Leaderboard

Popular Content

Showing content with the highest reputation on 01/26/18 in all areas

-

There seems to be some confusion over terminology here. Tempering is NOT hardening, and the blue colour of blued steel come from the tempering process, not the hardening process. Carbon steels are hardened by heating to a temperature high enough to change the crystal structure of the material from the Ferrite phase to the Austenite phase (about 800C to 900C), and then cooling it fast enough to prevent the formation of carbide precipitates. As the material cools it changes to a third crystaline phase called Martensite which is extremly hard but very brittle, sometimes referred to as glass hard, with all of the properties that the name implies. Tempering is the process of heating hardened steel to a precisely controlled temperature that is much lower than the Ferrite/Austenite phase change temperature (between about 170C and 380C depending on the required state of temper) and then allowing it to cool slowly. This allows for a partial reversal of the Martensite crystal phase to the Ferrite phase which reintroduces an element of elasticity and ductility, reducing the brittleness thus making the steel tougher (as opposed to harder). Tempering could be considered to be a controlled partial softening process. Different states of temper are referred to by colour as the colour of the oxide layer formed on the surface of the steel as it is heated in the tempering process is an accurate indicator of temperature (Google "steel tempering colours"), so blued steel is carbon steel that has been fully hardened (glass hard) and then tempered to a temperature of between 280C and 310C (purple to dark blue) to partially soften it to a state of toughness to suit its intended use. That is only half the hardness story though. The precise alloy (carbon content as well as the inclusion of other metals) also results in different levels of hardness, which means that you can have a whole range of blued steel with a whole range of hardness properties depending on the actual alloy. All that being said, I have never needed to anything other than HSS gravers to cut blue steel stock. As @khunter says "it's all about cutting angle, shape, and sharpness of the tool". I struggled cutting anything at all to start with and just about all I could do with blued steel was scrape off the blue oxide layer and make a shiny line. It turned out to be because I was trying to sharpen my gravers freehand, an envyable skill that I just haven't managed to acquire, and as a result I was just not getting a suitable cutting edge on the graver. That changed though when I got a honing guide. The difference was instant and dramatic, and the swarf began to fly. Once you have sharpness and technique sorted out the only practical differences between HSS and Tungsten Carbide gravers in watchmaking applications are ease and frequency of sharpening. HSS is easier to sharpen but looses its edge quicker so needs more frequent touching up, Tungsten Carbide is harder to sharpen but holds its edge longer. It is also more prone to chipping.4 points

-

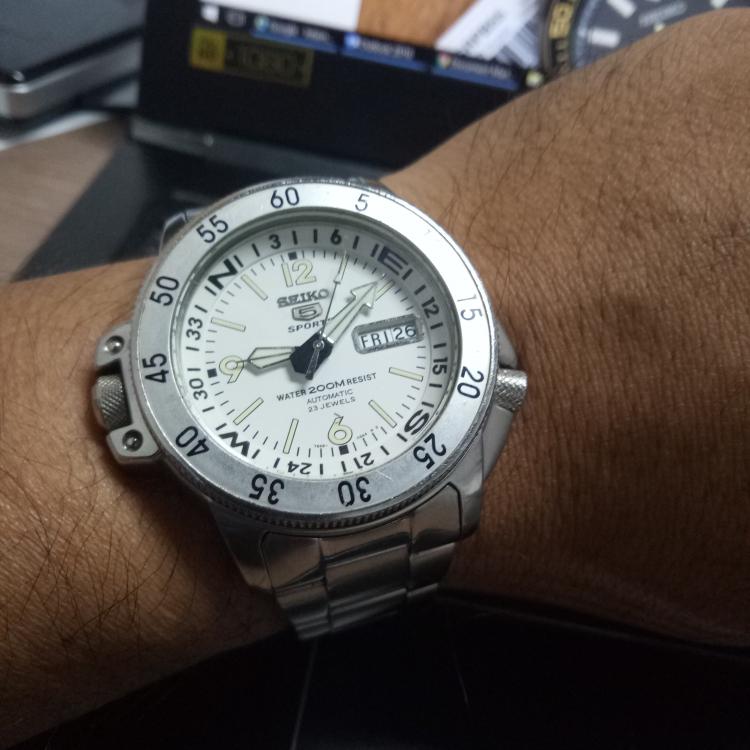

Very wet weather here in Kuala Lumpur over the last week. Since my transport to work a motorcycle I've been using my newer water resistant watches. Today it's my Seiko 7s36-01E0, or more commonly referred to by the cognoscenti as the 'Atlas'. Too chunky for other days but fine for Friday's. Have a good weekend guys Anilv2 points

-

I believe what they are talking about is a mainspring barrel with the hook on the inside of the barrel, not the arbor. I wouldn't file on the spring as you would likely introduce a weak point in it. If nothing else I would check the arbor hook under high magnification and make sure the engaging side is not worn. If it is you may be able to square it back up with a diamond file.1 point

-

No music wire is too hard, just plain round stock, either cold rolled or hot rolled. They have it in the hardware sections of most big box home improvement stores, in 3 ft sections.1 point

-

To anneal, carbon steel needs a long cool down - like 24 hours for a full anneal. A tiny part like that is being essentially air quenched (it may not be A2, but it is still being quenched at least partially) as you are doing it and might be harder than the tempered stuff you started with. If you do want to thoroughly anneal something small, the trick is to pack with some larger pieces, get them all to red hot, hold for a bit then place the lot in ashes (amazing insulator) in a steel box. To take it back to so called blue steel, heat to red, quench, the temper back to blue1 point

-

If the hook on the barrel arbor is in good shape as you stated, it may be that the spring is just a bit too "sprung" around the arbor. You can gently tighten the inner coil with a pair of smooth jaw needle nose pliers to make it fit tighter around the arbor. I've found some NOS springs that the very inner tip is actually curved too much, past the hole, that makes the spring sit off the arbor nearest the hook and it wont engage. Flattening this area slightly will also let the spring sit right on the arbor. Being a 0 size you'll have to use great care, not much material to work with. Last option is to try a different arbor.1 point

-

This isn’t going to be very helpful for you, but I have the same size movement, from the same company, with the same problem! I know there are 4 different model numbers of mainspring that are attributed to the Os Waltham. You have the smallest in width. I started with the largest (2.0 mm) and then realized that it was too large for my barrel. I tried to measure the barrel wall and with that went with the next size (1.7mm). I may still have the wrong size. And I’m not sure, other than trial and error, how to tell what the right mainspring is. I’ve also read that you can put a small bend at the outer end of the spring just below the hole (bend it in, towards the spring) and that will help it hook better. Haven’t tried that yet. I’m not experienced enough to know which end is slipping. I’m not a big fan of the way they do the arbor, you can’t see how it’s hooking to the mainspring. Hopefully an answer will come across here!! Sent from my iPhone using Tapatalk1 point

-

I use carbide and sharpen with a diamon Metal sheet I bought from China 2000 grit. I find cutting a balance staff with carbide graver better as I don't need any pressure and I can use a 0.2mm rounded tip for the cone part of the pivots. Sent from my GT-N5110 using Tapatalk1 point

-

For the date changing at 9 oclock, it may have to do with when you put hands back. Before putting the hands back on, did you set the date properly (turn the crown until the date just changes, no more)? That's midnight. Install the hands back on in the midnight position. You should be all set1 point

-

If the stem is seized by rust (which it sounds like may be the case) then it would hopefully remain static. If the outer half of stem is still present, then try threading on another crown with a long enough tube, and perhaps a crown one size larger if the corrosion has caused the stem to bloat in size. If there is nothing to thread onto reliably, then machine a tube to slide inside the pendant tube and over the rusty stem; use two-part epoxy to adhere the sleeve to the outer half of the stem and then remove. Of course, even if the outer half of the stem is still there, it doesn’t necessarily mean that the inner half isn’t seized too!1 point

-

1 point

-

Stubbs were made in Sheffield, many years ago when we still had a thriving steel industry. You can still buy new-old-stock files. I would have imagined that the Americans would have made files which were superior to the Swiss.1 point

-

You can't fit hole jewels upside down on a Seiko or any modern watch with anti-shock, because they have a chaton (free setting). But you can put the cap jewel inverted if not paying attention.1 point

-

Got it! Thanks guys... I will be checking that on the next couple of days if my daughter allows me :-P .... And whatever I find on the process I will let you know! [emoji120]???? Sent from my Mi Note 3 using Tapatalk1 point

-

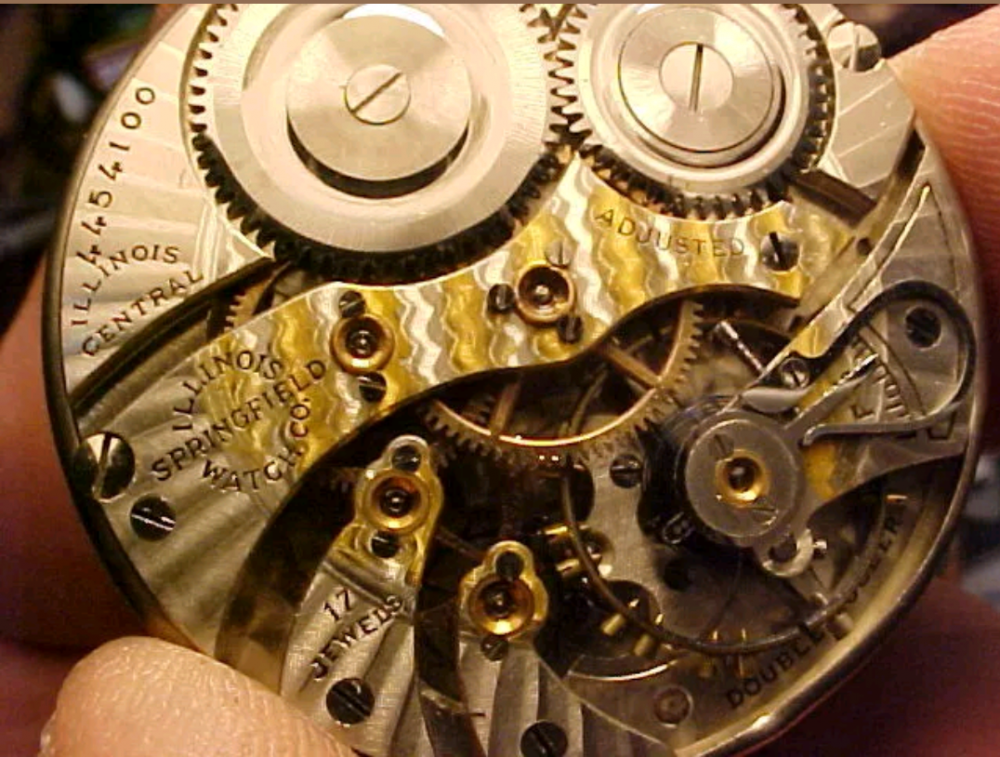

I purchased the mobeus oil several years ago and cant remember the actual number. I recently switched to a full synthetic (not mobeus) as an experiment and have been pleased with the results so far. That website on the 12 size Illinois movements is interesting and I hadn't seen it before. I generally stick to 16 and 18 size movements, but the Illinois Central will almost always get my attention. I recently restored another 12s 17j IC and gave it to my brother for Christmas.1 point

-

I have cut blued steel with carbide gravers and with no issue at all. Where did you get this stock. Perhaps it is not truly blued steal. Sent from my iPhone using Tapatalk Pro1 point

-

The best tool to find faults are the eyes in your head. There are so many things that can cause this. The most common will be from the effect of gravity on various parts since this is a single position issue. Hairspring rubbing something. Hairspring falling into an awkward position Staff/pivot bent or broken. Balance stop spring in wrong position that ends up interfering with balance in said position Trying to think of more I've seen in the past....... Sent from my Moto G (5) Plus using Tapatalk1 point

-

Like all Elinvar types, Seiko HS are susceptible to magnetism. All Elinvar or Invar alloys widely used as practical materials are ferromagnetic materials and, therefore, they have the disadvantage which is strongly influenced by an external magnetic field. https://www.jstage.jst.go.jp/article/matertrans/58/4/58_M2017027/_pdf/-char/en Seiko traditionally used Co-Elinvar as SPRON200 before introducing SPRON610 with better non-magnetic characteristics on high-end calibers. https://museum.seiko.co.jp/en/knowledge/type/regulator/ Timegrapher apps are without doubt the way forward. Main issue is that you really want a sensitive microphone with a movable stand. That alone cost two thirds of a complete basic machine. And then you need cable adapters, which I'm getting in order to do a review. However, if one wants to try the internal mic, be reassured that mobile device like a smartphone or tablet will not emit EMF as long radios are turned off (airplane mode). Unlike a desktop PC with its big AC section, all kinds of frequencies around etc, everything is designed to save energy, so no current is let around without a good reason.1 point

-

1 point

-

1 point

-

Giugiaro today. Just got it back from repair and service by George in Berlin. Could do with one extra link to be totally comfortable but they are hard to find [emoji22]1 point

-

Made a video on line explaining how I make a custom tapered shank that would fit into my Peerless Lathe tailstock spindle and receive a micro drill chuck. All so i could use micro drills in my tailstock to drill out and put in new pivots. Have a look and if you have any questions, just ask. Sent from my iPhone using Tapatalk Pro1 point

-

This is from a brand new 4R36 watch that stopped randomly and had an horrible pattern. Lubricating balance pivots and pallets improved the pattern a lot, but it would still stop easily. When testing the pallets on the escape wheel it had a slight tendency to "spring" to the exit positions, so I replaced it with another from the spares box. Much better, crossing fingers it seems to be running reliably, and the pattern and amplitude are almost perfect. I can kind of see that a stone is so slightly slant ?!?1 point

-

The correct way is to keep them separate when you dismantle and clean. I use an old contact lens case with compartments labelled top and bottom.1 point

-

1 point