Leaderboard

Popular Content

Showing content with the highest reputation on 08/21/22 in all areas

-

I've seen rings like that used as spacers on the crown wheels. Take off the two screws and plate holding it down, and you might find it goes in the center of the wheel between the wheel and its pivot.3 points

-

Here is a live footage of the process. To remove the crystal, you will need special tool, either a crystal lift or wrench.3 points

-

You gonna need to sharpen at least one of your tweezers to do this. I use a No 5 and a No 3. The No 5 being the sharp one I can use to manipulate the diafix. Your other challenge is getting oil on that jewel, placing it and getting the spring fitted without the oil being disturbed. After much swearing I caved in and bought an auto oiler to oil the jewel after it's fitted. It's possible without an auto oiler, but as you've seen it can take hours redoing the process till you've come right. And if I don't do these for a while, the first one usually takes a bit of effort till I get it right. You have my sympathies. I show this process in one of my videos at the 15:35 mark. https://www.youtube.com/watch?v=yrhYjLaoQvM2 points

-

Good Morning Shane! Thank you for checking in. Well....I had a successful movement transplant! I found an active 105 movement and completed my watch surgery. Works well and keeps accurate time. I also changed out the cracked acrylic crystal and replaced the damaged band/bracelet which left me with a very nice piece (I did scratch the number 9 a bit (right under the bottom hook of the number just a little bit while trying to place the acrylic dome). I can live with this little mistake. Recently I've completed a few other Mercury watch refurbishments using the same process. So thankful for the online resources that are available. I also refurbished a Seiko with a 7N43 movement. I replaced the stem, crown and movement. Once again, out of my curiosity I damaged the original movement that was in place. I wanted to get an idea of how the day and date dials operated. I could not get the movement to work correctly once I attempted to put the movement back together. Now this watch looks great after I completed the project! The watch was pretty scratched up with regards to the two tone surfaces, but a Green Brillo Pad added a nice brushed finish that I am so proud of. I can live with the light scratches on the crystal. Adds a bit of character to the watch. I have another Seiko upgrade on the horizon (found a nice 7N29 movement with a clean dial in a bargain bin that works well, but just needs a new watch case and bracelet). I have a vintage Swatch that has so much sentimental value to me. Unfortunately, the repair shop in my area called me and said they are unable to service my watch (after keeping my watch for a month) due to the fact that the tool to open the case is not available. I'll pick it up this week to see if I can find an alternate source for repair (or attempt to complete it myself). I have to really think about this attempt. In the back of my mind I think I can do it. This watch is a Swatch Irony Scuba 200 from the late 90's. I purchased this watch at Heathrow Airport while traveling back to the States after my summer study abroad program ended. I really love this watch. I'd like to get it back up and running. I'm researching a possible movement replacement which seems to be the easiest repair for Quartz watches. What caused me to inquire about repairing the watch was stiffness as I tried to set the time and date after a battery replacement. The watch does not keep accurate time and I cannot change the date (which seemed to just happen suddenly after I replaced the battery?). A complete movement swap seems to be the most sensible repair. Once again, thanks for checking in. Looking to learn more as I dive into this hobby.2 points

-

Worth to remarl for the casual reader again. Only the tiny ones on the train are difficulty to refit. The one on the balance are very easy to deal with, either with tweezers or rounded top tool.2 points

-

2 points

-

I am feeling the same. Reminds me of when I worked on an Elgin pocket watch. Even with front and back off it took some work to get the movement out. I know it’s only a Wyler Electronic but I hate not being able to get a 5 dollar Timex Easy Reader running. I’m diving into this one because I’ve run across a handful of Old electronic watches. I’ve a number of Timex, including their dynabeat. I’ve also a Bulova Electra that looks like it jumped off a man’s wrist and teleported to my mailbox. All brown and gold sunburst dial. I’m definitely a mechanical movement and not real satisfied with quartz. I don’t think it’s just a fad, lol. Quartz to me is like an electric car. Something is lost without the smell of spent fuel. They have their place mind you, but something is lost. It’s still a watch and I have a hard time giving up on it. This one frustrates me and I’ve had to hide my 4 pound square metal adjustment tool several times so I didn’t use it to try and crack open the case. Just want to say as well thank you. I’ve been looking for a forum to ask questions and ACTUALLY get some sort of intelligent response, for over a year. This site is the first that I’ve ever gotten an answer with. So I am definitely here to stay. I’ve purchased a dozen vintage mechanical movements last night Hamilton, Elgin, Waltham, Wittnauer and a pretty little Bulova 30 jewel automatic with date at 4 position, and I am sure will be asking many many questions. It’s great to finally find a group that shares my excitement and love for them.2 points

-

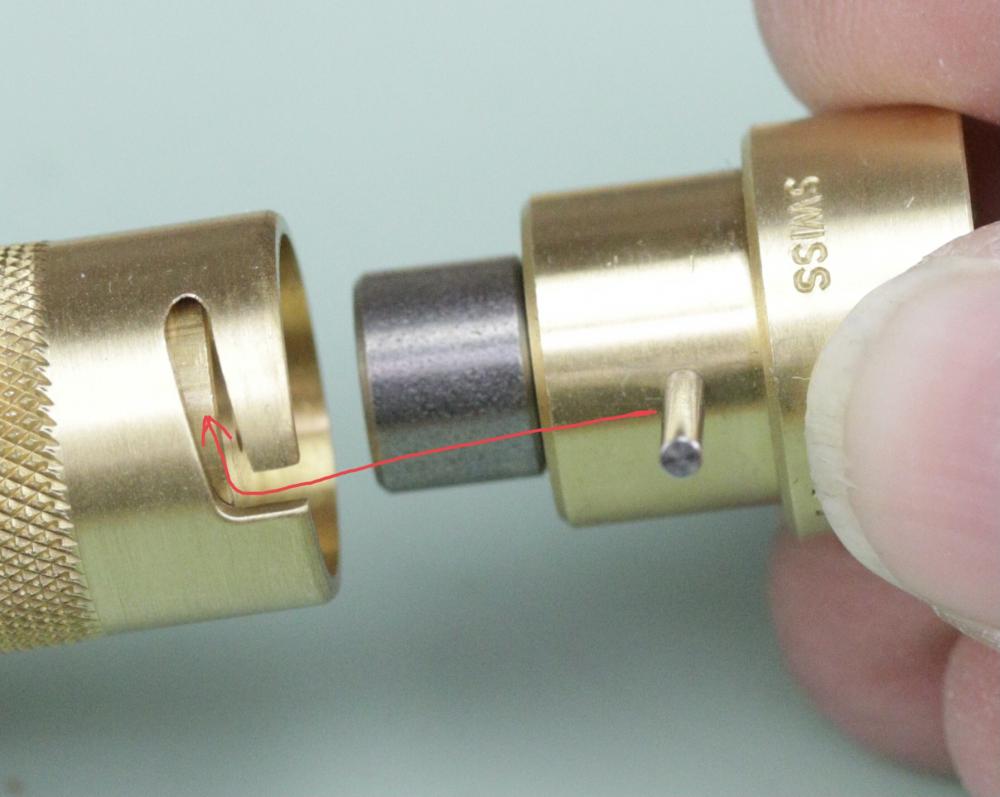

I've been curious about these pin polishers for quite a while, so I ordered the following from CousinsUK: In hindsight, I regret not ordering the two-millimetre versions instead as the polishers tend to hit the fingers/tweezers when rotated. Yes, indeed, but it depends on the hardness and grit. The medium grit and medium hardness polisher will quickly taper the pivot so stay away from it. It's very aggressive. I would say all you need is the extra fine grit and soft polisher. As far as I can tell it doesn't remove any material, except for perhaps a few microns. Of course, it also depends on how long you keep polishing. Although I made no extensive tests with the fine grit and soft polisher I'd stay away from that too. Just to make sure. Do not think that these polishers can be used to burnish/repair the pivot. A Jacot tool is required for that. However, for cleaning they are well suited.2 points

-

Mido is not the only case. Myself and others always advise to try to remove the mov.t by gently lifting it while slowly rotating the stem, and refit it with the cuts vertical and aligned. That can work for any maker and model, and save any stress to the joint. However, for some reason, you often read about nail clippers and forceful pushing. Not in my book.2 points

-

Something a little bit different, and a little contentious today. Perhaps the ultimate quartz crisis watch. A National Semiconductor LCD watch. This is from the brief era when these watches were relatively novel, and thus relatively expensive. The construction of this involves lots of gold plating and not many features. A few short years later they were dirt cheap, so much so that they were giving them away free when you filled your car with fuel. These days fuel is so expensive it wont be long before they give you a free Rolex if you can afford to fill your tank.2 points

-

When I pulled this little omega 484 down I noticed that the escape wheel was turning under duress so I thought I would show how I polish these tiny pivots on the escape wheel and pallet folk before I ultrasonically clean them. It gets a nice shine, I can do my hair in the reflection. Using a very fine pin polisher1 point

-

I don't think I ever saw a movement having a difference of fewer than 10 degrees. Among the best I've ever seen in any of my watches is an ETA 2824-2 in a Sinn 556 A watch which I haven't even serviced. Pictures of the TM here. Anyway, if you manage to get even "better" results it would be interesting to hear more about it. What kind of suspicions?1 point

-

Well it looks like an excellent go there! As you've noticed, most sources on staff dimensions give a lot but not all the info. If you had had the length from bottom pivot to hub you would have been fine- and the hub length dimension can vary quite a lot. If anything, I think the pivot on the left (top pivot) looks just right, the lower one is a bit long. Great work though.1 point

-

Update. The roller and hairspring fit fine except when I installed the balance, the roller jewel rides over the pallet horns, so the roller is sitting too high. I am going to have to nudge it down a bit. I use Rex Roller Remover whenever messing with rollers, so I think I will set it up and just tap the balance down a hair. My respect for you guys who do this stuff daily has gone up an order of magnitude!1 point

-

Another thing- if you keep the little rings the springs come in you can pretty much avoid needing the left hand arbors- just wind up the spring normally and insert into the ring, now you can install it in the barrel whichever way is needed.1 point

-

I have the identical bench to dadistic that I brought over from the States (many years ago). I always found it quite low, so I found a Bergeon top like in this post, which took it from 38" to 42". I just checked a couple other benches in my shared workshop; old Bergeon with arm rests, 38"; new Bergeon with armrests (on blocks to raise to 40"), ex-watch school bench with armrests, 38" on blocks to hit 40". So it does seem that somewhere in the past 38" became a standard somehow. The two 40" benches are used by folks around 175cm tall (5'8"). I'm 183cm, 6ft (using the 42" high bench).. I use a doctors stool on wheels that's easily adjustable in height at my bench. The general rule I learned early on was to find a bench height/ seat height combo that keeps your back straight and your thighs parallel to the ground. I will often vary my seat height depending on what I'm doing, or just to vary things. Would be nice to have an adjustable height bench too. I have two microscopes set up, one on a set of drawers 32" high, that I can straddle, and can roll right to it keeping my regular stool height. The other has a dedicated chair and sits a little higher.1 point

-

Thank you so much for those precisions. while looking at videos and reading online it made me think I needed the whole 1000$ Bergeon. But now with your answers I can get away for 120$ and be able to use on my 5 pocket watches / watches. It is cheaper than those Chinese winder packs. I'll get a new drum as I get a new watch. That should dilute my spendings over time. Thank you again!!1 point

-

Because the smallest the part, the less tolerance for non-optimal factors. In other words, you need to have exactly the right tool and technique, otherwise most attempts become futile, or yeld marginal results. These mov.ts, are largely assembled by sophisticated robots. After the end of cheap labor in Japan, the Japanese really excelled in producing an high volume of high quality electronic and mechanical devices. They may have factories offshore for general cost reduction and tax reasons, but the ace of their business is the incredible machines and automated processes that they have developed for themselves.1 point

-

Of course it's not. With a caseback there is no reason for a split stem. The cheaper the watch, the harder to repair. They were not made to be serviced, the idea being you would just buy another one. That's why all professionals refuse to work on cheap watches, beside that their time would cost many times their material value, they could have serious trouble fixing it. Electric / electronic / quartz digital or analog are all the hardest ones to repair without a donor watch for parts or complete replacement. Watch repair is best learnt on simple, largish mechanical mov.ts, as discussed below1 point

-

Just for clarity, there are the arbors (right and left), the drums (universal) and the handles (right and left). 1- The handles are specific for right or left hand wind springs. As Kalang said, you don't need the handle; it's easy enough to just hold the drum (I can't remember when I used the handle). 2- See 1 3- The dimensions given are the outside diameter of the drum of the winder. So a 13mm would fit inside a barrel with an internal diameter of 13+ mm. 4- The arbor is specific to its drum , with some exceptions. If you check this link, you will see all the Bergeon winders listed by number, also with drum diameter and arbor diameter. For a #9 winder, with 13mm drum, the arbor measures 4mm diameter. It happens that the #10 winder uses the same size arbor. Looking at that list, I see there are 8 different arbor diameters, for 19 different drum diameters. Yes, the arbor is performing the function of the barrel arbor when using the winder. 5- It depends. Sometimes you can go quite a bit smaller than the measured internal barrel diameter with the winder, but it isn't a hard rule. Remember that since the drum needs to fit inside the barrel, after accounting for the wall thickness of the drum the actual space to wind in the spring becomes significantly smaller than the normal space the spring should fit into even for a drum that is close in size to the internal diameter of the barrel.1 point

-

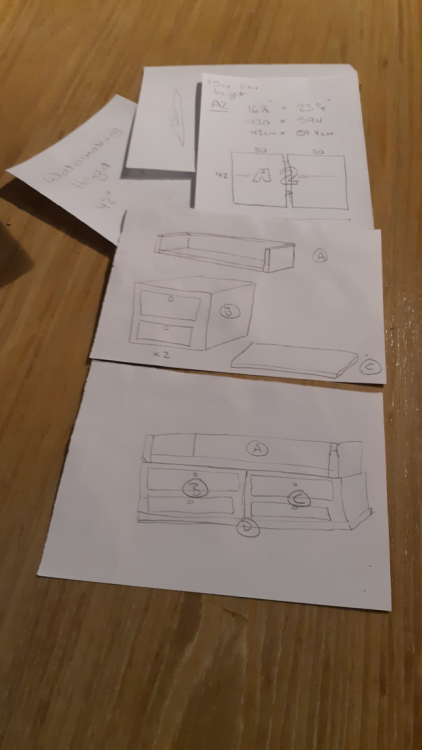

Hello @tomh207 No joy there: I am currently developing the plans for a simple Portable Watchmakers Desk. I have already started talking with some manufacturers in South China about making them from a sustainable source (Bamboo or Pine). They will have: - An A2-sized 3-sided top - Integrated carry handles - 2x2 drawers configuration (4 total) - Sturdy base w/ integrated adjustable feet Here's some concept drawings... Here's a general idea of what the material (bamboo) looks like. Personally, I like the way it looks. g. ----1 point

-

1 point

-

I got mine via DHL early this week and I am almost done fixing things to make it right. I am going to post things I did so as to maybe help someone else who may buy one, best regards to you jdrichard, james.1 point

-

Aye you right I blew up the picture and there it is. I have attached a coulpe od documents that might come in handy if you have never worked on one before cheers 577514301_03.CasingGuide.pdf 1034_Seiko5606A (2).pdf1 point

-

Hello, a slight tap with a rounded punch on the bottom side of the bore will close it enough for a tight seat (usually). Frank1 point

-

Safety razor blade. I would not hesitate. As you insert the blade, you will see some give...then proceed.1 point

-

Thank you SO much for the input! I find all that info really helpful. Going to apply that newly gained knowledge today. Again, Thank you SOOOOO much!!!1 point

-

Roughly measure the diameter of the dial and estimate if it is bigger than the expected opening in the back. If so it‘s a frontloader for sure.1 point

-

If anyone is taking bets, I'm going with "front loader". I've worked on a couple unmarked Wylers and both were front loaders.1 point

-

the nuclear powered watch was something different. Elgin with some other company did pioneer nuclear powered batteries which I think were used in other stuff I don't think it ever made it into a watch and definitely not a watch of anybody had in their possession. The other watch I talk about it have to go look it up was early LED watch with solar panels all casting transparent red plastic with rather sizable NiCad batteries conveniently buried in the plastic forever sealing the fate of the watch of not being practical to change the batteries. Oh and then as far as setting went there were magnetic reed switches with magnets so the watch truly was waterproof1 point

-

This is iteration number six or seven...it is hard to keep count. Methodology for this turn was aided by a number of phone calls with a forum member...coaching me... I made a carbide file to do the finish work on the roller side. It polishes extremely well. Full disclosure...I started with a large pocket watch staff because I have had some issues with my other starting material. However, I made every cut except for the hub. I am posting this now while I am happy before disaster strikes. Today, I will install the balance, check the fitting in the watch...then install the rest. No matter what happens, I can say for sure that my skills (minimal as they are) are improving. I think the pivot on the left is a little short, but hoping it will work fine.1 point

-

yes batteries are supposed to be changed but what if you have a watch with rechargeable batteries what if it's entirely sealed a block of plastic then it can't ever be changed and yes they did make a watch like that once it was solar powered they never anticipated that the nickel cadmium batteries might need to be replaced at some point in time in the universe oh and then there is a minor problem with the back if the back is not to fit a stem which is sometimes common and that would explain why it's in perfect alignment but usually backs that are meant to come off will have some place for you to pry the back off. Which is why it's still be nice to see a side view with a case to see if maybe it does go out through the front.1 point

-

Yep! This Ebel has a split stem as most front loaders have. Here is an example of a Wyler frontloader case where the solid case back looks like a snap on but isn‘t. The bezel has to come off. https://www.ebay.com/itm/1329606486401 point

-

I've worked on a Ebel ladies quartz with a really user unfriendly design. It's a front loader with a monocoque case. To change the battery, everything has to come out to get to the battery. A real pain to work on.1 point

-

1 point

-

I just had to quote these words of wisdom as well.1 point

-

yes that perfectly aligned case back definitely is an issue. We need a picture of the side of the case and a better picture of the front of the case as I don't think the back is coming off well not without a lot of force and then it may never go back on again1 point

-

brunomartins, I recently had a crown in similar condition and since the plating was long gone, I just re-knurled it. I went about it very lightly because I didn't want to loose the rounded appearance and feel from the passage of time. Shane1 point

-

I love these logos. As an electrical engineer, I particularly like the inductor-battery-switch shown on the electronic watch.1 point

-

1 point

-

Thanks for the replies and advice @JohnR725 and @VWatchie and also for the charts. Happily, this particular movement falls within the above specification as it was running pretty awful prior to a service. I've also had to poise the balance to stop some horrendous rate changes and all is a lot better now. I agree with @gbyleveldtabout the Seiko's. I've never been able to get my 6309's to run much above 230. I've had to learn to be happy with that.1 point

-

yes that's one of the amusements with this group an obsession with amplitude. obviously nobody from Seiko factories ever on this group they would be so unhappy their watches totally suck for amplitude at least according to group specifications. Notice how normally and never find a Seiko referenced amplitude except the 4006 a manual specifies fully wound up you should have a minimum of what? typically for the watch companies if they have specifications are concerned if they have too much amplitude like over 300+ degrees otherwise they could care less until 24 hours later. Then it's supposed to have a minimum but the big thing they want is time keeping. So while Omega specifications are almost everything they have a section on vintage watches not found in the normal specifications and I snipped out that image. Notice the minimum amplitudes I'm not sure I want to say what those minimums are because somebody's go find some tar and feather and track me down for daring to suggest a watch could even run at those amplitudes. On the other hand these are Omega watches which are usually really really nice other watches probably would keep horrible time of those amplitudes but still it tells us that they don't care about amplitude wound up the only care about timekeeping amplitude at 24 hours then taking a quick look at the rest the Omega timing sheets looks like the highest of the low amplitude is 200° and the low as 160 and then it just depends on the watch it could be as I said 160, 170, 180, 190 and then 200 But there's no specification that says you've done a good job if you watch is doing 271.9° I'm just joking about that particular number but that's not in the specifications. Realistically it seems to me that if the watch was running before you cleaned that if you ran a timing profile and if afterwords it was doing better amplitude and preferably better timekeeping you did good enough at the end of 24 hours it still running and keeping reasonable time than you did outstanding.1 point

-

Heh, till you work on Seiko 6309's where you're considered a master of the art if you get 230deg amplitude. It really depends on the piece and how it was designed1 point

-

That chart is very interesting @JohnR725 in the respect that reading many posts on this forum you get the impression that an amplitude below about 270 degrees in the horizontal position (fully wound) should be considered a failure. I've serviced a few watches now since I started this hobby some five years ago. Very often I have found the amplitude to be somewhat below 270 degrees and I have always thought of that as a failure (which has been very disappointing at times). Still, many of those watches have proved to be excellent timekeepers despite not being able to reach an amplitude above 270 degrees. So, through practical experience, I have learned not to overestimate the importance of high amplitude. If you think that amplitude is all-important, you probably get tired of repairing and servicing watches pretty quickly.1 point

-

other than looking similar there are many differences between the 104 and 24. The center wheel for example is different.1 point

-

The above post should have read incentive not insensitive. Don't know where my phone got that one.1 point

-

Upgrad1978, How are you making out with your Timex project? JerseyMo would probably know about interchangeability from first hand exercises. My thoughts on the subject where based on what I remembered reading on, https://en.m.wikibooks.org/wiki/Budget_Watch_Collecting/Timex_movements "Model 25 is the same as Model 24, with the addition of a date calendar." "Model 104 is nearly identical to Model 24, with simplified click and different dial mounting. Note extra holes in the corners." "Model 105 is a Model 104 with date." It took me some time to re-find the page. I suppose the author may have simplified the wording they chose or just based their wording from visual cues, not actually meaning that they were all the same and identical. Based on what they wrote and given the insensitive of what interchangeability would mean for a company like Timex I made the assumption that all the wheels within a companies movements of the same rate would be the same unless a difference was absolutely necessary. Perhaps I stand corrected. Shane1 point

-

I checked al of the pushers on my Chinese set after reading the issue VWatchie had and there was no fit issues with any of them, so they do get it right so fingers crossed yours will be fine as well Neverenoughwatches1 point

-

if you have a watchmaker's lathe reducing shouldn't be a problem. I suppose if you're really careful with some sandpaper1 point

-

No it doesn't taper the edges, in fact you can also polish the pinion shoulders at the same time. No abrasives used as such. Just a 3mm very fine pin polisher which I push over the pivot and gently rotate until shiny. I also do the balance wheel pivots. I do this before the ultrasonic wash it's a sure way of getting the pivots in optimal cleanliness. Hope this helps1 point