Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/22 in all areas

-

Today I'm wearing the two hander, date, "French Ebauch" Montine with a blue green sunburst dial. As I have mentioned before, I'm a sucker for a well executed blue dial, and this one really hits the spot. The camera doesn't really do the dial justice, as it changes hue depending on the angle of the light. Someone had been fiddling with its Cupillard 233-66 (FE 233-66) heart to try to regulate it, so there was a little bit of delicate correction of the hairspring necessary to get it running reliably, but now it is swinging along nicely once more. As you can see, it was also more than a little "crusty" when it arrived. My guess from the styling is possibly mid to late seventies, although ranft suggests the Cupillard 233-60 family started life in the 1960s. This is yet another 404 club member, with a price tag just a little over half of the club entry requirements. It still needs a crystal replacement, as the one that it came with has a small crack in it, but I'll do that once I've worn it for a couple of days and I'm happy with its performance, and once I have a little more time to dig through my crystal stash to find something suitable, or order one. I paired it with a soft Italian leather strap with a similar blue green styling.3 points

-

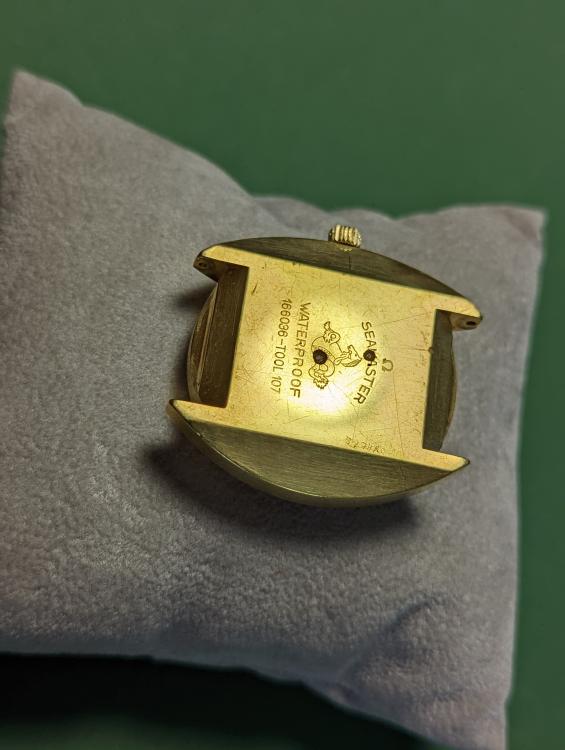

Hello everyone! So, finally, after months of waiting, tons of nerves lost countless hours spent online searching parts and information (not to mention wrong parts ordered and initial investment in tools). I would like to present to you my very first attempt at repairing and servicing a Omega Seamaster Cosmic. I call it the Pawn Omega. I found this watch online, on a local eBay-ish like site, where a guy having a pawn shop listed this piece. Judging by his reviews, and the way he was communicating, the person felt really-really sketchy. Nevertheless, I paid the guy and drove down to him around 200km back and forth (I did not want to wait for him shipping etc.). Initial input: (The first one, although its not that informative). - Watch not running. - Crystal was broken and missing the tension ring. - Dial dirty. But in really good condition (win win for me). - After disassembly I found some screws just laying around. Automatic winding was damaged, assuming from the screws getting between the wheels. - Calendar plate had just one screw and that one was a wrong one. (Big thank you to this forum for the help in identifying the correct screws.) It felt like, that someone wanted to make a quick fix and just flip it, but it didn’t turn out as planned. Output: Well, judging by the looks, I personally think it turned out genuinely nice after all my manipulations. I am very happy with the result. What do you think? P.S. There is some corrosion on the bottom side of the case. Should I just leave it as is or is there a way to fix that also?2 points

-

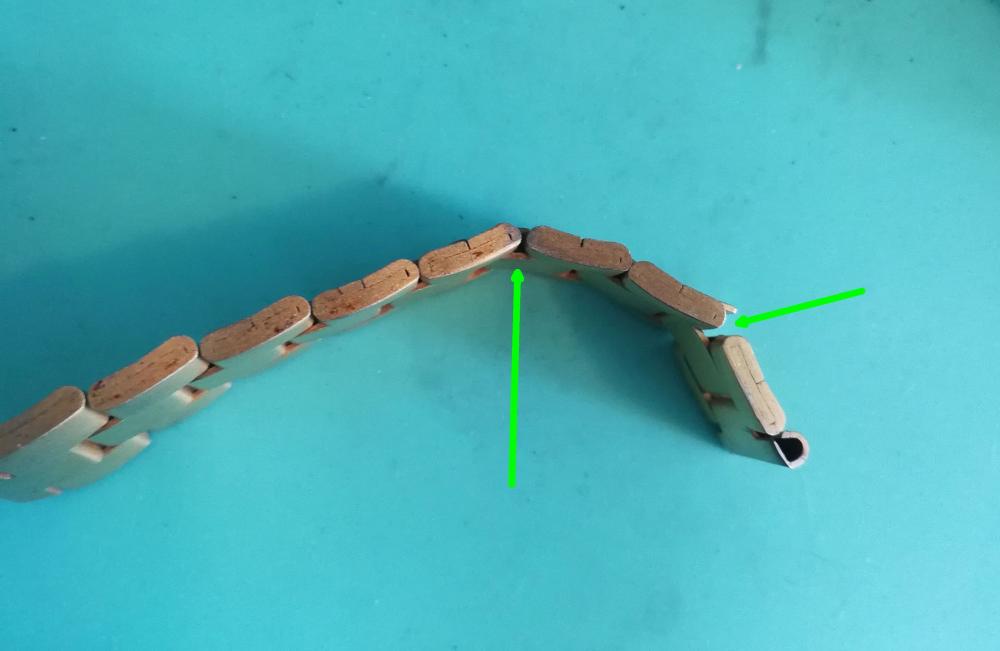

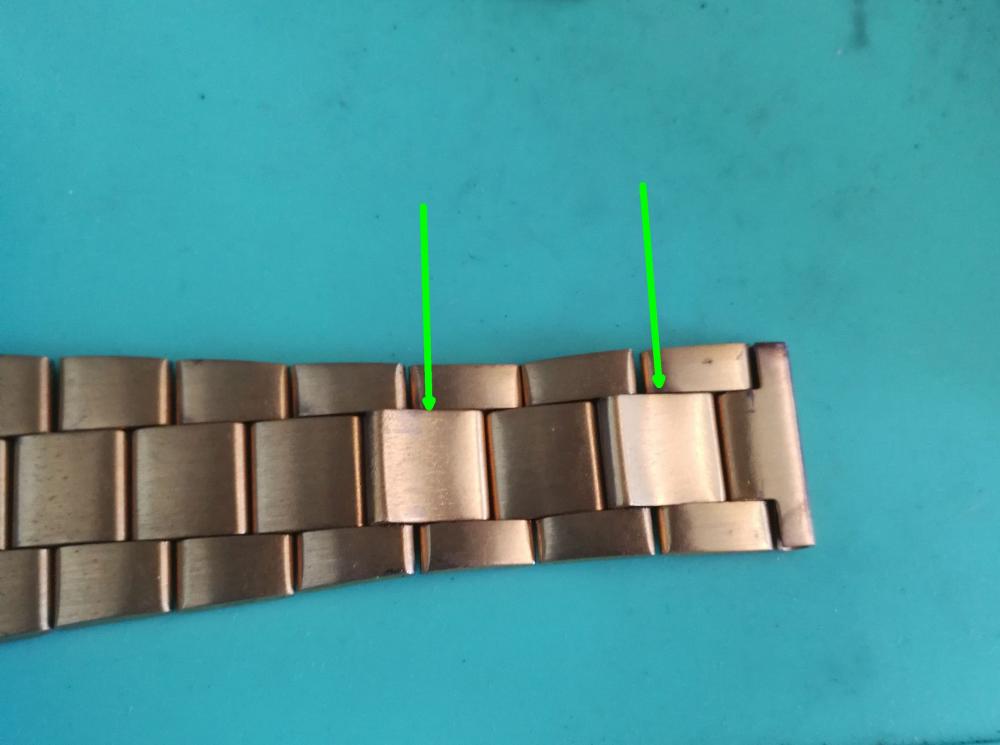

Well, I had no other choice than to go destructive. The links are too tight to put any tool inside to push out the joining pieces. My focus was to do as little damage as possible. The band naturally will only bend backwards a limited amount. Either with my hands, or with one end of the bracelet held in a vise with nylon jaws, I bent the bracelet backwards, which opens up the links on the inside. To the right you can see a link that is fully opened (after prying open; bending backward doesn't open the links this much). With that little gap opened up, I could put a screwdriver in there and carefully open up the links further so that they could be disconnected. This opening of the links creates some reverse bending on the outside, so you don't want to open them up any more than is absolutely necessary. Here, the links are opened and the bracelet can be disassembled. After removing the extra links. I closed the links by first placing the bracelet in the vice (soft nylon jaws!) and using the vice to start closing the links. Then I did the last bit by pushing down with a blunt tool with the bracelet on a soft (silicone) surface. This mostly got rid of the reverse bends on the outside. You can see that the cheap gold plating came off from the distortion of the steel underneath. It was already starting to come off in spots anyway from nearly 50 years of oxidation. I am pleased with the results! I'm not sure yet what I think of the watch! It looks like I might be wearing it as a consequence of court-ordered monitoring!2 points

-

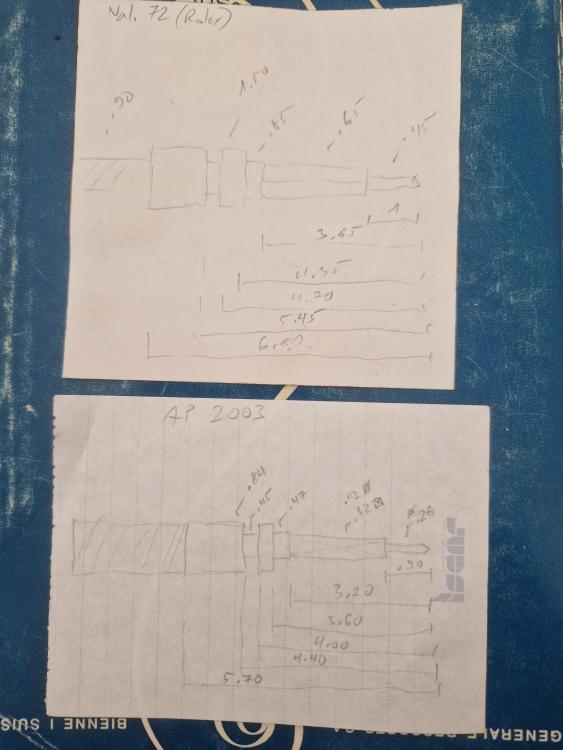

I'm seeing around 3 bucks per 3ft length in sizes around what you're looking for https://www.mcmaster.com/metals/tool-steel-3/tight-tolerance-multipurpose-oil-hardening-o1-tool-steel-rods/ It's good to get it a bit oversized from the largest diameter you will end up with; at full stem length you will have a fair bit sticking out of the collet and a general rule is you want about 3x diameter of your material as max stick out. You can go over, but you have to take more care when cutting so it doesn't flex and climb up over your graver. For a typical stem I usually start with 2.5mm or 3mm stock, and end up with a max diameter frequently of 1.2mm or so. You work from the end back, to maintain rigidity. My usual procedure: -cut pivot to the diameter that the square will be across the flats -cut the diameter of the square (usually this will be equal to the diameter for the winding pinion) -file the square. the oversize pivot diameter you cut first acts as a guide for when to stop filing -finish pivot -cut diameter for winding pinion -cut the bearing diameter that rides between the mainplate and barrel bridge -cut slot -cut diameter and length for the thread, part off -flip around and cut thread In some cases it's better to cut the thread first. This depends on the overall stem dimensions and also how freely your die cuts; there can be a lot of torque needed to cut the thread, and you can have a situation where the stem wants to spin in the collet, or if you hold it tightly enough so it doesn't spin you deform the diameter you are holding. Couple of drawings below. For the Valjoux 72 with 0.9 thread I would cut the thread last. On the skinny little AP I'd do it first for sure (also 0.9mm thread).2 points

-

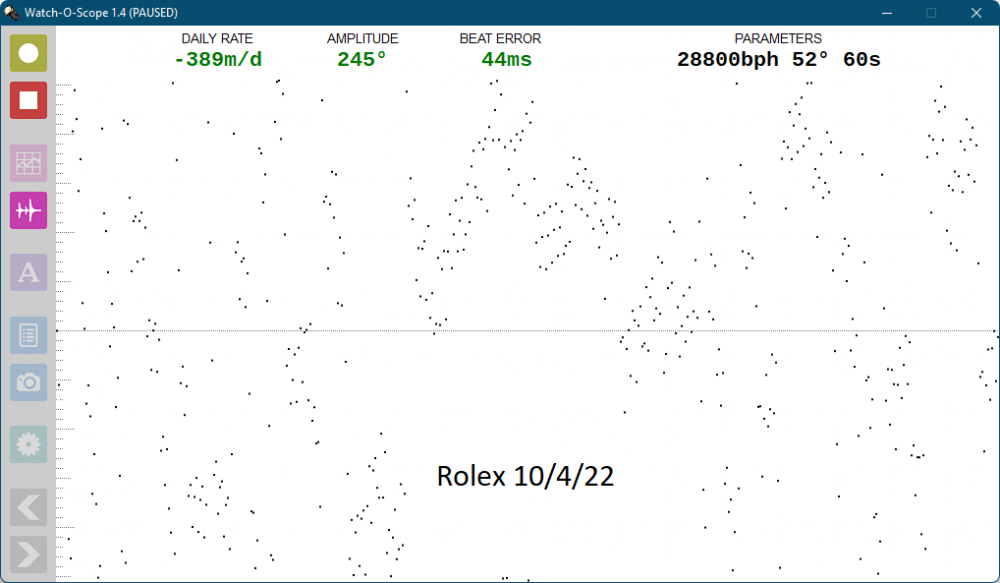

if you have the snow globe affect like this then all the numbers will typically be invalid. towards always really important that visually the watch should agree with the timing machine and the timing machine numbers in the graphical display should all be similar and when things are this bad of the graphical display well everything else is worthless. basically all reverser wheels have to be treated in a specific way for each the various types otherwise undesirable things will occur. typically on the Rolex am attaching some images they have to be epilam. That's to keep the oil from going where it's not supposed to be. Then you can see it's only on the post at the wheel goes on nowhere else.2 points

-

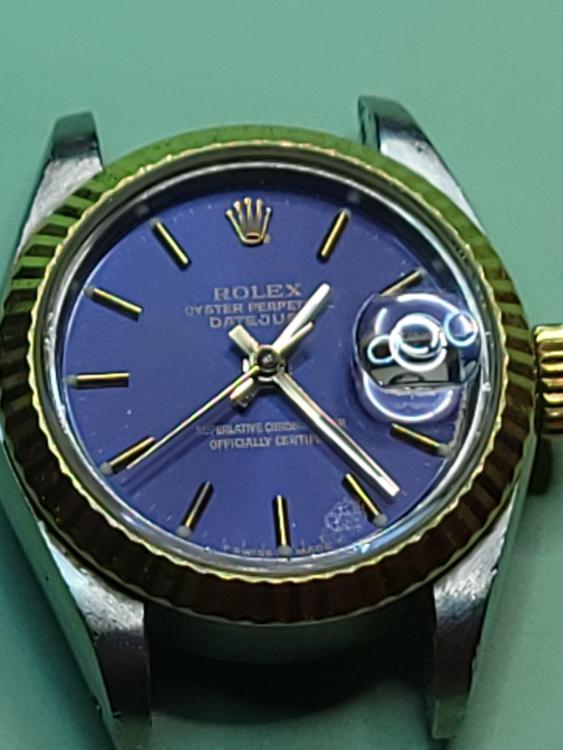

My girlfriend's mom was trusting enough to let me work on her Rolex She said it was serviced at a local jeweler a few years ago, but hasn't been keeping good time recently, and hooooooo boy. It is absolutely filthy on the outside, and drenched in oil on the inside. Every part is glistening, and there are puddles of oil everywhere. I'm FAR from an expert here, and even I know this thing is kind of a mess. I just finished my second negroni, so no more watches for the evening, but I can share some photos. Timegrapher reading is super exciting. 14k fluted bezel. Crystal looks decent, at least. The face shows some surprising wear around the date window. No, that's not a gear at the top, that's a gear-shaped puddle of oil. Mainspring looks worn and misshapen to me, so I sourced a new one. The inside of the barrel was also seriously filthy. Mmmmm, skin. So much nicer clean and organized into a dust tray. Edit to note this is a 2135 movement, for future forum searchers. Hello from the past!1 point

-

I'm working on a Rolex 2135 movement, and I figured for $15 I'd buy the Horotec movement holder specifically for that caliber. Having never used one like this, I feel kind of dumb making this post, but I have to be missing something. The bottom side here has a rabbet (or rebate) around the inside, and the movement fits nicely into it. The problem is that it's not held in by friction in any way, making it difficult to work on the movement, since it's always slipping around. The top side has no shoulder/rebate, but the movement doesn't fit inside. There is a ridge around the edge of the main plate, but for the life of me I can't get it to fit, and even then I'd only be working on the dial side. What am I missing here?1 point

-

Dr Crane it all started when I could no longer play in my personal auto shop on account of we sold our house in Minnesota and moved to Florida. Well all that extra time on my hands caused me to start chasing my wife around the house and she said I needed a hobby or a new wife and since Jet Fighters are not practical in an HOA I thought why not play with the tick tocks. So I bought me a set of high end screw drivers told my wife to stop vacuuming the darn carpet in the guest room. That was months ago and well the wife is as happy as I have ever seen her on account of me being stuck behind a microscope and not chasing her in forever. Now if I can just figure out how to pronounce Bersheeon I will die a happy man. Anyone have a spare mainspring I can borrow?1 point

-

Yesterday I received my copy of the AWCI magazine HOROLOGICAL TIMES. It contains a short article about the De Bethune DB28XP Meteorite watch. Some years ago my wife got me a watch with a meteorite dial, so I dug it out and like most of the quartz watches hiding in that drawer: it needs a battery. While my dial is utterly plain when compared to the De Bethune, it is in fact a meteorite dial and it didn't cost me $50,000.00 (and I suspect there were more than 10 made). If you have a watch with a meteorite dial, let's see it!1 point

-

1 point

-

one of my friends learned from his grandfather probably about the time that your father was practicing. We used to bicker over lubrication because he only used three lubricants. Basically a light oil I heavy oil and a grease and that was it. Whereas will skip over how many I have then add a nawcc chapter meeting at his house he talked about his grandfather and show the logbook. Everyone marveled at how inexpensive watch repair was back then. Until I pointed out how long was a service expected for. It is expected one year because the watches were not sealed up like they are today. Then when I got home I took the price for one year put it into one of the websites and converted it to modern dollars made the assumption that if the person was practicing today the watch would go for five years and that inexpensive price was actually considerably more money than it was today. So one year servicing you challenges are less other than to try to actually get the customer back every single year. out of curiosity can I get the exact part number of which one you purchased as there are a few variations then as I have to run out the door at this exact minute but just give is super quick answer the fixodrop/epilam is to keep your lubrication from spreading so you have to use lubricant. You only using him on the reverser wheels because you want the lubrication in the center part not to spread outward to the click parts where they would not work correctly. On the escape wheel and pallet stones is a procedure and you want it definitely lubricate not with 9010 though ideally want to use 9415. And then I think somewhere I did see you can put it on the end stone but are all of this there is a procedure it depends upon exactly which one you have. The procedure comes about because some of them the solvent the stuff is dissolved is extremely volatile and of evaporates too fast doubts the older version it would cause a chilling effect with the possibility of condensation forming. Think of an ice cold glass of water sitting somewhere and it's covered with sweat that's what will happen at your parts are on the parts and there's a possibility of rust forming which is very bad. And then there's the newer safer kind where they can be set aside someplace warm to dry and you don't have to be so aggressive on drawing fast with heat. So I get a chance I'll look up and see what the procedure is but all they epilam is for is to keep the lubrication from spreading you still have to lubricate preferably with cracked lubrication1 point

-

Wasn't aware we had a thread like that. Lots of blue candy. Guess I'll have to add my Enicar to it.1 point

-

No one sees the back so I wouldnt sweat it, the front looks really good and thats what its all about, you were totally right about that dial...1 point

-

several problems that occur in watch repair. Often times people have never actually looked at the service guide may be because they just never could find one. I was talking to somebody who used to work at a store that was authorized by Rolex as asking about the literature and he said that they would get a new package a literature and all the old habit go back. It explains why we don't really see much bold Rolex literature out there because it's all gone back the Rolex they just don't want it out. Not that it can't be found on eBay occasionally there is a seller in Italy who sell technical manuals. But if you've never seen the technical guide then you don't actually know what you're supposed to be doing. Then depending upon when the guide was produced they may not mention that there's other stuff like epilam. That's been a very common à la the Swiss stuff it's only recently that they even talk about it. Omega I have a guide from the mid-50s precleaning a lubrication and they basically epilam almost the entire watch and that's never mentioned in the technical guides. So using insanely thin lubricants on the keyless work having to epilam keep it in place and if you fall the tech guide your oils going to fall over the place1 point

-

1 point

-

The reverser wheels should be epilamed and must nut be oiled at all (the pivots only).1 point

-

Lol timegrapher / digital snowglobe, just in time for xmas shopping ☺. Is a beat error that high even possible ? The collet must be slipping around in the oil slick. On the positive side you can't make your potential mother in law's watch any worse. God help you if you do . Might be worth signing up for a tinder account now just in case.1 point

-

Looks pretty nice! I love the Omegas for their clean lines.1 point

-

you should probably give us a picture of the classic style because I think there's a lot of movement holders that we currently are using which would be considered the classic style so I'm not 100% sure which classic style were talking about here I'm attaching an image and the PDF catalog pages of movement holders. the images for a reversible movement holder which apparently now comes in plastic I wonder if it's cheaper? Which means you could conceivably 3-D print these. Verse will aspect is nice because one side is basically for holding the dial side and the other sides for holding the other side and the automatic weight doesn't bump in the anything and it after really try hard to break the balance. so in your situation this is what I would be using as they do work really well that just don't work for my American pocket watch movements. 7103 A B C D movement holder's.pdf1 point

-

I'm typically doing pocket watches so I use grease on basically everything on the dial side including the minute will post. As far as I know I'm not having any issues. But if I was doing little tiny ladies watches I probably rethink some of that perhaps. I've heard of that but I never actually of ever used it. when I was first in school I really don't remember what we used for lubrication at all. but I did memorize school in Switzerland was pretty simple 8300 for everything that was heavy including the mainspring. 9020 for the gear train and 9010 for the balance and the pallet fork or escapement. But other than one timing machine with analog amplitude meter they weren't obsessed with amplitude yet. but that was to change Greiner came with this nifty machine that did a little of everything including at a amplitude meter. After a discussion with the instructor lots of yelling and screaming in the office when they left their demo machines stayed. And on the machine was a digital amplitude meter probably the started becoming obsessed with amplitude. This is where 8300 is far too heavy in my mind for the mainspring. While the rest the lubrication is it recommended today that would really be an issue. I was looking for something and stumble across vintage Rolex lubrication so I'm attaching that. That's because the center wheel is lubricated with what exactly? And seeing as how this is vintage lubrication we have no idea what these lubrication's actually are other than there's the word grease. Maybe Rolex at that time was not upset with epilam. Because of you look at vintage Omega they were obsessed with epilam and superlight lubrication's on the keyless mechanism. then up until I discovered 9504 the grease of choice for the keyless works for me was PML stem grease. I think Rolex at one time was using it but then they switched to all Swiss products at least that was the rumor. Anyone ever described it said it always gave the keyless works a nice silky smooth feeling. Plus I like that seem to have a really really long life. thinking about the HP 1300 let's have a controversy were not having a controversy this discussion yet we need to have a one of those. you go to cousins at the link below you get the list of Omega working instructions that they have which is limited but you still get the lubrication guide which hasn't really changed much so we can get idea what Omega's using an Omega's part of Swatch group. https://www.cousinsuk.com/document/search?SearchString=working as you go down the list you'll find working instruction number 40 that's the lubrication guide and let's see what they recommend the HP oils for?although I am going to narrow it down because it to recommendations for HP oil but I only care about the HP 1300 and because it's easier to do I do snipped out the image and we can see what they're using the HP oil for plus the 9504 I indicated those then of course they describe places where you should use of various lubricants like the HP 1300 high-pressure rotating items such as the mainspring barrel. https://www.moebius-lubricants.ch/en while I was here I stepped out the famous lubrication chart they were publishing this for years but the last several years there's now a warning at the bottom of the page which I circled. Notice if you have brass bearings which Lotta mainspring barrels would be considered breakfast notice what the recommendation for lubrication is. I suppose this is open to a certain degree of interpretation as to what a brass bearings like would some of the keyless components be considered brass even though their plated or of your mainspring barrel is pleaded I suppose maybe it's not brass even though it's made out of brass. Or what about center wheels in pocket watches non-jeweled there definitely brass. it would be really nice if moebius would've explained at the bottom of the chart why they have this recommendation as far as I can tell it's the only place they have the recommendation I haven't looked lately but it does not appear in the technical sheets only on the chart.1 point

-

I've noticed that in the short time of one year that I've been collecting. Nothing like the prices in Rome though, I've come across half a dozen vintage watch and antique shops. Veeeery expensive to back home. Even a flee market, A very small laco travelling push together case clock, the guy wanted 130 euro. He never batted an eyelid when I put it back down.1 point

-

I had a little time to work on the machine again and this is where I'm at. Very much still prototyping but key elements of the design is working. I've just shortened the cycles to 5 seconds each, as opposed to probably the 5 minutes that it should be - I'll have to go soil up a watch movement to get an idea how much time it needs in practice. It turns out that it's a lot more stable now at 900rpm than I initially thought it was going to be. Now I just need to work on the wavebreakers and make things a little more permanent.1 point

-

Honestly you can use whatever you like. I think 1300 would be a bit thick for an actual micrometer, but on the Horia I can't see it being an issue, perhaps it's even better on something like the Horia where the "micrometer" is actually a pressing tool (you'd get slapped if you clamped a measuring micrometer on something in a workshop!).1 point

-

this is a lubrication question that means everyone's going to have an opinion as it tends to be a lot of confusion over lubrication. a lot of the answers will depend upon whose lubrication chart or information you looking at and of course when it was published. Typically if you're using the oil your supposed Epilam everything to keep it from spreading all over the place. then so I don't have to write several paragraphs I just stepped out an image for you. Basically 9501 is the base of 9504 which just has an additive of the dry high-pressure lubricant. so 950 what is just a basically nice general-purpose grease but personally I find the 9504 Is Way better. It's what I use on the entire it keyless mechanism all of all the watches that I work on. I don't have to worry about typically a manufacturers tech sheet because vintage watches don't have tech sheets. I found places where the 9504 has worked so much better than anything else because it's designed for much higher pressures. So give a lot of metal on metal bearings 18 size pocket watches for instance it has made a big improvement. The basically don't need both of them and I'd go for the 9504.1 point

-

I've got guests staying at the moment, so I've not got much spare time, however I still made time to watch this. Its a beautiful little movement, and the video is well worth watching.1 point

-

Disassembly sequence here (Please sort by name in ascending order) Assembly sequence here (Please sort by name in ascending order) The watch is an Enicar Star Jewels Ocean Pearl from the 1970s A bit of background I bought this watch on tradera.com (Swedish eBay) listed in the category "Klockor/Renoveringsobjekt" ("Watches / Renovation items"). It was listed as "working" despite lacking the winding stem. I bought it for three reasons. I wanted to try my hands on an inexpensive watch in visual need of renovation. I was curious of the Enicar brand and their in-house movements, and I thought the blue dial with its applied indices had potential. It was clear that the watch needed a new winding stem, crown, and armoured crystal. I found an original stem on eBay from Spain for less than €10 including shipping (a bit of a bargain I think). I bought a bunch of inexpensive waterproof crowns from CousinsUK.com so that I could select the most comfortable and at least somewhat nice looking. I also bought a couple of inexpensive Sternkreutz armoured glasses from CousinsUK.com Overall the movement looked pretty OK except for a third wheel pivot that was rusty. Removing the rust (using vinegar essence) the pivot became Coca Cola bottle shaped so I burnished it and in the process had to remove approx. 2 to 3/100 mm. This in turn created too much side-shake so I replaced the jewel as well. The mainspring looked pretty OK too so I kept it. The cannon pinion also needed a bit of tightening. I guess the friction between the centre wheel arbor and the cannon pinion really can't last forever when a watch is being used for many, many years, perhaps even for decades (looking at the case back of this watch it has seen massive use). Anyway, to tighten the cannon pinion I first tried with my Seitz jewelling pusher and stake for lanterning cannon pinions, but it feels like the edges of the pusher and stake are somehow too blunt or perhaps not designed for wrist watch movements?! So, I resorted to my cannon pinion tightening tool (Bergeon 4733) which is really a bit scary to use but works very well once you've destroyed your first two or three cannon pinions learning how to use it. The trick is not to alter the position of the screw (unscrew it) once it reaches the inside of the handle. As soon as the screw touches the inside of the handle it's time to press. That will usually tighten the cannon pinion the required 1-3/100 mm (I would guess). To give back some of the luster to the dial and hands I simply used a Dial & Hand Cleaning Pen from CousinsUK.com. It worked better than I had expected. The old lume was partly missing and what was left was completely crusty so I simply scratched the remains off and didn't bother to replace it (the blue colour shining through the hands looked pretty great and I don't care much for lume anyway) Despite throwing everything in my arsenal of collected knowledge and experience on the this watch I couldn't get it to run perfectly. The amplitude (as well as the rate) in the horizontal positions fluctuates between 260 and 280 degrees but mostly stays around 260 degrees. I did adjust the curb pin as the hairspring was pinched between the boot and the curb pin and made sure it bounced evenly between the two, but the effect was only marginal. I suspect that the hairspring touches the lower part of the boot. Anyway, I decided to wait with further investigations, put it together, wear it and enjoy it. Despite this shortcoming it performs very well as a daily wearer, only varying in rate between about +1 and -1 seconds per day.1 point

-

I had to remove a cap jewel today and only found this thread after the fact. In my case, the cap jewel was not so stuck, but it was stubborn. I wondered about pushing from below as described in this thread, but ultimately was successful popping out the cap jewel. In the future, I will put my Seitz to work and press the whole thing out.1 point

-

1 point

-

1 point

-

1 point

-

Powder blue dial (which doesn't really show in these pictures) with light blue lettering, so it kind of qualifies as a Blue dialled Timex. Circa 1964, and manufactured in Dundee. I must admit the mystery dial above puts this one in the shade. I don't suppose you would consider a swap? No? Thought not. There are several versions of "Timex Cinderella", and later versions have a picture of the Disney character on the dial. Omnia BG866 based late seventies pin lever with the ubiquitous for the time, offset crown. I posted this recently on the Watch of Today thread. Of the three, it is far and away the winner, despite the pitting on the plating.1 point

-

1 point

-

1 point

-

1 point

-

Wearing this one today, will post a new picture in the appropriate thread later.....1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Where do I start? In no particular order, here are a 'few'........ There are more........1 point

-

1 point

-

1 point

-

1 point

-

The Milgauss models appeal to me more that the Rolex divers, and that is a particularly nice example. I'm more likely to find myself dealing with strong magnetic fields and high voltages than 300m of water. That model in particular with the smooth bezel and the blue dial really hits the spot. I think I'd need to blow my normal budget a little bit to add one to the collection though.... but that blue dial may be the temptation that breaks my normally steely resolve. The 2007 version for example or this 2014 mode (Rolex Milgauss Blue 116400GV)l, are just quirky enough to fit in nicely with the other 404 club members, with their blue dial, green crystals and red hands.. maybe I could give it honorary membership... who would know? Very tempting.1 point

-

1 point

-

A couple of Adrems, a Franken-citizen and a franken HMT, a probably genuine HMT, a Seiko Titanium and a Sindaco. I'll have another trawl through the service and repair folders and see if I can find a few more when I get a spare moment. All of the ones I've shown are working. I may have some donors with blue dials too. There are a couple more blue dialed examples in the pipeline from ebay too, including another Ingersol. I'll post them when they have arrived and I have them working.1 point

-

1 point

.thumb.jpg.da49858b8870c37a35bdc5db82daf2f0.jpg)