Leaderboard

Popular Content

Showing content with the highest reputation on 08/01/20 in Posts

-

No. The crown wheel screw may be be left threaded because the crown wheel, which turns counter clockwise under it, may tend to undo it. But the ratchet wheel screw does not move related to the ratchet wheel and barrel arbor airbor, no need for it being special, no matter which direction it turns. That being said, if left threaded the manufacturer gains commonality of two machining steps, and of two parts if it's identical to the crown wheel screw. To the cost of confusing most repairers as happened here, and the risk of an unpleasant breakage. At least, both of them should have three slots not one.3 points

-

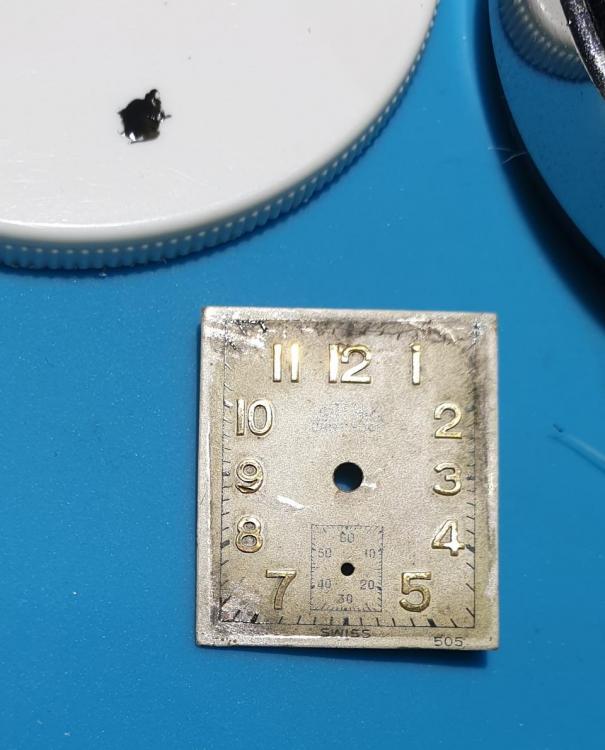

I guess you guys were right. My friend was pleased with my work after all. He was hoping I would try to paint in the numeral. I learned apparently many people who do a bit of dial restoration often just repair chips and cracks, but they often do not repaint numbers or markers. He liked it. He liked the face, and the polished case, and the fact that it runs now and he can carry it on formal occasions like his father and grandfather did. I made him happy. That's the best thing about this little side job of mine. And just for being here, I thank all of you in this forum. I am really enjoying this hobby/second job.3 points

-

you don't. that is a front loading case. Model 87 movement and there should be a bezel ring around the dial.3 points

-

Yes, I nudged it to the right and it didn't take much for it to loosen. I had applied Marvel penetrating oil to the screw and let it sit overnight so that might have helped. At the outset when I didn't know it was left handed, I did give it a little nudge to the right but it didn't move and I didn't want to make matters worse if I nudged too hard. I did buy a can of coke just in case and now I can enjoy it with some popcorn!2 points

-

Hi all, Mystery solved - the ratchet wheel screw is left handed. Wow. I briefly thought that could be the case, but still being new to this (just under a year with the tweezers) I assumed that most if not all crown wheel screws are left handed, ratchet wheels are right. Oh well, lesson learned. I looked for technical info on the movement on the AWCI site but could only find parts info. I should have checked the Ranftt page sooner (thanks Klassiker for that reminder). So the screw is out now, no damage done. Thanks again to all. Dan2 points

-

The movement is a caliber 6500. I still favour it is a reverse thread.2 points

-

2 points

-

The light you use also needs to work with the surface you are going to work on. A green surface is very good, you don't want a light that throws out heat, you need something that doesn't give off a shadow but also flexible so you can adjust it. You also need good light in the room. I have strip lighting on the ceiling and around the side of some of the walls. My preference was a green surface and a light like this type. Found this on the internet its not my bench2 points

-

I have disassembled the movment. Springs.. I was determined to not..Have one go! Result: The keyway spring took off! But, it kept close. and I did find it emeidietly. (pure luck!) The movment has never been running. So a easy clean. Not sur what to do with the hairspring/balance assembly. Have no lighter fluid on hand. But acetone, and isopropanol. So, I have left the pallet fork and hairspring assy. As is, for now. Have taken a lot, I mean, a lot of photos. But I don't want to wait to long before reassembly. Memory is like teflon now days. Well, not that bad. But its getting there. The glue on the mainplate. Did come off, after about an hour or so. But has left some etching on the plating. that won't come off. But, its looking better anyway. Tomorrow, assembly time!2 points

-

Thanks for your input @rodabod! Yes I did, but in a different thread. Images here and as you can see, no hiccups in the train. My conclusion (but I guess I could be wrong even if I don't think so) is that the bridle of the GR2378X spring just isn't compatible with certain Seiko (cal. 7S36) and Orient (cal. 46E40, 46943, etc) calibres. The GR bridle simply doesn't exert enough pressure on the barrel wall. As noted previously it is thinner and lacks the introductory and concluding dent of the Seiko/Orient spring. So, I've just installed an original but quite battered original Orient spring (the only one I was able to source on eBay) in the barrel. Preliminary results are a major improvement. The spring now slips after about 7 revolutions of the ratchet wheel compared to the 3.5-4 revolutions of the GR spring. Anyway, within a couple of days I should be able to report the actual power reserve measures in hours. The greed of the watch manufacturers are refusing to freely supply parts to hobbyists. To me personally it's beginning to kill the fun and in the long run possibly the hobby1 point

-

I was going to ask that question one of the problems with pocket watches is trying to figure out if it's a screw back or it snaps off. usually if the bezel what the crystal screws off the back will also screw off but never 100%. usually on the pop off back's there will be some sort of lip or indent to indicate that but sometimes people enthusiastically try to pry off screw backs and the leave the same sort of marks. they do make commercial things were moving back slight this one it's really nice and cheap https://www.amazon.com/OTOOLWORLD-Watch-Case-Friction-Opener/dp/B07417BNF9/ref=sr_1_34?dchild=1&keywords=pocket+watch+case+opener&qid=1596314003&sr=8-34 specifically more for pocket watch back soon as this one http://www.ofrei.com/page270.html1 point

-

Its a triumph! I always say thats its only cheaper to do something yourself if you don't value your time [emoji1787] Sent from my SM-G973F using Tapatalk1 point

-

Just to show another dial restoration that I have been working on. I first clean the dial in soapy water, brushing gently with an artist brush. Then use pegwood on the more stubborn stains. The paint that I used is black UV nail varnish. I do a small bit at a time then cure it under a UV light when it looks ok. Then proceed further. If the next bit doesn't look good, I simply wipe it off and redo it. The "brush" that I used is a homemade brush with a single bristle from an old toothbrush. This is still a work in progress. I will post another photo when I'm done.1 point

-

I'm wondering that too. Physics being what it is, if the crown wheel screw was left-handed, then the ratchet gear screw couldn't be. But!...if the crown wheel screw was standard, wouldn't the ratchet gear have to be the one to be left-handed?1 point

-

Hi service manual attached for the 87 full of good stuff timex 87.pdf1 point

-

It's a 16.5 ligne/36.6mm movement. It really is almost identical to the ETA/Unitas 6497 except the motion works are at 12:00 since it's a pocket watch. I didn't think that the ratchet screw could be cross-threaded which would really make it stick if it is, but based on how flush it's lying to the ratchet wheel, that may not be the case. The good news is I have a spare parts 6497 movement to call upon in case anything gets really botched up related to the barrel and arbor, so there's not much to lose by trying different techniques. Plus the watch was passed on to me by a friend who knew of my recent interest in this stuff (so nice when that happens) so it's not an heirloom or anything extremely valuable. Thanks again for weighing in. Dan1 point

-

And that's why we love you, Mo. Who else can identify a Timex watch from a blurry photo.1 point

-

Hi Dan-do looks like a nice clean movement. did you try to give it a nudge clockwise to feel any resistance or tightening? don't force it. I've not seen a left handed ratchet screw but you never know. do you have any kind of penetrant laying around and oilers? maybe some lighter fluid? once you get the bridge with barrel assy. out, I would apply penetrant around the screw head, then turn it over and apply more at the barrel arbor, and a few more dabs to the holes(if any) thru the barrel cap and let it sit. better if over night, checking on it once in awhile. if that doesn't work, I might let it soak in lighter fluid(naptha) for an extended period. overnight is best, checking on it, seeing if it frees up. if all that fails, give the thing a short rinse in iso alcohol to dry it completely. at this point, you might have to add a little heat such as a jewelers lamp if you have one, or a cig lighter. apply the heat SPARINGLY, with the flame about 1/2 to 3/4 inch from the screw, using a circular motion. in other words, don't hold the flame in one place, keep it moving. you don't want to overheat the thing and run the risk of burning fingers. also, make sure your screwdriver width is as close to the width of the screw slot as possible so as not to slip, gouge, scratch or damage the slot or anything else and don't force anything. no expert here-just a couple things that have worked for me. try these and get back to us. good luck. Mike1 point

-

This is what I'm using and love it and only 20 bucks. https://www.walmart.com/ip/Mainstays-LED-Swing-Arm-Architect-Desk-Lamp-Black/553473091 point

-

1 point

-

Today's watch is my grandads old Roamer which I acquired in 1986. It had been sat in the cupboard all this time but finally I have had it repaired and serviced. It required a new main spring. It keeps great time although I only wear it when sat in the office. I don't know its age but I do know that the movement is an MST 430.1 point

-

From experience, I've been able to open all "do not open" barrels and close them except Zodiac. The ones I've seen are truly crimped/burnished such that the cap is destroyed in removal. Last one I did I made a new cap.1 point

-

Ok, that's not a baby lathe, but not one known for its rigidity. HSS is ok but you will need to sharpen often. Stickout from the chuck needs to be as small as possible. For something like this I use my 4 jaw chuck; for one the gripping power is greater than a 3 jaw, and on my machine it sits about a centimeter closer to the headstock- that cm makes a world of difference. You can think of overhang (stickout) as decreasing rigidity as a square; if you have 15mm and that gives you x rigidity, then go to 30mm it not half as rigid, it's way way less rigid. So if your raw stock is 50mm and you need a 15mm slice, stick 16mm in your chuck, and part off right next to the jaws. Then face it off to thickness.1 point

-

1 point

-

1 point

-

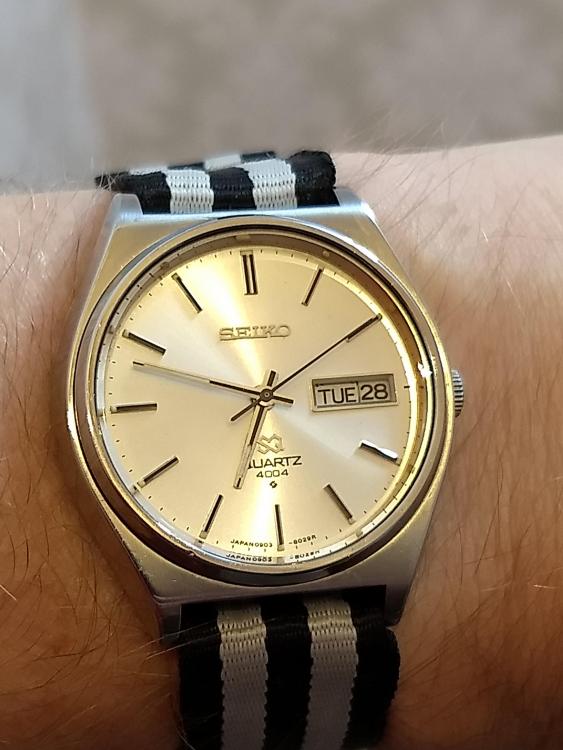

My watch of the day, just finished this as a present for my daughter's 16th this Friday. Seiko 4004 Quartz from mid 70s. The lengths I have gone to with this watch, I even had to find a case back for it as the one it came with was from another watch and stuck on with double sided tape. She will love the retro look.1 point

-

GeoMontreal This may be a redundant post of this manual, but it its the first time I've known of it's existence. I won't have know to search for it. Military manuals are of some of my favorite referance reading. Thank you for posting it. Nora1 point

-

I wouldn't try that if I was you! As you have already found out, the Chinese springs are made from poor quality metal and break just by breathing on them. Would you rather have two broken springs, rather than one?!1 point