Leaderboard

Popular Content

Showing content with the highest reputation on 08/12/18 in all areas

-

I just purchased a set of tools and think they are for Hairspring work but not sure specifically what for. Any help would be appreciated. Thanks.uploads.tapatalk-cdn.com/20180812/142bff319e529d0bad8778e2b13e50f8.png[/img] Sent from my iPhone using Tapatalk Pro1 point

-

I think it was 5/32”. Not that small. Once I centered to drill, I changed to the mill and kept my center for a perfect o ring pocket. Then I tapped with the correct tap. Worked out perfectly.1 point

-

Get yourself a good quality variable brightness LED workbench lamp. Having a good and bright white light makes such a difference for me.1 point

-

McMaster is great for lots of stuff. I recently purchased Case back gaskets, drills and an end mil to clean up the crown tube counterbore in a project. Good prices and many things are “name brand” although they always hide the names. They have the best prices in Whia drivers but you need to know what part number as they don’t show the brand.1 point

-

by keeper joint I assume you mean the friction spring and end of centre seconds pinion ? if so a tiny drop of 9010 can be used the springs job is to provide just enough friction on the pinion to stop the second hand moving in a jittery fashion when the watch is running. No not needed1 point

-

Glad center second hand pinion is found undamaged. My question is: Do we oil the hand and keeper joint?1 point

-

Follow wls 1971' drawing. If it still does not function check you have not put a incorrect length screw in on the train side. If you have it will stop the calendar wheel turning.1 point

-

You can check the watch hand sizes by using a sight called Ranfft : http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Bulova_11BLC In your case the pinion is 0.18mm for the seconds hand. Yes yes with movement held in movement holder there is enough clearance on my staking set Yes1 point

-

I think most guys with this type crystal use some G-S cement on the crystal as cheap insurance. Some even use it with the Rolex ones which is way overkill with the crystal between two surfaces. Ok as to the o-ring for tension, any rubber band would work. Just to keep the fingers collected as you adjust it. McMaster-Carr is a good source for o-rings. I’d suggest a silicone one for that job as they tend to be more “stretchy” than buna.1 point

-

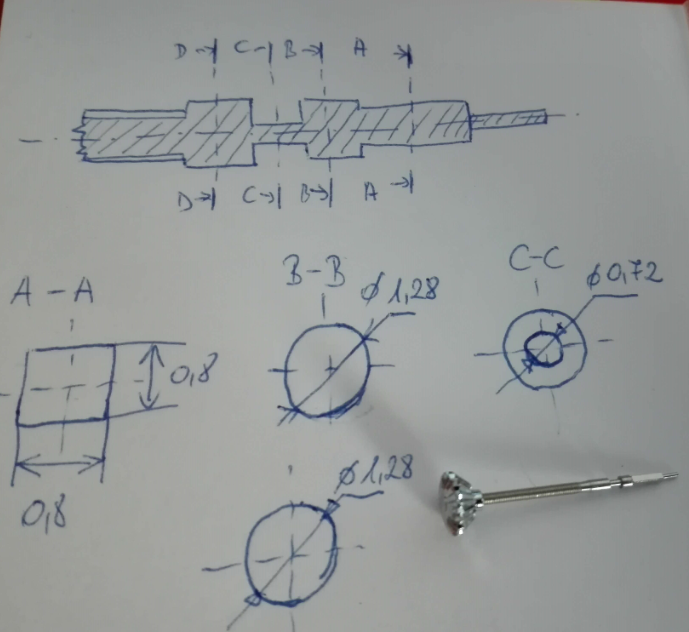

Dear Nucejoe, there are two kind of winding sterms for Molnijas (3602) what I can buy on e-bay. Unfortunately I can't find any drawing from these parts or the recommended technical data of my Molnijas to have an answer to my question. I bought this winding sterm for my older 15 jewel Molnija, for the first try it seems to be good. To understand here is a drawing (not the best one, maybe I will make a digital 3D wariant of these parts to create the recommended technical data), the last cut is D-D, I forgot to write it on the paper, sorry. I hope this information will be useful for other people to find the right part. So, It is not easy to buy spare parts for old watches without the important dimensions, drawings, technical informations...etc. I'm searching for old books to find them, but till now I was not lucky enough.1 point

-

Its best to post pics as there are many movements, but similar assemblies apply to the many of them. It makes it easier to give sound advice with a pic or two.1 point

-

pictures would help a bit. the pushers are locked in by the "C" clips AFTER the movement is installed. it's easy to get frustrated and worried that you messed it up. it happens to us all. just relax and it'll go.1 point

-

Welcome to this friendly forum. Send in pictures, lucky lots of help here.1 point

-

Hi Danny, stop beating yourself up, go have a break and relax! You with the assistance of many of the learned guys on here will fix it. ( not me through) What you have to do is listen to them, don't guess, stop doing anything until someone brighter than I comes along. I doubt you will have to wait very long. Good luck. PS, the man that never made a mess up never did anything.1 point

-

The above post by Tim Fitz is perfect - a great example of why this forum is different from any other watch forum. It provides the answer to many of the beginner posts here.1 point

-

You need to remove the pushers and the movement will drop in. The hard bit is getting the C clip back on the pushers after. Be patient and take a deep breath.1 point

-

Hi, Take TimFitz advice and do Not panic, Regards, Mike.1 point

-

First off we assume that the watch always had the regulator in the zero everything was always perfect it may not have been. If it's been worked on especially the older watches that is the pocket watches things get changed the chance of the regulator going back to zero is almost 0. This is also where I really like before and after timing results which unfortunately can't be done with the balance staff issue. Added weight? If you added weight to poise the roller jewel issue the watch will now run slow. Typically when you're poising your removing weight because that's usually the easiest thing to do. Then the balance wheel is to light you'll have to add timing washers but? before adding timing washers make sure the regulator is back at zero. then the mean time screws in poising? The mean time screw purpose is for regulation I'm attaching a chart. True it's a chart for Hamilton but you can see the effect of moving the screws in it out changes the rate of the watch. so they can be used for tiny poising issues but in a dramatic moving you're going to screw up timekeeping. All of the normal screws need to be in tight not so tight that they break off which they will do occasionally. They need to stay stationary. then depending upon the cleaning machine sometimes they loosen up and they may just a bit loose before. It's always good just to check their down. In a ideal perfect world when restaffing you mark where the hairspring stud is and the roller jewel is. Typically though I do not mark where the hairspring is. If I knew they hairspring stud was where it's supposed to be because the watch was in beat yes but I find it's easier to figure out where they hairspring study is supposed to go by visually verify that the balance is in beat and then putting the hairspring there. then the collet slot it doesn't have to go in any exacting position other than its position determines where the stud goes. On some watches more common on modern the shape of a collet is done for poising purposes.1 point

-

Danny We have all been there, know one who isn't highly experienced in watch repair could ever do what you attempted. I believe you have a few choices on where to go from here. 1. Take it to a shop & have your heirloom fixed & serviced. 2. You could put that watch safely away , until you learn how to repair watches. Which you can do right here! You can purchase a basic watch movement & take Marks great course. That's if your really interested in fixing watches , if not go to step 1, there will be setbacks at first (which we all have had) after that the rewards start coming, like how you feel when a watch that was written off as dead scrap comes back to life. I still get that every time. We will be here for back up and encouragement all the way through. we will even tell you the our stories of what not to do. Good luck TimFitz1 point

-

1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)