Leaderboard

Popular Content

Showing content with the highest reputation on 03/10/24 in all areas

-

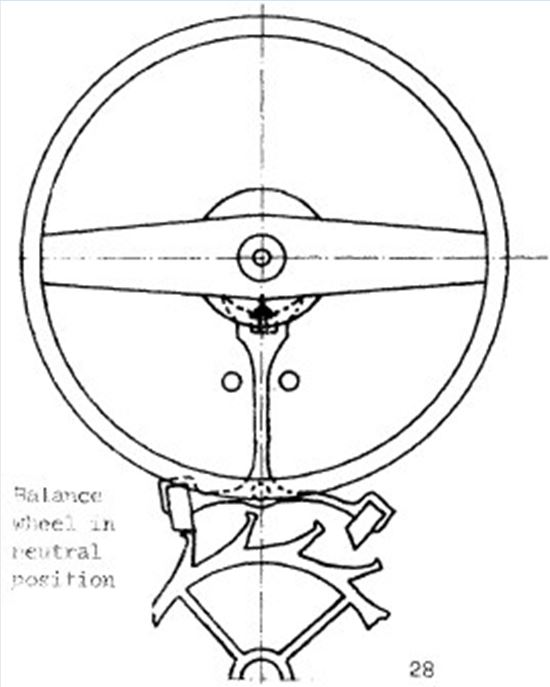

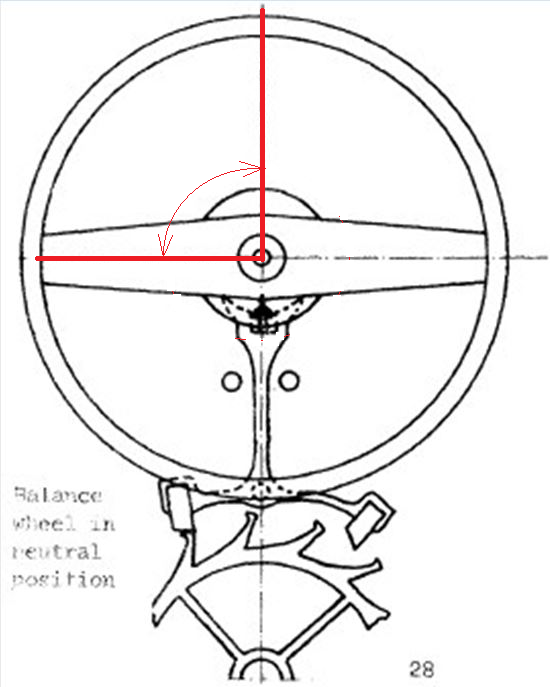

the ramifications of putting the roller jewel in the wrong location is the watch will not be in beat and it will never run. one of things you should always check on a watch especially after replacing the balance staff is to verify that the watch visually is in beat. The above quote is telling you that and I'm attaching a picture so you can visually see what it should look like.5 points

-

Pull the roller table and put it back where it should be. The position of the hairspring is (very) important too, there is often a little "pip" on the balance rim marking where the stud should line up. When in the watch, no power, the roller jewel should be in the fork slot, and the fork should be midway between the bankings.5 points

-

5 points

-

Hi, Just thought I'd post this as I was truly shocked earlier today. Amplitude horizontal full wind was getting 300 degrees. Vertical positions were very low in the range 170 to 180 degrees. That was before I lubricated the escape wheel teeth with Moebius 941. Amplitude in the vertical positions increased instantly to 240-250 degrees. Horizontal amplitude increased a bit to 310 degrees. I was truly shocked with the increase. Watch is gold cased from 1956, awarded for 38 years service, wow!!! Steve3 points

-

3 points

-

3 points

-

Hi Khan. Before proceeding make a thorough check of the repaired areas to be sure you are not bridging tracks and causing short circuits as some look a bit rough. Then assemble the watch and fit battery or use a1.55v supply connected to the Plus +. And Minus - contacts The contact points for the supply with the meter to verify the power is reaching the circuit board and reaching the CMOS. Chip then check each coil with the meter for a pulse. If your meter will allow you to with micro amps scale. Some meters don’t go as low as that. Checking the circuit board without proper instruments is not easy (oscilloscope) and meters. If the CMOS is not getting power it will not work.and will not pulse the coils and the rotor. The attached below will help you understand the quartz watch a little better. Cheers. Witschi Training Course.pdf2 points

-

one of the most important places to lubricate in a watch is the escapement. This is where you'll see spectacular increases in amplitude if you would do that.2 points

-

2 points

-

2 points

-

Hi. The movement has a look of the BFG866 pin lever a solid watch, usually the logo is under the balance but have seen some on the front plate.2 points

-

So I sort of semi-finished the Omega. Right now I have a replacement set of hands on that came with lume rather than black cutouts. I did order an extra set of hands that I intend to replace the lume with the black paint as original. I haven't quite given up on the original hands but they are in rough shape and I think they will need to be taken down to the original brass and replated to be usable.2 points

-

The extreme hype around this watch was difficult to understand, but it shows that what really matters is looks and brand. Other than that, a plastic quartz watch, not making me too excited.2 points

-

1 point

-

https://www.cousinsuk.com/product/seiko-part-number-from-014?code=015703 Try This Most seiko part numbers on the Cousins site only seen to work in this format eg: 000.000 so 0015703 will be 015.703 Regard CJ1 point

-

If you had a Witchi Cyclonic you could possibly spin the train and free it up but sounds like it could use a cleaning/service.....you did say it ran for a few seconds....1 point

-

Something to add: The angle marked on the drawing should be always 90 degr. It is not important for the movement, as it will work regardless what the angle is, but it is important for the watcmakers that will service the watch. The balance arm forms certain figures when the balance rotates. This figures are symmetrical and in case the angle is exactly 90 degr. and the movement is 'in beat', then the axe of symmetry coincides with the line of bearings balance-lever (the vertical axe on the drawing). So, a watcmaker will be able to say if the watch is exactly in beat just by a look at the oscillating balance, and no timegrapher or other device will be needed.1 point

-

From the picture the stud holder is mobile, it alao is a beat adjustor arm, move it to bring the oscilator in-beat, thats impulse be in midpoint of ........ as said above. In case that didn't do, then impulse jewel must have been positioned nowhere close to in- beat position, so needs repositioning.1 point

-

Yes, that is what needs to be done, but some don't and leave them in claiming that all you need is efficient cleaning fluids. I highly doubt it though.1 point

-

When it comes to replacing a platform. You need to know the size is the same, depth and length of the escape wheel so it will mesh with the contrite wheel, how many teeth does the escape wheel have, are the holes on the platform in the same place for fixing. If you can get all these measurements from the seller and they are the same as what you have then go for it. It well certainly be cheaper then having a balance staff made.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

I can find barrels complete but not the actual spring. You can remove the spring and measure it.1 point

-

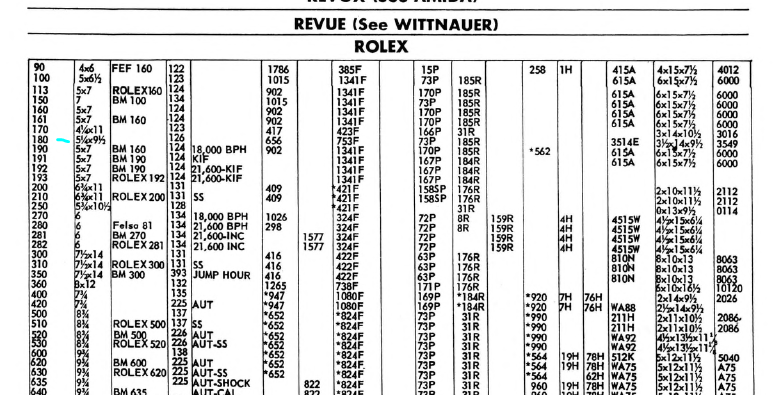

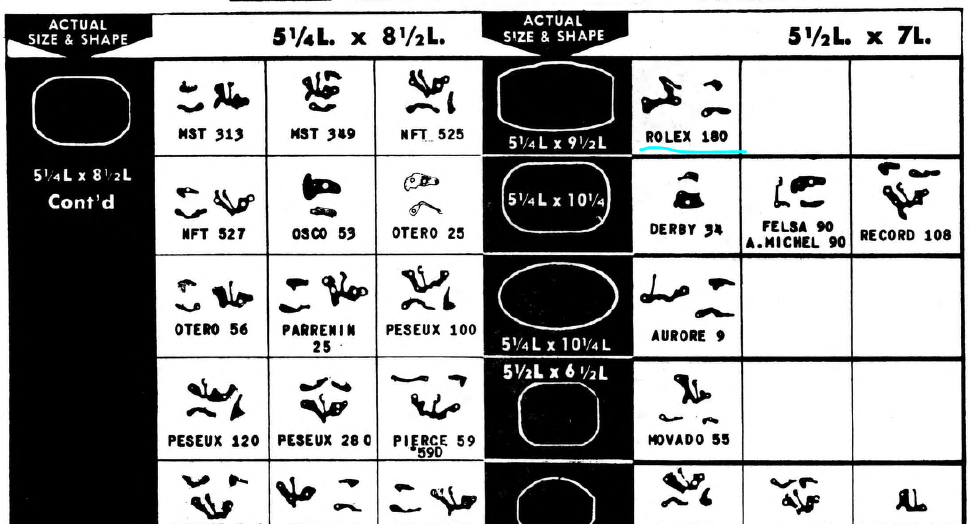

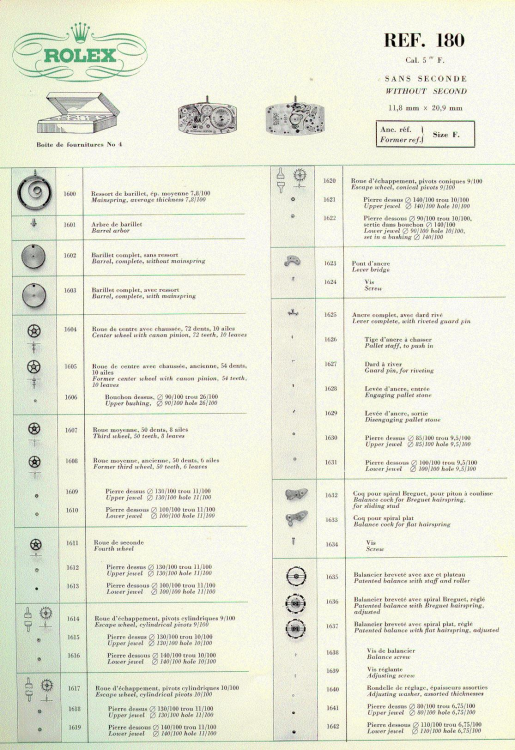

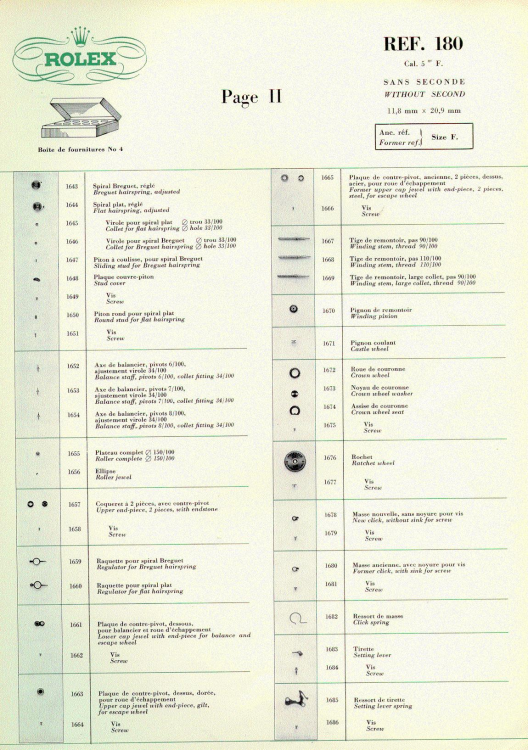

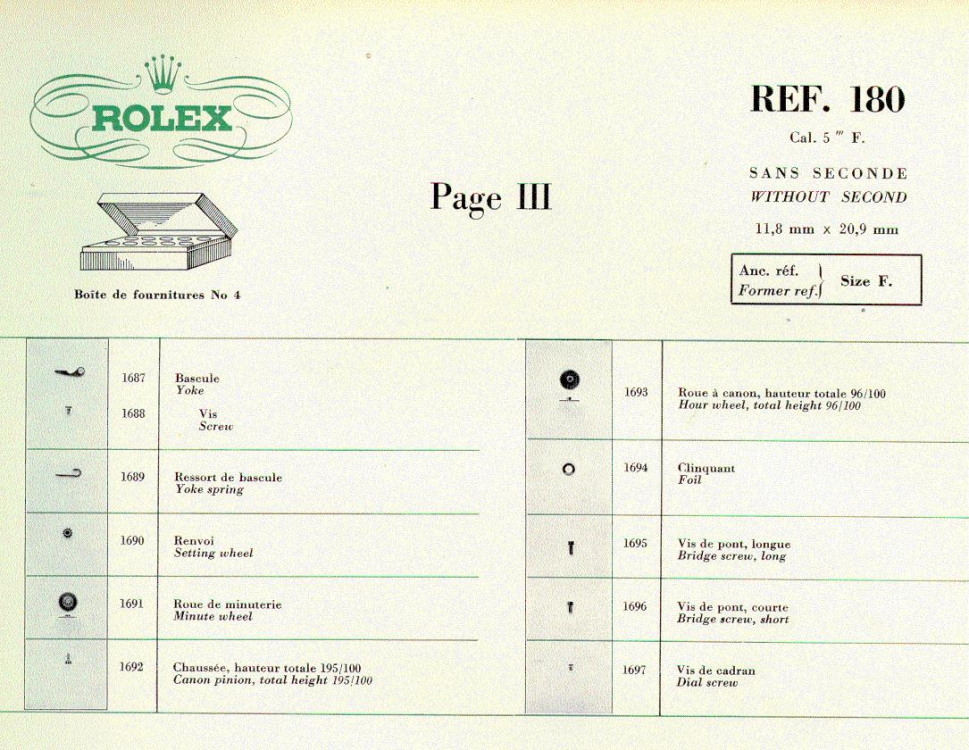

standardization is not quite the right term here. Basically manufacturing tolerances it's only in relatively recent times can hair Springs and balance wheels be manufactured precisely enough that they can be put together with out the process of matching which is called vibrating. This is why traditionally you typically never find hairsprings available separately. The exception is hairsprings that are premade typically not flat to very exacting specifications then the balance wheel would've been matched the hairspring. Timing screws would've been available to achieve that. On some rare occasions I have seen flat hairsprings available but typically they were vibrated to the balance wheel. now this doesn't mean that hairsprings art available like there's a website hairsprings so they don't have a stud much problem but could that be? Then for hairspring vibrating do a search we've talked about it before and the group. https://www.ofrei.com/page820.html this does bring up an interesting problem though? Typically when were looking for watch parts we need to know which calibrate is but maybe we really don't need to know that? For instance here's a link on eBay what are we searching for movements in this case Rolex movements. There's a problem we don't have a caliber number on the other hand the sellers don't have a caliber number either because they have the same problem we do unless they take the dial off they don't know what they're selling other than it's Rolex. https://www.ebay.com/sch/i.html?_from=R40&_trksid=p2499334.m570.l1313&_nkw=Rolex&_sacat=57720 so this one looks promising I do like the descriptions and sellers use for their watches. Probably should downgrade any of the positive wording they use because well they're trying to sell the watch. https://www.ebay.com/itm/296128856768 we may have to come up with the definition of extremely expensive when looking at the various eBay listings like the above indicated that well it has potential and this one is slightly cheaper indicates less potential https://www.ebay.com/itm/225375118109 finally? You'll have to go through all the rest of them I found what I was looking for its cheap but that's not what I was looking for https://www.ebay.com/itm/285748960785 looks right few parts fell off how hard would that be to put them back? yes for the people read the fine print it's past my bedtime. When you get a weird sense a humor and we get a partial answer I wish the picture was a little better the was the setting parts were back where there supposed to be as we could possibly identify the movement from that but there is the other problem? description only gives us one thing which is this Movement is 12mm x 21.5mm that was something I was looking for will have to translate to something I'll attach a PDF for that watches are not usually specified in millimeters sizes their specified another way is with the PDF is for. Looks like it's a 5.5 x 9.5. Then a course the caliber information is printed on the back kind of sort of and has to be translated because of time not going to explain in detail bestfit book looks like it could be a 180? Page 126 if you're in a vintage you really should find a PDF of a bestfit book ask someone on the group will probably tell you where to get one for free. I typically won't tell you where to get it for free because I paid for my. then because I'm being somewhat helpful I snipped out more than just the one Rolex. If you have the physical book the pages are actual sizes otherwise the PDFs are not actual sizes but you can still looked at the setting parts and see if they match. it looks like we have a match oh but notice the balance completes two different types a hairsprings I classic problem of variations. then second page look hairsprings were available even flat ones. then providing I guessed correctly we get a parts listing http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ROL_180 then we get this I bet it's not available which is sad it has a cheap price http://cgi.julesborel.com/cgi-bin/matcgi2?ref=[__DycotUPU then yes we all saw this one coming but it was available http://www.julesborel.com/s.nl/it.A/id.81835/.f notice we have a trend http://www.julesborel.com/s.nl/it.A/id.79752/.f so it really is past my bedtime yes you can get movements who knows what condition there in perhaps if you buy enough of them you might build get enough to build a complete watch. On the other hand a lot of the movements are here because somebody scrapped the gold not because the watch was necessarily bad because typically women's movements have no value at all at least up until gold became more valuable. watch-ligne-size-chart.pdf1 point

-

Yes, members here have been very helpful already! This has prompted me to actually attack this job myself instead of just replacing the movement. I wish I could do it right now, but I can't get to this until later this month. Looking forward to it. Thanks Nucejoe.1 point

-

1 point

-

You can demagnetise the fully assembled watch, or just the movement, or if disassembled all the (steel) components individually. Obviously, the first option is the easiest, but sometimes the case is designed to shield the movement from magnetism. I doubt this is true with Elgin pocket watches, but as you are disassembling anyway, your best option would be to demagnetise the whole movement outside the case. There are a wide range of demagnetisers available, in all price classes. In my experience, the cheap blue ones with the red button work fine if used correctly.1 point

-

Hello Qutadah, I'll try to keep this short, but it's a big subject with a lot of possible answers. As always, it depends. For some calibres, especially older ones which are no longer in production, you can get parts lists and even service instructions. A good source is the Cousins UK website, or the kind people on this forum. That doesn't guarantee that you can still buy the spare part, however. Some parts are interchangeable between calibres. For this information you need the Best Fit catalogues, also available here from time to time. None of this applies to Rolex, who are extremely restrictive with information and spare parts. This practice is common amongst the big brands, and it makes spares hard to come by and very expensive. With mainsprings, it's usually possible to find a generic part from a manufacturer like Générale Ressorts which will work fine. With hairsprings that doesn't work. You need to find the complete balance assembly.1 point

-

G`Day, My name is Chris from Australia, I am a hobbyist watch repairer and I enjoy this forum and the tips and assistance I have gained from it. I hope to also share my journey, tips and my mistakes and disasters with others in Watch repair Regards1 point

-

1 point

-

There is a screw missing in the green circle. Without it, the (-) terminal is not making proper contact with the circuit board.1 point

-

Hi khan. Where the tracks have been destroyed it may be possible ti re connect them using conductive paint to bridge the gaps. The same stuff used in repairing car window heaters and larger circuit boards. Can be used to repair scuffed coils.1 point

-

Hello everyone, just sharing with the forum what I found out in the end. In case someone else faces this issue at some point. So, the pictured axle is indeed the axle for Rolex calibre 2230/2235. The axle for calibre 2130/2135 measures exactly 0.60mm at the indicated point. Cheerio1 point

-

I am sorry. My pen is sometimes more sharp than neded, and this is due my temper. The idea that someone might think the plates may be made not of brass, but of still, made me wonder how and why is this possible. But Rich is right, i don't see any difference in the meaning of the both phrases. See, the main problem of no jewels Timex watches is the wear of the balance staff tips. They wear for 2-3-4 years of constant use and the watch may still work, but with lo amplitude and bad timekeepinng. The way to restore the movement is to sharpen the tips and if they have been sharpened allready 2-3-times, then the cup bearings must be restored too. Just forget the other bearings, no significant inprovement will happen from there.1 point

-

I believe that the fundamental principals of shaping and moving metal with punches remain the same irrespective of what metal you are considering; i.e the material under consideration has to be sufficiently malleable to deform rather than break, the punches that you are using to push the metal around must be harder than the material that you are trying to move, and you need to hit the punch hard enough to to move it. In the case of steel you have to consider the grade of the material. Any kind of carbon or tool steel is going to present problems on at least two counts. Firstly it is unlikely to be malleable enough to deform before it breaks, especially if it hasn't been tempered from its full hardened state, in which case it could well just shatter. Secondly, the punches in your staking set are made of the same material and are therefore going to have about the same level of hardness as the material that you are trying to form. As a result you are going to deform you punches to the same extent as the work piece. If we're talking about mild steel or some other free machining alloy then this is likely to be softer so you will have a greater chance of success, although you may have to use more force to achieve the same level of deformation as you would with brass. This is a perfectly reasonable and sensible question to ask. You have deduced that the plates in your Timex are made from steel, which would be an unusual choice of material for this application but not impossible. Someone who doesn't absolutely know if your deduction is right or wrong and has doubts about your conclusion might well be reluctant to provide an answer on the grounds that they get it wrong, so a request for further information is perfectly reasonable and sensible. It is in fact a "good response" in the "Safe zone for learners" as it helps to encourage a more thorough investigative approach to identifying the problem, something that is of enormous value if if the most appropriate solution is to be found. In this instance your conclusion is incorrect. In common with general horological* practice Timex watch plates are made from brass. Timex (and a lot of other manufacturers) have then electroplated it with another material, either for aesthetic reasons or to protect the underlying brass, or both. Whatever Timex use is silver in colour, but it is not steel. One simple test for this is a magnet, but if you're feeling a little more adventurous and don't mind the damage then try lightly running a file over the edge of the plate in a non-critical area, you'll very quickly see the silver colour come off and the yellow brass colour show through. This of course is good news as it means that you are dealing with a material that you already know. *One of the more notable exceptions to this is the use of an alloy called German Silver, which is actually a copper alloy with zinc and nickel (no actual silver). It is silver in colour but is non-magnetic.1 point

-

Well they don't appear to be brass.... BTW hardly a good response for the "Safe Zone for learners"....1 point

-

I would modify a bezel to fit, better than no bezel in my opinion. Plastic can be chrome plated so a 3D printed on may be an option.1 point

-

Originality is important to the best of us but how long you will be waiting and how much you might spend is unknown. All the while you could be wearing this with what would be a good looking match that only you will know is not genuine. As long as no alteration is made to the case you can both have it on your wrist and continue to search for the correct bezel. Just think of it as a temporary fixture.1 point

-

I just want to say hello, I'm new to the forum. I hope to take my watch repair knowledge to another level this year. If there is any help I can give, please ask. I'm basically a technician now and can do simple watch overhaul work. I also hope to get some help. I'm going to need to get better if I'm going to reach my goal of making money at it.1 point

-

1 point

-

I use a simple hair dryer to blow hot air on the parts after the final IPA rinse.1 point

-

repeating what others have said you need the highest proof alcohol which is 99 as opposed to the rubbing alcohol which has water preferred thing rather than letting it sit around to evaporate would be a source of warm air. It's amazing how well things dry when you can elevate the temperature and blow air across them. then just for clarification sake in what order he do you clean things you have it in the cleaner for how long then here is exactly how many cleaning rinse cycles how long for each and how long them alcohol before you air dry which as I said isn't really what you want to be doing.1 point

-

Hello. Wlcome. You've done nothing wrong. It's just the learning process. Are you taking part in Mark Lovick's course. Does this video help? https://www.watchfix.com/watch-repair-videos/the-seagull-st3600-low-amplitude-performance-problem-unitas-6498/1 point

-

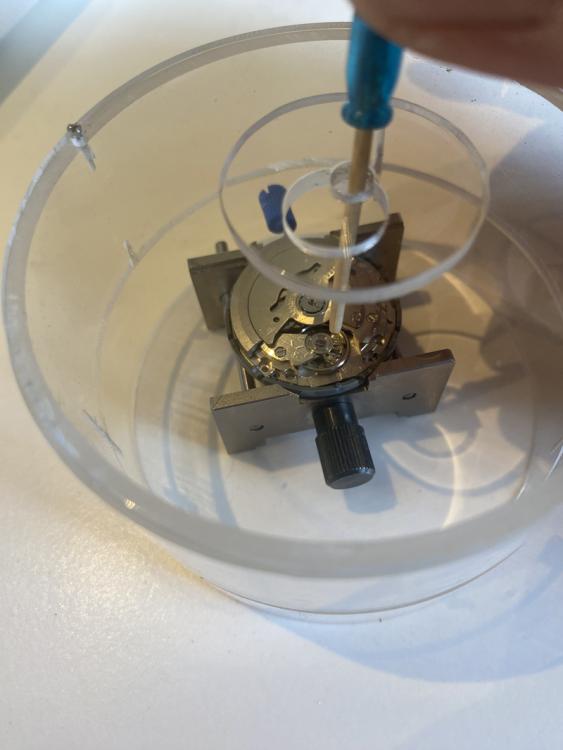

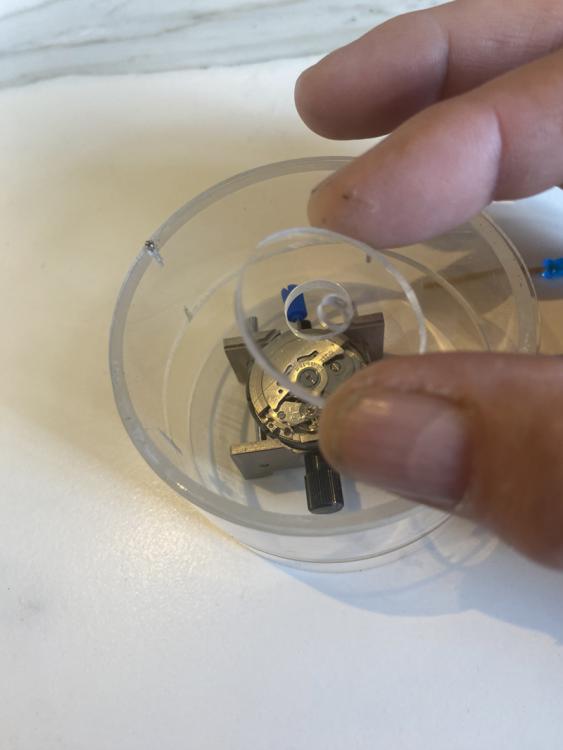

Hello everyone, I came across this tutorial while looking on the net for parts for an NH36. I'm just an amateur and rather a beginner (and French. Forgive me my English) but my level today allows me to disassemble / reassemble a movement, clean it, oil it, and finally adjust it. I mainly work on NH36, ETA 2836 and Miyota 8200 (watch mod). My first attempts with these small parts were catastrophic, losing them most of the time! Also not having tons of money to buy tons of expensive tools, I make them as much as possible. Specifically for these parts, I made a small box out of plexigass to avoid losing them if they jump out and a small tool which makes the operation incredibly easy in few secondes without loosing spring. If it can help newbies like me, I would appreciate it. . If1 point

-

1 point

-

1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)