Leaderboard

Popular Content

Showing content with the highest reputation on 02/10/22 in all areas

-

2 points

-

I don't know of anything online, even some of the old course materials one finds don't seem to go in depth on it. The book The watch escapement: How to analyze, how to adjust, how to repair by Henry Fried is pretty good; I can't find mine at the moment to review it but we did use it as our text in school.2 points

-

I picked up a badly scratched and very dirty Seiko quartz chronograph (7T94 0BS0) on Ebay for next to nothing. Idea was to practice stripping down a watch with pushers, to try a few case renovation techniques and have a general fiddle. A had a little bit of an issue with the fact the previous owner had made a dog's dinner of the battery bay (that was attended to). Mucking about - I decided to give it face-lift. A sort of a nod to speedmaster mkii...or not... Anyway....I'm pleased with it... and will wear it... leather strap? James.1 point

-

Ha! I feel you. Major spreadsheet household here between my wife and me. Very few things manage to get by without appearing on some spreadsheet or another. That said, I don't use a spreadsheet to keep track of watches. I have a few dozen on hand at a time lately. I play the 404 game, and when one comes in, I remove the strap (and 99% of the time, toss it), then it goes in one of four boxes: "A Team" (successful buy that meets all of my buy criteria), "B Team" (I took a gamble and lost, was lied to, or just made a mistake; borderline throw aways, but are probably worth fettling for the cheap practice), "Keepers" (go into my personal collection), and "More skill/tools/parts required" (self explanatory). A watch doesn't come out of its box until it goes under the knife, and I work on one at a time owing in part to the limitations of other organization strategies. When a watch is done, it goes into a little plastic bag with whatever notes seem pertinent for listing it for sale, and into a fifth box with the others. If I hit a snag, or am waiting to build up a reasonable parts order, I'll reassemble as far as practical, and put it in a small plastic bag with a handwritten note into the last box saying what it needs/what's wrong/what still needs to be done/etc. Once that box is full, I go through and order whatever is needed parts wise. If there are any that fall under the tools category that I feel ready/have the funds for, I'll hunt down whatever tool. If it needs more skills, it just goes back into the box until I feel like I can handle it. In another setting, I might have a spreadsheet, but my desk serves n-tuple duty. It's my work desk (computer, keyboard, mouse, documents, etc.), watchmaking desk (fill in the blank), electronics, toy repair, etc. etc. etc. It's a roll top desk with limited space, and in order to roll out the watchmaking spread, I have to put away the computing spread, etc. If it were easy to have both available simultaneously, I might have landed on a spreadsheet approach. Admittedly though, part of the attraction to the hobby is that it's entirely analog. I do enough with computers every day ever that it's nice to get a break.1 point

-

The balance jewels need to be removed and cleaned. Old oil and dirt will affect timekeeping. While it is a bit hard to do, it is something worth doing... you will get better at this. For the moment, stick to simple swiss watches with incabloc first. Those non-shock jewels and other types of shock absorber can come later! Anilv1 point

-

1 point

-

This setup was typically used by Patek- I wouldn't be surprised if this watch has a "moustache" counterpoised pallet fork. Otherwise they're usually as John described. Have a look at the finger. They usually have a small boss on one side, that fits the center hole of the bridge. If that's facing down it will bind. Also it's probable the bridge isn't symmetrical despite looking like it, it may work better one way than the other. Otherwise, just check for burrs or debris that may be causing the binding. If all checks out, figure out if it's the finger or cross or both that are binding, and when you're 200% sure it's not something else, you can reduce the thickness of the guilty component until it's free.1 point

-

I doubt that but there are spread sheets to work out mainspring strengths etc. A good practice is to keep a notebook to make notes of date of repair any complications encountered etc. Another essential practice is to take pics as you strip any movement. I have a folder in my picture app just for watch and clock repairs.1 point

-

1 point

-

My Bergeon winders is 12.05 in the handle, and 12.00 where you measering. So they will fit.1 point

-

1 point

-

Welcome to WRT forum. Try online searching for documents on the caliber your working on, data sheet, schematic diagrams etc. Taking piictures at every stage of disassembly is useful.1 point

-

Here is another spin on that story. I had heard the first story but later got wind of it being a myth.1 point

-

1 point

-

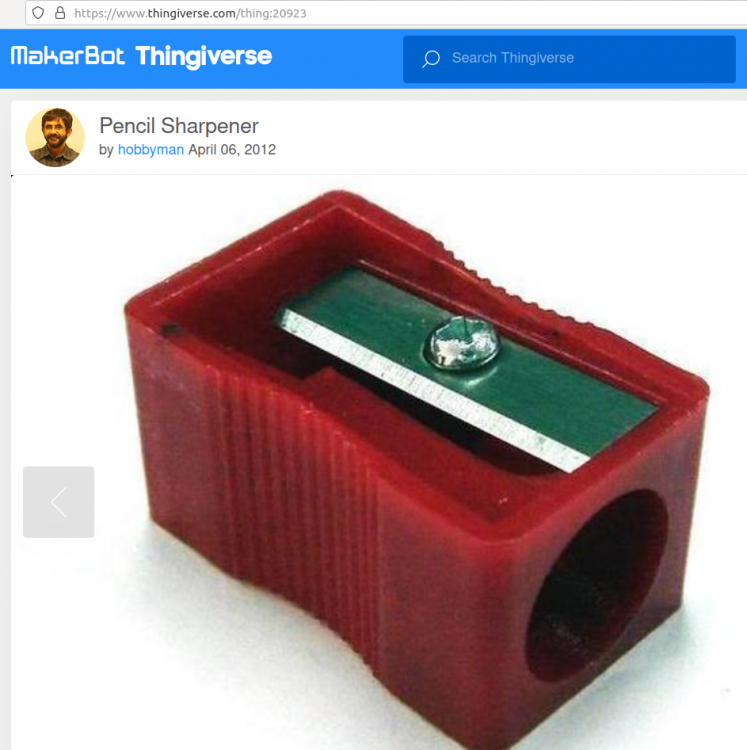

Only if you factor in my time...which I don't! PLA filament is pennies!!1 point

-

1 point

-

This post is I am afraid a common issue on this forum. Many including myself watch vids and it looks so, so easy BUT most of the vids have been edited with the flyers up- cocks etc edited out. Successful watch repair requires skill, experience and knowledge which can not be gained by watching the pros vids. Anyone considering watch repair start on a easy low cost movements such as a pocket watch and treat it as part of the learning curve. Handling a screwdriver and small parts requires skill and patience, assembling is yet another skill that can destroy a watch if not carful. In this case a stuck stem would not be a huge issue for a watch repairer with experience. However it can also be extremely satisfying when the final result is a dead movement has been transformed into a up and running movement.1 point

-

Oh Gosh, you are so right. For Seiko, read Sekonda. Sorry folks. Bad day at Black Rock. Thank you Ross1 point

-

I think KWONG YUEN's tools are relatively good, their screwdrivers and some gadgets are great, but I don't know what platforms they sell on. BIAO ZHUN and YONGJIU, TIANJIU, RUIHUA tools are cheap, so don't expect too much from their quality. LING HUI is a brand that has appeared recently, and their quality is relatively good. Mainspring Winders There are many suppliers, their manufacturing costs are not the same, I think they are all produced by the same factory, you'd better ask what material the center shaft is before buying. Best Mainspring Winders There should be no purchase channel, we contact the purchase in WeChat, and it is relatively not cheap.1 point

-

Watch some of the videos from Esslinger. They expain the basics quite well. You can also check out the videos in the resource section of this forum. But anyway, breaking things is all part of the learning process. We learn from our mistakes. Whenever you break something, find out what went wrong and don't do it again. (Yeah! Right!) I just broke a mineral glass crystal moments ago.1 point

-

Welcome to the forum Julie. And to your husband. Post up some photos of the watches that you have as well. Not just the tools in question.1 point

-

Hello Juec and welcome to the forum, you will not be short of help as we always endeavour to solve he many problems we get.1 point

-

1 point

-

Bergeon Platax No. 2677 How to Guide.pdf Bergeon Platax No. 2677.pdf Background In the old days, before shock protection, I’m sure replacing balance staffs was one of the most common tasks for a watch repairer. They probably replaced several staffs every day. There are many ways to remove a balance staff. One very convenient and quick method is to use a Platax tool. However, this method is considered a destructive method by some repairers, meaning you can only replace the balance staff so many times before the hole in the centre of the balance wheel will become too wide. You can read a more about it here. I guess I would think twice or trice before using use a Platax tool on a Philippe Dufour balance. Anyway, for my standard ETA, Sellita, Unitas, Vostok, etc. balances I have no reservations about using a Platax tool. One dilemma with the Platax tool is that it has been discontinued by Bergeon (No. 2677). The offerings on eBay are few and far between, and as with everything else Bergeon, they are silly expensive. I would feel a bit embarrassed to let you know what I paid for my used copy which probably has seen hundreds if not thousands balance staffs in its life. Anyway, as with most everything else Bergeon, the quality of the tool is second to none, so I’m pretty sure I’d get my money back (if not more) should I decide to sell it in the future. That’s a major benefit with quality tools which makes it a lot easier to pull the trigger. So, how often do I expect to use this tool? Well, as all my watches so far have been equipped with shock protection and as I expect most future watches that I’ll be working on will be as well, the answer is, not very often. As a matter of fact, I expect it to be so rare that I might forget how to use my Platax tool when I need it the next time. For this reason, I decided to document my findings and that is what you’ll find in the attached PDF document. Do note that the document isn’t a tutorial, it is my personal notes, gathered from watching two YouTube videos (see below) and my own thinking and experimenting. For this reason, it is possible I got something backwards. If so, please let me know!1 point

-

I'm the other extreme. i purchased a Chinese set that look like Bergeon, I have used them for four years now and only dressed them once. That was only because I made a jig for sharpening them. They have never bent or chipped in all the time I have had them, and all for £5.29 delivered. The proof of the pudding is long term use!1 point

-

1 point

-

I agree with respect to functionality but a.mini with a rolls royce badge is still a mini both will get granny to the shops I will save up for "horotec made in france" (joke)1 point

-

Does it really matter whether or not they are genuine Favourite. For a long time I used a cheapish set marked A*F which have served me well. When a watchmaker friend sold up he let me have a Bergeon set and as far as I can tell, apart from the knob being a little smoother, there isn't a lot of difference. You need to be using them all day on a professional basis to really say you can distinguish differences. Another point is that I think the really important thing is the quality of the blades. If the ones you have turn out to have faults then just buy new blades and if you want supposed really top quality then buy Bergeon ones but I'm sure it will be a long time before you can tell the difference. It's a known fact that we all get carried away with acquiring tools and we strive for the best but it"s been pointed out many times that "the best" i.e. Bergeon are ripping us of to a ridiculous extent. You have a box marked " Favourite " who's going to fake that ? Accept them for what they are. Use them to repair some watches and be happy. Stop worrying about brand names, it doesn't matter. What does matter is how well you repair watches.1 point