL, keep up the good work. It seems we are on a similar journey although as work and family commitments seem to have intermingled and eaten all my time I have some catching up to do!1 point

-

1 point

-

I bushed & repaired quite a few clocks but never seen a worn barrel like that. As oldhippy states it must be made of real poor quality metal. I have seen many posts showing how to change broken teeth on a barrel but not the complete set of barrel teeth. Cousins do complete barrels see below: https://www.cousinsuk.com/product/barrels-complete I found this site that sells complete barrels but they are across the pond. http://www.perrinwatchparts.com/cat_name/assorted_clock_barrels.aspx Or give this company a call they have helped me in the past. http://www.m-p.co.uk/index.htm1 point

-

That's the lower balance cap jewel. It's not sprung so it won't fly away when you remove it. You'll want to remove it, clean it, and apply a new droplet of oil for the the lower balance pivot. That's also one of the three smallest screws on the movement too. This movement doesn't have incabloc shock protection so you'll just want to be extra careful handling the watch once the balance is back in place. My very first service was a Pierce chronograph and I managed to get the thing apart and back together without incident. Unfortunately very shortly thereafter it took a spill and this was enough to bend a pivot. I can only imagine how busy watchmakers were back before shock protection was introduced! You can probably purchase watch and clock cleaning solutions from Otto. These are non-aqueous and will not rust the steel bits. Alternately lighter fluid can be used but extreme care must be observed due to it's flammable nature. Always a good idea to replace the mainspring if you can afford it too. Keep up the good work!1 point

-

I always have a few left over after a service and collect those.......Isn't it satisfying turning the washer basket upside down after a job and seeing nothing is left over.... Started with ebay and after awhile the store grew with odds and ends....I also use magnetic sheets (the ones the pollies/advertisers give us in the mail) to pick up for the ones that slip through...seems to work quite well.1 point

-

I don't like that nasty mark round the side of the glass. I'm thinking it might need a tension ring glass.1 point

-

I got assortments of screws from Old Swiss Watches , and also Esslinger .1 point

-

I love this thread! I mentioned to my wife shortly after getting into watch repair how relaxing it is to work on a watch. Her reply was, "I don't see how spending an evening on your hands and knees looking for a screw can be relaxing at all!" Sent from my iPhone using Tapatalk1 point

-

1 point

-

I fully agree. I just wish the company would be more realistic with their MSRP's. Carnival cruise line promotes them on their vessels, its a shame they would probably sell better if Invicta adjusted the MSRP, people just shy away from them when they see Citizen and Seiko. Moreover, the competition just got stiffer as Carnival has started selling refurbished Cartier's, and they look really good.1 point

-

Interesting thread. As said I have no knowledge of clocks but to clarify. If we take an imaginary movement and think of set of wheels all in perfect alignment in a circle and an arrow going to each wheel in a perfect straight line. Then when wear occurs, think of a wheel tilting and how this would effect the direction of power of the arrow to the other wheels. First effect (tilting arrow causing loss power) movement sluggish with low amplitude. Second effect (Wear exceeds more then one third the diameter of the pivot) friction to great for the movement to function. Also if it's a cheap movement it may be possible to close the pivot holes with a staking set, messy and not a neat repair. With the wear to the barrel teeth as well and probable wear to the pivot I think success is unlikely. Sent from my SM-T585 using Tapatalk1 point

-

1 point

-

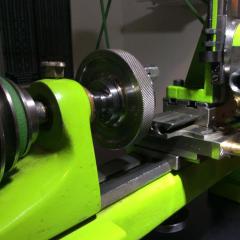

The tops of the teeth from that barrel have worn right off due to the wear in the holes. This would not normally be as bad as this if it had been hard brass. Because the barrel teeth have lost there tops it is possible that by re-bushing the wheel next to the barrel it might not engage, the depth will certainly be wrong, it is also possible the pivots have worn. Have you compared both barrels to see how much of the teeth have worn off, it might need a new barrel. Wear like this will cause the whole of the strike side to bind together and prevent power getting through. To sort this out because of the worn teeth you will certainly need a clock depthing tool, then you will have to make the runners to hold a barrel, they only normaly come with runners for wheels that hold pivots.1 point

-

Hi, Mark! Welcome to the most soothing frustration you'll ever experience... lol Shirley1 point

-

Okay here is my first, (virginal) walkthrough, I got this 17j Hampden for less than $30, it's not uber rare scarce or anything uncommon, anyway upon arrival, I immediately noticed some rusty hands and lack of winding (AAAARRRGGH), fortunately it was just from cheap crystal, (I think) the seconds hand is almost gone!) Next off they came and things still looked pretty good. I don't like dust shields and read somewhere they are not recommended/necessary on Hampdens anyway. when I got under dial, the cannon pinion and hour wheel were pretty toasty, otherwise it was pretty clean. Next, off comes balance assm and out comes pallet bridge and fork. Just in case, I did try to let down mainspring, but that appeared to be part of problem. Then comes main barrel bridge, winding wheel, third and fourth wheels and bridge, note steel escape wheel and white/clear jewels on pallet fork. Out comes barrel and arbor And just as suspected, mainspring is a goner! Note the serial number inside barrel, matches the rest of watch Dial cleaned up pretty nice, lot's of hairline dirt removed. Still has some nibbles between the 10 and 11, that's what I call character! New spring In goes the new spring, I did this by hand, (too cheap to invest in winder!) Just a pinch more to tighten up arbor and greased. Patiently awaiting their return after cleaning. The cannon and hour wheel were replaced, I got lots of parts, so no issues there. Now with everything tidy, back goes barrel and bridge Third and fourth wheel bridge, plus touching up pivots/jewels with oil as we go. This last part can be a bugger if you don't line everything up, I give it a "soft screw", pardon the expression, but I'd rather check everything before it gets tightened, (learned the hard way on that one) New Cannon Pinion, hour wheel and dial washer on and dial ready for replacement. A few more touches of oil on dial side pivots. ( a bit heavy handed on the barrel, did clean that up a bit) I picked out new hands, pretty fancy scmancy and had to replace second hand too. Now I know I didn't show all that boring stuff with the keyless works, set springs and winding wheels and mainplate cleaning, but it all had to be done, I just wanted to show how relatively simple these movements and others like them are to work on and hopefully get some others to try their hand. One quick vid, she's running like a scalded cat! DSCF0401.AVI1 point