Leaderboard

Popular Content

Showing content with the highest reputation on 09/20/19 in all areas

-

2 points

-

I have never heard or seen the recommendation of glueing wheels, pinions, etc with shellac or anything else. These should always be friction fit.2 points

-

Looking at this site they both have the same Balance staff. However I am not sure they have the same balance assembly but it is highly likely. https://www.balancestaffs.com/eta.php2 points

-

Stem cut a bit too short? No problem, drop a minuscule piece of wire in the crown, apply locking agent and screw down well. Shhh don't tell anyone!2 points

-

1 point

-

1 point

-

If you damage a punch on an escape pinion it was a bad punch. But yes, lots of light taps, as you can very easily damage the pinion leaves.1 point

-

1 point

-

1 point

-

what would a "flat ground" look like? it might make the tip too long and weak. have you ever twisted the tip off a tight screw? a compromise is hollow grind. vin1 point

-

1 point

-

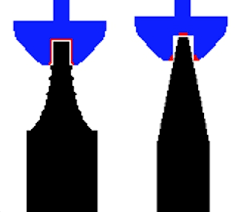

From experience escape wheels are friction fitted, usually onto a turned portion of the pinion leaves. The pinion is so small it's hard to form a rivet without introducing other issues; perhaps some makers 'peened' the leaves where they extend past the wheel. The forces are so light there friction works fine. Balance staffs get rivetted very securely as they have to hold up to the installation and possible manipulation of the hairspring collet and roller table without shifting, not to mention truing of the balance. Then of course train wheels need to be very secure, particularly the center wheel.1 point

-

Too much math. I would just make another stem on a lathe Sent from my GT-N5110 using Tapatalk1 point

-

Well because with hollow screwdrivers, you have more grip the teacher say ( Omega service center ) and les chance to slip away or to damage screws... You don't want to damage movements, especially now with open case backs. But thats what we learn the first lesson, I am only the pianist. ;-)1 point

-

Hi, wheels are rivetted onto the pinion. Yes, if it is a new, never before used pinion. Honestly, I am astonished on this question by you. Frank1 point

-

An hairspring stud pin, as used on some cheap mov't is way smaller. The advice given above is the right one, get a complete fork replacement. I think you are skipping steps for a beginner, get first to the point where you can comfortably service a regular mov't without breaking or loosing anything, and enjoy the pleasure of having it run perfectly. You will have plenty of time and better skills for more demanding repairs.1 point

-

1 point

-

The Snoopy one was just a simple band, more like this rather tatty example. Those ones you have wouldn't look out of place with the understated fashions of the time.1 point

-

I don,t know, surely master watchmaker dose. I guess the movement alone is a prototype and what better than a transparent case to give a sepherical view all around.1 point

-

Is there a video of this timepiece posted somewhere? I've only seen stills. And, welcome to the forum, Sid. Fine fellows here.1 point

-

It seems to me that India must be overflowing with watches.all you really need is a few good tools,good lighting ,magnification and the good will of the fine people in this forum.1 point

-

1 point

-

1 point

-

Hi and pranam and welcome to this friendly forum, As you are no doubt aware, India has quite a number of current and historical watch companies. I look forward to seeing your progress in building your own watches. Kind regards Andy Hull1 point

-

If there is no friction fit stud. You have to fit the hairspring to the balance so the roller is in the center of the pallets. Most repairers will mark on the balance the position where the stud should be . This helps when fixing it all back in place.1 point

-

1 point

-

Hollow ground screwdrivers are really only of use if you work on the same model of watch all the time. The reason is if your flat ground screwdriver is too thin you just stone a tiny bit off the end to make it fatter. On a hollow ground screwdriver you need to remove a lot more material to make it fatter, and then hollow grind it again to suit the screw you want to undo, so its harder to swap between brands of watches that you need to adjust your screwdrivers for. If you worked as an 'in house' watch repairer of an expensive brand of watches, and always did the same movements then hollow ground is the best, but for most of us that works on what ever watch comes our way the flat ground is best being a compromise between time taken to reshape screwedrivers and the risk to 'chewing' screws.1 point