Leaderboard

Popular Content

Showing content with the highest reputation on 02/23/22 in all areas

-

2 points

-

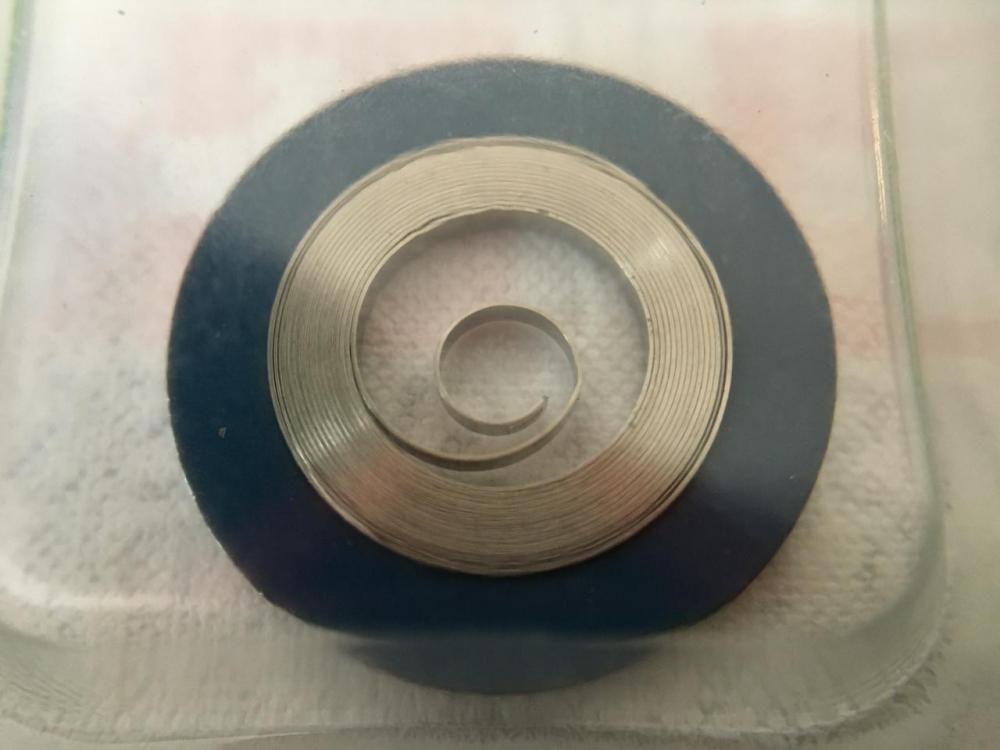

I have several of these, some marked Bergeon, some no name (depose' is French for "patent pending"). These older sets have larger winding arbors than the newer ones marked "Nivaflex", but you can use a smaller arbor in a larger winder- the hole difference doesn't really matter, and if the cap on the winding arbor is really too small you can cut a hole in thin plastic sheet and fit it over the arbor under the cap. On all of these, often, the winding hook is sticking out too far- it's good to trim it down with a file so it's about as high as the thickest mainspring it might see (the hook can damage the coils as you wind if it's sticking way out). Sometimes the hook is too wide too, again, easy to trim up with a file.2 points

-

2 points

-

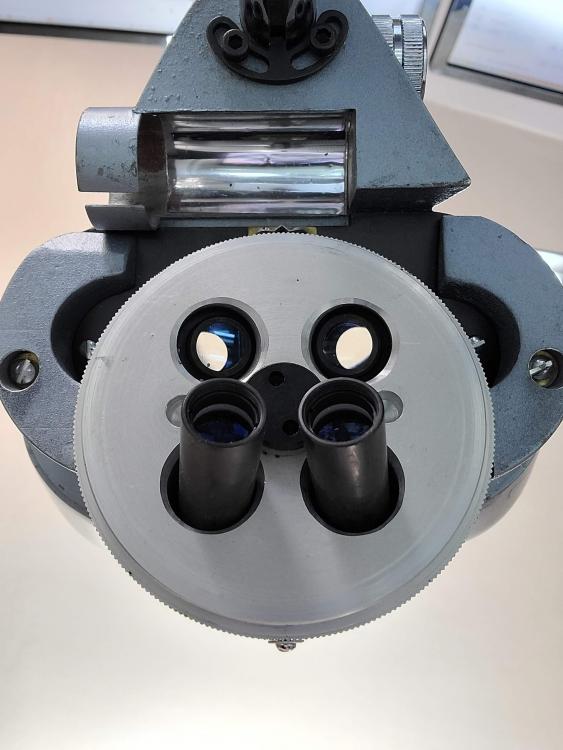

If you get the one that WW showed above, you could attach a HDMI/USB/VGA camera to the trinocular lens and see the image on your monitor. And when you need to actually work on the movement, the stereo eyepieces will give you 3D vision. I owned a microscope for many years but was resistant to using it for working on watches until I learned that the microscope can be tilted back for a more comfortable working posture. Now I use it for everything except when fitting the balance back on the movement. I still have to use a loupe for that.2 points

-

Even though you fixed all your problems I'm still going to comment a few things. So initially you're describing something that looks exactly like Rebanking. I have a link to a video which explains basically of too much energy when the watches fully wound up. This can sometimes happen with variety reasons or if the mainspring is too strong which can happen on American pocket watches because we don't have the choice of mainsprings that we once had. Typically today one size fits all but one time you would had several different strengths for your pocket watch. https://youtu.be/Rcqrb3_vin8 There's nothing that says that you can't move the stud up a little so that the hairspring stays between the regulator pins. I always thought this was standard watch repair practice? In other words once the watches running you verify it's running on the timing machine without the dial and hands. But typically on this group and other places the enthusiastic repair person will case up the watch and only then put on a timing machine and discover perhaps there's a problem. This is where either a different timing machine which is very expensive or the old days of the paper tape machine was better. Because of the paper tape machine you can run enough paper tape to try to find a pattern. It's harder to find patterns on a liquid crystal screen when you of a limited amount of time. But you do watch the numbers go up and down and see if you can find a pattern. I assume you change the escape wheel? Even though it has a happy ending did you notice the pocket watches serial numbers on all the plates? Typically the watches were made in batches the plates roll made for each watch. You can swap a lot of components on a pocket watch but you want to be careful about swapping everything. Especially when you get close to the escapement because each escapement was adjusted for each watch. As the pocket watches no manufacturing progressed the ability to make things to tighter tolerances it becomes less of problem. But an earlier watches swapping all the parts out can be an issue. So just a warning for the future you have to be careful when you do this because sometimes the parts are really exactly the same. Then the timing machine? The microphone rotates you can look at the watch in different positions. Sometimes is nice for diagnostics like dial-up and dial down should basically be identical. Typically with a pocket watch you like to check it crown up as that's a position that the watch might be and if somebody was carrying it. Then I don't know if you're familiar with the site at the next link? Is looking at your movements and something caught my eye? Notice the ratchet and the crown will both have decorations? They usually don't do that on all of their watches which is why I took the trouble to look up the serial number. You'll notice they made the watch which was typical of the day in batches of 1000 and they made 20,000 of these which is a relatively small run. Also they time the watch and three positions so you can at least rotate your microphone and see what it does in other positions. Basically they're saying this is a little nicer grade watch your standard 17 jewel Elgin watch https://pocketwatchdatabase.com/search/result/elgin/190934542 points

-

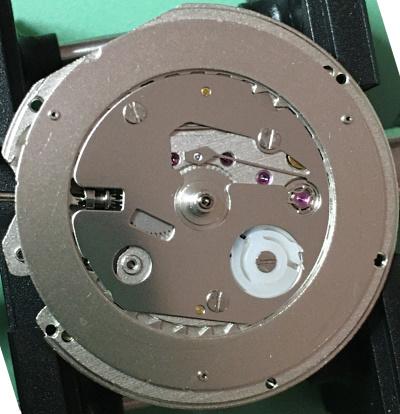

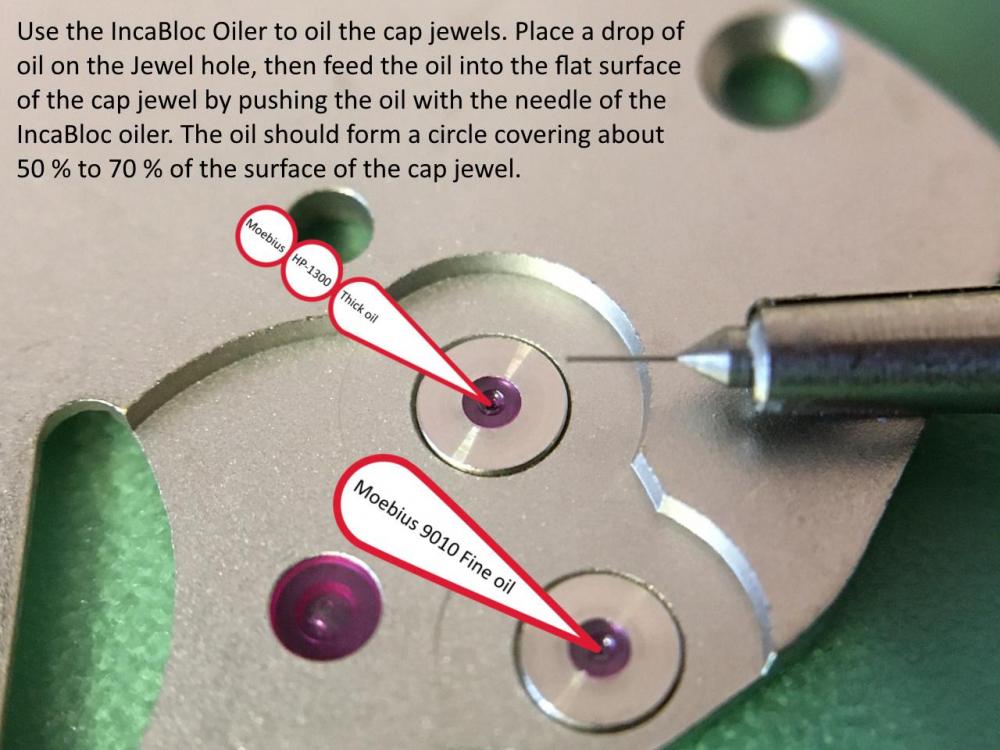

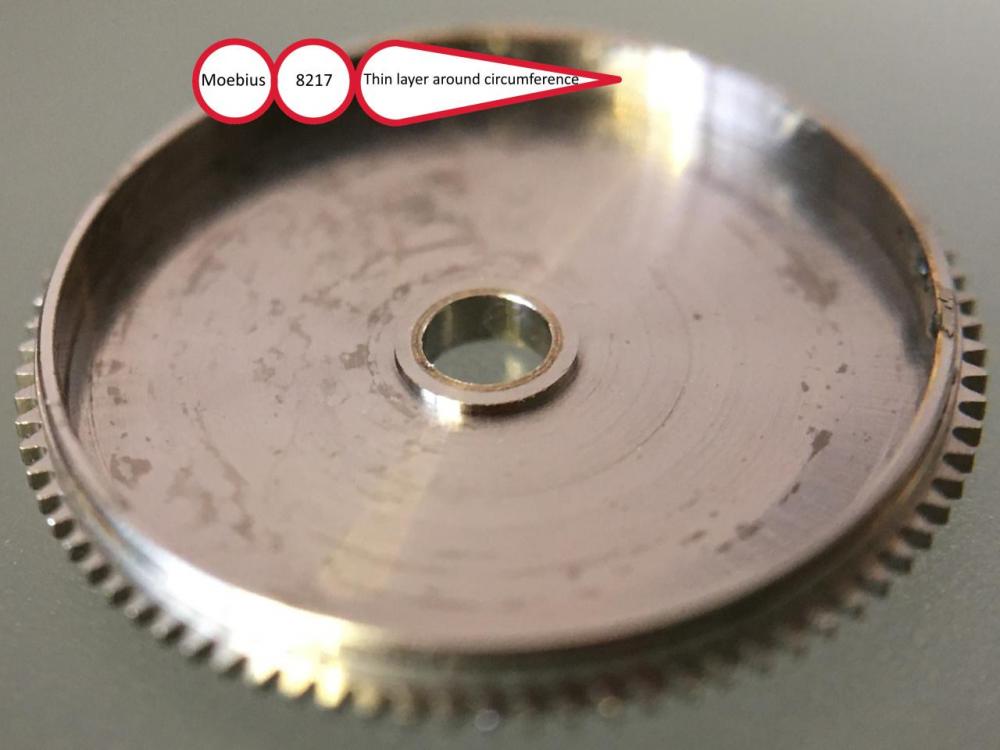

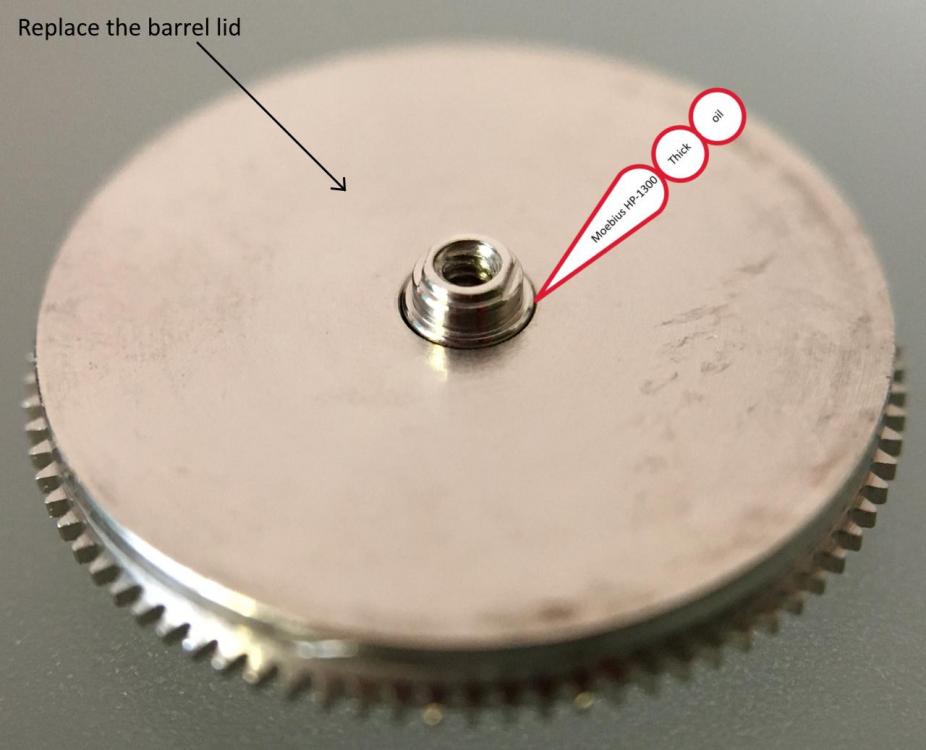

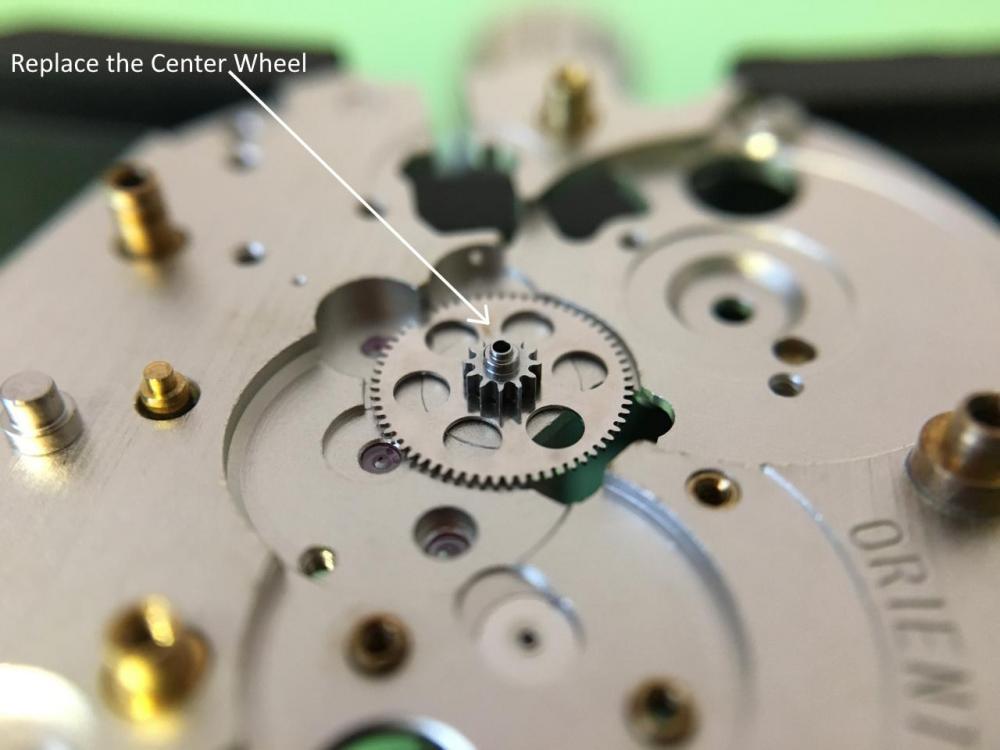

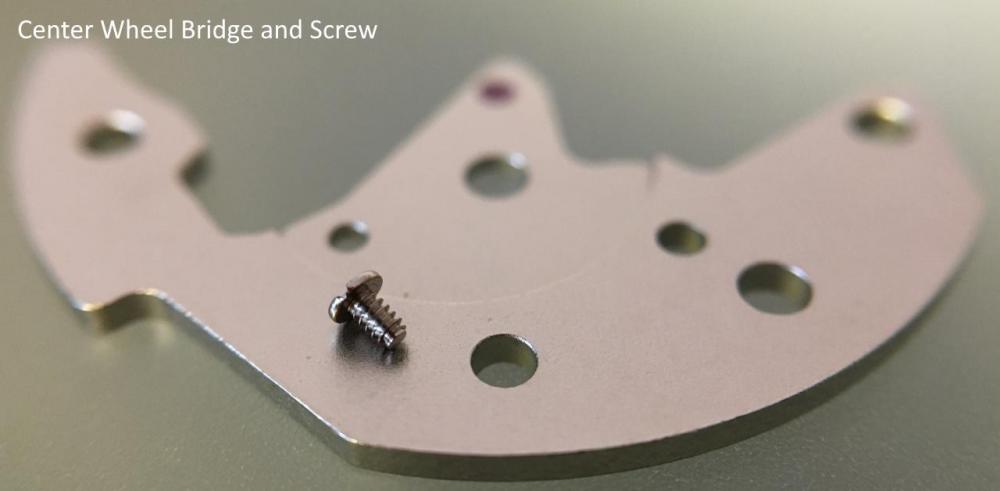

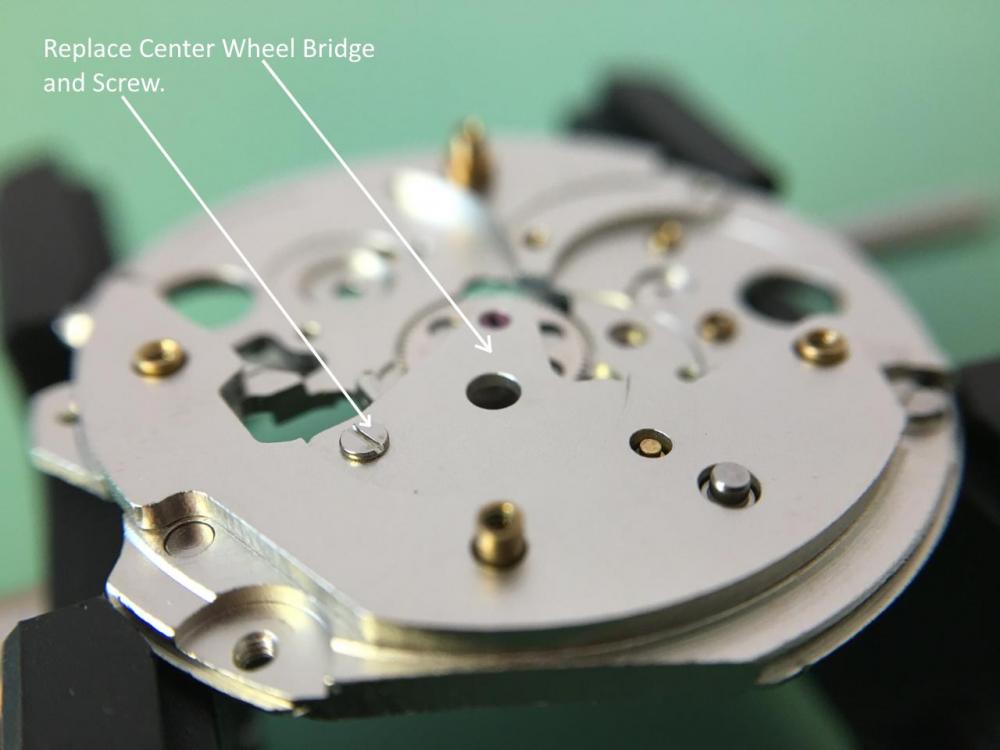

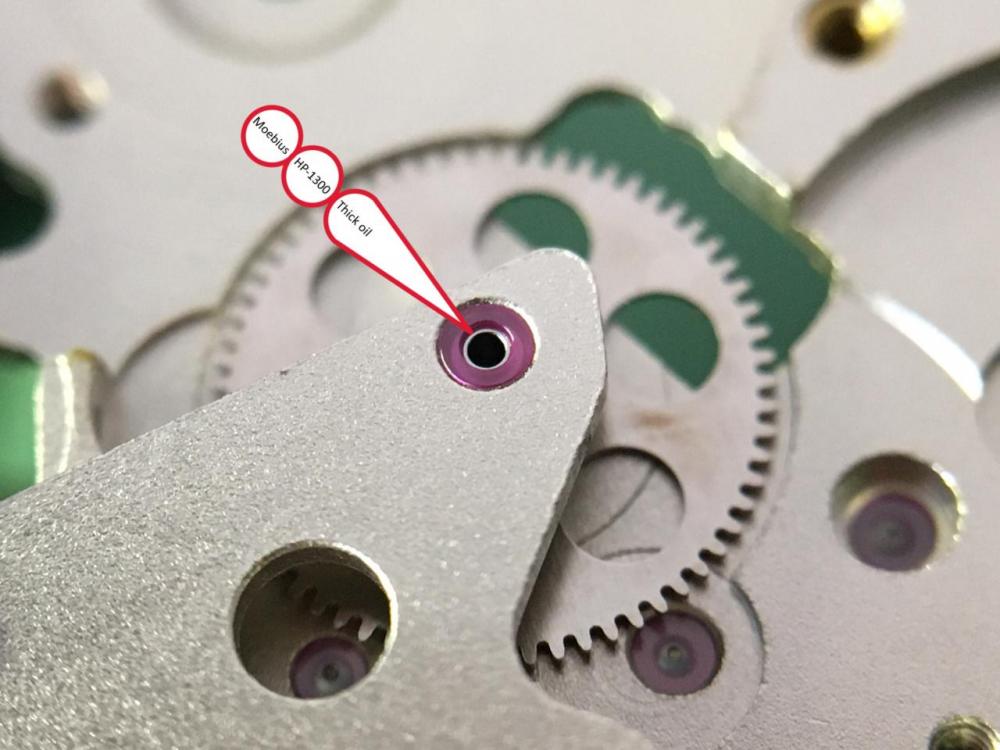

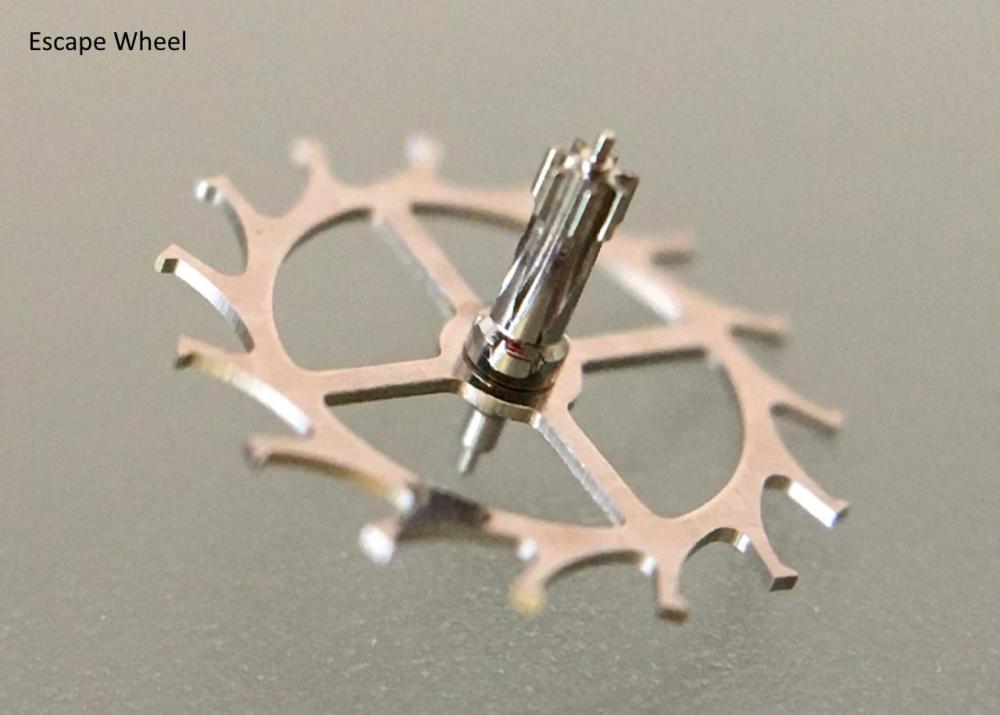

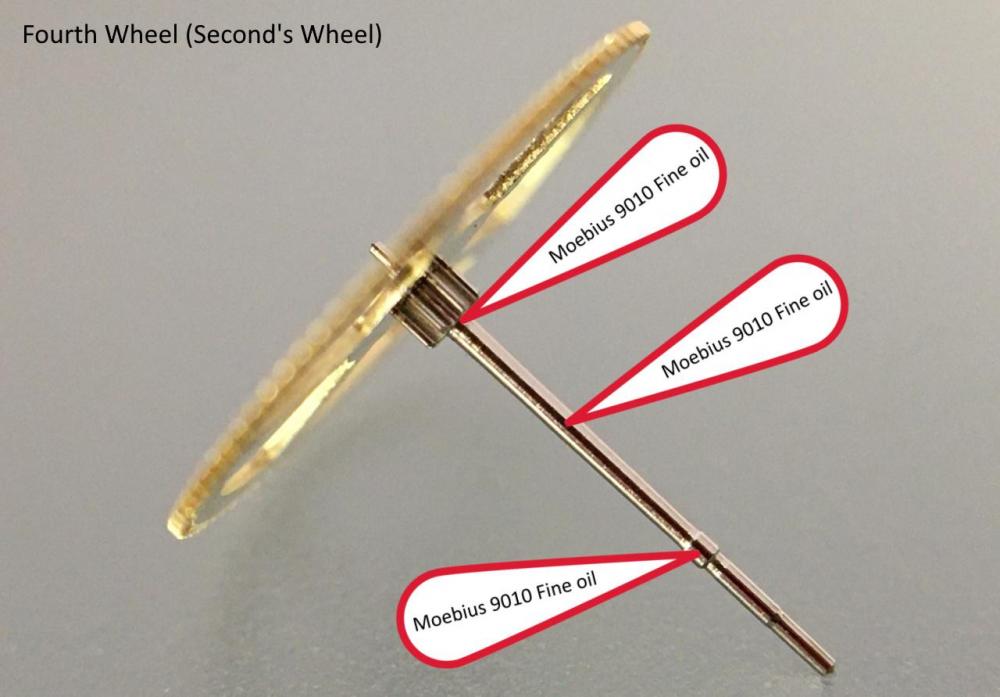

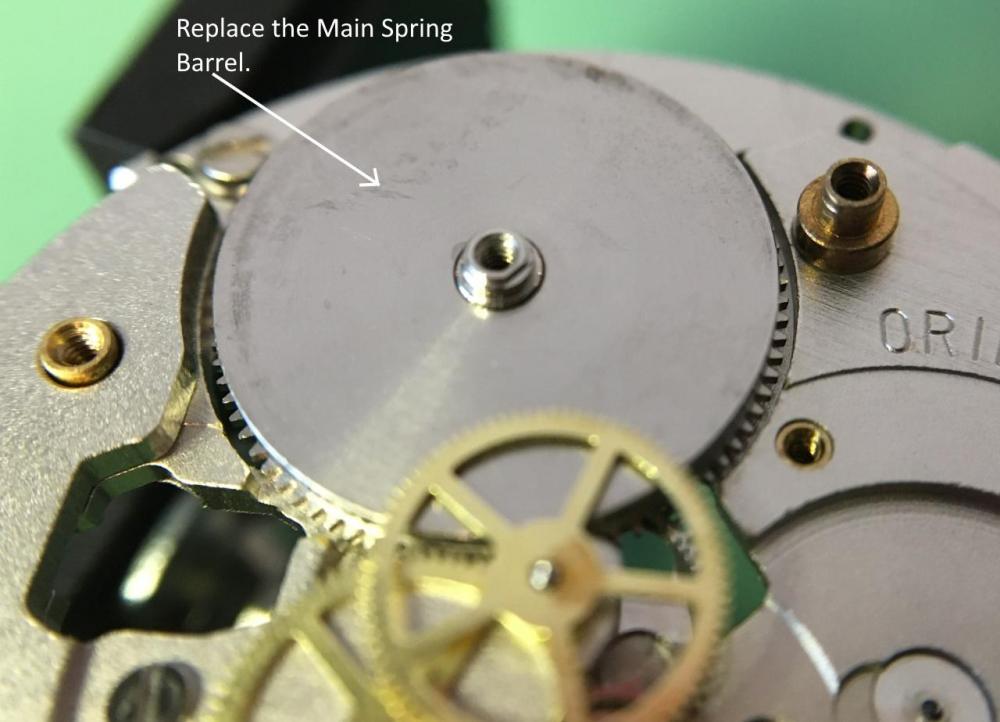

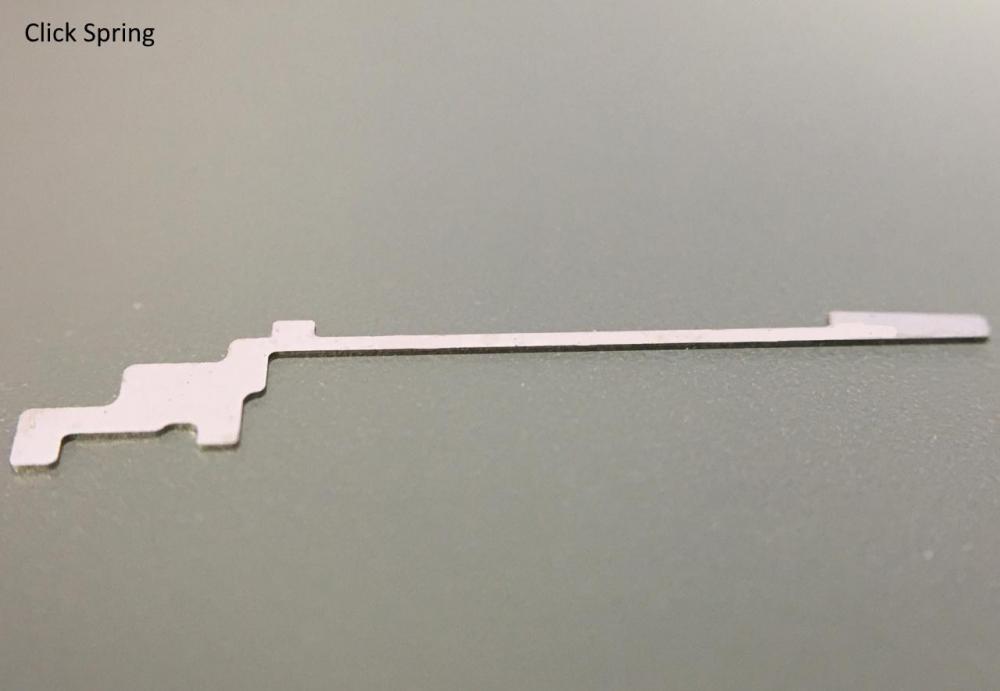

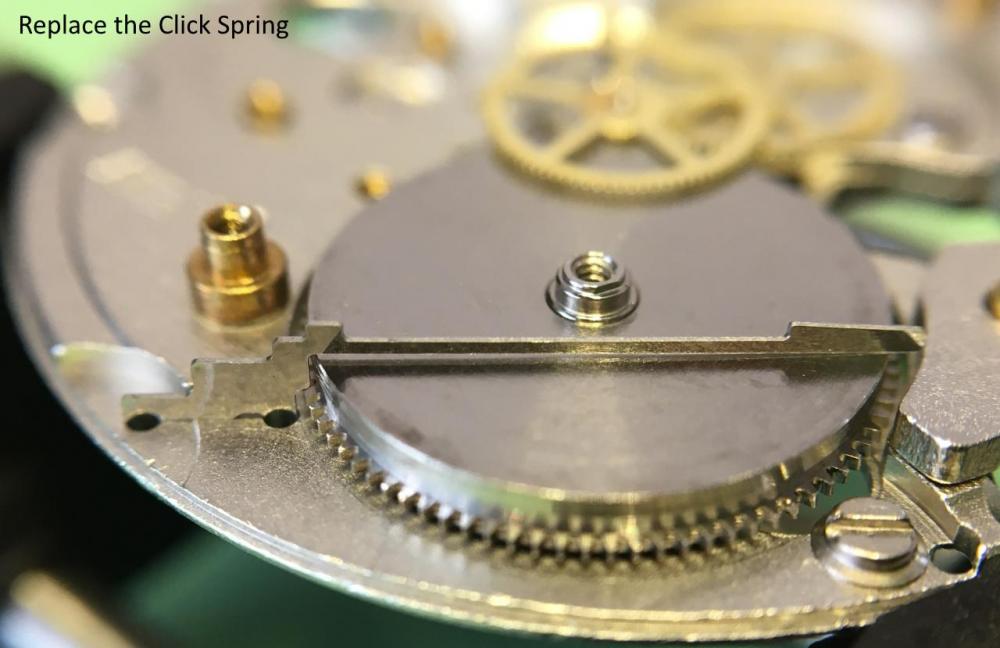

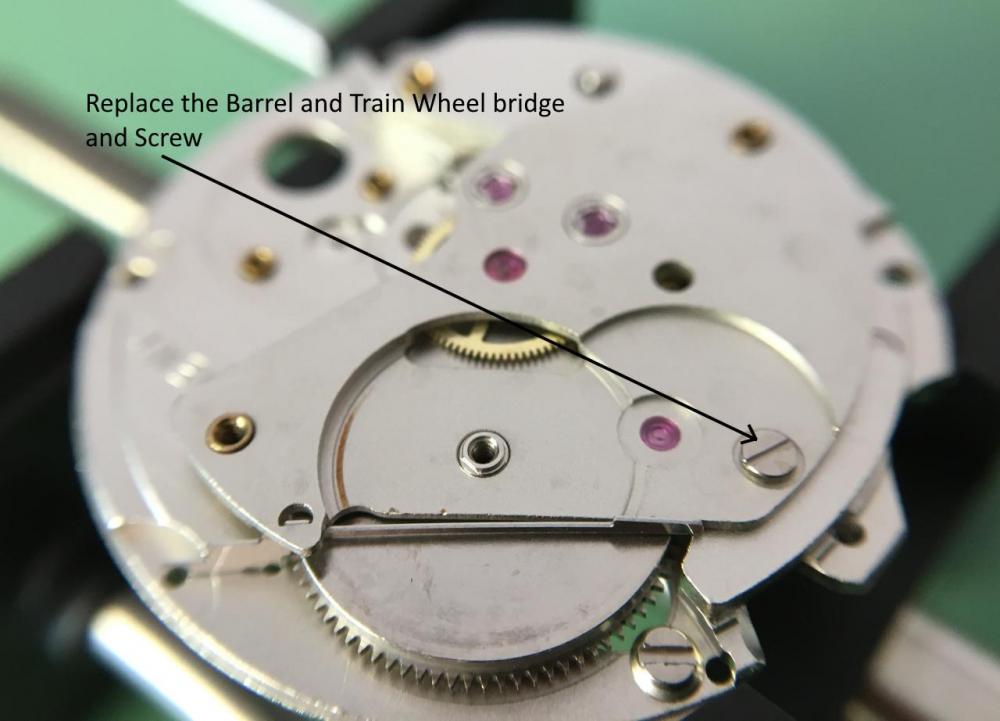

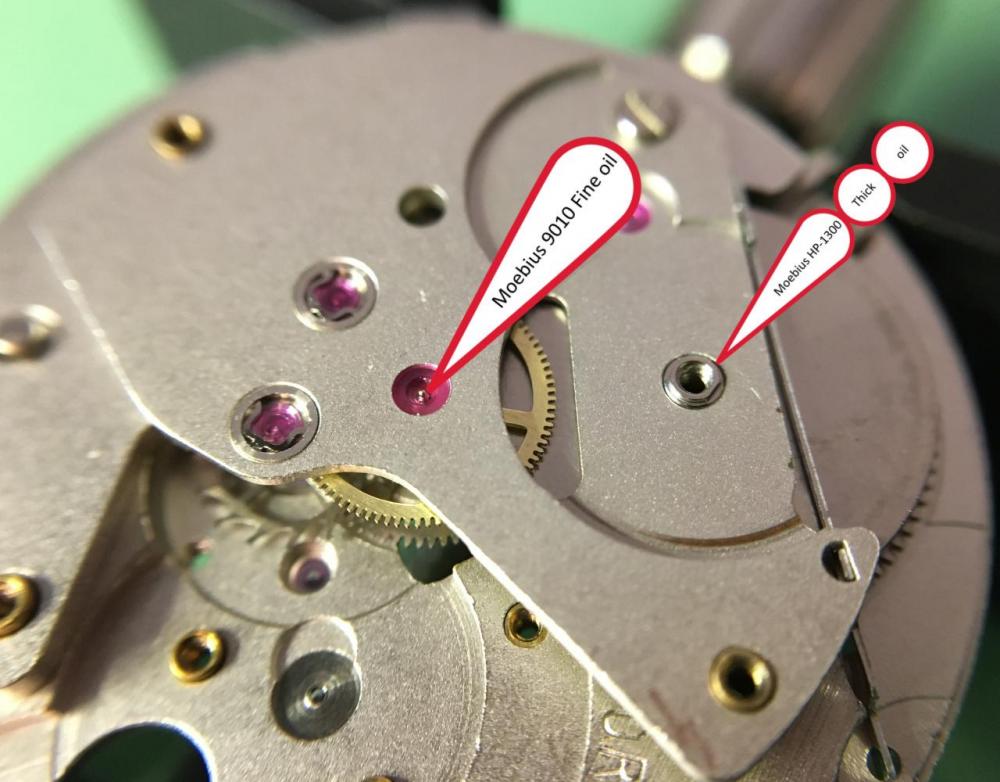

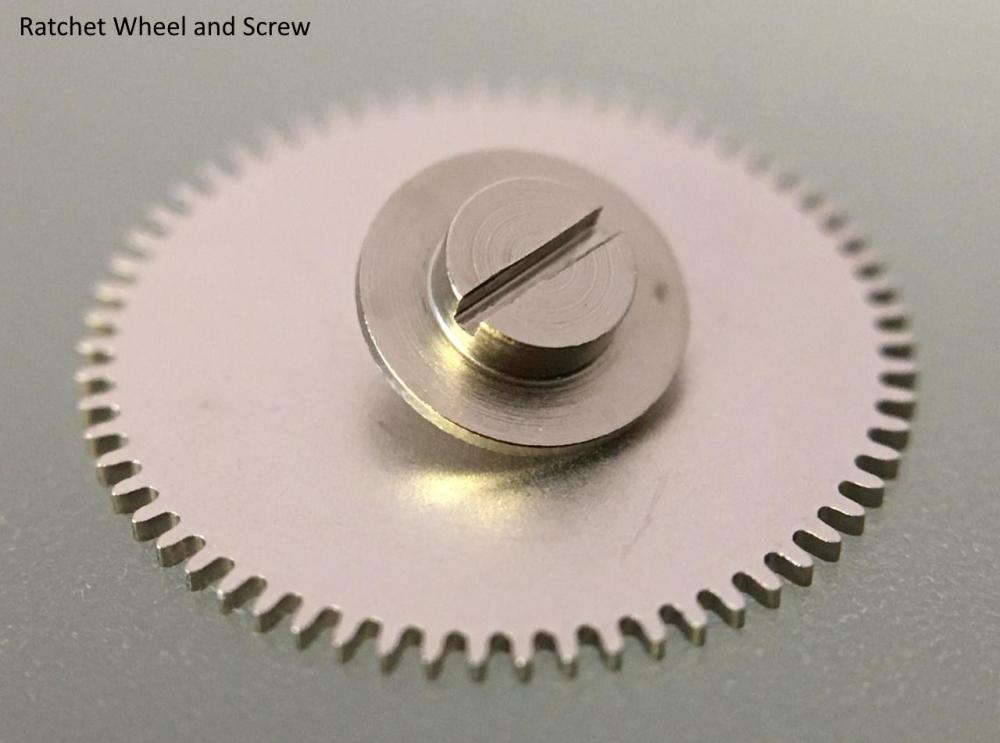

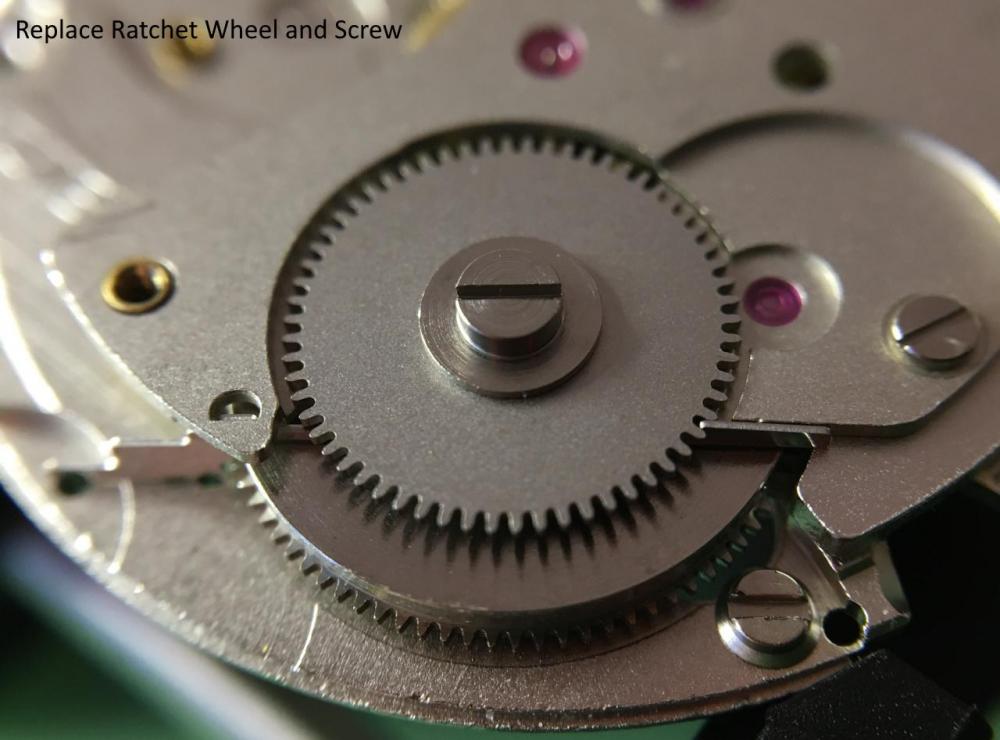

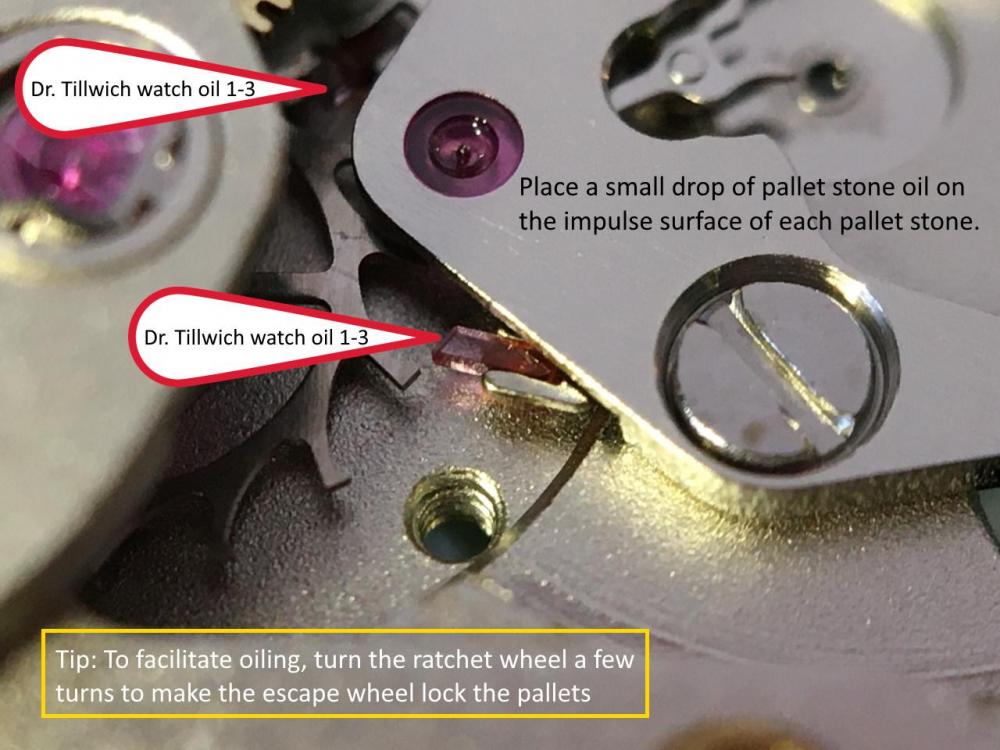

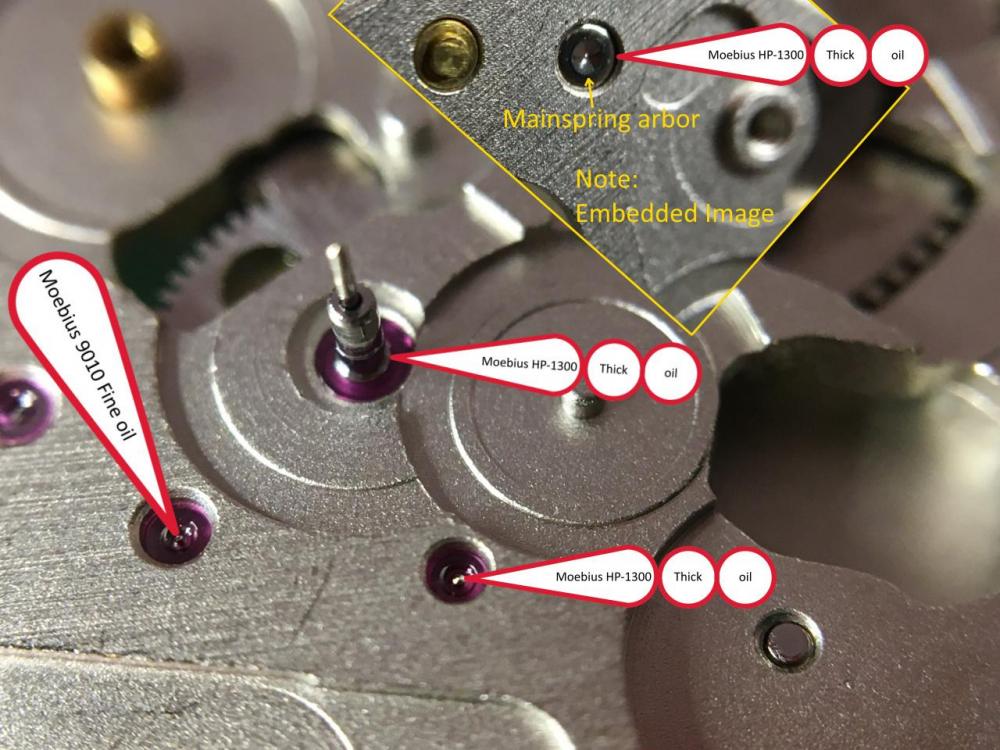

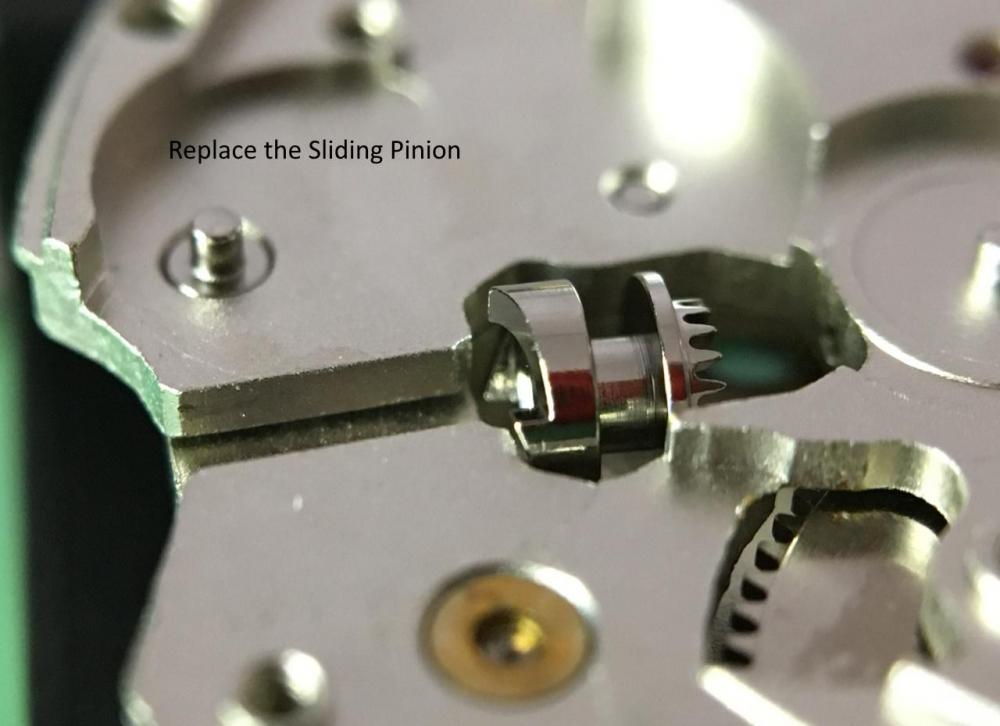

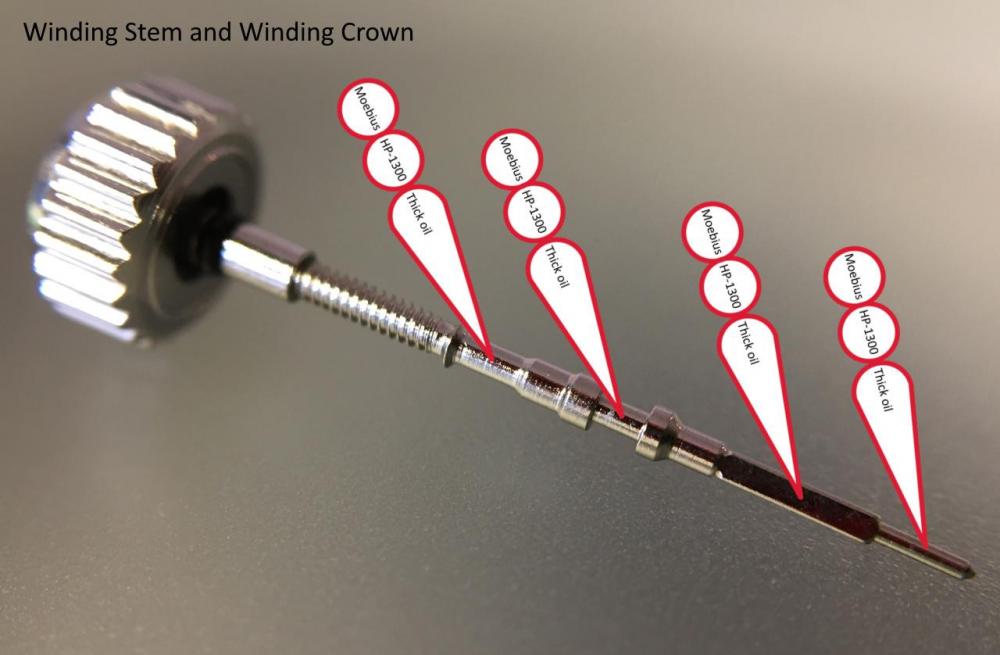

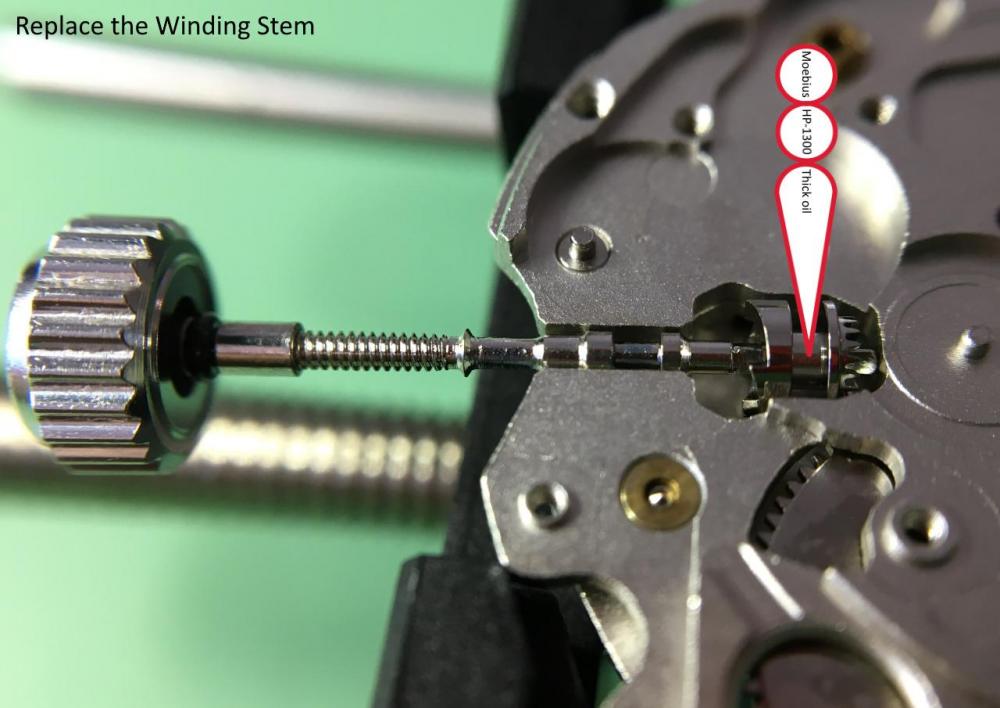

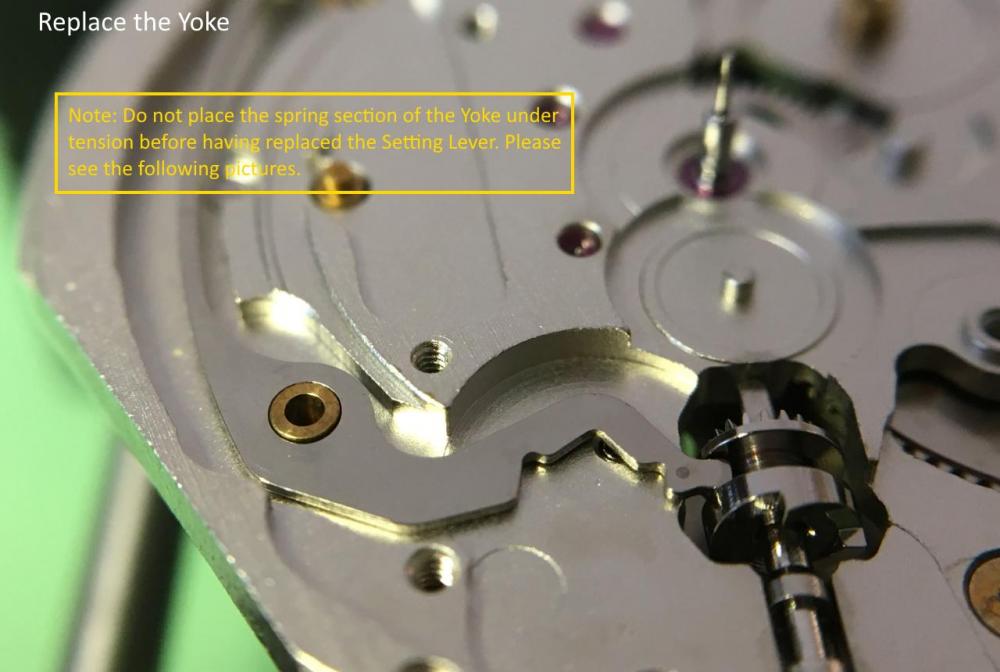

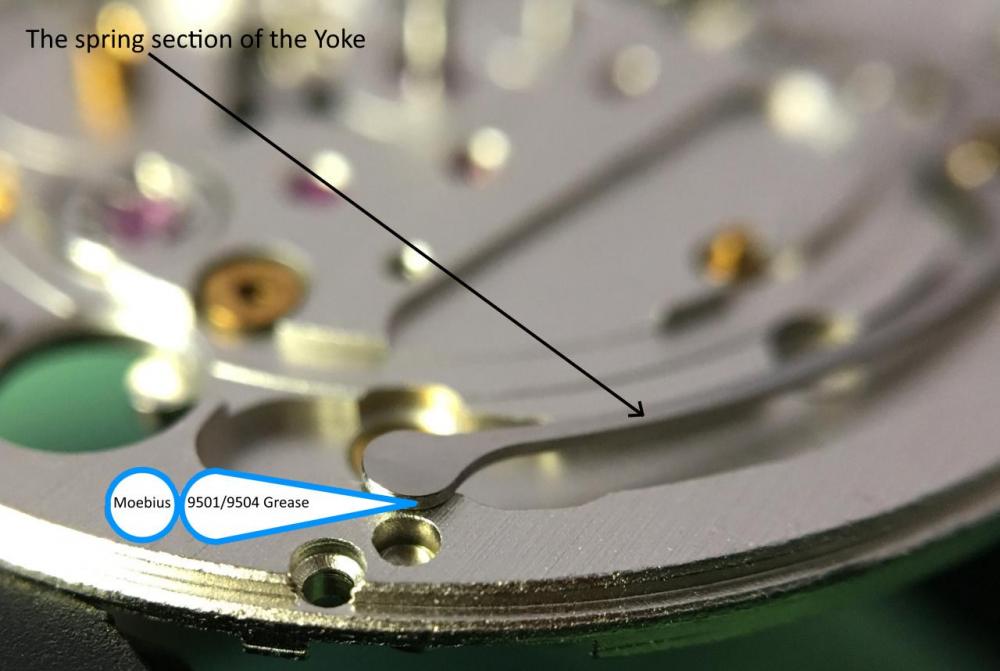

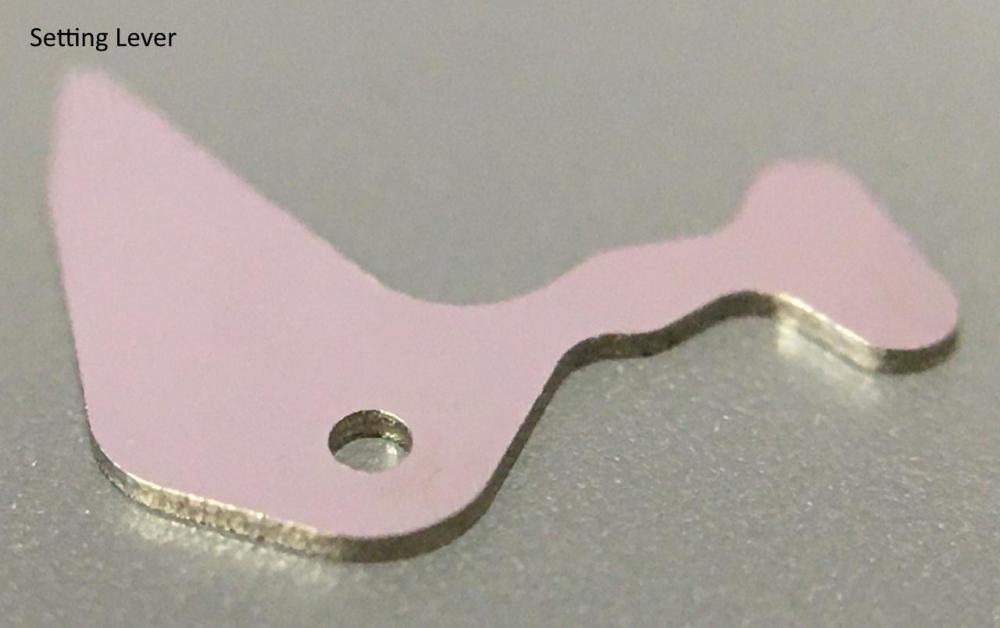

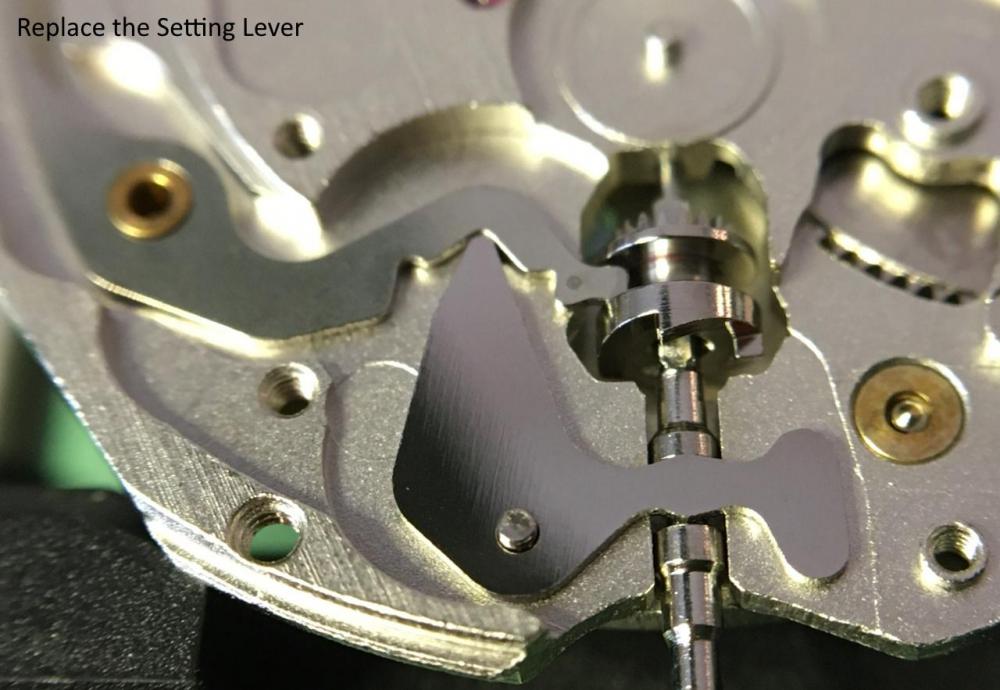

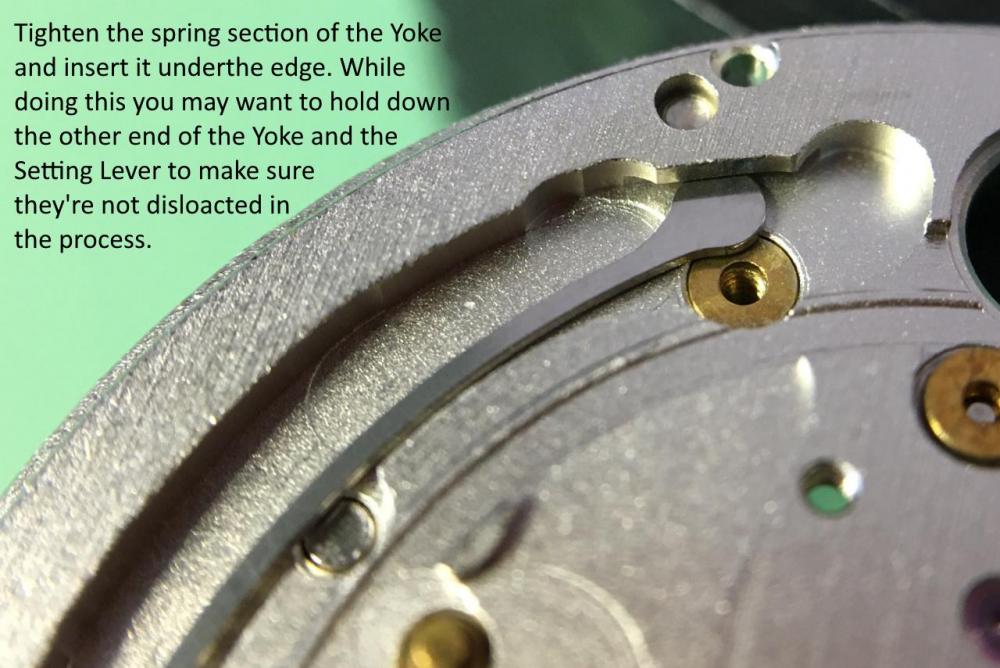

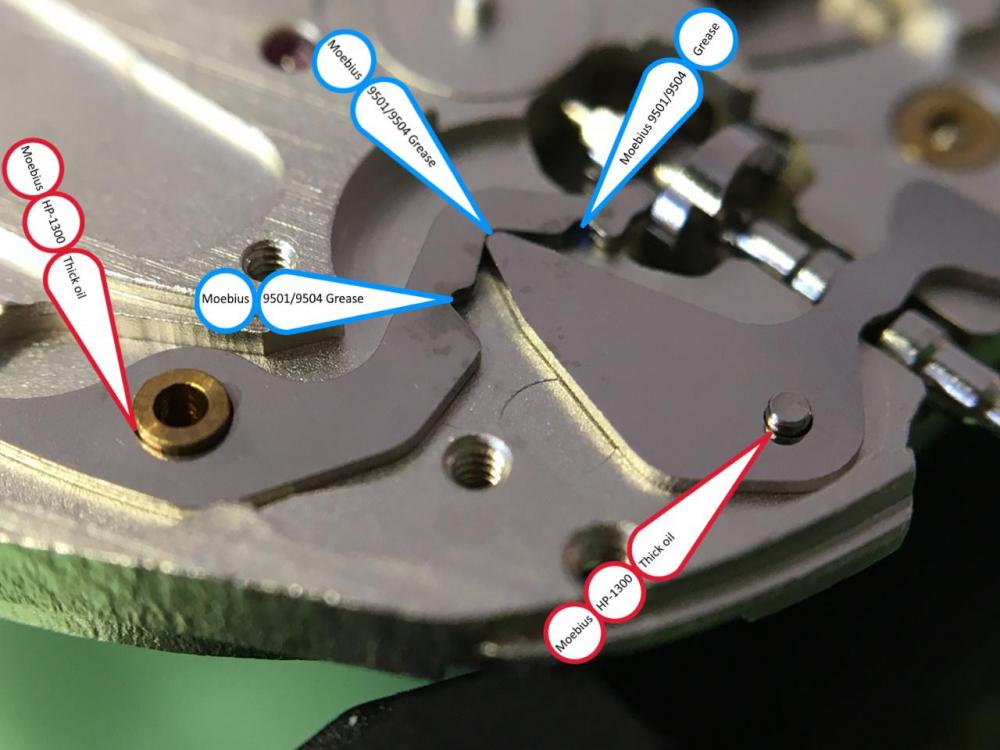

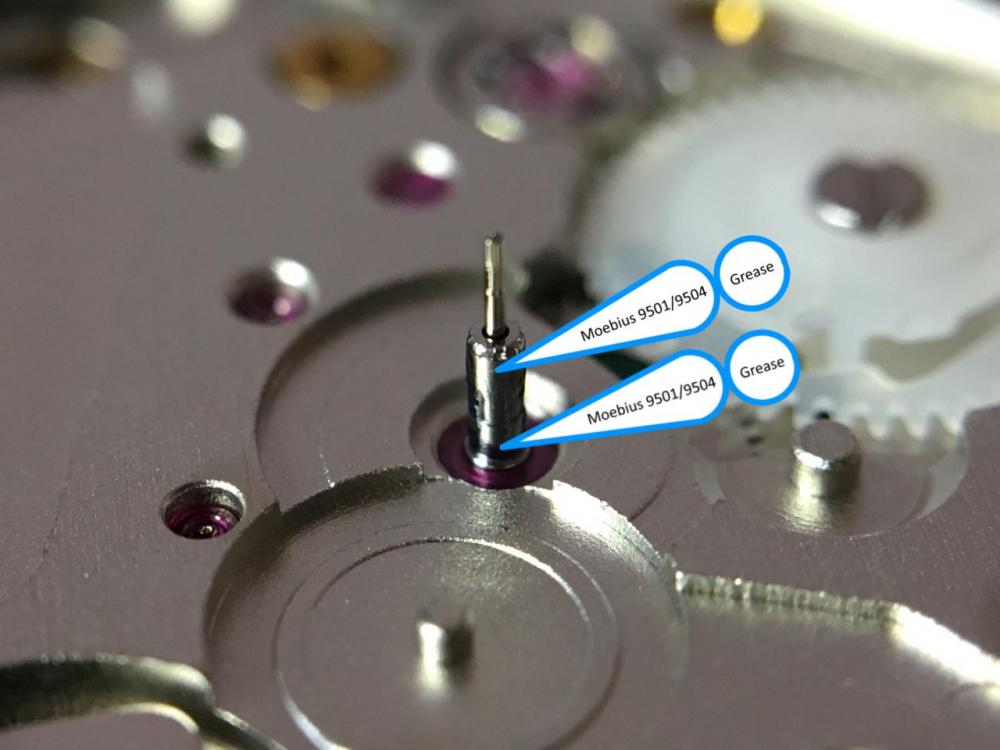

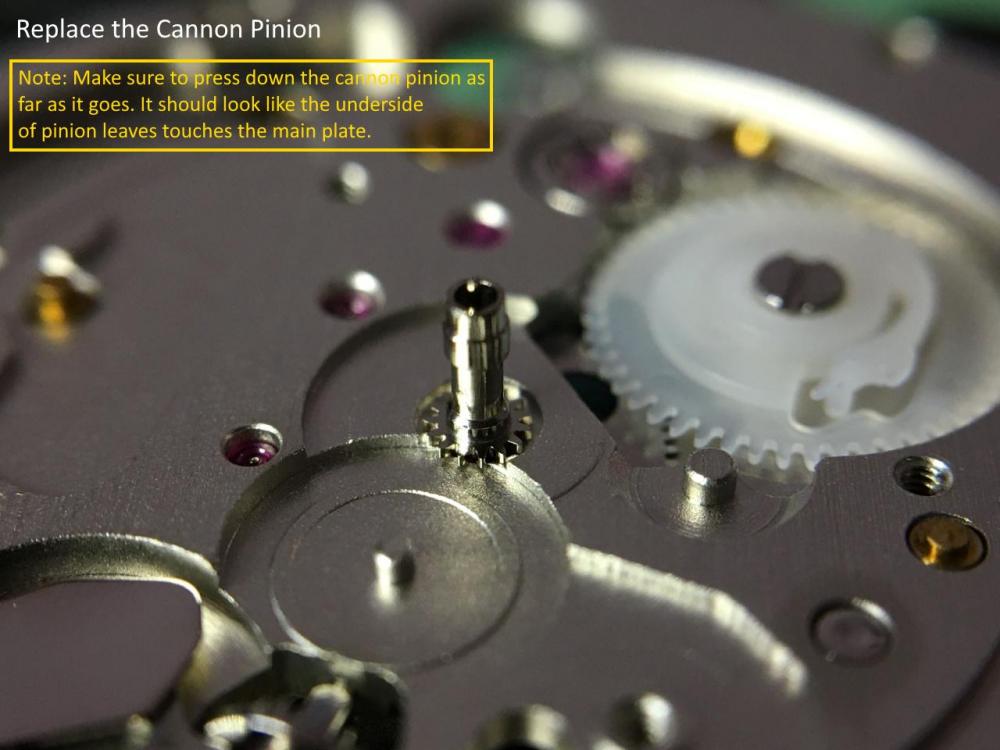

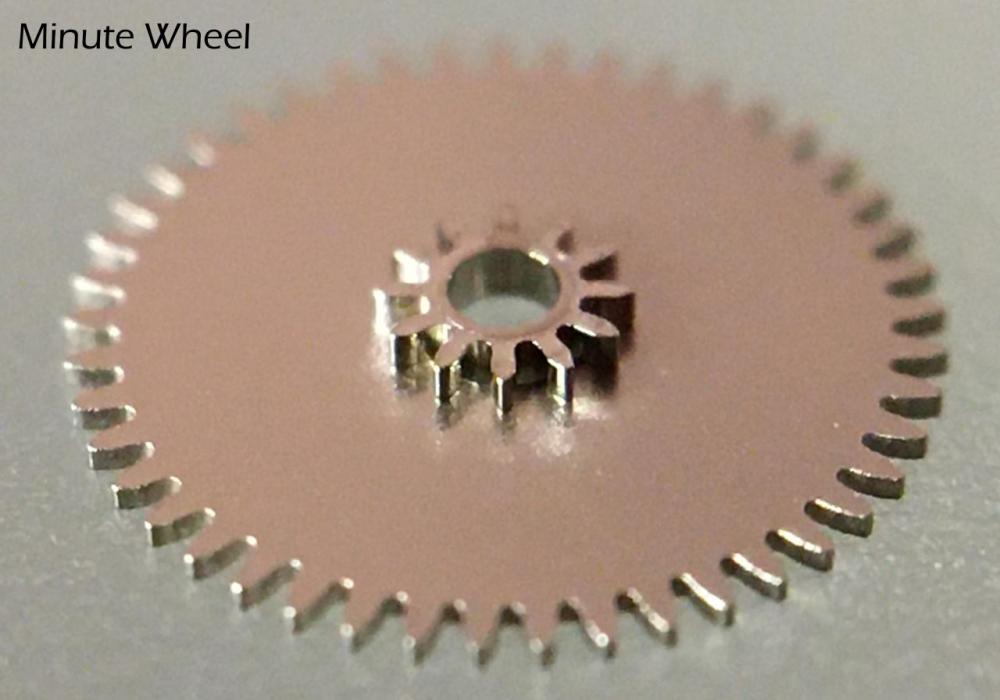

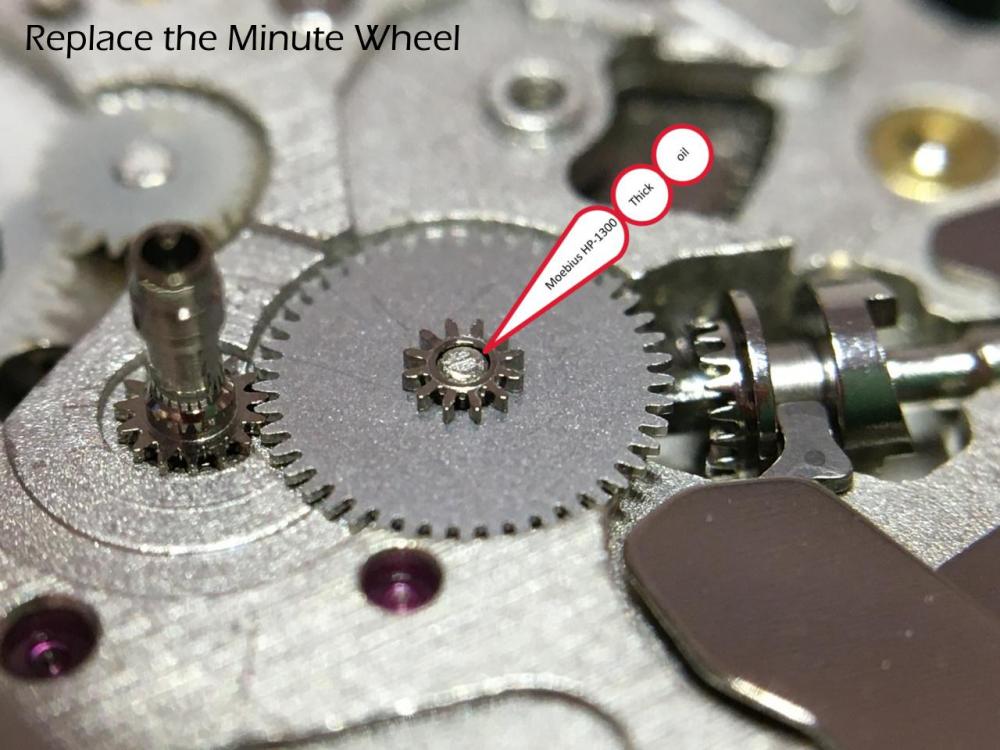

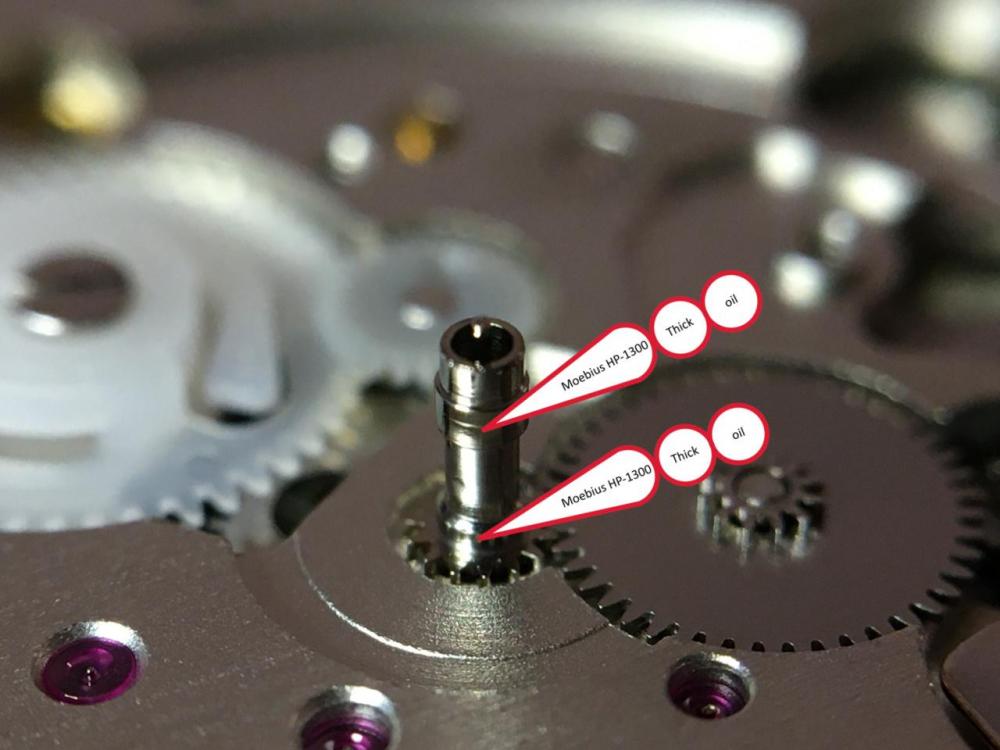

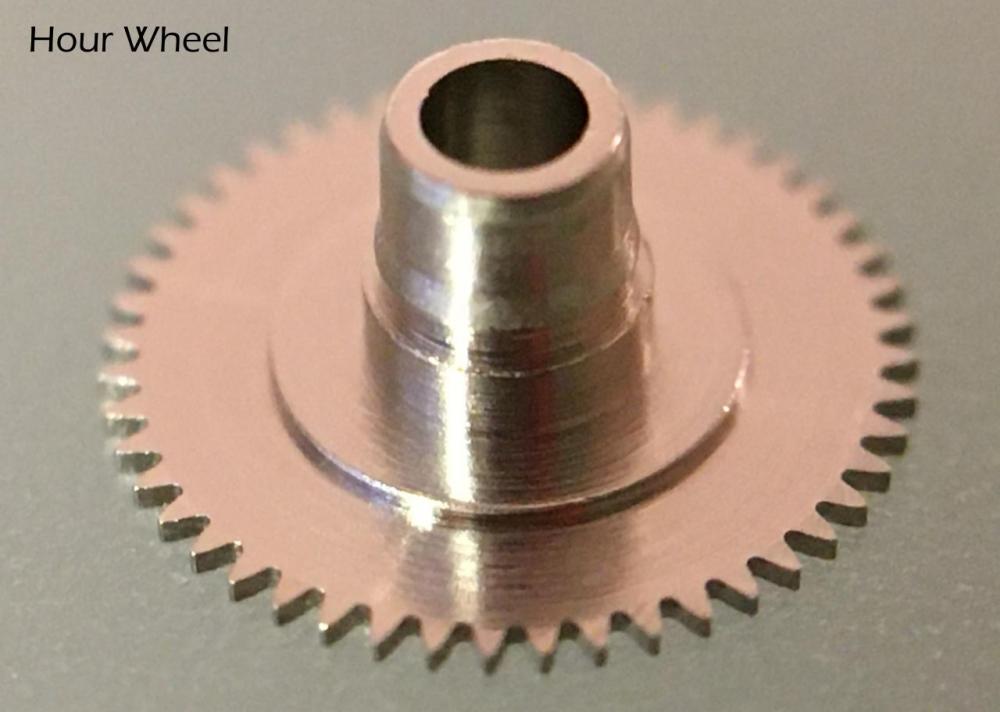

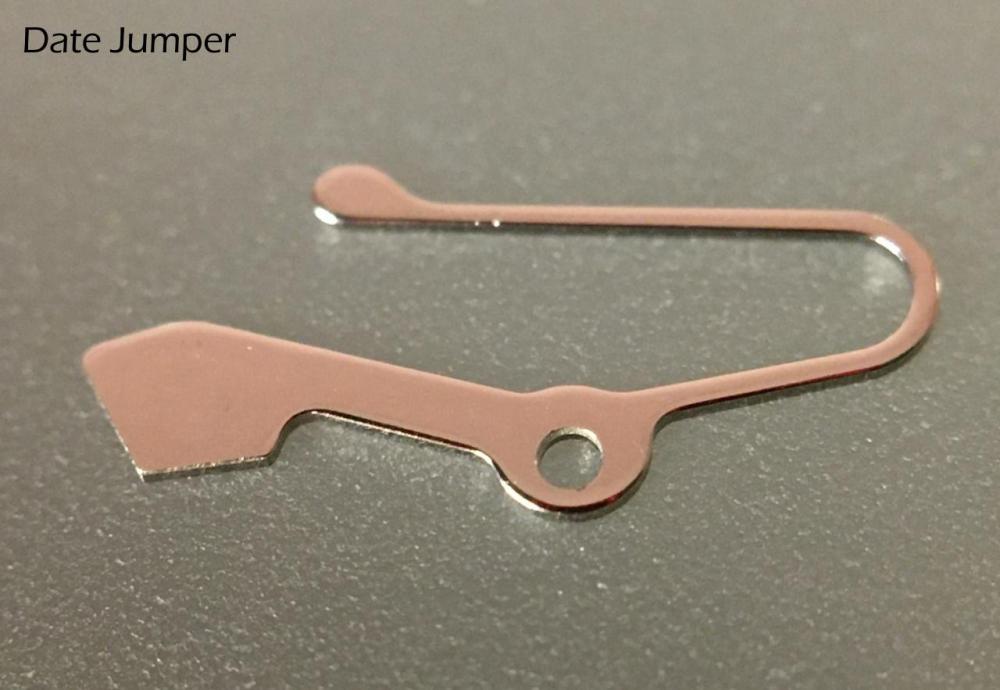

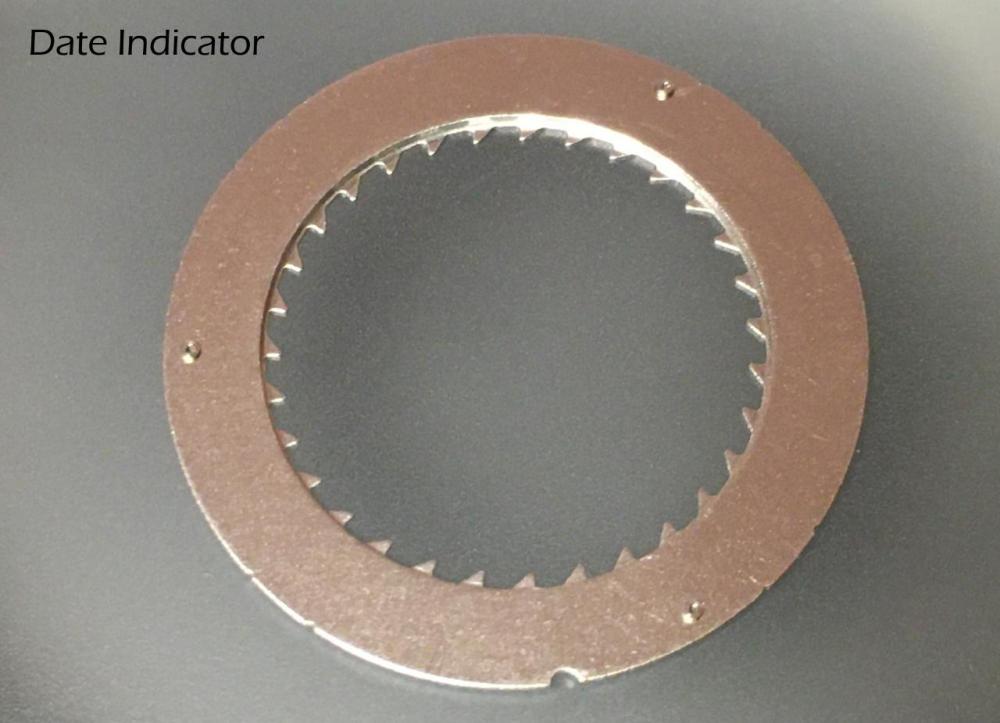

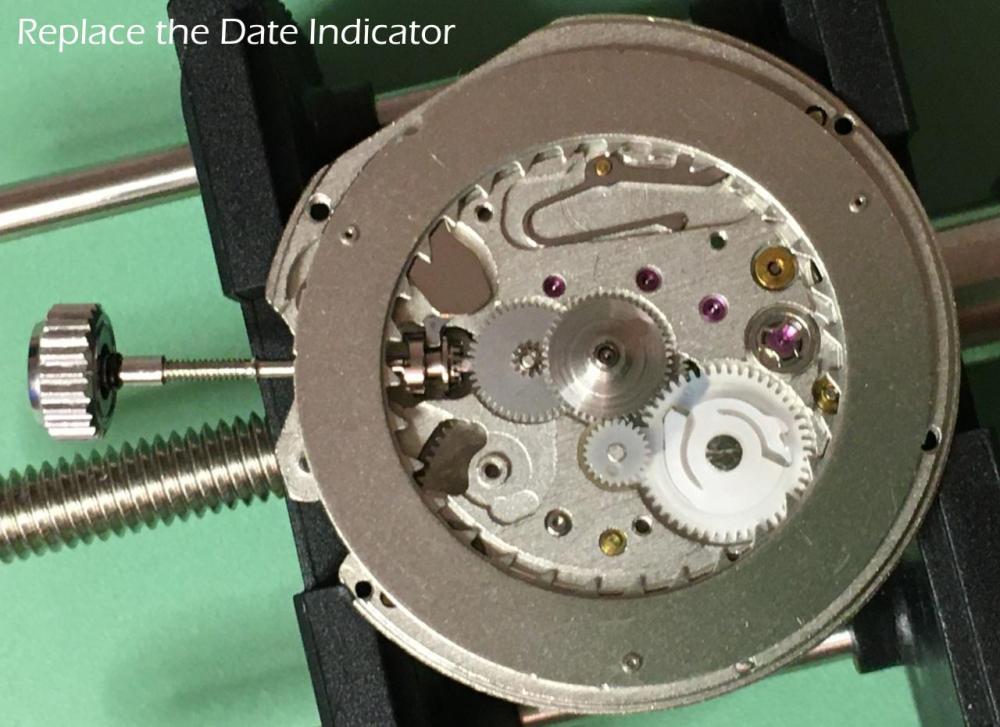

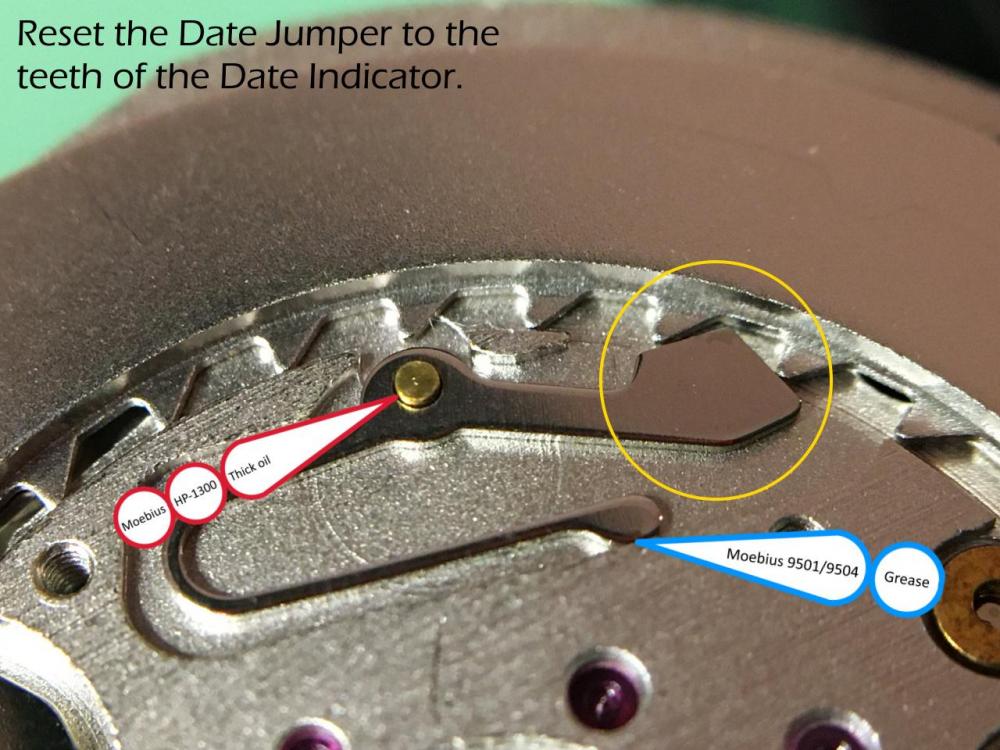

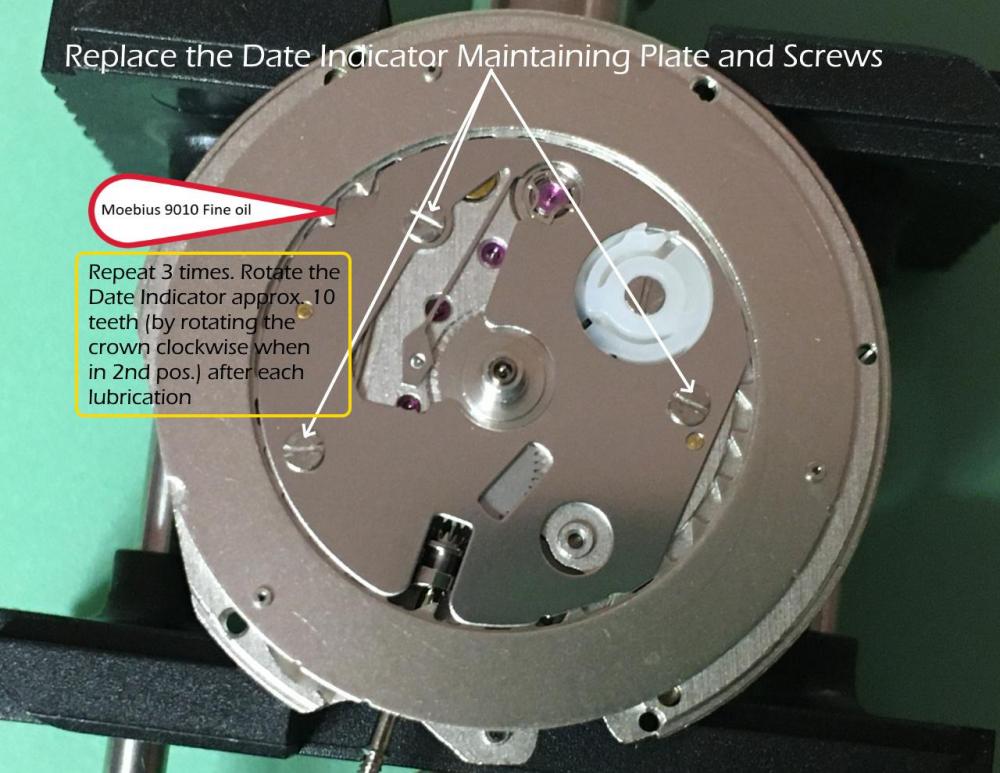

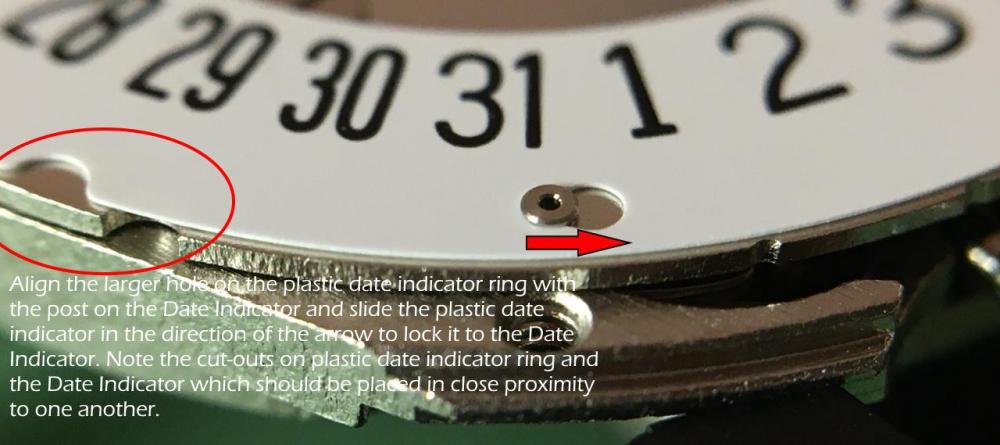

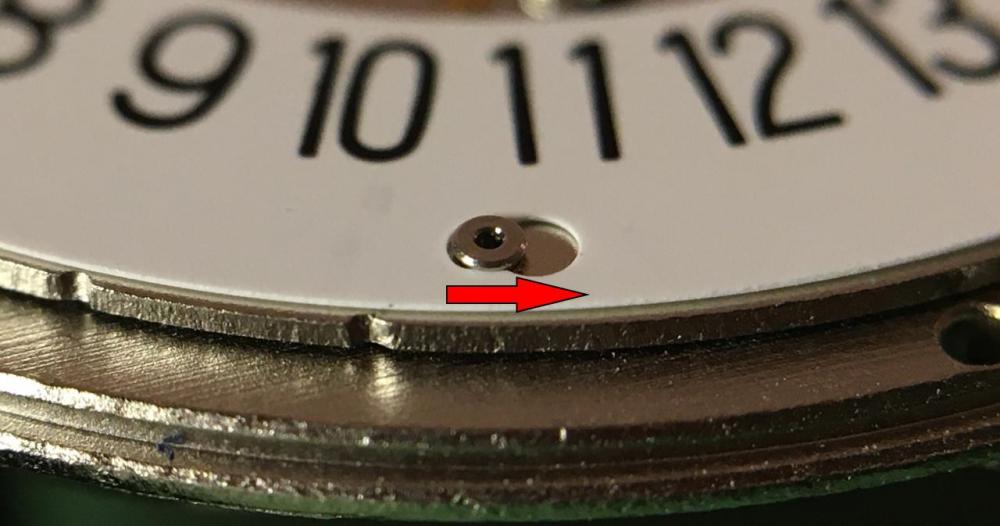

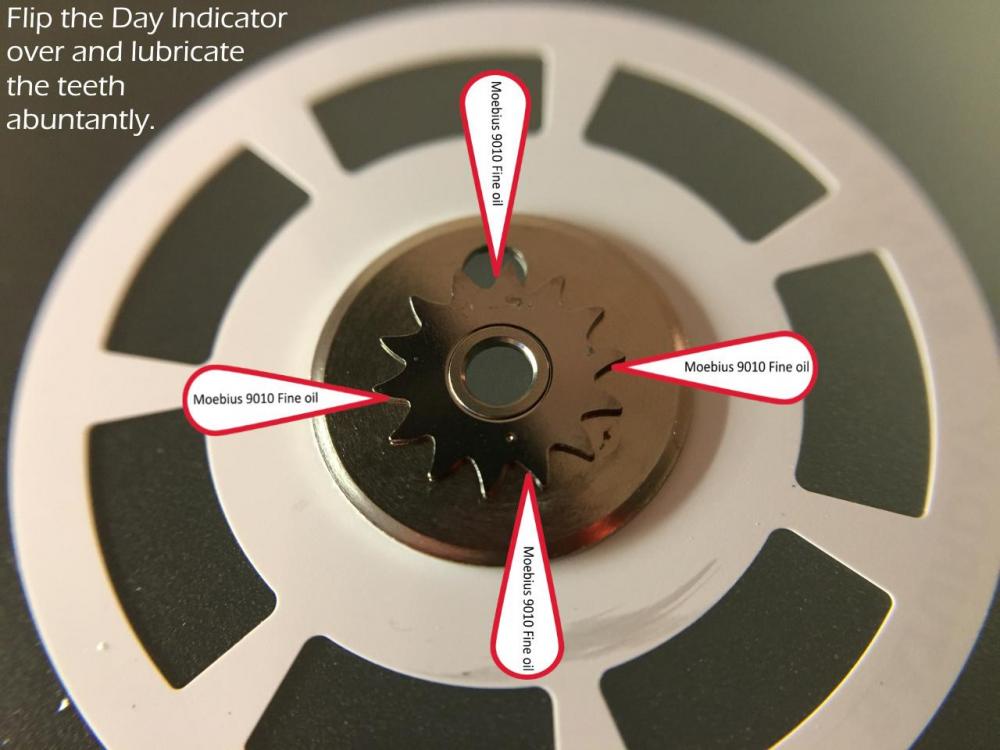

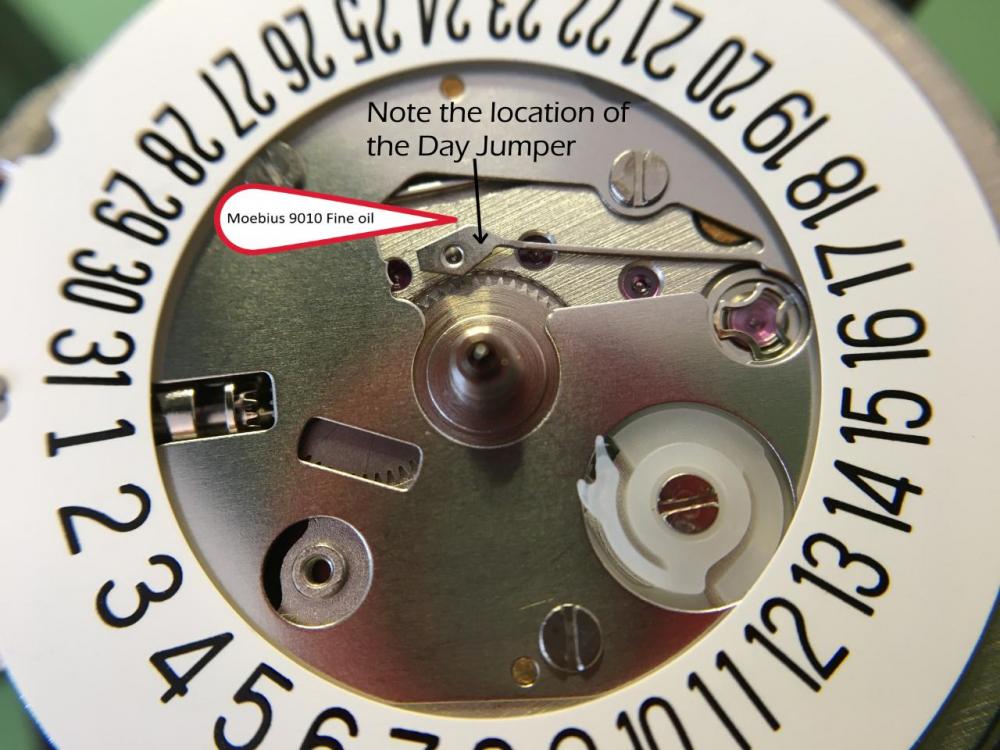

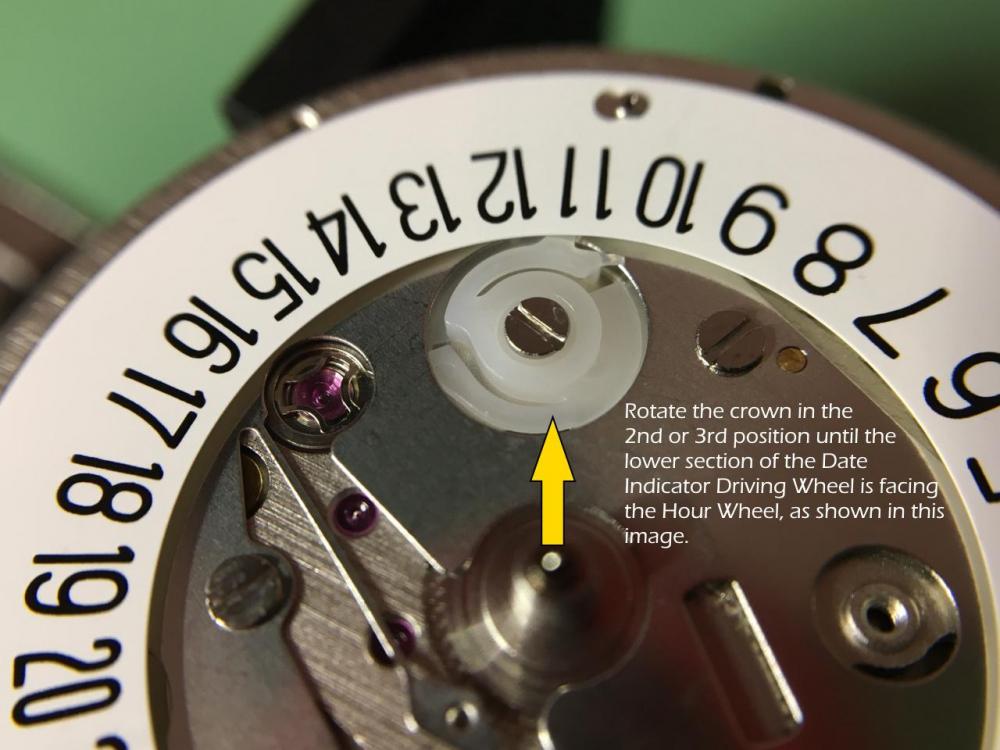

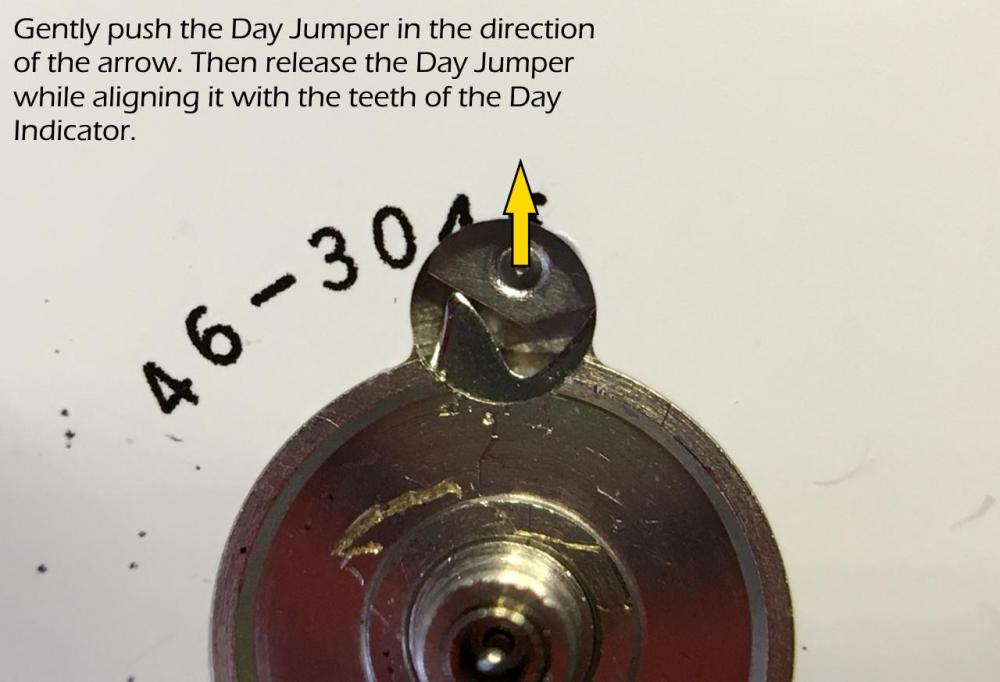

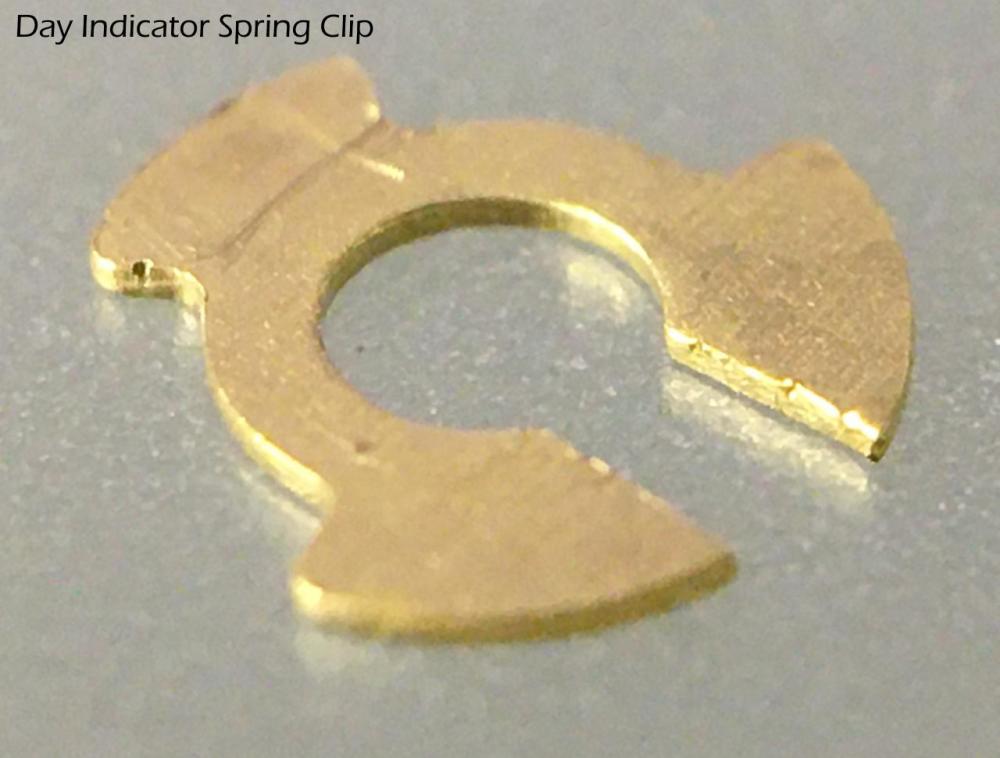

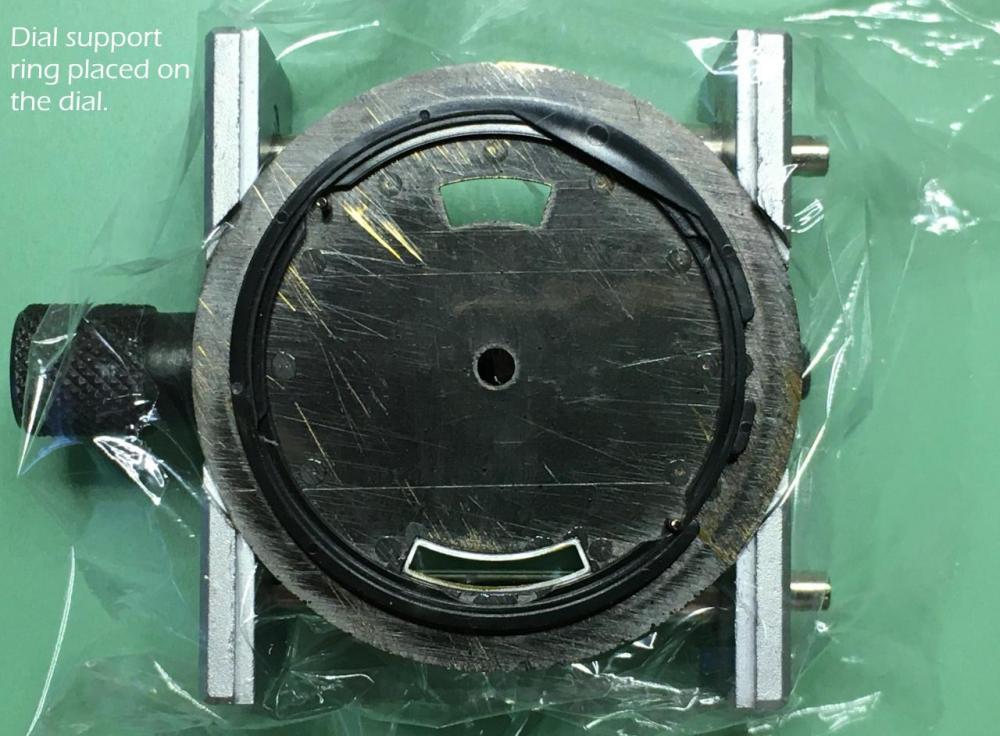

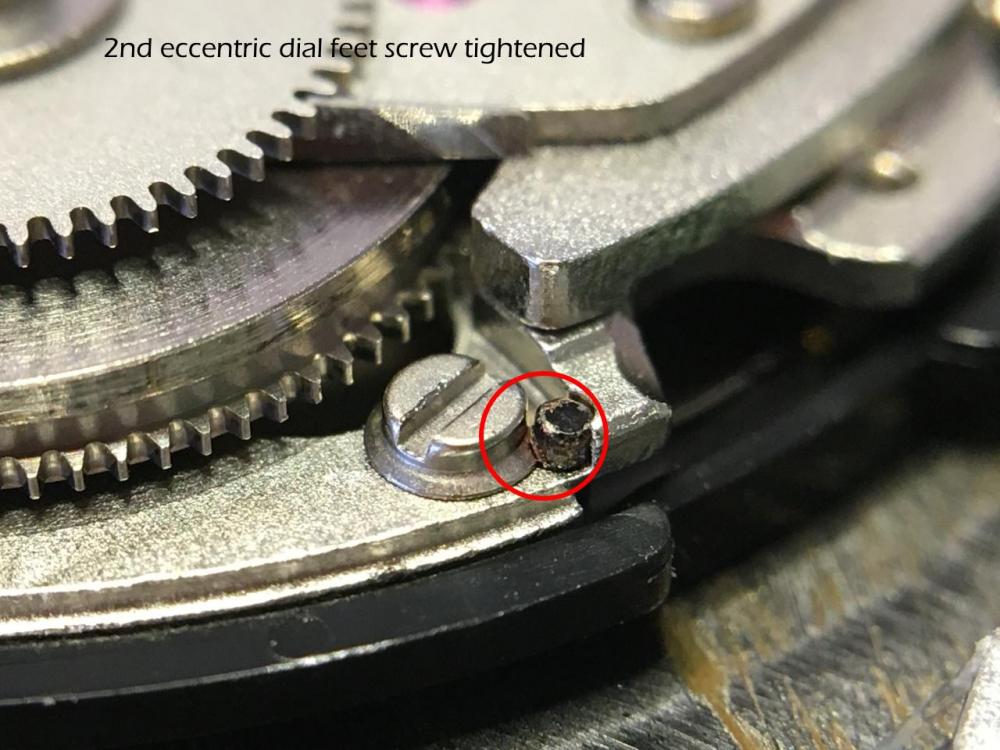

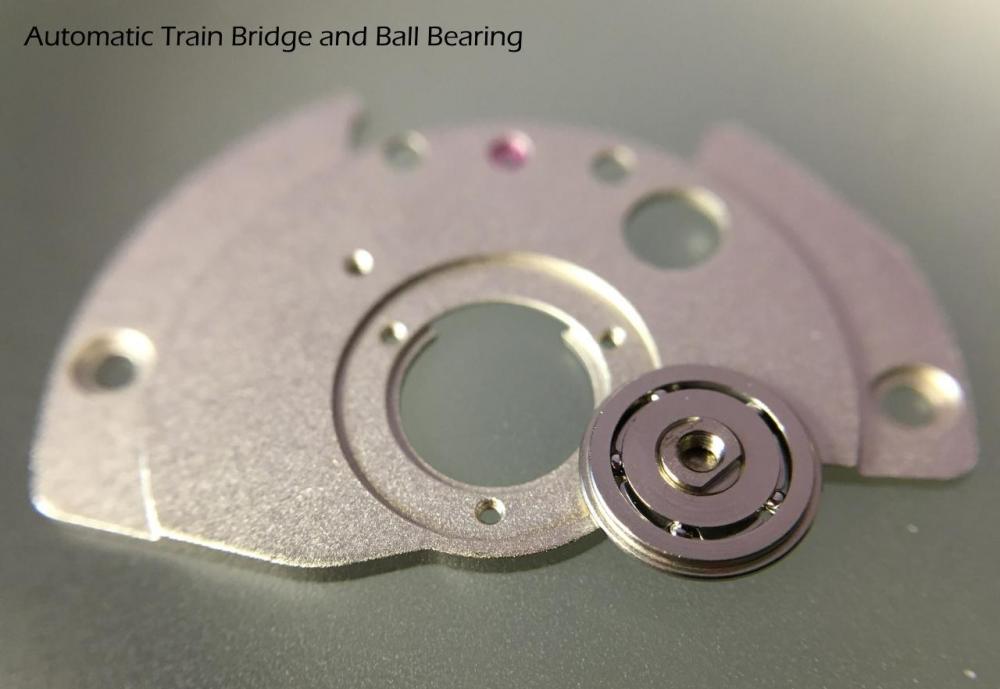

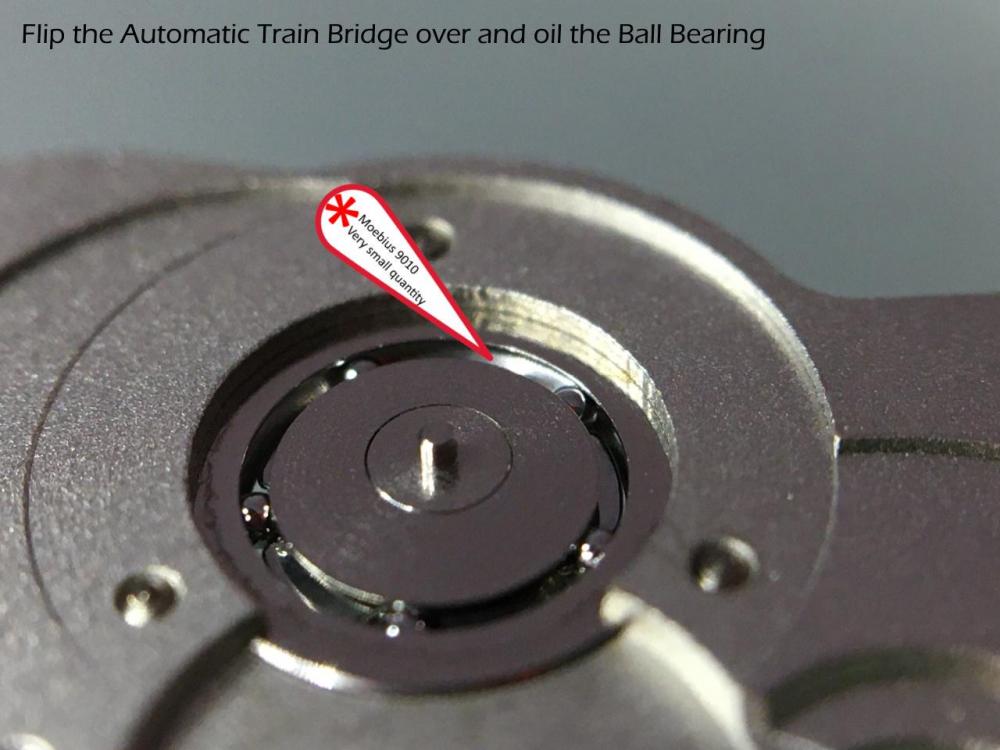

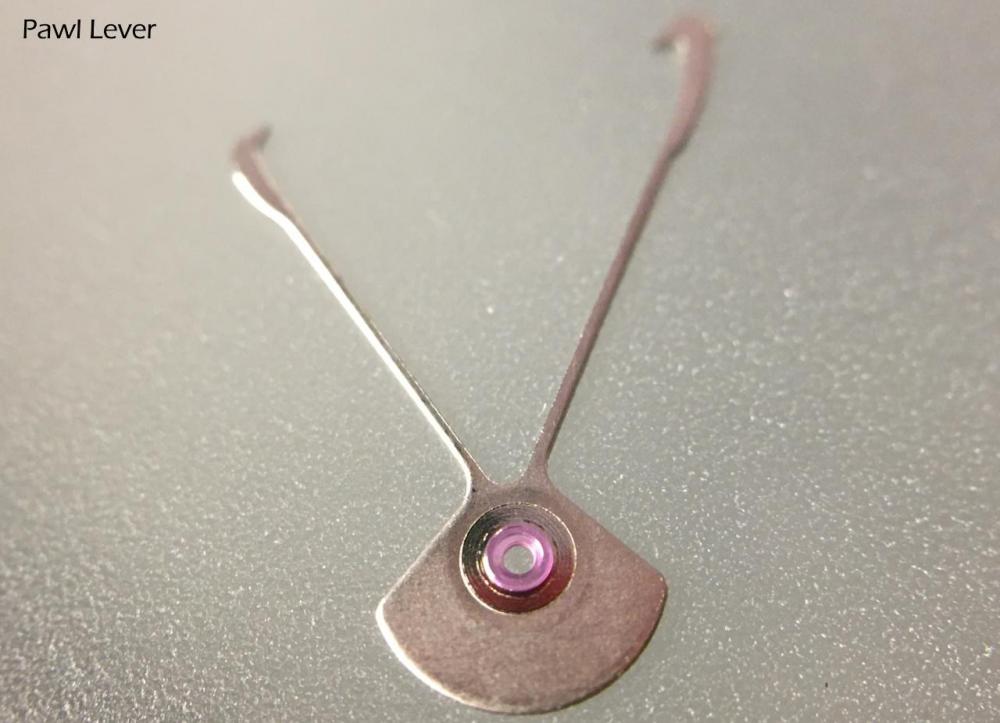

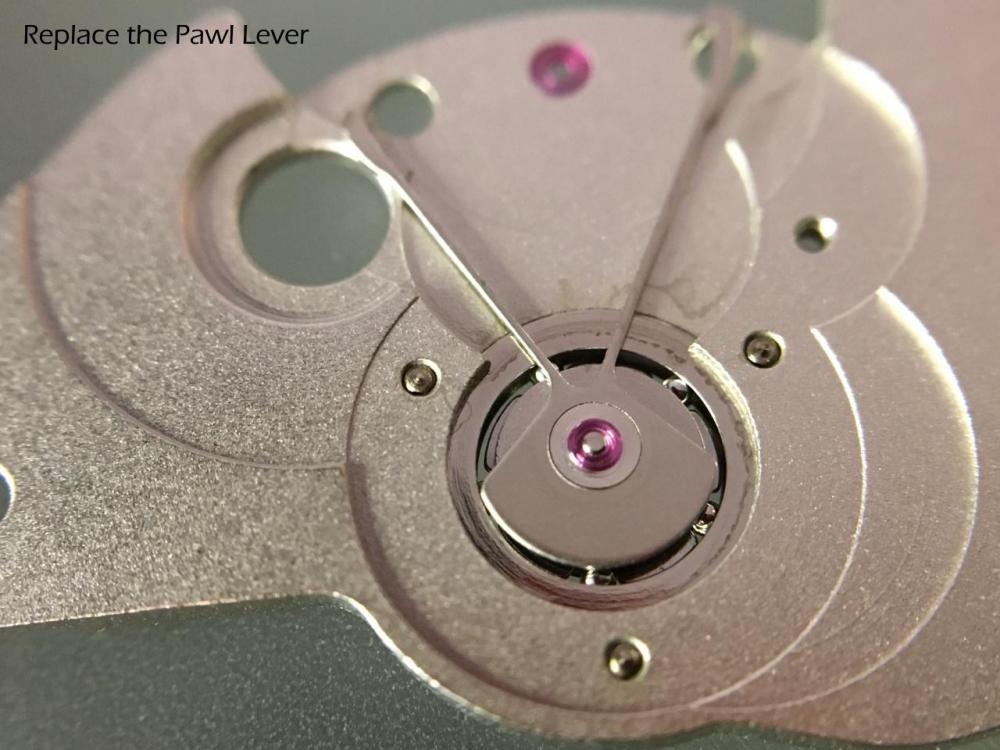

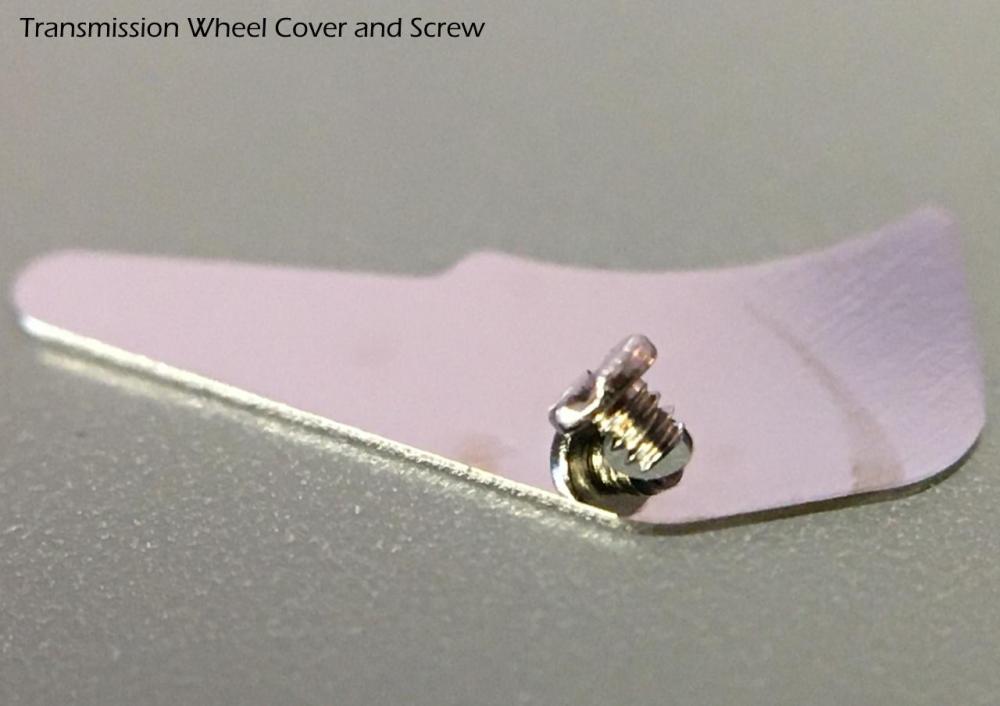

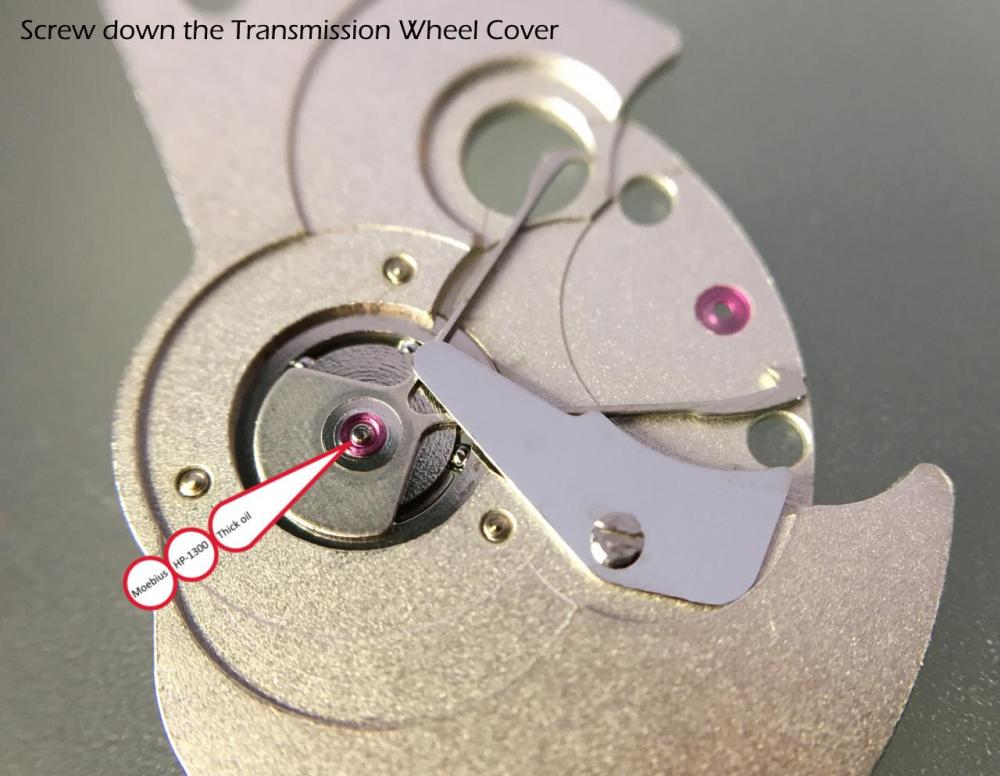

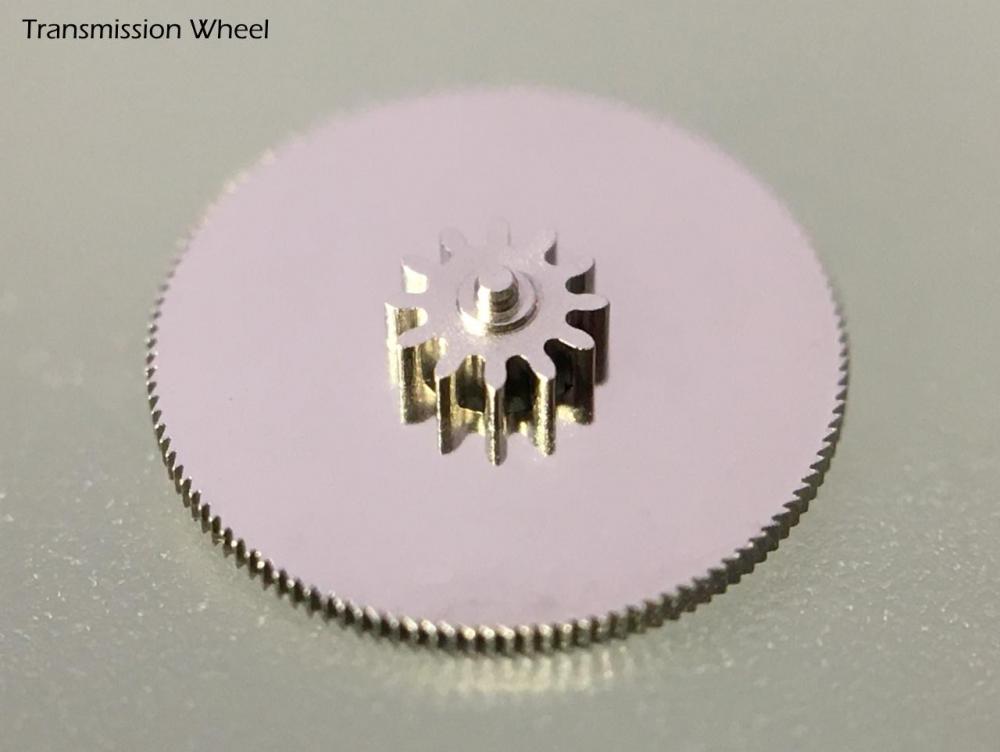

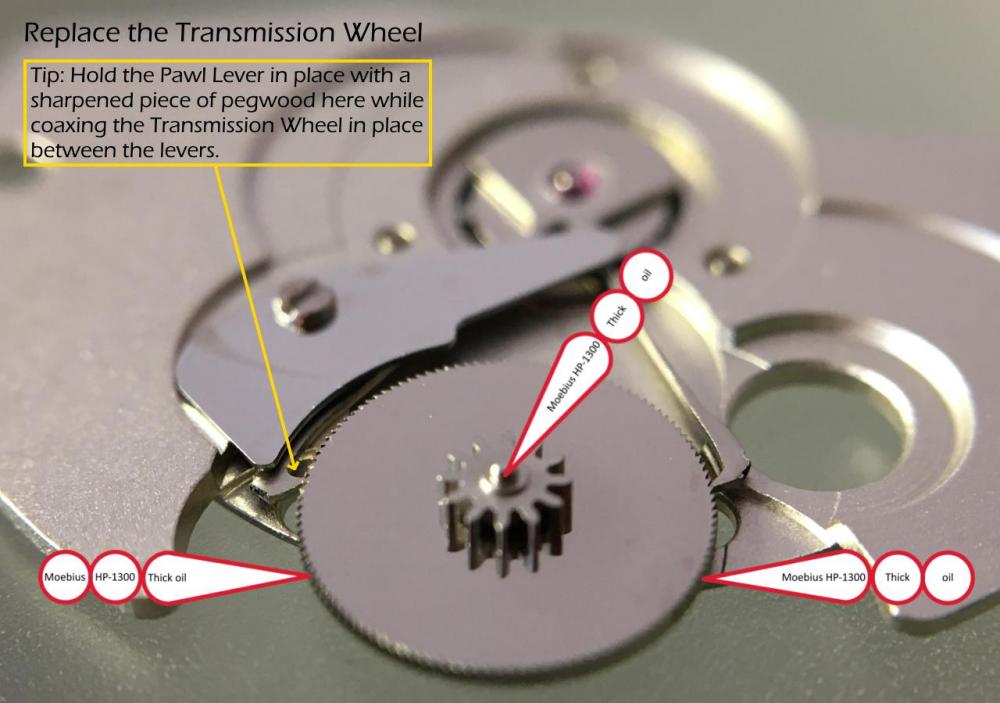

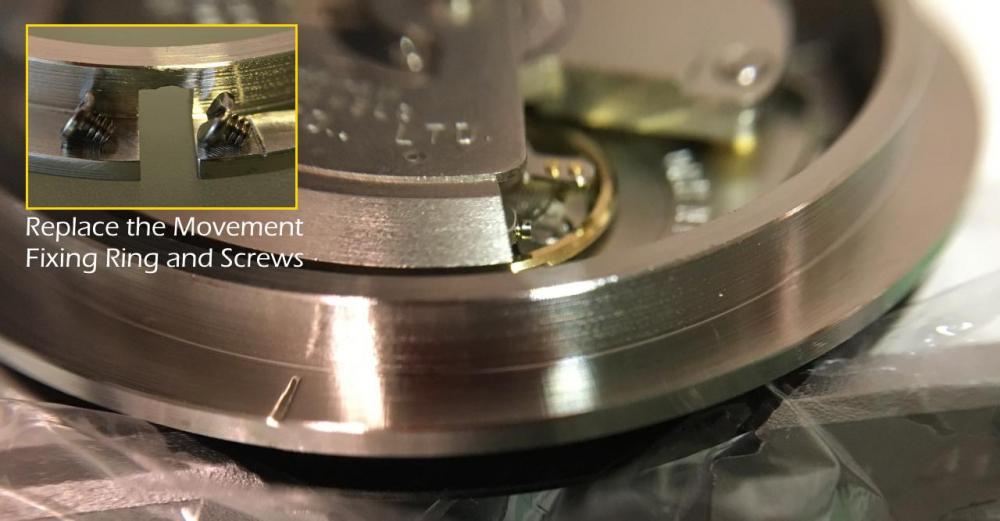

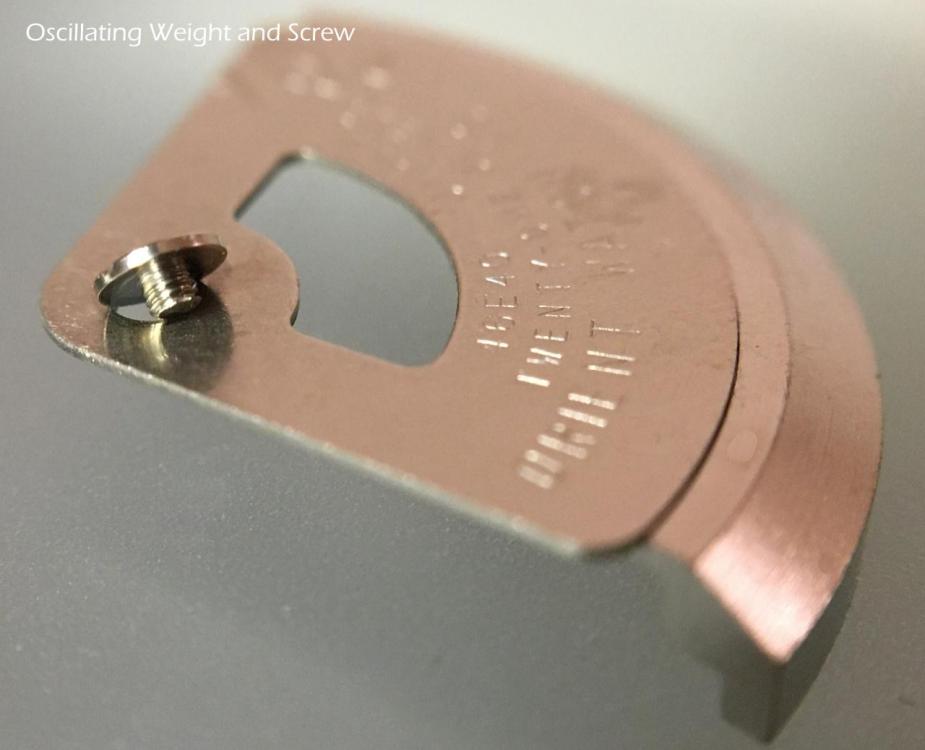

ORIENT Calibre 46E40 Service Walkthrough If you search the Internet for technical information about the ORIENT calibres, you won’t find much, not even the lift angles, not to mention spare parts. However, I did find a few "expanded view" PDFs, but that was it. The reason for this is perhaps partly that the brand is a typical wear and tear brand. The price range is between US $100 and US $300 and few would be interested in servicing such a cheap watch when you can get a brand new (or five!) for less than the cost of a service. I used the word "cheap" to describe ORIENT. A much better word is affordable. I have two ORIENT watches (this one and a diver) and they are both very well made and have proven to be reliable and accurate. I really like them and have no reservations recommending ORIENT. Simply great value for money! The ORIENT Calibre 46E40 is my first Japanese calibre to service. I wanted the classic SEIKO 7S26 calibre to be my first Japanese movement to service, but after having studied @Mark's SEIKO 7S26 service video and having compared it to the expanded view of a an ORIENT calibre similar to mine (ORIENT Calibre 46943.pdf), I saw the kinship between ORIENT and SEIKO and since I already had the ORIENT it felt like a more logical and interesting service project. I never found any ORIENT lubrication suggestions on the Internet but read somewhere that the ORIENT 46XXX calibres are akin to the SEIKO 7000 series of movements. In the service documents for the SEIKO watches, SEIKO’s own watch oils are recommended but I as you will see in my assembly pictures, I decided to use my Swiss Moebius oils to save me the money. What I appreciate the most about this calibre is that there aren’t any tiny springs (destined for outer space exploration) to operate the click, yoke, date and day jumpers as the spring tension is integrated into these parts. Quite ingenious if you ask me. So, in this respect I say 1 – 0 to the Japanese! What I do not like is the plastic parts, like the date indicator driving wheel. I don’t know why plastic parts are used but I guess they keep cost down and facilitate the design of the movement in a way that perhaps wouldn’t have been possible (or way too expensive) using metal. Did I mention that I do not like plastic parts? My walkthrough consists of many, very many, pictures. The idea is to show the procedure is such small steps that words will be unnecessary. Nevertheless, in the assembly pictures I have included the names of all parts, what oils I have used, and now and then an instruction, tip, and/or a warning. Finally, I should mention that this walkthrough isn’t intended as a tutorial but as a guide to be used by myself (and other interested WRT members) the next time I service an ORIENT movement. To learn about watch servicing and repairing I recommend www.watchrepairlessons.com which in my opinion is the best and most affordable site for learning (I’m not associated with the site in any way). So, before I get too long winded, here goes… (Please see the following posts)1 point

-

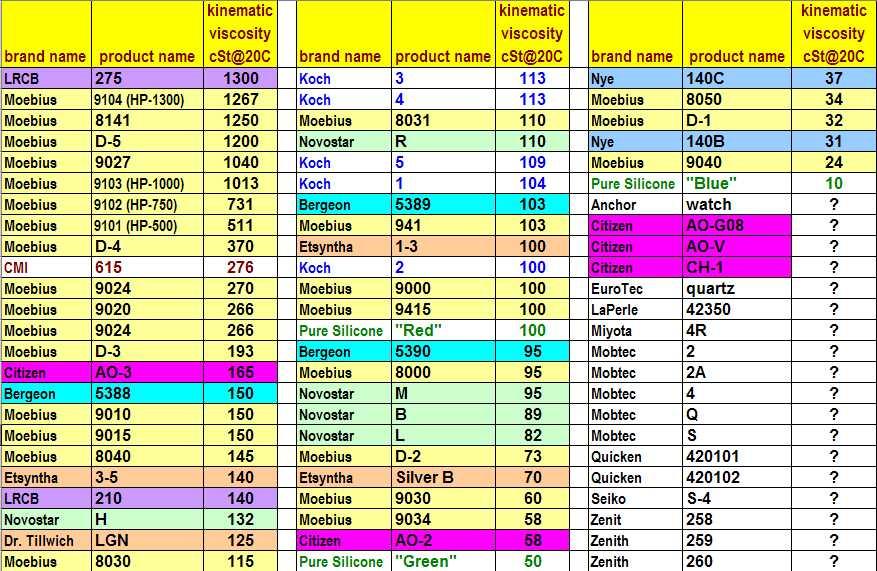

Nye did develop some horological lubricants for Hamilton back in the day, and they still make them. Moly-disulfide grease and lithium grease are probably fine on keyless works and manual-wind mainsprings. The moly might even work ok on automatic barrels, only experimentation will tell us. I vaguely recall someone recently reporting good results with a Chevron moly grease that is roughly the same consistency as Klueber grease for chrono parts. Nye clock oil is highly regarded in some circles. Nye 140C and 140B are (or were) marketed for wristwatches. There's also "Nye Fulcrum" oil which is apparently another product and the SDS sheet says it is about half derived from olive oil. My guess is that for practice it might be fine to use the nyoil you have, and if that doesn't work out and you still have budget restrictions, you could pick up a vial of Moebius 8000 for $10ish. Some of the Novostar oils are good and economical too, but they can be a little trickier to find, though there are sources in the US. Like this: https://www.watchmaterial.com/novastar-type-b-oil-ol-nov-b2/ Some years ago there was a project at another forum to compile a viscosity chart containing all of the currently available lubricants. It wasn't entirely successful but did produce some useful data. Note that the use of the silicone oils on this chart is very controversial, particularly as being "pure" silicone it is questionable whether or not they spread over time. There's no data available on them other than what is on the label, which isn't much. Only a couple supply houses carry them.1 point

-

1 point

-

Safer is to remove the balance as you did, but I am not sure if Ross has practiced pulling out balance and cock. Regs1 point

-

Hi Ross I see the members have come to your assistance, have you tried a little releasing agent ie WD40 on the release to soften any gunk before taking it apart as suggested, Although If you are stripping it to cleanand lube no problem, do as the chaps have suggested. good luck1 point

-

1 point

-

Don't cancel, it should be the same quality as the current Bergeon. The design has changed little over the years.1 point

-

1 point

-

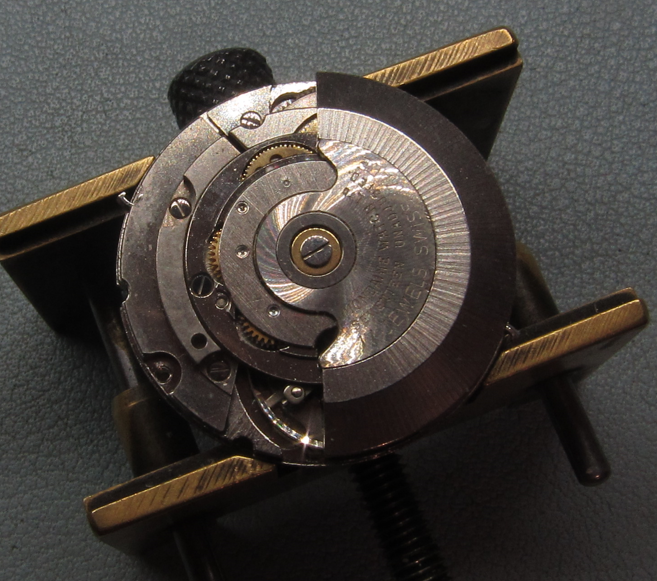

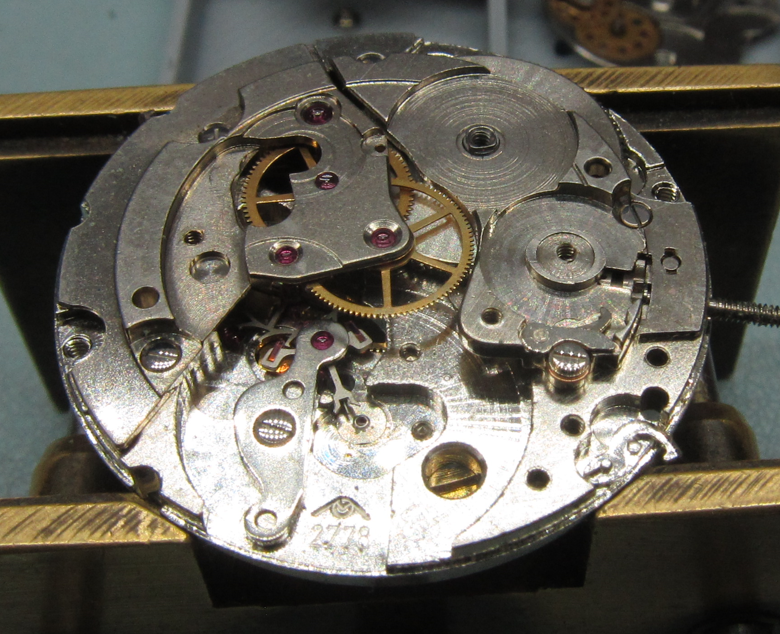

Hi Ross. ETA 2789-1 has a date ring so you will encounter fiddly springs if you attack from dial side, but not much can go wrong when you approach from the rotor side. So take pix as you go. Remove the two screws( gun metal colour) to the auto device, the module with rotor attached will come off. Release barrel power by pushing the crown wheel ring aside. Remove ratchet wheel screw Remove barrel bridge. You have access to the stem. Good luck1 point

-

1 point

-

I don't suppose you of access to a timing machine? In other words what is the watch doing as far as timekeeping goes versus what are the hands doing? Often times are not the same things so it be helpful to have a timing machine for diagnostic purposes.1 point

-

1 point

-

1 point

-

I guess i should clarify that it's likely that the pedal on my mom's electric conversion Singer is probably resistive in nature. But that was a backup sewing machine, and the rest of them were electronic, even back to the 70's. She doesn't go cheap on those machines. It was new to me, new for the element to be on edge with vents. The only markings i can find on it are "115V" stamped on the vent side, and "NM" on the ceramic insulator. The rayon jacketed twisted wire i bought turned up finally, so i've wired up the pedal properly earthed. Still waiting on a new rubber grommet for the motor housing. And i am going to have to fab up a tool to pull a rough bearing off of the motor spindle. Couple pieces of angle iron, some nuts and bolts, etc. The bearing on the brush end of the armature is gonna buzz, get hot, and cook its oil if i don't replace it. Already sourced a high quality replacement. I suspect that i could cobble an electronic speed control pedal from the guts of a Harbor Freight router speed control unit and a modified electric piano expression pedal. But there are enough unknowns in that project that if the resistive control works well enough i will just use it until and unless it ends up not working.1 point

-

Thanks, Nucejoe. I rechecked the movement on timegrapher and realized that every 5 minutes it was still jumping minutes fast per day. So I decided to take a better look at the train and found some slightly damaged teeth on third wheel and fourth wheel pinion where they meet. I counted teeth and pinion and luckily had spare parts so I went ahead and changed all train wheels except for center wheel and now the watch is staying running steady and strong. This time I left it on timegrapher for 20 minutes and no problems.amplitude also improved some. I figured this information may help someone else with this.1 point

-

1 point

-

Lets keep this a secret, I did the same, thats all Chinese ones are good for.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Hi The problem may well be magnetism causing the balancespring to stick the coils but this could also be due to oil /dirt/grease. What we require is if possible some pictures of the watch its movement and a close up of the balance area and or the make/caliber number. Armed with that information the members will be able to assist you with the diagnosis and hopefully repair. cheers1 point

-

I am very pleased to report that to my surprise, the watch came to life upon reinstalling the balance wheel. That moment is the reason I was drawn to this hobby, so I was very happy with that. With the new mainspring I installed, it seems to be ticking along very strong, although I don't yet have a way to measure. I'm going to let it wind down from a full wind once before setting it aside - to see if it continues running, and I'll note how far off it drifts in 24 hours. Thanks, I will definitely come back to this one at some point after I expand my tool collection. I am tracking staking set listings on ebay, and I'll keep my eye out for a decent micrometer also. Based on jdrichard's jewel replacement video, and seeing the size difference between the top- and bottom-side of the jewels, I was under the impression those jewels on this movement were burnished in. How can I tell for sure if they are friction-fit or burnished?1 point

-

1 point

-

1 point

-

Try here; http://www.timezonewatchschool.com/WatchSchool/Glossary/glossary.shtml or for a downloadable .pdf version; http://people.timezone.com/mdisher/WatchSchool/pdfs/TZIllustratedGlossary.pdf1 point

-

I know what you mean, sometimes these things are pretty hard to find. It's probably a bit difficult to do this as each movement has it's own type and it's parts and you won't really find one movement to show all types of parts. Here's a couple of images that should help.1 point

-

Had a few messages about the wiring diagram, so uploaded it for all to see.. super elite wiring diagram by Micky.!, on Flickr1 point