Leaderboard

Popular Content

Showing content with the highest reputation on 02/05/22 in all areas

-

I use a safety razor as littlewatchshop explained above. Uncase the movement before you start on the rim to reduce the risk of damage to the dial in case of mishap. Good luck3 points

-

After a number of false starts I've got a hairspring in to better condition that where I started, following the techniques on the excellent Watch Repair Channel. I've sharpened some inexpensive no.7 tweezers and used them with a ground down and polished medium oiler. The starting point was this: The spring is non concentric and rubbing close to the stud. The stud is wonky and the end curve doesn't fit. Also it was kinked off flat 270 degrees back from the stud. I've got it flat, fairly concentric and fitting the regulator. My only concern is it's a little off concentric and has some small kinks in it. I'm afraid to continue in case I make it worse. The bit I've really struggle with is the technique to flatten the spring by means of gripping and twisting with two tweezers. Each time I do so, I seem to introduce a kink which I have to correct. The end result now seems concentric with a slight increase in the gap on the final coil. It fits the regulator. The bit I'm dissatisfied with is the slight kinkiness where I flattened it, but I'm afraid to keep manipulating the same spot and I'm at the limit of my dexterity getting it to this stage. I'll refit it when I finish cleaning the movement and see how it goes.2 points

-

No 4, tweezers. Gives you excellent control over the workpiece. If you don't drop it and use it for hairspring only، it will last a lifetime. I drop the spring on a white sheet of paper to see details in better contrast. Good luck2 points

-

If you are paranoid...as I am often in these situations...use a safety razor to start the process of lifting the bezel. Go around very carefully and "generally" a gap will form. Then you a case knife. It is scary...unless it is a junker.2 points

-

Small success story... not long after my wife and I were married (25 years ago) we were walking through Fordingbridge UK and the small jeweller's shop was closing down. In the window they had a display of new old stock Oris watches including an SA7445 with an exhibition back... later on that year, my wife presented me with the 7445 for my birthday. I wore the watch every day for 10 years, had it regularly serviced. However, about 15 years ago I was giving a lecture (cell biology (yawn)) in Belgium and whilst waving my hands around enthusiastically I felt something go cataclismically "sproing" inside it. The auto-winder span round and it died. The watch has sat in a draw neglected since. I've made half hearted attempts to get it fixed but no watchmender has been interested. Recently have been reading around, watching various videos, acquiring tools and started renovating quartz watches. Last weekend I plucked up the courage, sharpened my screwdrivers, got out rhe tweezers, loupe and rodico and investigated the Oris... I found that the all the screws in the rotor and the automatic mechanism were loose and the click had become disengaged. After a couple of hours I reassembled the auto wind, re engaged the click ratchet but the watch still didn't work. Then I noticed that one of the screws that holds the auto wind mechanism in place was missing. As I'd never had the watch apart before the logical conclusion was that the screw was somewhere inside. So... I carefully disassembled everything again and started to delve deeper into the movement... sure enough... there was the screw, jammed in the gear train. Gentle prodding and coaxing loosened it and I was able to shake it loose. Hey-Presto... the watch immediately started ticking and woke up after 15 years of suspended animation. After reassembly and ensuring everything was screwed tight... I proudly showed my wife the fruits of my labours. Sadly... she can't remember giving me the watch in the first place... oh well....1 point

-

I am not really happy with this but it could have been worse. This is a sweep second pinion that had a broken pivot. I already found the replacement and really do not need this, but I thought it would be fun to try. I started without doing any annealing. Then realized that I needed to. Just heated it over an alcohol burner. I know there is an art to knowing when to stop...give me some time. Also, failed to center properly. Tomorrow, I will turn a pivot--needs to be 0.2mm. I was thinking about @nickelsilverwhile I was doing this...knowing he could do it in minutes...likely with his eyes closed. One thing I got from this was some confidence building (even though I broke the 0.1mm drill bit grrrrr).1 point

-

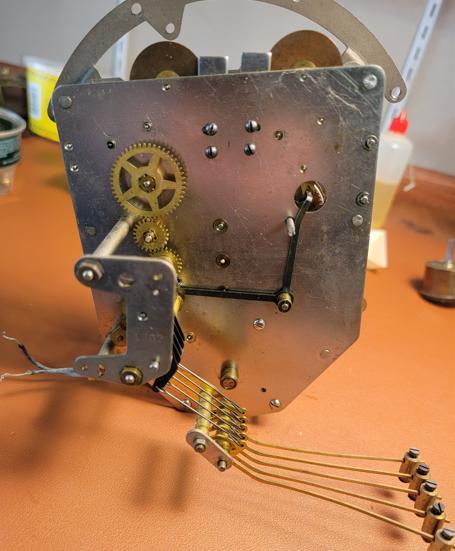

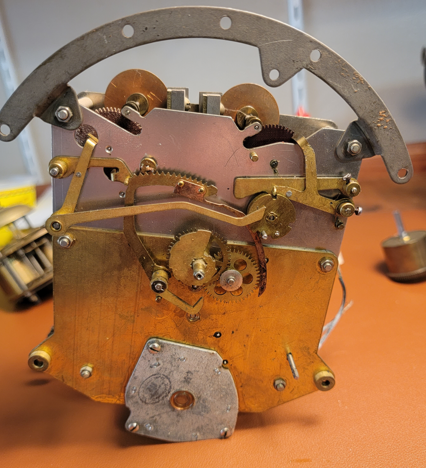

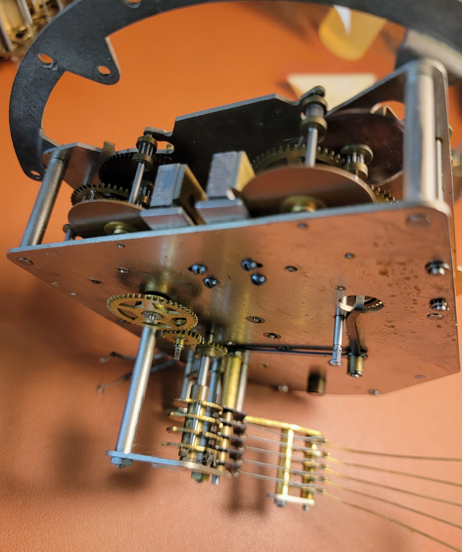

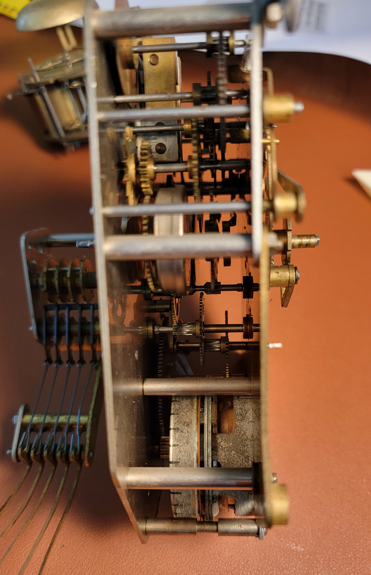

On to my next clock project!!! Before opening this up, I figured it to be a boring motor replacement with a cleaning job. Nope. I think this will be interesting...at least because of the novelty. May be time for a little brain teaser, no?? Looking at the pictures, you see two round things protruding above the plates. They are made of copper. What are they for? Put your thinking cap on. OK after you figure that out...anybody ever work on one of these? There are a couple of enclosed mainsprings, so that is something I will have to explore (to open or not to open) when I get it apart.1 point

-

That synchronous motor at the bottom. It runs but I am thinking either replace it or service it. Has anyone ever serviced one of these? --edit--It is trivial. Just remove the rotor and clean it, give it a little oil and done.1 point

-

It might be wise to take the hands off first in case you damage them.1 point

-

I'm pretty sure it's best not to just add more oil to a dirty movement as any debris will remain and further wear the pivots. Probably best not to use it daily until you're ready to service the watch properly.1 point

-

I don't suppose I could have the case number? Or even better the serial number found on the back of the case so I could look up something?1 point

-

Thank you!! I will try with try warming up a thin screw driver. If I understood correctly, I should try to burn a hole through the outer part of the crystal in order to access the tension ring and push it out, right? If that doesn't work I will try gluing a flat plate to the upper rim of the remaining crystall and pull when it dries.1 point

-

There are watch repair tools you just can't work without, on which you should spend the budget you have considered, in a case like this alternative approach works, so we save.1 point

-

With the 'tight fit' you should be able to turn the minute wheel on the barrel with your finger and thumb. The tighter it is, the tighter it feels when you 'hand set' the hands and looser that friction is, will feel sloppy and loose when setting the hands. It takes a bit of practice to find that 'Goldilocks' spot of how much friction to create with the staking tool.1 point

-

Nice! Just keep at it and don't lose hope. It also helps to take a break and do something else as enlightenment is usually only a few hours away. I've just been fighting through two movements with screwed up hairsprings. And I'm the one that screwed both up by trying to adjust Beat Error and have the tweezers slip. Lots of swearing, crying and gnashing of teeth. I think I ended up in the fetal position under my bench at one point (but only once). I consulted Mark's video's and training videos religiously. It truly is intimidating doing work on hairsprings when you starting out like me, but I learnt a lot taking the hairsprings off the bridge and figured out how to identify rubbing of the coils against each other and/or the bridge on a Timegrapher. I can kick myself in the nuts for screwing up, but I'm glad I did it as it gave me more insight into how hairsprings actually work.1 point

-

When it comes to hairspring work you shouldn't expect the best outcome working with poor quality tweezers. You should stop using this tweezers before you get used to it, purchase good quality dumont for hairspring work, to see the difference and discover farther limit of your dexterity and stay with one size/ type twèezers. Regards1 point

-

Thanks for the replies and video. The video made it really easy to understand their purpose.1 point

-

Remainder of crystal sits in gap between tension ring& the case, heat up a thin balde screwdriver to burn down a hole in the crystal so to pry the ring out. Good luck1 point

-

If you were careful enough, you could place a thin film of glue (2-part epoxy or cyanoacrylate) on a flat plate and then glue the rim of the crystal to it. Then lift. This crystal will have a ridge on its edge, so you may have to be slightly sudden when lifting.1 point

-

Welcome to WRT forum. There should be two dial screws on the side of the mainplate. see pic. https://cdn.watchrepairtalk.com/monthly_2020_03/20200308_155755.jpg.eb75e8674909141c1ad22124df19533f.jpg1 point

-

These are for rounding the edges of jewel settings or jewel holes on plates. You simply stick it into the hole and then twist it in a circle grinds off the edge without an issue You simply stick it into the hole and then twist it in a circle grinds off the edge without an issue1 point

-

1 point

-

Masters of contemptuous greed. Try offering $20 for an answer with all vowels stripped?1 point

-

They are used to countersink any holes, not just for making oil sinks in unjeweled holes. As you can see in Dean's video above, he has given the jeweled centre hole a decorative chamfer around the jewel, and he has also chamfered the screw holes. It makes an attractive contrasting surface finish and a neat transition from one surface to another.1 point

-

These would be used mainly on clocks, pocket watches and unjewelled plates.1 point

-

There's a good example of them in use here at 7:30 min:1 point

-

I'm sure this makes perfect sense to most people, but I'm not totally following. Is this for unjeweled pivots? Are they used like a spoon drill?1 point

-

OK. So, business mind kicking in here... A [b][i][u]SUBSTANTIAL[/b][/i][/u] percentage of the market price of a number of the name brands, i.e. Rolex, is tied up in the logo (I'm intentionally oversimplifying, but not by much). What's to stop someone from making an exact copy of the same level of quality, and selling it for a more justifiable price? You're just as deep in the manufacturing costs, but engineering/R&D is effectively just the cost of getting your hands on one to reverse engineer it. It wouldn't be an homage or anything. Hell, be transparent about it: "We copied [such and such caliber] to the last detail with the same level of quality, and just didn't put the badge on it." Completely legal according to the above. Why would that not sell like hotcakes? Faux exclusivity, marque chauvinism, etc. are certainly selling points for a lot of people, but for what I imagine is majority, it would be a no brainer.1 point

-

That's an ETA 2789. You can find additional information below. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&2&2uswk&ETA_2789_11 point

-

Watchmakers lathes are different from machine shop or even model engineer ones, where in many cases the use of collets is unknown. An error of 0.01mm really matters, but would be negligible in many other applications. Precise and beautiful items, worth to be collected as well.1 point

-

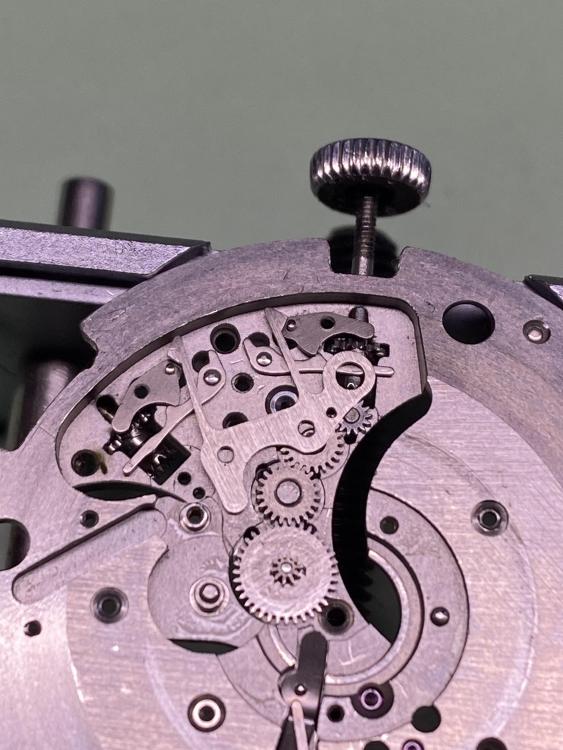

Hello fellow watch repairers, a few days before christmas I scrolled through a website for used stuff and came across an unbelievable offer for a vintage JLC Memovox for just under 1000€. It said that the dial was restored but for this price I just couldn’t say no to it, although I feared that it might be a scam. So on the twenty-third of December I drove four hours to pick it up, still with the feeling that it is to good to be true. But everything worked out well and I bought the watch what makes me the proud owner of my first JLC: And with a new strap it was a really lovely piece: At first everything worked well but after a few days the alarm wasn’t functioning anymore. Diagnosis: broken alarm mainspring. So I had to replace it and give the whole movement a service. The movement itself seemed to be in good condition and marks in the caseback showed that it was at least serviced a couple of times during its lifetime: Here a some impressions from the stripdown: And indeed the alarm mainspring was broken: I cleaned all the parts, replaced the spring and reassembled it. Now the alarm works flawlessly again, it is running nicely and is ready for its next life chapter. I never worked on such a valuable and complicated watch, so I‘m really happy that everything went well and that the watch is working again. I hope you enjoyed this short report!1 point

-

1 point

-

Did this only on one watch so far and didnt use a special tool. Turned it anti-clockwise with a very fine tweezer end about 45 deg, then just fold it up like a inca. Didnt take it out.1 point

-

Check the end stones, they generally are domed on the outer side and concave on the inner. The idea is to benefit from the said diference. End stone on the dial side is set in a retainer plate, remove and flip it over, so to have the domed side of end stone facing balance pivot, you have reduced the end shake. Though this trick might be frowned upon, it works and extends the life of the staff for a good ten years of running. Hopefully in future you will have acquired the skill and a staking set to replace the balance staff. Mark Lovic teaches you how to replace a staff and we are your classmates here. Regs1 point

-

To understand part of the problem we need to go to the link below and look at the size chart. It's only part of the problem because of the thickness of the movement. So a modern replacement watch would have to be the same size or it could be smaller but the thickness will be wrong. Because it's a military movement they made a lot of them you could keep an eye on eBay and see if he can find another movement. But the military movements tended to have a hard life and finding one in good running condition is a bit problematic. Then from your description of the balance wheel it's probably a broken balance staff and of course a complete overhaul. It's very common for these watches the end up with broken staffs because the balance system is not shock protected like modern watches. https://blog.esslinger.com/watch-size-ligne-conversion-chart/1 point

-

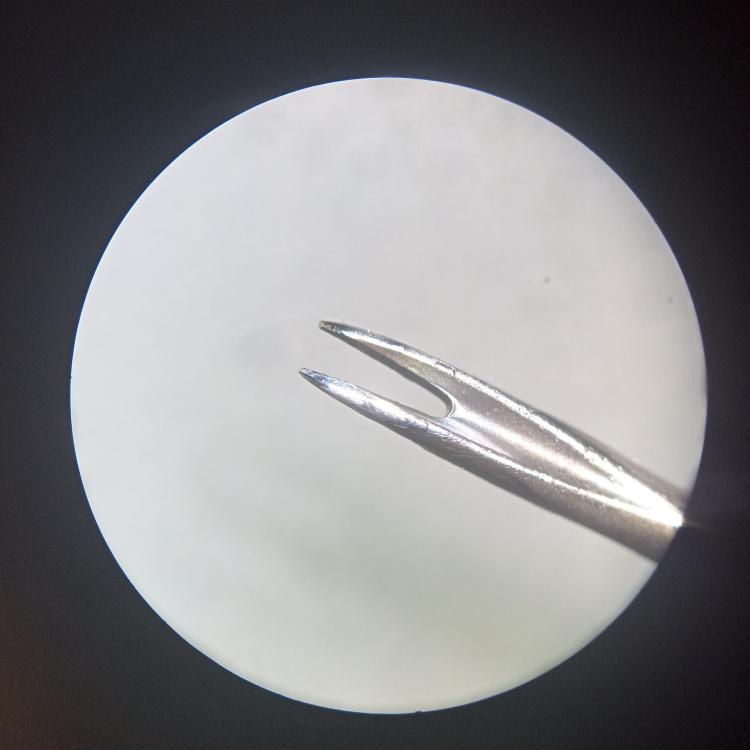

I read somewhere that old watchmakers trick was to make a fork tool out of a sewing needle. So I made my own and working with diafix has never been easier. I don't even need rodico to keep the spring in place, you have such a good control with the tool. When replacing the cap jewel and finally closing the spring I use tweezers to press the little tab in. So the tool is a sewing needle glued to a peg wood. Eye has been cut and filed/polished to final shape. I initially made one with longer prongs that were bent more but it was prone to breaking and you have better control with shorter prongs anyway.1 point

-

Nice result. The other handy thing that you find with stem extenders is that they can be found with different sized male and female threads, so if you have a crown that you like but it has the wrong thread size for your stem you can still couple them up with the right extender.1 point

-

0 points