Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/22 in all areas

-

5 points

-

That is not a Seiko mov.t, it's a Russian craba / slava, and the number is not an ID but a serial. Idon't know if can find the parts but a donor watch or mov.t could be easier.2 points

-

Hmmm.... very strange. This doesn't look like a Seiko at all. In fact it looks Russian. Like my Sekonda that is using a Slava 2414 movement.2 points

-

2 points

-

1 point

-

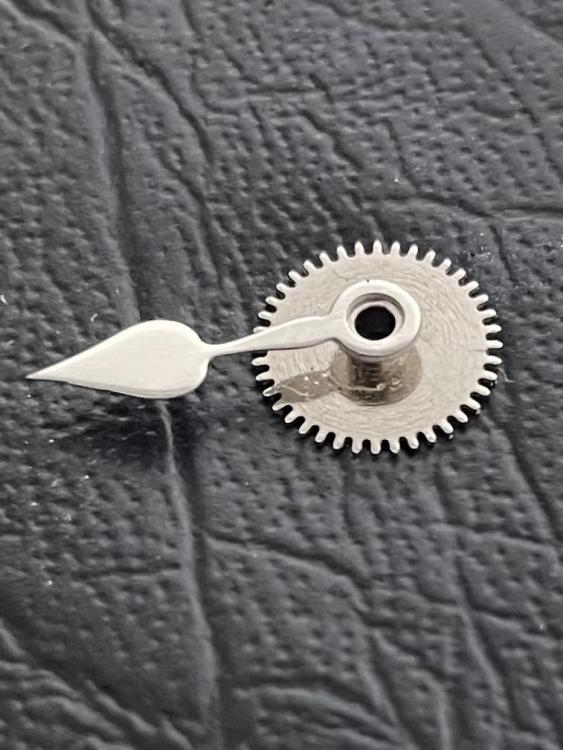

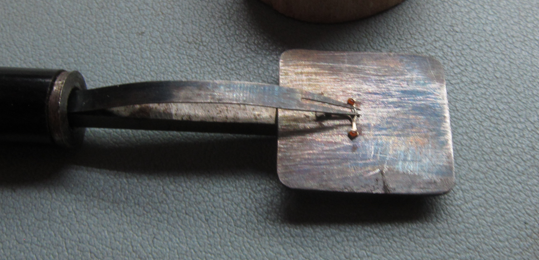

Got this practice watch identical to another watch I was doing for a friend. Wanted a backup plan!! Anyway, when cleaning I discovered the pallet jewels were loose and the shellac was dissolved in one-dip. So...time to learn a new skill. Fortunately, I anticipated this many months ago and bought a lifetime supply of shellac!! More like ten lifetimes. Here in these pictures are the results. I hope I did it right. Was careful to pay attention to location and orientation, but, hey...coulda got it wrong.1 point

-

1 point

-

This post is I am afraid a common issue on this forum. Many including myself watch vids and it looks so, so easy BUT most of the vids have been edited with the flyers up- cocks etc edited out. Successful watch repair requires skill, experience and knowledge which can not be gained by watching the pros vids. Anyone considering watch repair start on a easy low cost movements such as a pocket watch and treat it as part of the learning curve. Handling a screwdriver and small parts requires skill and patience, assembling is yet another skill that can destroy a watch if not carful. In this case a stuck stem would not be a huge issue for a watch repairer with experience. However it can also be extremely satisfying when the final result is a dead movement has been transformed into a up and running movement.1 point

-

Remember: shellac dissolves in alcohol. You can ease up to your desired level of clean with an alcohol soaked Q-tip or similar. I've noodled on whether or not it might be possible to do the reverse as well: rather than melt the shellac and glob it on, dissolve it and brush it on in thick coats sort of. I mentioned in another thread recently that I also dabble in luthiery/fine woodworking, and French polish is one of my go to finishes. A French polish is mostly a technique, but the material aspect is just shellac dissolved in ethanol, and the terminology is "X# cut", i.e. 2# cut which is 2 pounds of shellac flakes to a gallon of ethanol or something along those lines. It doesn't keep, so a gallon is way too much for my purposes, hence the fuzziness on the specifics. It's definitely more art than science, so you get quite a bit of wiggle room. The Brits probably have a name for things of the sort, and it probably rhymes cognitively with "that'll do". Anyway, my thought was that it might be possible to make up a really heavy cut, and brush it on, or maybe use a small dropper/pipette (utilizing capillary action rather than an actual drop). You'd get better penetration into the joint via capillary action (assuming it's not too viscous), while adding almost no mass or mess. It might take a few applications to get where you want, and you'd be wasting the majority of your shellac/hooch, but as LWS discovered, shellac is dirt cheap on the scale we're talking here. The booze is a bit more pricey, but shellac is totally non-toxic and edible (it's often used to coat apples to keep them shiny and marketable), so....1 point

-

1 point

-

Looks like adjustable reamers for crowns and/or crown tubes for pocket watches.1 point

-

1 point

-

1 point

-

Just from the look of the fork they appear to be far too "out", the gap between the rear of the pallet jewel and rear of the fork slot is generally quite small. But you will only know if you check the function of the escapement.1 point

-

Heat a piece of shellac in the flame until it just melts (don't burn it), and poke a sharpened piece of pegwood in the gooey shellac and pull away. You'll end up with a long fine thread of shellac on the pegwood, which you can shorten to a usable length by breaking off the excess. Now you have an applicator that makes it very easy to apply just the right amount.1 point

-

Worth to remind however that 99% of current watches having a flat mineral crystal are sized in steps of 0.5mm not 0.1. If measuring the gasket tells otherwise be in doubt and measure again.1 point

-

That is way to much, you only need a tiny amount. You know what they say practice makes perfect1 point

-

1 point

-

1 point

-

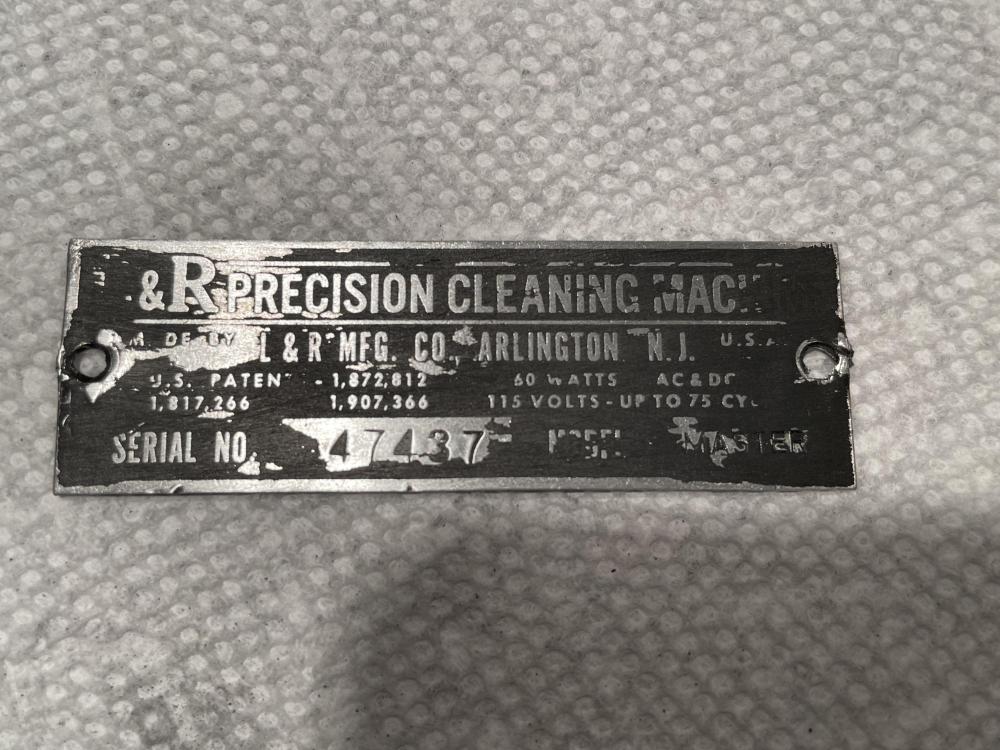

Update so far.... Primed, 3 coats of Hammered paint (actually 4 coats as the first coat was Gray Hammered and thought the gray had a darker tint but it didn’t so went with Hammered Black, 3 coats). Then I added 3 coats of lacquer and everything was looking good, no drips or runs. But then after an hour I noticed a ring around of a run and here I thought I was getting better, but after thinking about it more and also seeing inside where you put the jars, I think the lacquer did end up reacting and causing the run, so lesson learned. So I have two options regarding the paint, strip and do over or be glad it is better than it was before, see pics below. I am going with the 2nd option, not because I”m lazy but because I plan to use this as my goal is to just do preventative maintenance (update switches and wiring) as well as make the appearance better than it was when I got it and I feel, even with the runs, I did that. This lead me to the next step, the panel (where the switches and dial are) and the manufacturer’s tag (metal tab on motor top housing). At first I tried one of those oil paint pens and while I was able to scrape off the lettering, the rest looked terrible. So I went with a Semi-Gloss black, just 2 coats, and then had to find a way to expose the lettering. I really wanted to use sandpaper but the lettering is hardly raised at all and when I tried it with the oil paint, it didn’t work. I then tried a toothpick and just went around and scraped slowly and BINGO, it worked great. Does it look like factory, of course not, especially for the smaller lettering at the bottom as the lettering is so close, but it does look better than what it originally looked like, pics below. However the manufacturer’s tag has such small writing, the toothpick really didn’t work as well, so I tried sandpaper at first (2000 grit) and while it started to work, I guess due to the letters being so tiny and not raised much, it took some of the background off. I then took the route of using a Scotch Brite pad, and this worked A LOT better. I think I will redo the paint job on this and put a couple more coats and then do the Scotch Brite pad again. If anyone has any tips on how to make the main rod that holds the motor a little shinier or what to use to clean the spots off of it, looks like water spots, please let me know as I’ve tried steel wool as well as metal polish, but that didn’t work. I don’t have a buffing wheel, only a Dremel sized one, and thinking that is the really only way to shine it up. I mean it’s not bad from a distance. Well that’s the update so far, next goal for hopefully tomorrow is the wiring as I got my Rheostat and switched in today and didn’t need to replace the ceramic resistor nor the heating resistor. I’m going to let the unit dry for at least 48 hours (can says 24 for fully dry) due to paint and lacquer but just after 2 hours, it’s was dry to the touch. Hope everyone this helps someone in the future and hope everyone has a great night, stay safe.1 point

-

I'm strange. I've worked on a very wide and eclectic variety of watch makes, from very cheap - to so extremely expensive that I was quite nervous when stripping them. But my own collection is rather small. Maybe 12 pocket watches and 8 wrist watches. But I like to wear or carry each one. Partly I wear them because, at my insurance job, it's a data-secure environment so we can't have a smart phone at our desk (because it can record information) so we tell time with our watches. But mostly, I just like them. I prefer them. I have one which is an old key wind/set Vacheron & Constantin (made before they dropped the "&") which could be worth a great deal. I cannot afford to have it appraised yet. But I'm in no hurry; I'm not selling it. I adore it just as it is, and carry it now and then. Maybe someday, I will learn how much some stranger would try to pay me for it. I have an Elgin in an 18k case too. And a gorgeous silver Longines from 1919. In all, they are likely worth far more to me than to anyone else. All mine are serviced and are as accurate as they are capable of being. So I figure, why not use them, and show them off a bit now and again?1 point

-

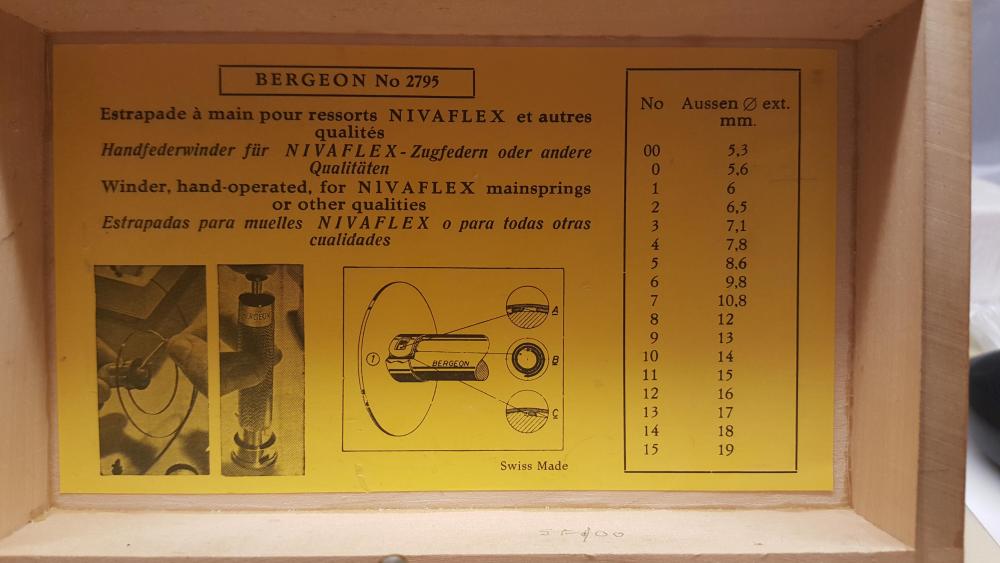

I think KWONG YUEN's tools are relatively good, their screwdrivers and some gadgets are great, but I don't know what platforms they sell on. BIAO ZHUN and YONGJIU, TIANJIU, RUIHUA tools are cheap, so don't expect too much from their quality. LING HUI is a brand that has appeared recently, and their quality is relatively good. Mainspring Winders There are many suppliers, their manufacturing costs are not the same, I think they are all produced by the same factory, you'd better ask what material the center shaft is before buying. Best Mainspring Winders There should be no purchase channel, we contact the purchase in WeChat, and it is relatively not cheap.1 point

-

1 point

-

Yes, readers here know about the different versions as discussed in some previous posts of this topic.1 point

-

1 point

-

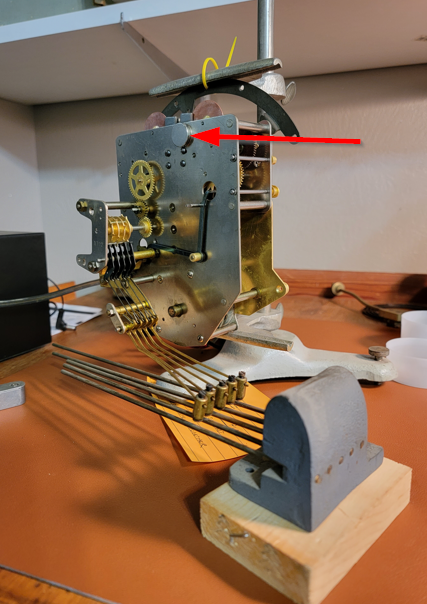

Andy, you win the prize that is exactly what they are for. Those blocks are magnets. When a conductor passes through a magnetic field, a current is induced which in turn creates a magnetic field. The fields are opposing so that resistance is placed on the spinning disk. Take a neodymium magnet and drop it down a copper pipe. It defies gravity!! Falls slowly. Same concept. I noticed that one of the chimes was going too fast. I suspect that the permanent magnet had weakened. I just put another small neodymium disk magnet on the plate...problem solved.1 point

-

Recently while scrolling through eBay, this watch caught my eye. It's a dead ringer for the one my father wore for most of my childhood (band not withstanding). I'm not sure what ever happened to his but this "as-is" "does not run" watch that shipped from only miles away from my home town, ment something to someone. For all I know, it could actually be his. It's a all stainless steel, Kaltron, 17 jewel, selfwinding watch with a Felsa 4007N movement. Not overly expensive in its day but very smart looking and dependable. It's failure to run resulted from the second hand arbor being seized within it's bore. A few nerveracking hours of chasing three small springs around my bench last weekend and it's up and ticking again. Thanks for all of your support. Yes, I know the date is wrong. Shane1 point

-

It's the 3 I have I have two both with the milling attachments and loads of accessories. Yo can do your re-bushing on what you have I expect it's all most the same as the 3 if so it will take the center wheel of a longcase clock and it will also hold the barrel of a longcase clock. If you are a little bit apprehensive about using the tooling you could just use a file to get the right diameter and finish with a smooth emery stick. I suggest you start using the cutting tools on brass as it is much softer then steel.1 point

-

Hi, Levine: I could be wrong but my understanding is that there is a piece in the staking kit for punching out the balance staff as well as a piece for re-establishing the rivet once the new staff is in place. I have watched this same procedure done by a couple of different folks on YT and apparently the toughest part is getting the hairspring, et a,l dismounted to remove the broken balance staff. Time is a craftsman's finest tool, so use as much as you like. Best Wishes, Bruce1 point

-

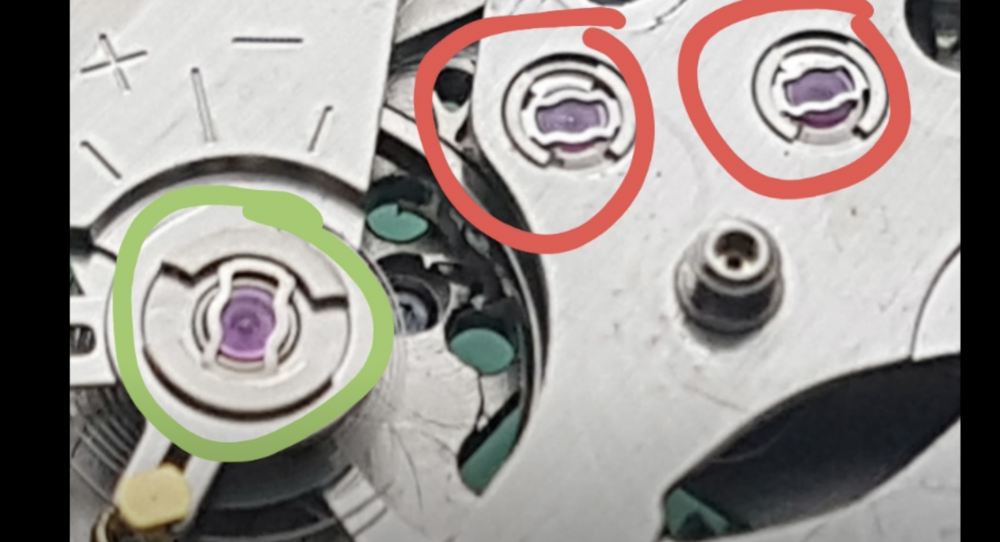

I recommend this. You can hacksaw to size, easy to put a small taper on by using a fine needle file. The poor devil has been through the wars, nasty repair to the crutch and a very bad bush to the pallets that has been filed down. The ones in red are causing the trouble as you point out with the red mark, I ones in red are ones that have been repaired and are not in my option good repairs, the one in blue also looks as if it need to be looked at, or it might be the photo. https://www.etsy.com/uk/listing/876146296/clocks-bushing-wire-8x-hollow-brass?gpla=1&gao=1&&utm_source=google&utm_medium=cpc&utm_campaign=shopping_uk_en_gb_a-craft_supplies_and_tools-other&utm_custom1=_k_Cj0KCQiAxoiQBhCRARIsAPsvo-z3JTiNCS7-tDJkO_dMHZHGkRnHZOGqkDXXxv-udYjTyHwvGHyVK_waApRGEALw_wcB_k_&utm_content=go_6479444532_72974637810_380837596062_aud-371913912633:pla-295462056907_c__876146296engb_142203909&utm_custom2=6479444532&gclid=Cj0KCQiAxoiQBhCRARIsAPsvo-z3JTiNCS7-tDJkO_dMHZHGkRnHZOGqkDXXxv-udYjTyHwvGHyVK_waApRGEALw_wcB1 point

-

1 point

-

1 point

-

Hi When working on watches there are many things get your goat, removing backs and bezels and re fitting them as some are very hard to get back on. Pictured below as a few of the required tools. As always there are cheaper and ones that function well for the occasional user Case op1 will remove bezels and backs and can be had for around the £30 mark. A supplier of the chinese copies Is Ali Express an bit like the Chinese amazon. Hope you find this info useful cheers1 point

-

That same tool is sold on a well known Chinese site for only half the price. I always use a stanley knife in same way as the razorblade methode mentioned above.1 point

-

1 point

-

I agree with @Nibbler and @jdm - if you don't have the skills yet, leave the smaller ones in place. I really struggled the first time I refitted them. The blob of oil in the centre of the jewel end up all over the place. I can now refit them easily enough (usually) but do it under a stereo microscope, and I don't oil the jewel before fitting the spring. As I don't have an automatic oiler, I sharpened an old oiler to a point which I use to feed oil through the jewel hole. Capillary action takes the oil through the hole. I then have to clean the hole side with some Rodico.1 point

-

From a donor watch. The jewels on the main bridge are not to be removed when cleaning, as the spring is too small to be refitted without trouble, especially for beginners. Next time you embark in doing some watch work, even it if seems easy to you or videos make it seem easy, is better to ask here for advice first.1 point

-

Your comment got me thinking and I passed. I'm really glad I did because a NOS C&E Marshall came up, totally unused and 100% complete. Including newspaper packing from Wednesday May 4th 1949 The packing paper was from THE LIFE newspaper Chicago Ill. (Same as the company) Here is an interesting thought. I bought in on May 7th 2021 and it arrived yesterday.1 point

-

If I didn't have a microscope already, this is what I would get. https://a.aliexpress.com/_Bf9BlrRT Get a 10X eyepiece, a 0.7X - 4.5X zoom objective lens. If you want to increase the working length, get a 0.33X or 0.5X auxillary lens. You'll sacrifice some magnification for for the increase in working length. But it'll be more than enough for watch repair work.1 point

-

Hello all! I have been struggling with the matter of mainspring winders for a while and I want to share some of my experience with Bergeon mainspring winders. First, there two major types: the old ones, with a spoke on the arbor (30081): and the newer ones with a recess on the arbor (Nivarox): Side by side #6: to be continued...1 point