Leaderboard

Popular Content

Showing content with the highest reputation on 08/24/16 in all areas

-

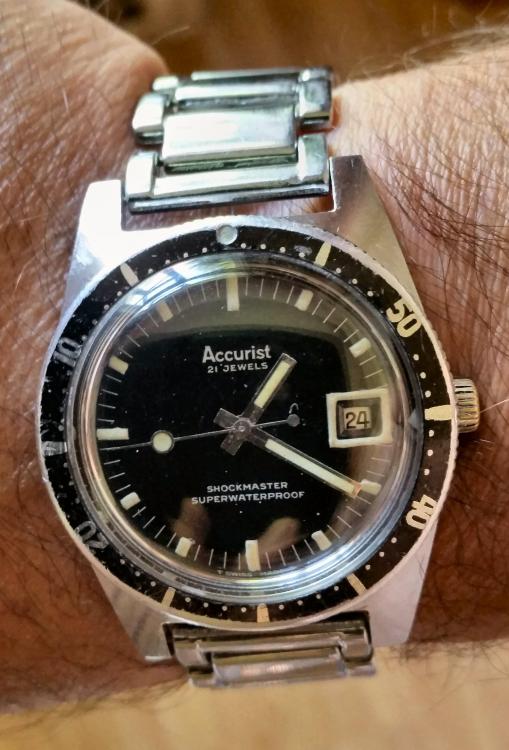

I haven't posted one of these for a while so I thought I had better. This is my current favourite. 1970's Accurist diver, ETA Cal.2472, all stainless case. eBay score in a very tatty state but for reasonable money. All it needed was a full clean and service, relume of the hands, and a new crystal, it's now keeping great time. I can't do much about the wear on the bezel as it is not an insert, but printed directly on the aluminium but I actually quite like the "well used but not abused" air that it lends the watch. It's on a second hand Mont Blanc stainless steel bracelet (also off the bay) which I think looks great and is extreemly comfy.4 points

-

3 points

-

3 points

-

2 points

-

Good morning all from Minnesota. Sort of a long time viewer of Mark's videos on Utube and been lurking here in the forums for about two weeks since I joined WRT through Patreon. Been buying broken clocks of all shapes and sizes for years and restoring them. Only non-functioning clocks did it for me. It was/is the challenge of diagnosing the problem and implementing a solution. Recently retired after 31 years at UPS and after a trip to the UK to celebrate I have started wearing watches again. The job was too hard on watches so almost all of us there learned the hard way to stop wearing them. Of course I love vintage things and trying my hand at minor repairs lead me initially to Mark's wonderful tutorials. (Many Many Thanks Mark!) I would rather find a well worn (and loved) watch that needed help and help it tick again, than buy something new. Towards that end I have started buying the tools I will need (Thanks again Mark), set up a medium sized roll top desk in a well lit area and of course joined here for knowledge, help and encouragement. Roll top desk was a must as the grandkid likes to "look" at everything if it's left out. And I found out rather soon that my accumulated clock tools were so out of scale as to be of little use. And the same goes for drinking too much coffee I found. No good. Currently I have an old Ball automatic watch that says admes on the bottom of the dial ready to be disassembled. It runs okay, but the stem turns far too hard when setting the time so will sort that out. I actually bought the watch more for the vintage leather band it had and the watch is a bonus. Yesterday I found an old thread here where Mark was teed off because someone on Utube accused him of giving away all the secrets. I think what Mark had to say sums up why I decided to support this site and why I spent so much time watching his vids. He is genuine and cares so much about this craft that he wants to see it carry on. (So once again, Thanks Mark!) On a side note. I absolutely fell in love with cask ales in the U.K. We spent some time in York where a couple of small pubs called Snickleways, The Blue Bell and Red Lion were on my daily visits. And a place called Ye Olde Trippe in Nottingham was much attended during our week there. I could be wrong about those names, as the trip was back in May and my consumption of "pints" was rather high. My wife and I have found a local brewery here that one night a week has a cask ale they make, but it's almost 10% alcohol and for me that takes a lot of the fun out of it. I guess I just like drinking the pints more than the getting drunk part. Cheers!2 points

-

2 points

-

2 points

-

2 points

-

I have over the years refinished a few Speedmaster MkII cases for friends. They are fun to work on as they are,usually quite beat up och the surfaces have been polished a few times to many. Last week a friend of mine told me that there was a 1970 MkII for sale on a Swedish auction site. I was born 1970 so this watch I just had to have! On Sunday when the auction was about to close the website where the auction was held started to act up and I could not log on......... About thirty seconds before it closed the webpage loaded and I was able to submit my offer....then it was down again......did I win or not!!??, I waited for the usual confirmation mail when you have won an object and five minutes later I had mail, -Yesssssss..... The watch arrived On Tuesday and looked like this: Not to bad, but the sunburst was gone and the top surface had......"straight graining" .....I guess the previous owner used a abrasive rotating mop or something! The case was practically free of deeper scratches and dings so a good prospect for a lapping session! The case was stripped and I started with the sides: I do this part in my small Boley lathe with 90mm discs that I have made and a small tiltable table to set the angle. Depending on the geometry of the case you can either slide the case directly on the table or use a adaptor to get the right angle - in this case no adaptor was used. First run on one side done: First disc is 400P so you have to be careful, especially with the start/edge where the case can grip the disc - and you do NOT want this as you will have a case with scratches in places they where not intended to be! After 400P I move up to 1000P and finally a last run with 2000P. This usually gets the surface almost up to mirror finish but,a quick final touch with a mop gives it,that final shine. When the surfaces are flat and when needed polished, it is time to grain the sides and lapp the sunburstpattern on the top. This is done in a small mill I have with a tiltable spindle using a 305mm rotating disc and another home made tiltable table. For this case I use a 120P paper so you really have to take it slow and be sure all the angles are set up correct or the disc will chew material in places you do nor want it to! The result I was not 100% pleased! There where some spots there the graining did not go al the way up to the grained edge around the glass. This was obvious in the pictures and reflections in some angles on the wrist - I relapped to top surface.... Some grease from my fingers on the chamfer in the pictures but the graining is better now! I am waiting for a NOS dial and crown - when they get here I will strip and clean the movement as well.1 point

-

1 point

-

the notch in the case, for the set lever, will not interfear with a stem set mvt.. many of my watches have the un used notch. vinn1 point

-

1 point

-

1 point

-

@bobm12 Oh my; I forgot folks take vacations/holiday around this time of year! LOL, I keep telling myself that I will take a vacation one day...eh, maybe next year, haha;)1 point

-

1 point

-

1 point

-

Welcome back jeff and yes, we have missed you...I was absent too for a few weeks too...it is that time of the year! Cheers, Bob1 point

-

Alexander, I have no words! That caliper explanation dispels all the mystery about it! Very useful to me at this point and I appreciate you taking the time to do it. Thank you very much. Also, that picture at 3 in. from a cliff! I would never attempt it! That was pure daring but the result is outstanding! I'm happy for you that you enjoyed your trip to my country and the amazing pictures you took! Thank you for showing them to us. Cheers, Bob1 point

-

Everybody loves a safety pinion without it there would be alot more destroyed wheel trains. An American invention if I remember correctly.1 point

-

1 point

-

I finally got my parts from Old Swiss Watches , and Thanks to all the members that supported me with the issues I was having with this watch , ...I finally got this watch repaired and running . I just have to put it on the timegrapher and remove the scratch and then polish the crystal . The silver dial watch is my donor watch . I broke the shaft on this one also , just as I did on the first . I ordered the parts to get both movements repaired and a few stems and crowns , so I will have the donor running soon also .1 point

-

My lapping attempts have been posted on other sites as well so it's probably my mill you have seen before! Lapping can be done in many different ways but with a disc seams to be the easiest way! I actually built a small machine from a belt sander where I can index my existing chuck to the right angle. This will produce 100% straight graining IF I can get hold of good sanding belts that have no overlap (where they are glued together to a circle) => same thickness all around! A lathe is a good starting point for setting up a lapping rig but my mill actually has one big advantage - I can set x, y AND z (the height) This makes setting pup the tiltable table and chuck so much easier! " Do you think one could achieve a good setup with a lathe (provided it can take a 305mm grinding disc of course)? I have been thinking along those lines... " Do not get stuck with my 305mm discs - the commercial lappingmachines I have seen all have 240mm discs! A titable table on you cross slide and a suitable chuck or holder for the case and you are good to go! Simple chuck I used when I started testing different lapping setups:1 point

-

1 point

-

1 point

-

A member here has an awsome tutorial how to make dials with lume markers. http://www.stefanv.com/watches/making-custom-watch-dials-1.html Myself did some experiments with dial etching with FeCl2 but have no pictures of that. I can post hovewer about watch hands etching from brass. Its the same you can do to dials. The shape was drawn in paint. Printed to the back of a sticky paper and then transferred to the copper sheet with flat iron. The back and the rest was masked and then etched.1 point

-

I was told by Amscope that simul-focus allows you to use both eyepieces and the camera port at the same time, otherwise it's either eyepieces or camera and you have to re-focus when you switch. Cheers!1 point

-

As your new to this how about we take a different approach? So first in order for us to help you we need more information. Timing machine is wonderful for doing diagnostics but we still need additional information such as when was the watch last serviced? The reason why we need to know when it was last serviced Is it changes what were seeing on the timing machine. For instance if the watch hasn't been serviced in a very long time the timing machine is confirming with low amplitude that it hasn't been serviced. Then the timing variations across an indication of a watch that need servicing possibly. If the watch was just serviced it is telling us you're having a problem. Then from the original question it looks like you're trying to do precision timing? In other words you want this watch to keep time within a few seconds a day in all positions which it can't do unless it's been serviced in the last couple of years. Then if you're going to do precision timing with the timing machine Omega has a procedure. So on watches like this the procedure is to time in six positions usually measuring rate and amplitude then 24 hours later doing it again based on that you can make a prediction of how your watche is going to do on your wrist. Then even if the timing machine says the watches going to be perfect in all positions directions amplitudes etc. it may still keep crappy time on your wrist if whatever you're comparing to keeps worst time in your watch. That it's very important to only use one reference not multiple of references because more than likely the references won't be in sync with each other. So it understand a little more precision timing two PDFs. Delta is a big thing for watch companies not just for the rate you want to see everything consistent in all positions and then preferably 24 hours later it should be really really close. So I've attached a couple of PDFs to get you started on precision timing but all of this is a total waste of time if the watch hasn't properly been serviced recently. A gets harder and harder to do precision timekeeping as the lubrication's breakdown and if they gum up it's going to be impossible. http://www.awci.com/wp-content/uploads/2013/07/HT_JUNE_TomsTips.pdf http://www.witschi.com/assets/files/sheets/Calculation of the values X-D-DVH-Di-Im-N.pdf1 point

-

1 point

-

Vintage Cherry bench from the Joseph Bulova School of Watchmaking in Woodside, New York My Bulova Watchmaster ultrasonic and an older L&R cleaner Work in progress: Parts and supplies: Larger tools and more supplies: Various Horotec presses - Crystal, case, hands, crown/pusher tube press. Some other crystal presses including a BB. Timing machine is on the right. Ultrasonic and steamer Lathe - in parts awaiting cleaning.... Waiting their turn:1 point

-

1 point

-

My "new to me" 7t42-6a50 Too much gold on bracelet and a link too short fort true comfort so just ordered a brown stingray leather strap.1 point

-

I was looking at Jeffc83 posting showing the Helbros, in my travels I picked up a Gruen for spares/ repair that bears a remarkable similarity, I was attracted by the date at 6 and it does tick for a while so I live in hope. Makes me wonder if there was a relationship between Helbros and Gruen but apart from the American connection there does not seem to be one Cheers, Vic1 point

-

1 point