Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/24 in all areas

-

It's clear the spring was slamming against the hook when he was knocking on it. I wish he had tried to wind it up in the vid, I bet it didn't catch. Also his homebrew cleaning solution he notes at the end- he adds oleic acid, which is a classical ingredient in a lot of commercial and homebrew solutions, but it has to be combined with a base to form a soap. In the Finnish recipe I use for clocks the base is ammonia, which is added until it has combined with all the oleic acid. And finally--- Is it a requirement these days to wear black gloves for everything? From cooking to machining everywhere you look it's black gloves.3 points

-

Yes, I shall! I've taken apart the gear train again and there's absolutely nothing wrong. I also re-oiled all jewel settings. Same results as before. That's a good point. It looks all good, though. Hahahaha, you guys make me laugh! Thanks for that! I needed that. You know, I went into this hobby because when I'm working on a watch, it's like meditation for me. I forget the stress at work etc. But working on this Rolex made me see another side of it and of myself -- the obsessive side. And that's not healthy indeed. I'll let it go. I'll celebrate that it runs 100% within the Rolex factory specifications. Beyond that, it's really overthinking. Thank you all for bearing with me!!!2 points

-

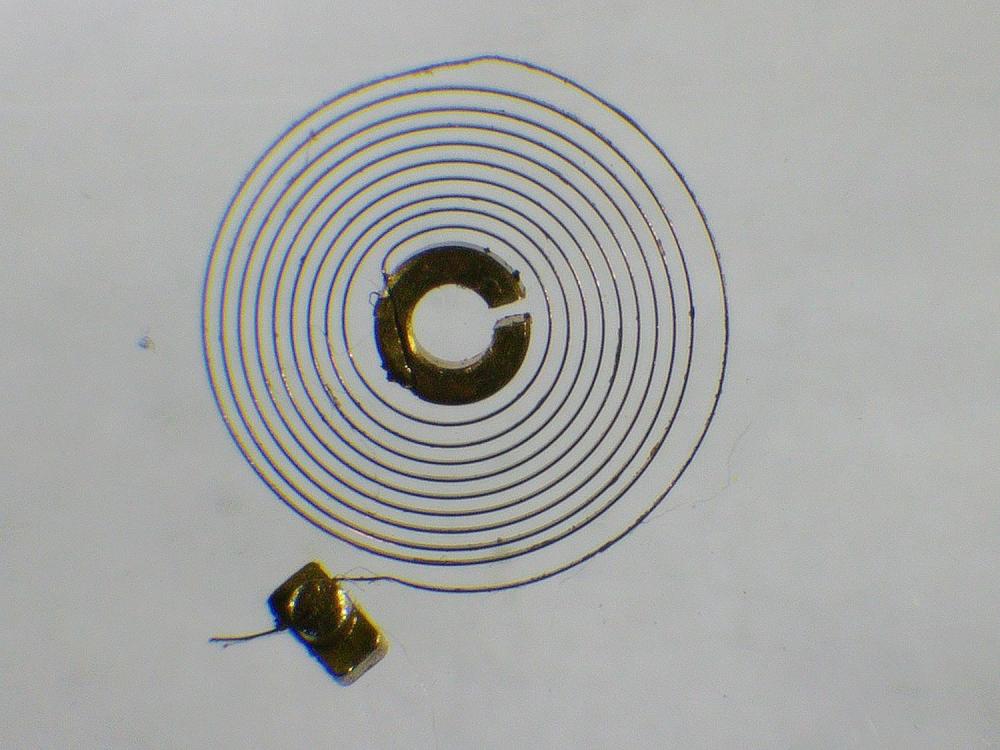

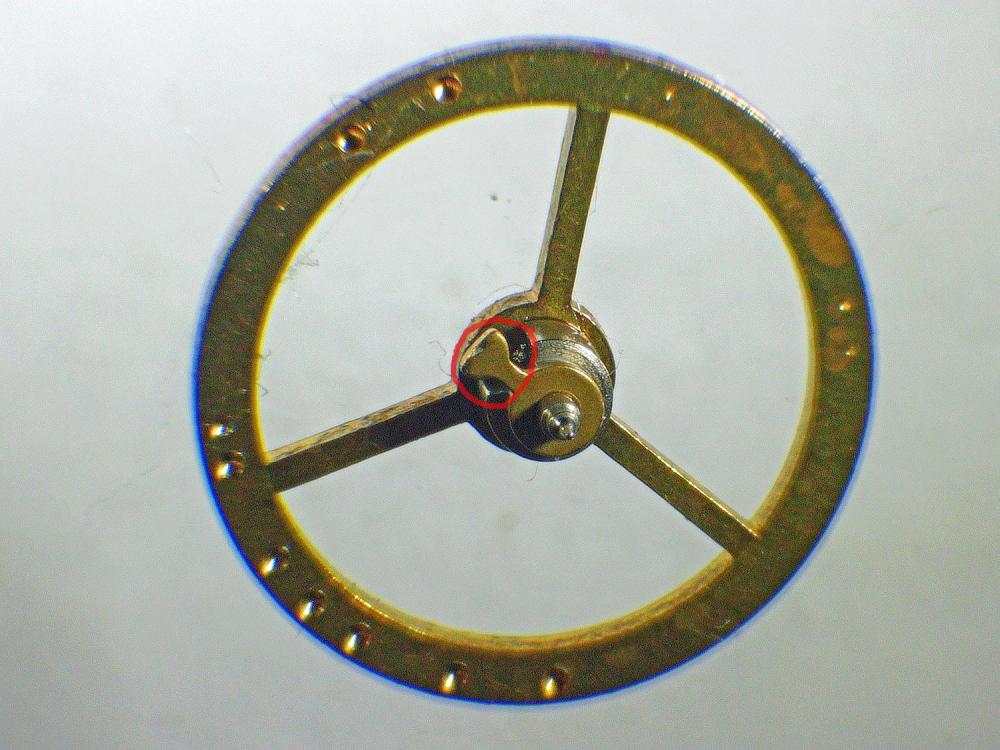

I hope this is close enough. And given my lack of experience, it's as good as I can get it. It's a $5 Waldan watch, so no worries. To me it looks ok, although there's a small kink at the outer coil. The coil is flat. It was pointed out the spring might be too long. It could be, but I think it's original. Thanks for all your help! Now I have to reassemble the balance. I got some advice on how to orient the stud. I know how to guide the spring around the regulator pin and shut it. I'm not sure about the alignment between pins. I don't have a jewel, but I think this is what they're talking about (circled in red) in photo.2 points

-

2 points

-

I realize not everybody has a 3d Printer, but this gentleman design more a less an open source watch cleaner and I actually bought his plans about a week ago at $99 and I'm going to start the build of this machine. The documentation is excellent and with the purchase of the manual you get the license to build it along with the .stl files needed to print the main parts and a BOM for the hardware etc with the link to where it can be purchased. The link to his site is https://www.diywatchcleaner.com/ There are a few videos of folks that have built the machine and reviewed it as well. I know that there are over 100 of these self built systems in use now. Worth a look. Also you can have the 3d printed parts printed for you, tons of people that provide this service. I'd be curious what everybody thinks and I will provide updates here with my progress on this watch cleaner build if interested. Forgot to mention that if you already have the baskets from a non-working watch cleaner I believe those baskets will work on this machine.2 points

-

2 points

-

The problem is that the youtube algorithm seems to like his videos, when I started my first clock, I only have a few under my belt (must do more), it was his videos that popped up first. Having some grounding in watchmaking I had a feeling something was 'off' and @oldhippy quickly confirmed this with his usual gusto and gave sound advice saving me from making expansive and potentially dangerous mistakes (clock springs are scary!). I thought about commenting on his page, but then decided against it:2 points

-

2 points

-

The spring is not pinned to the stud. It is put in a notch and the notch is (riveted)? So, no good idea to detouch from the stud2 points

-

This is my reply to this clown. What a bloody shambles. Use the proper tool a clock mainspring winder. You should always measure the inside of the barrel for the correct height because the spring to be replaced might not be the correct one Why don't you use a bigger hammer you clown. You never cleaned the new spring or oiled it, no oil on the ends of the arbor. I have watched many of your videos and find faults with all. People what ever you do never ever follow what this fool shows you. He is a complete menace to clock makers. I have around 30 years experience working on high grade clocks. I wouldn't let him inside my workshop. I look forward to your reply, that's if you have to guts to do so.2 points

-

Notice I quoted something again you had to start somewhere that's acceptable. You didn't start with great grandfather's priceless vintage something so that's not buried in the picture. Instead you started with a whole bunch of miscellaneous watches and I see a lot a balance wheels without their hair Springs. So basically what we have here is the pictures of the watches you started with that you're now going to sweep off your bench and find some new watches to work on as you learned hopefully something from playing with all these parts but? When I first started watch repair the instructor George Lewis had all sorts of interesting sayings or comments about things. So he would comment that students would see the glass half full in reference to well in your case the glass is half-full look at all these parts I can build these watches again. Where he would look at this as the glass is half empty and all those parts could be used in other watches. This is where you have to look at is it worth your time and effort to straighten out your assortment of parts? Or would your time be better spent on finding other watches to work on? I was really hoping he only had one or two watches but you have quite a few which makes it well if you have lots of time I suppose you could try every single part and figure out how to put these all back together again but I don't think some of them would ever run and is it really worth the effort? So not annoyed you started off you learned how to take watches apart some of them you learned how to put back together and now it's time to move on to some new more spectacular and better things preferably learning how to keep the parts separate and secure from external influences of other people cats dogs whatever.2 points

-

2 points

-

I just watched this video on YouTube. Scottie just bashed the spring into the barrel without cutting off the wire retainer, pre-oiling the mainspring and winding it into containment ring. Is this an acceptable technique? One can't even be sure that the hole end of the new mainspring is properly engaged with the barrel hook.1 point

-

Well, say what you will about the Russian leader, but taking off the watch at the beginning of the interview is a very respectful way to signal that the time for the interview is unlimited and open to reflection. I'll remember that if I find myself in that situation.1 point

-

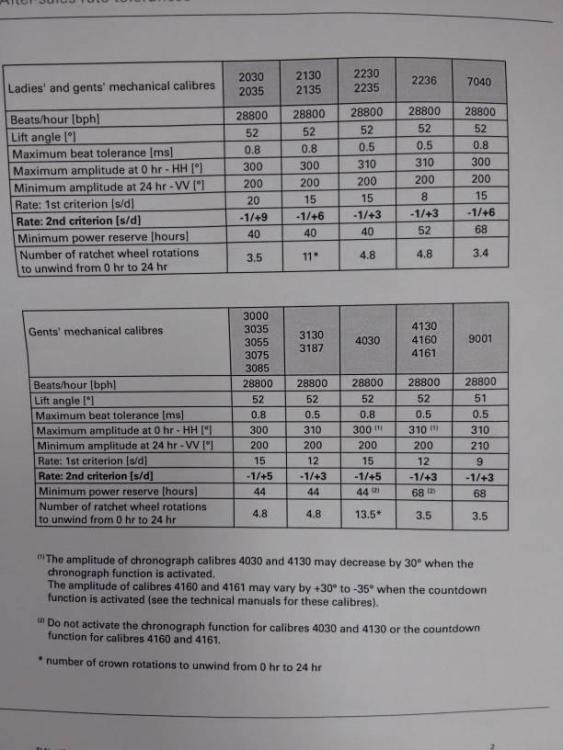

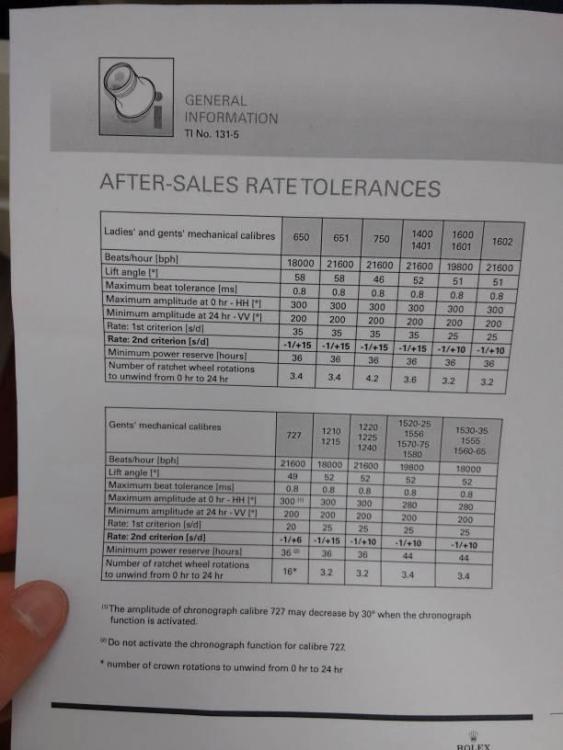

Actually it's why the watch companies specify a minimum amplitude at 24 hours. If you're amplitude totally sucked because of gremlins Or UFO abductions of your amplitude then you wouldn't get the minimum amplitude at 24 hours. So there is a target to be higher than 200° at 24 hours. Yesterday I was looking at a Rolex discussion group somebody was upset their amplitude sucked where of I heard that before? It had just been serviced by the service center and they weren't happy and feel other people in the group seemed to think the amplitude sucked. Then along came those silly Rolex people that were authorized to work on Rolex watches or watchmakers or other silly people and they gave us this image from the idiots at Rolex because Rolex isn't specifying that magic number that we need Oh dear as I said Rolex are idiots or are they? The assumption on the group is that my watches start off with the amplitude of 1000 to make up for imperfections not running efficiently etc. so that 24 hours later it might be hopping along at 200+ degrees. As opposed to if your mainspring is shaped properly your watch conceivably could maintain a nice amplitude which by the way is much better for timekeeping over the first 24 hours and just have that number above 200 and the silly notion is should keep time. So to a certain degree the obsessed people want to have 300° plus which by the way is a bad thing for other reasons hoping that you'll still have your 200 at the end of 24 hours well that would indicate your watch has a problem you shouldn't have to start off with a super high amplitude and hopefully try to get your 200 at the end. So a certain degree looking at this all wrong and backwards. Oh and I would suggest you should never work on an Omega watch because they will actually take lower amplitudes at 24 hours I'd have to go look at spec sheets and I think they might take 160 and yes that would probably be very upsetting for people on this group that the watch was doing hundred and 60 and still keeping time so I would stay away from crappy Omega's who can still keep time at low amplitudes I thought there was an indication that he had a service manual? Yes if you scour the Internet you can get them or you can purchase them on the eBay there a bit pricey is a seller in Italy that likes to sell Rolex manuals so yes they are available. The reason I bring this up is for those of you who haven't seen a Rolex service manual the rather detailed and providing our OCD obsessed person was following his manual he when I got to this page. Rolex does unfortunately like Omega leave things out of the manuals because you're supposed to have the supplemental manuals which are even harder to get. But still I think it's pretty detailed of the mainspring barrel checking. We end up with a interesting problem here. Yes I can understand the obsession and watch repair my obsessions sent me eventually to the hospital -2/3 of my blood with bleeding ulcers. So I try not to get obsessed well I try is an ongoing process. But? So in thinking about this I'm going to come up with a new term for us a new specification that you must strive for or else. The new specification is what I'm not call the phantoms specifications? Phantoms specifications are obsessions of watchmakers who perceive a watch should have a certain specification that the watch company does not specify. So in this case you're phantoms specification is that my Rolex has to run at 300+ degrees or I will not be happy but who cares whether it meets the actual Rolex specifications are not. So the problem with our phantoms specifications are as it's not specified anywhere in the universe you would really need to get more of the identical Rolex watch to compare all of them and see if any of them meet your phantoms specifications. In other words you have to define these specifications and verify that the majority of watches exceed or equal whatever specification you're striving for. Although we do know that Rolex does specify a weaker mainsprings so yes some of them can have too much power. Conceivably which you might find if we could gather enough watches the majority of them would fit in a specific range of this is their amplitude fully wound up. Conceivably some of them might actually have high amplitudes which is why they have the weaker mainspring. Then there is going to be on the percentage some of them a little or but Rolex doesn't care as long as it meets the specifications of 24 hours.Oh and of course the other one would be does the watch run for the required 48 I believe ours? If it does the watches fine and is running efficiently the watchmaker is not.1 point

-

Jack great job on your build of the cleaner btw. I hope to have mine up and running soon. I have been reading over their Discord server site and it appears to be a friendly site and lots of information.1 point

-

1 point

-

Looks good, you've made a decent job of straightening it out. The terminal curve does look long but thats not given, something you will discover when you get it mounted up. In red is the impulse finger .1 point

-

Update, few weeks after... There's a lot I could say, so I'll try to focus on actions and results. My first service, on a simple but small movement, was given for junk from the start: A Seko 2220-3470 "socie" No hope? After a truly artisanal cleaning: But in the end, while trying to polish the pinion, the wheel came off its balance shaft. No hope Anyway, I reassembled and lubricated the rest of the parts (with NOVOSTAR 17313 Type B for everything, and Moebius 8300 grease) (I'll probably make a separate post for all the equipment and techniques I use, in the right topic). After that I opened the main spring barrel (thanks to WRT I found hints here, thanks to my luck at the end I retrieved very shortly all the pieces 1 meter away). I also started to polish/renovate some cases and acrylic glasses, and started to implement a diary system (python/mkdocs). During the Christmas holidays I brought back to life a Lord Matic, but that's another story1 point

-

1 point

-

It would be close. But these Accutron dials are relatively thick. I think there would be enough surface area to make a good bond.1 point

-

1 point

-

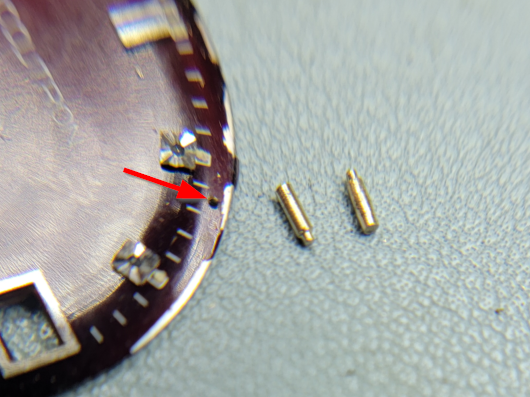

Hi with this bit of metal removed and balance fitted does the watch run.If so it’s probably historic, a pivot lost in the works, but having said that I would dismantle the watch clean/service and start with a clean sheet.1 point

-

I finished my cleaner a month ago. There is plenty of DIY and purchasing the hardware etc. but I like to do that stuff anyway. I had to learn 3D printing and it took me a while to print out everything. It is a very nice machine and I have run about 4 movements in it. You can use the inexpensive baskets from China or the Elma baskets. Please excuse my messy garage...Let me know if you have any question on the build. They have a discord server available to ask questions too.1 point

-

Then I'd say you're looking for squirrels in a Baobob (barking up the wrong tree ) This is why amplitude is a range and not a target. Think of it like blood pressure ... as long as you are within the over/under, there's no need to call the doctor.1 point

-

I was able to get replacements from Cousins UK https://www.cousinsuk.com/product/0120mm-tubes-pins-notched Cheers1 point

-

Hi There! I recently fell into the deep hole that is watch repair, and have been learning as I go. Recently started taking apart and reassembling Raketa movements as practice, as well as an NH36. I have a Seiko 4205-0155 on my bench that I am currently restoring, (challenging with the 17mm movement!), and have assembled two Seiko based watches with new movements. I have a selection of oils arriving shortly, and will dig into that, and I am saving up for a trinocular microscope to help these older eyes manage. Looking forward to learning more! Yani3651 point

-

I forgot to mention he was trying to fit a spring into a Smiths barrel I recognised the factory markings inside the barrel and the barrel cap is different from the barrel.1 point

-

@nevenbekriev has already identified the obvious faults that I can see at this stage. He's also given you some good advice on how to correct them. Of course, knowing what to do and actually having the hand / eye coordination, technique and tools to do it are two very different things. It takes a lot of practice to do well, and most of us ruined hairsprings in the beginning. Everyone has to start somewhere though, so as long as this isn't a valuable piece to you, go ahead. You will need some very sharp-pointed tweezers, a fine needle or oiler, a hard clean surface, good magnification, good lighting and lots of time and patience. Go slowly. It's better to make five tiny adjustments in the right direction than overshooting back and forth. Whenever you are not sure what to do next, come back for advice.1 point

-

Completely agree, I was using other devices and after going to the scope, I don't know how I lasted this long without one. I got one with a camera which helps to take snaps during the disassembly, just in case my memory fails me and I can't remember where everything goes. I got mine from Ali Express, I was a little cautious, but after a year of use I am very happy.1 point

-

You have shown it to be 3.3mm , thats where( called regulator arm slot ) the outer most circle ( the terminal curve ) should pass through. Lucky the coil looks flat, adjustment for levelness is most likely needed near the collet, sort out the terminal curve and relevent area first. Good luck1 point

-

that's what is called dollar watch, like an Ingraham or New Haven, there are other makes too...1 point

-

My name is Michael, I retired a couple of years ago and started repairing old clocks as a hobby, which I am really enjoying. I found this forum today and decided to join and share my experiences with other like minded individuals. Looking forward to getting to know you all.1 point

-

sorry late, everyone should watch Andy Hulls video.....on refinishing & plating ........1 point

-

Regarding donor movements, I found that Etsy has many of the old 2609, 2628, etc, movements for sale for use as parts for jewelry. I got 10 movements for $2.50 each. They are rough, and all have snipped cannon pinions and stems, so they can't be used for dial side donors, and the center wheel is usually damaged. But all the rest is there. I've made several of them fully working as a running wheel train. So, good cheap source for some of the parts.1 point

-

They were actually designed for one purpose but now they can have two purposes. As you noted the watches cleaned entirely assembled if you are following a modern or some modern shops typically with Rolex for instance you will do a pre-cleaned cycle. This is where the watches left together the movement and its cleaned in that condition usually in a slightly shorter cycle the purpose of giving you a nice clean watch to evaluate. But the real reason for this is it's a faster way to service a watch. At one time they would make a substance it went by the name miracle lube or one step. There were others is also a dual lube method that did the same thing. The basic principle is you clean the watch assembled that saves that pesky time of disassembling. As far as lubrication goes I really like miracle lube as I think the miracle it works But? So I finally got to see a material safety sheets for one of these substances and basically it was mineral oil which is a high-temperature oil in your last rinse. So your watches all nice and clean with no lubrication and the last rinse has the high temperature oil dissolved in the rinse itself so now you have oil covering everything but don't worry the magic of capillary action. As the solvent evaporates the lubrication will migrate to all of the crevices like where the pivots are. So now your watch is 100% lubricated and yes that was the selling point you can increase productivity by quite a huge percentage because you don't have to disassemble a you don't have to do manual lubrication. Obviously there's a reason why this no longer exists but it didn't exist at one time and it was very popular with production shops.1 point

-

Hi HectorLooi I am laughing because i know what oldhippy would think, that's his favourite person1 point

-

Only by adjustment of the collet that holds the hairspring. Its an interesting exercise for a beginner in how to trash the hairspring. Any way you can practice on something that doesn't matter first.1 point

-

If You are asking in which direction to wind the spring in the barrel, then place the barrel arbour in the barrel (in the correct way) and look at the hook on the arbour. It will show You the direction of the spring. If it happens to wind the spring in the wrong direction, then rotating the arbour in winding direction will lead not to winding, but to deforming the internal end.1 point

-

no that little bit of metal was stuck to the underside of the balance cock hence i assumed a broken pivot, you have confirmed what i really thought so i an thinking just dirt or congealed oil, the balance pivot was black on the end and i have now cleaned it and polishes it a bit, i have stripped the cock and cleaned the jewel and cap so will put back together and hope this solves the problem. thanks for the input.1 point

-

Hello all, Originally from PIttsburgh, PA USA but have been living in Ibarra, Ecuador for the last 20 years and work at Yachay University as an English teacher. Along the way, I met a nice gentleman here who does watch repair and helped me out with a mechanical watch that my father had gifted me. But, he is getting older and his sons do not know mechanical watch repair. So, I like to do things with my hands (electronics and motorcycle repair) and decided I would learn how to take care of my watches. My interest lies mainly in Japanese watches like Seiko, Orient, and Citizen as I gifted my father's Swiss timepiece to my nephew on his graduation since I do not want to walk around the streets with an expensive timepiece here. The drawbacks to doing repair here is that nothing is easily accesible from solutions for cleaning (restricted due to government control) to replacement parts. But, things are possible with planning. Thanks for the welcome and will enjoy reading the posts here on WatchRepairTalk. All the best Kev1 point

-

Hi Well, "boy" is a bit of an exaggeration as I've been retired a few years, live in Yorkshire. Was a repro and printing press engineer, then for 15 years an X-Ray engineer & service manager, so like to keep my hands busy Always enjoyed good mechanical watches, and one or two quartz ones too. Always considered purely as a hobby, watch repair. Just seeing what's involved and where to start. Always willing to learn and be guided. Cheers! Barry1 point

-

1 point

-

1 point

-

1 point

-

Hello everyone, My name is Ben, I am a new member on the forum, as well as a subscriber to Mark‘s online lessons. I have been fascinated by watches for many years and once attended a live course, which really got me hooked. I am at a stage where I still struggle to comprehend how one can fix a part so tiny and fragile as a hairspring, and I hope that it will one day feel natural to me. I look forward to exchanging with you all about our common passion! Best, Ben1 point

-

I was amazed when I saw this. I thought it was going to be a cheap Chinese movement. (I friend once asked me to repair his Tissot skeleton movement. It was the most horrible cheap Chinese movement. I was shocked it was in a Tissot. It was impossible to take apart and repair. I gave up, and bought a new movement for about £25). But this is a true ETA movement. I can't see why they would do this in a movement with 23J ! It's only the C07.1XX which have this 'feature'. The C07.6XX and 8XX have regular escapements.1 point

-

1 point

-

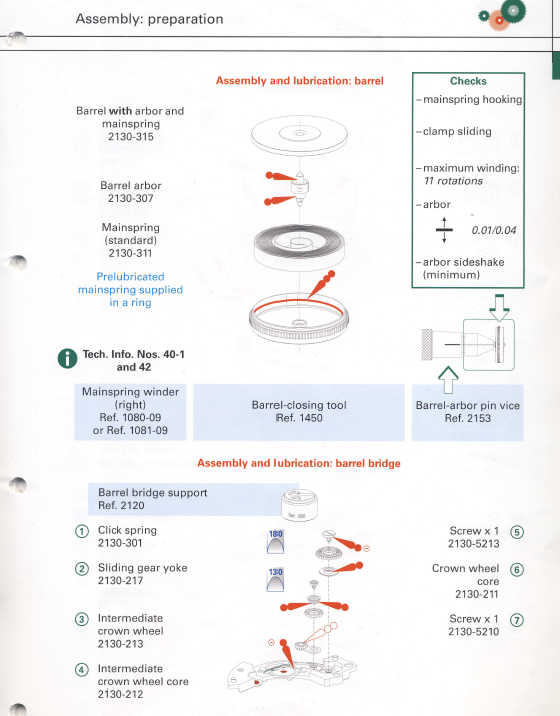

Tissot calibre 781 Disassembly (Please sort the images by name in ascending order) Tissot calibre 781 Assembly (Please sort the images by name in ascending order) Tissot calibre 781 ranfft facts Some time ago my brother handed me this Tissot dress watch from the mid-1960s housing a Tissot calibre 781. My brother collects watches but doesn’t tinker with them (yet). Anyway, I thought it would be interesting to give this Tissot 781 an overhaul (you always learn something). It did seem to run and being a 17-jewel manual wind watch I thought a service shouldn’t take too long or pose any challenges in particular. Anyway, when I removed the case back, I noticed to my surprise that the balance had stopped. I thought “that’s funny”, as it was fully wound and had been ticking along fine while I was looking at the dial. Going deeper I realized that the one of the balance staff pivots was broken off. So, I called my brother and told him the bad news and that I had no experience replacing balance staffs. Well, my brother didn’t become too upset about this but simply told me to keep the watch and possibly repair it in the future if and when I would learn how to replace a balance staff. I wasn’t sure I was ready for it, but life is unpredictable so I thought that it was now or never that I would learn how to replace a balance staff and get the necessary tools to do it. Long story short, I did learn how to replace a balance staff and the watch is now ticking along just fine. In the process I got first class help and illustrations from my fellow Swede @HSL, and if you are in the process of learning how to replace a balance staff, I do recommend reading the following thread where you’ll find HSL’s (and other helpful) posts about this “Staff replacement, balance wheel wobble”. To call this post of mine a “Service Walkthrough” is perhaps a bit of a stretch as the pictures don’t include any oiling suggestions and/or tips/instructions. Nevertheless, I’m thinking that the pictures still might be useful to anyone servicing this calibre and perhaps pondering in what direction the main spring should go and/or what screws to use where, and so on.1 point

-

Hi friends, I could finally finished the elgin pocket watch. It took me many many days between sourcing the parts and working on the watch jjj. But it's finally done. I put a video together wrapping up the process. Here I'm posting the video and link. Thank you so much to every single one of you who tolerated me along the way. Without your advices I wouldn't have done it.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)