Leaderboard

Popular Content

Showing content with the highest reputation on 11/05/19 in all areas

-

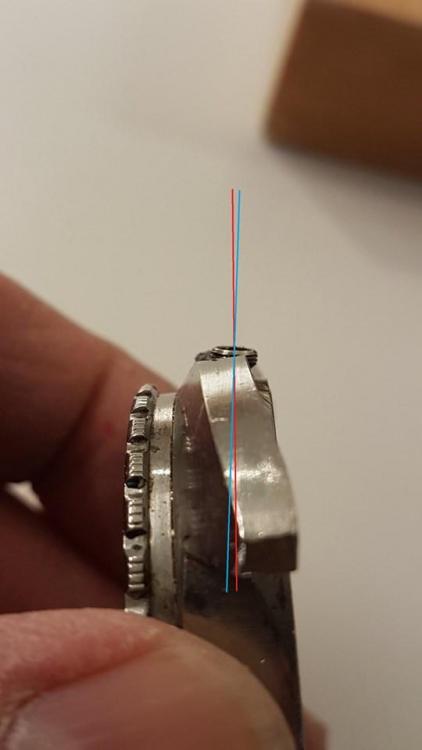

Hello to you all folks, thought I should share this story with you ,,,, Then I finally completed my big project "Doxa Searambler 300T from 1968" which I have been working on from March 11 to June 27 this year, for about 14 weeks. And I have to say very happy, although I have not yet managed to find a good solution on the BoR link. Have been in contact with the Doxa factory via an acquaintance who is AD in Sweden, so let's see what gets there. But anyway, here's the story: Bought this on March 11 in miserable condition, see photo 1. It was pretty messed up after been worn after 50 years of use as a professional dive watch, so all of the marks were gone on the bezel ring, the glass was scratched, really needed a service, see photo 2 and 3. Some had also tried to change the casetube and crown without knowing how to do this. And should rather been doing things they fully master insted. The casetube was inserted with an wrong angel into the case, so the result was that the crown did not enter the movment right. See photo 4. To fix this, the old casetube had to be drilled out / pulled out. This one was not fastend good enought, so I could just pulled it out. If this is done right, they is stuck like hell. .. See photo 4. you can see the red line that shows the correct angle into the case, while the casetube that was mounted befor was incorrectly angeled into the case, see the blue line. A incorrect crown was also inserted, the original crown is 6.92 mm in diameter and 4.60 mm high, stem thread is 0.9 mm. The one sitting here was far too small and is completely wrong compared to the original. The dial was very spotty and had lots of marks after many dives. And that the lume had got the greyish color. See photo 5. So full dismantling was needed, stripping everything, movment out, glass out, bezel ring dismantled from the case, cleaning of all parts. So when everything was cleaned up, the build-up could begin. First the old case tube had to be drilled and pulled out, so it was dismantled, and the new casetube was inserted with a crown. See photo 6. Found a crown that is quite similar in appearance and about the same size. Doxa is known to have very little parts to these olde watch available unfortunately. So finding original casetube with crown seems like a pretty impossible task. See photo 6. Did service work on the movment, ETA 2783, no parts had to be replaced, just a little tightening of canon pinion, because it was a little loose in motion. Painted bezel ring by original colors. See photo 7. When it comes to the dial, I wanted a crisp and fresh dial, so I chose to use an friend of mine who is an specialist in restoring dials, and who is the real magician when it comes to repaint of dials. See for yourself....See photo 8. Lumes on the hands and indexes was put on by me, had to mix ut a certain light cream color lume to match ut the right patina. Also managed to source a glass made according to original spec. which was fitted. Then after about 3 months, all parts were mounted in place, the work was installed, the test round was done with brilliant results. And I could finally take this piece of jewelry on my arm ... See photo 9. Beautiful!!! Go...Go....Switzerland !!!5 points

-

It's a sign that your beat error is amplitude dependent. Is the hairspring concentric? Centered in the Regulator pins? How wide is the pin gap? What's the beat error with the movement in a position that has the pallet fork pointing straight down compared with horizontal?3 points

-

Does stay pretty good, I used Humbrol Enamel, used for model airplanes, can get them in all colors..2 points

-

There was humidity at the time it has been cased. Open it and dry the case and crystal well with an hairdryer. After closing with new gaskets touched by silicone grease on them, test it warming the whole and placing two drops on cold water on the crystal. That won't however replace a proper pressure test.2 points

-

Press the indent, indicated by the arrow, with a suitably small screwdriver, or the tip of your tweezers, and pull the crown.2 points

-

True. Repositioning the HS is the standard approch and for good reasons. Having special tools be nice. According to Nicklesilver small beat error there. Best Oh I learned, thanks.1 point

-

1 point

-

Make sure you alternate wrists otherwise you'll end up like Tessa Sanderson [emoji23]1 point

-

It lives! The 1/2 Kg strap monster lives. I was sure I must have at least one BG 866 balance fork in the junk pile and sure enough after a bit of a rummage I found one in a very beat up 21 jewel scrap movement. Ignore for the moment the fact that I am clearly an idiot, since I have set the wrong date on it, and listen very carefully, wherever in the world you are, and you can probably hear it tick. It may not be the most refined watch in the collection, but it sure is fun.1 point

-

I didn't conclude a need to correct the beat, it was asked how one corrects the beat on a balance cock with no movable stud lever which I advised on using the method I tend to use. (However with a BE above 1.0 I would), personally if it's above 0.5 I like to get it as close as possible. I haven't tried adjusting the roller table but it would still require removal of the cock to do so and they tend to be quite a tight interference fit whereas the the hairspring collet (most often but not always) is slotted to facilitate adjustment. I imagine moving the roller table would necessitate poising the balance again also?1 point

-

Regarding putting the watch in beat, the normal thing to do is move the hs collet. But you can move the roller table too, there are tweezers to do it and even more sophisticated tools as well. When you're within 1.5-2 ms beat error the movements are really small.1 point

-

Okay theoretically with the hairspring in place if you could rotate the roller you could put the watch in beat. The problem is the roller table is friction on the staff and rotating it would be very likely impossible. It's so much easier to rotate the hairspring collet it's meant to be rotated as long as you're careful .1 point

-

As a reminder marks and videos are educational there to teach things but they're not necessarily the only way of doing something. So another way to do this that I find this simpler is the following. Rotate balance wheel like Mark shows until watch is in beat. You can do this with the pallet fork in place. If you're using the pallet fork as a reference placing it between the banking pins will be really close not necessarily perfect. There is a little bit of play between the roller jewel and the fork slot so even with the pallet fork perfectly centered that additional play of the roller jewel may leave you a little out of beat but you'll be very very close. Now place a felt pen mark on the rim of the balance wheel corresponding to where they hairspring stud is supposed to go. Felt pen is used because it's easy to clean up it's not permanent. Remove the balance wheel like Mark shows leave the hairspring on the balance wheel rotate collet until stud is in alignment with the mark. Then reassemble and verify that things look correct. Then if you have a problem just note which direction you have to go in relationship to the mark you made remove and do this again avoid the balance tack method as I will explain below. You will note I have an aversion to the balance tack. The problem is in the video he shows pulling and stretching the hairspring on a very large balance wheel and it's a very stiff hairspring. When hanging watches with softer hairsprings they don't like that sort of hanging and if you not super careful it's really easy to distort them.1 point

-

Can you give us a link to the specific video as Mark has a lot of videos. Then the preferred method is rotating the hairspring collet. The problem with moving the roller is you have to disassemble the balance to do so and you screw up the poise. Then you still have to put their hairspring back on and get it in the right position so it's much easier just to rotate the collet if the balance is already assembled. You should look carefully at your balance wheel on the top and see if there is a mark? A lot of times on older wristwatches the watch company will put a mark where the stud is supposed to be in alignment with. It usually really tiny and it's not always there but if it is it's very helpful for putting the watch back in beat. Then it would be really nice if you would take a picture of the timing machine when the Watch is in the position when it's making noise just so we can see what it looks like. Omega's specification for your movement and beat error is 0.8 ms with the measurement being taken anywhere from 30 minutes to 90 minutes after the watch is fully wound up. Then so you get your amplitude right the lift angles 49°. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_2661 point

-

I'm not sure if there's a problem here. Some watches can really belt out a "twang twang" , like a tiny banjo getting tuned. Maybe in the vertical positions the change in effect of gravity is enough to permit that. That's a pretty good size movement, wouldn't surprise me.1 point

-

That's a pretty broad question! Without writing a book, pretty much if you are a professional you have the training and experience to do work in a timely manner, charge a fair price for both you and your client, and have a good life. Every situation is different, there are killer pros who work from home almost entirely by post, others with storefronts who also buy and sell, some like me who do a mix of repair as well as prototyping work for industry (that aspect would probably be limited to folks here in Switzerland). The investment in equipment can add up quickly, though not everyone needs a 15k buck Greiner cleaning machine, nor does everyone need jig boring and CNC equipment. If you're doing lots of watches the Greiner will pay for itself pretty quickly. If you do lots of clocks a Rollimat pivot polisher pays for itself in a month or two (and makes life sooooo nice). There are sort of limits to what one can charge, you can't expect people to send you a 7750 based watch for a general service if you charge 1500 bucks, there are too many good options. But if you can make a staff and vibrate a new overcoil hairspring for a rare vintage piece you are in special territory. Prices go up- but often not actual profit... this is a realm where often the few who do it do it because they love it.1 point

-

Guys, Thank you all for your input. Given my schedule - it may be this coming weekend before I can spend any time with it to answer some of the questions you have posted. I have ordered a balance tack though. So will have available in a few days. Planing to correct the beat error first - since the cause/correction is pretty definite. Then see if the noise persists with that correction made. As always - many thanks to all that share their knowledge and take time to post! -Paul1 point

-

I have noticed this whenever I clean a case with hot soapy water. If it is not absolutely and completely dry upon reassembly this will happen.It doesn't take very much moisture at all.1 point

-

That description is what I would expect from the teeth of the escape wheel, it could also be worn pallets, worn holes escape wheel or pallets or both. Sending it back is the right thing providing if the seller said it was going and keeping good time. Ebay have a guarantee these days so the person will have a full refund. Pity the seller didn't spend time with the movement instead of concentrating on the case. No good having a nice looking case if the insides don't work.1 point

-

A video by Mark, shows to set impulse jewel in beat, is at the stage that he is building the balance complete. At this stage you have reassembled. why not re-set the roller in beat? No need to disassemble again.1 point

-

Check out Marks YouTube videos, he has an excellent one showing how to adjust the collet on a fixed stud post. How big a variance in beat error are you seeing from DD / DU to the other positions, a little variation is normal but if you're seeing huge variations you could have variational error due to the balance needing poising.1 point

-

Some unconventional advice. Lubricant distribution on escape teeth has not yet fully taken place, this may take several days of running. If you now see appropriate to add oil, apply directly on escape teeth, allow time for distribution. Previous balance complete build could be inaccurate.1 point

-

The beat error is regulated at the collet on the balance staff, I find that a medium to large oiler is ideal depending on the balance, (wristwatch / pocket watch), while the cock is suspended from a balance tack. You need to ascertain the direction of adjustment before removing the balance cock then it's trial and error. For future reference it's handy to eyeball and adjust as near as possible while the movement is stripped as you can physically see the impulse jewel and align it, adjustment must still be made with the cock removed. Addressing the other issue, if you're hearing the noise then chances are something is rubbing or catching when it's side on, have you inspected the jewel holes and pivots for wear and tested for side shake? Overbanking is a possibility also, do you know the amplitude? Also is the variance in beat error between positions or regardless of position?1 point

-

I thought you might be interested in this article that appeared on Hackaday https://www.empa.ch/web/s604/liga-watch1 point

-

Printing of watch parts has been done for at least 20 years, normally referred to as liga or one of the company's name Mimotec. Hairsprings have been done, I didn't really see what's different here but perhaps the alloys are improving. It's not a technique used in mass production generally, but does work well for parts that would be impossible to machine otherwise.1 point

-

It looks like their processes competing with Omega's process I wonder what the advantage would be? Then here's a link to what Omega is up to with their hairspring. https://youtu.be/MZ9j-MYDs9Y1 point

-

1 point

-

I could not find a single video on how to wind a mainspring back into the barrel after cleaning. I purchased a three set tool and figured it out myself and then made a video for others to learn. Thanks Sent from my iPhone using Tapatalk1 point

-

A smoothing broach is not a good idea you could easerly cause damage to the jewel. A good soak in one-dip / lighter fuel and sharp peg wood should do the trick.1 point

-

This is what you need. If you get anything that is to powerful it can distort the hairspring which is the main part that needs demagnetizing. http://www.ebay.co.uk/itm/like/161822826949?limghlpsr=true&hlpv=2&ops=true&viphx=1&hlpht=true&lpid=122&chn=ps&googleloc=9045125&poi=&campaignid=207297426&device=c&adgroupid=13585920426&rlsatarget=aud-133395220866%3Apla-131843272146&adtype=pla&crdt=0&ff3=1&ff11=ICEP3.0.0-L&ff12=67&ff13=80&ff14=122&ff19=01 point