Leaderboard

Popular Content

Showing content with the highest reputation on 02/04/22 in all areas

-

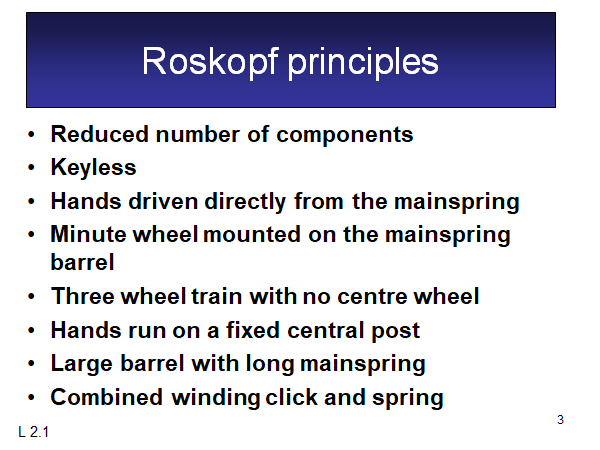

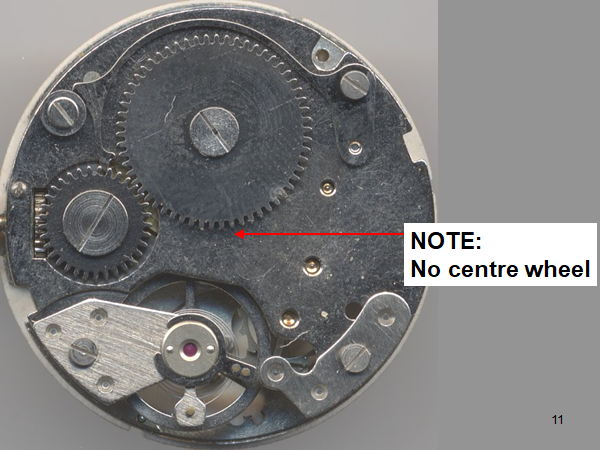

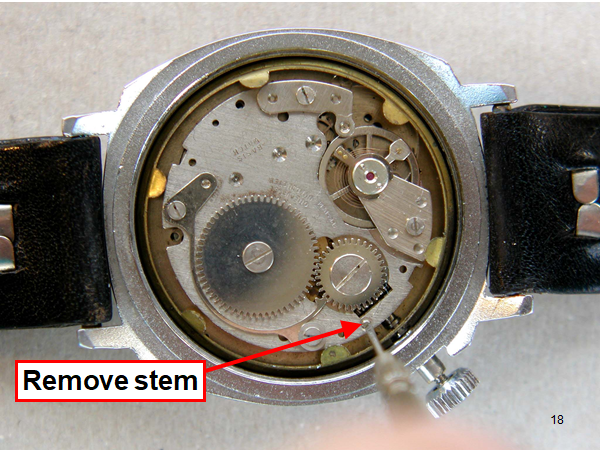

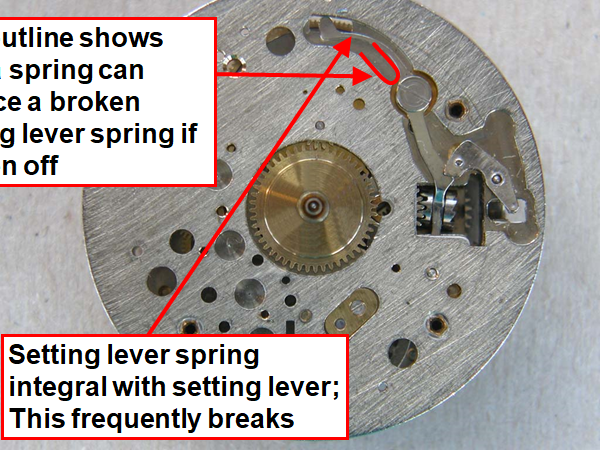

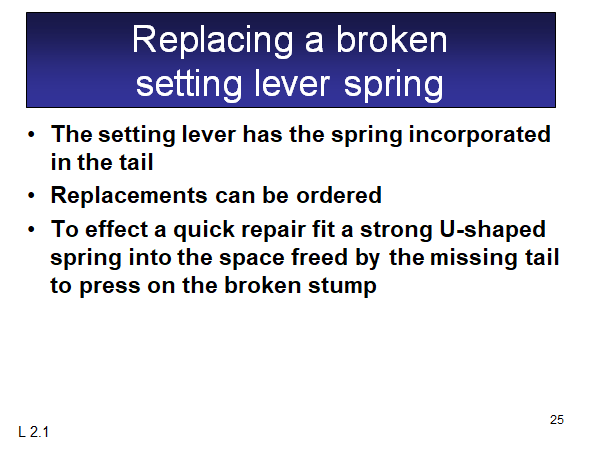

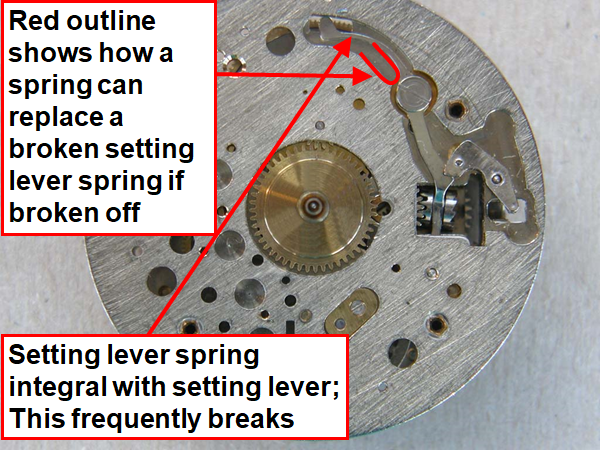

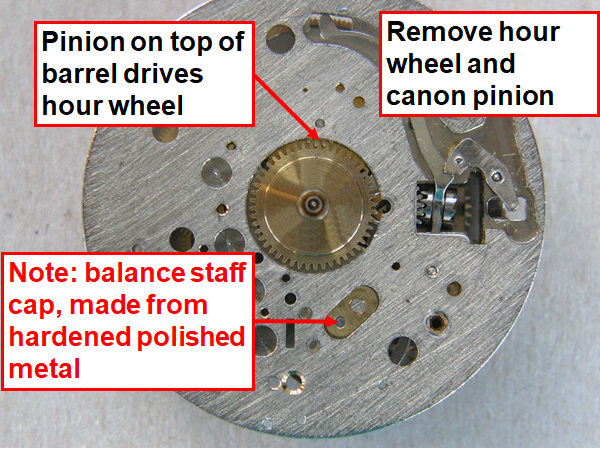

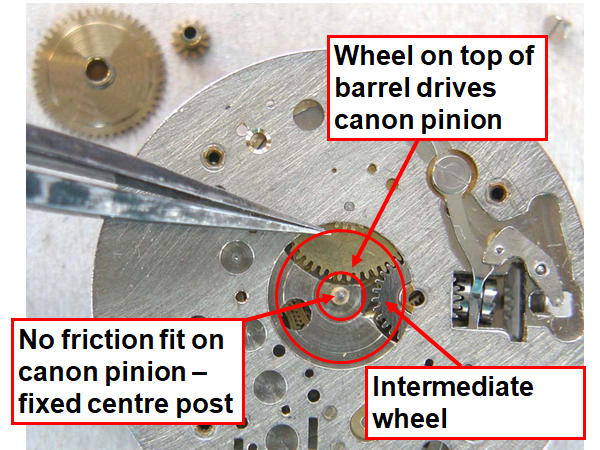

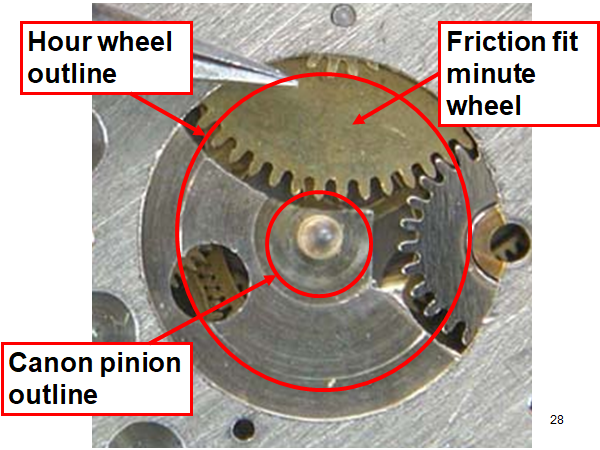

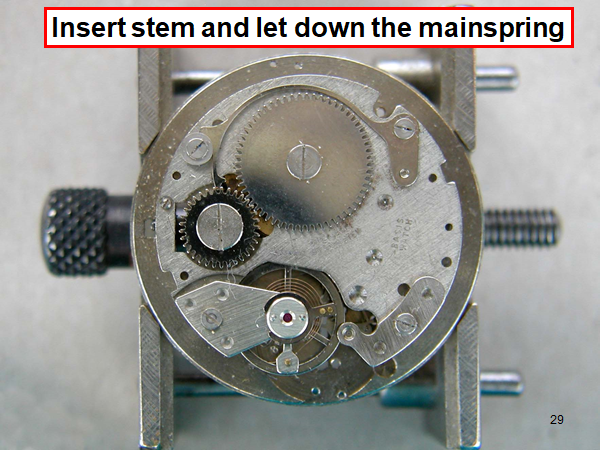

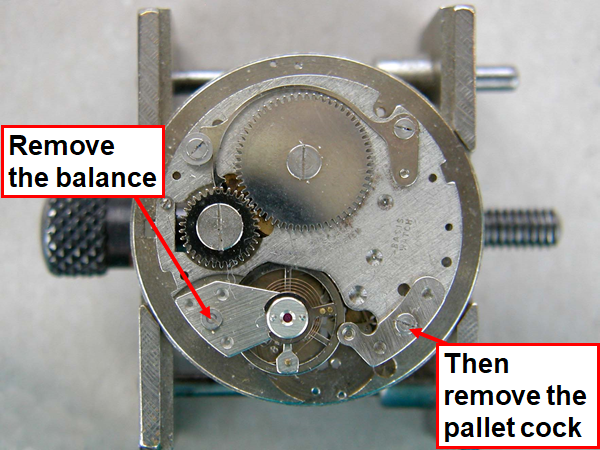

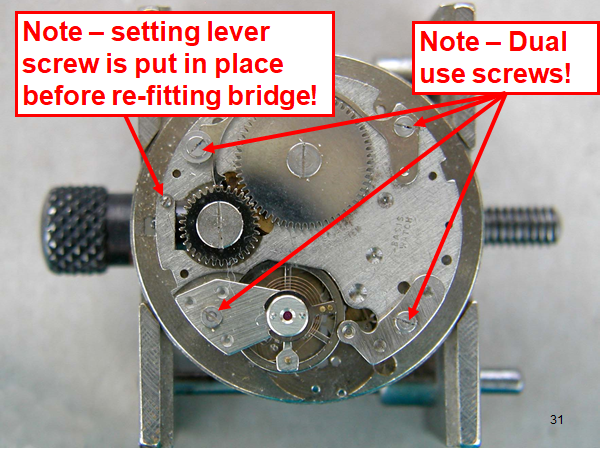

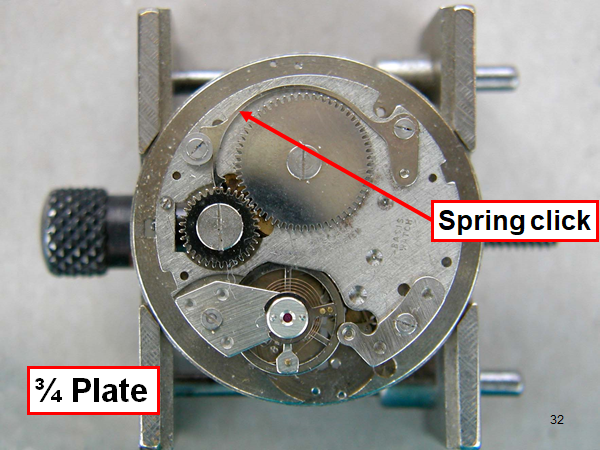

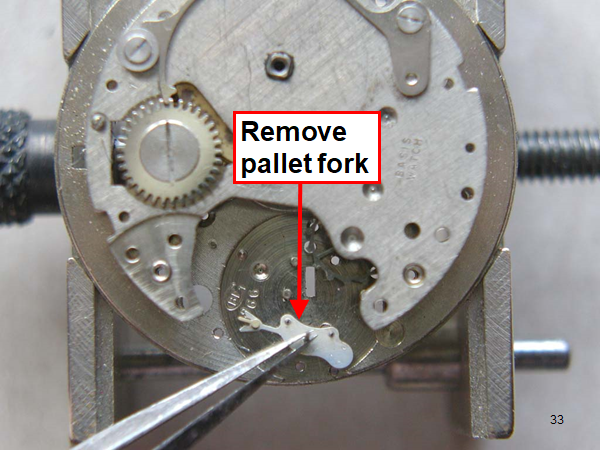

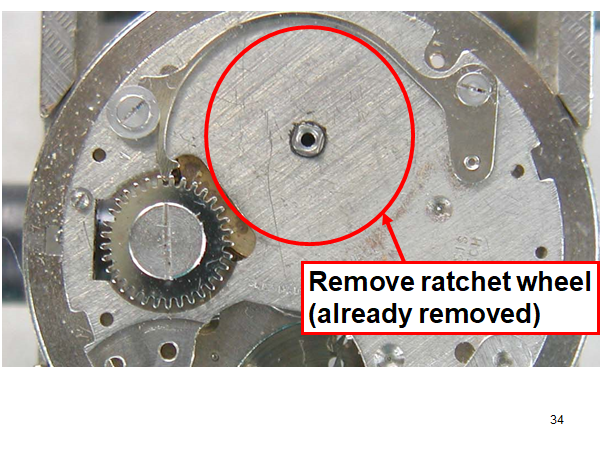

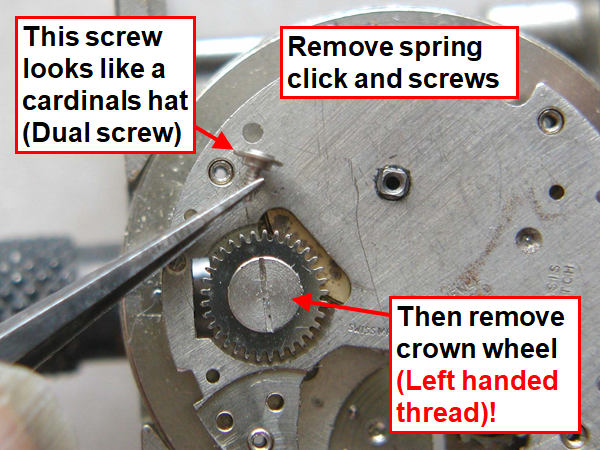

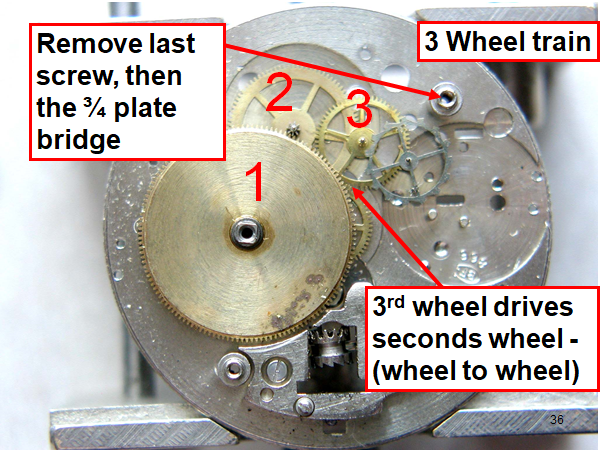

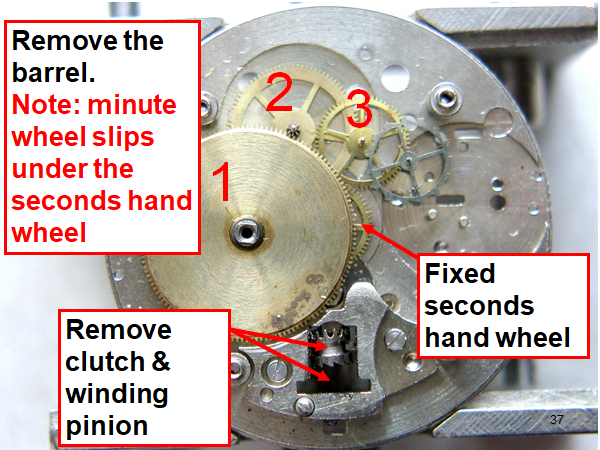

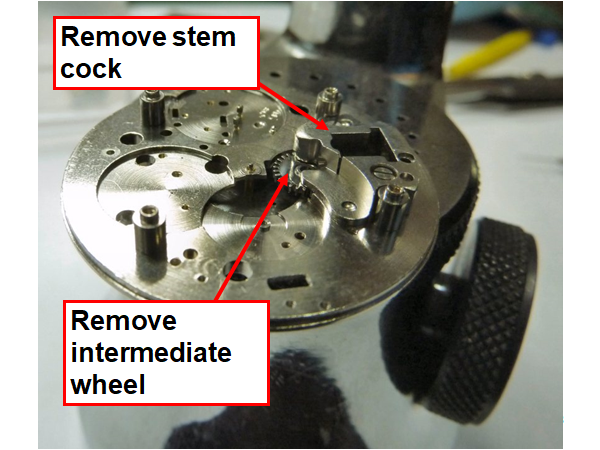

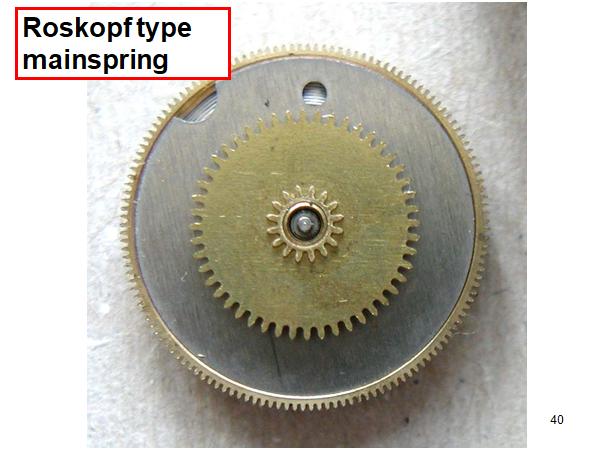

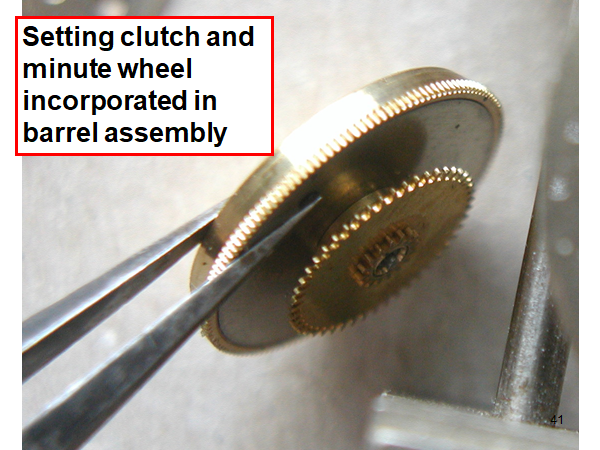

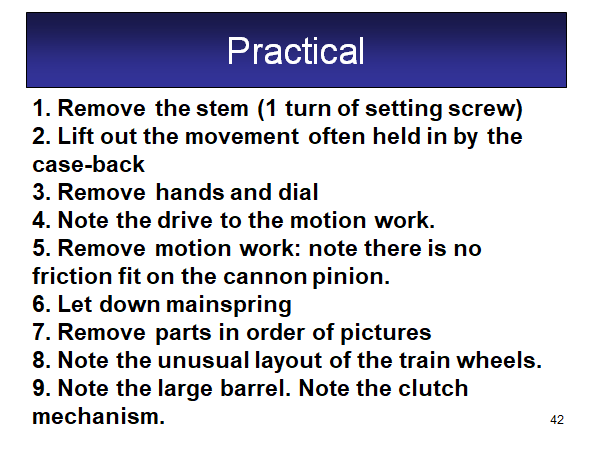

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....2 points

-

Masters of contemptuous greed. Try offering $20 for an answer with all vowels stripped?2 points

-

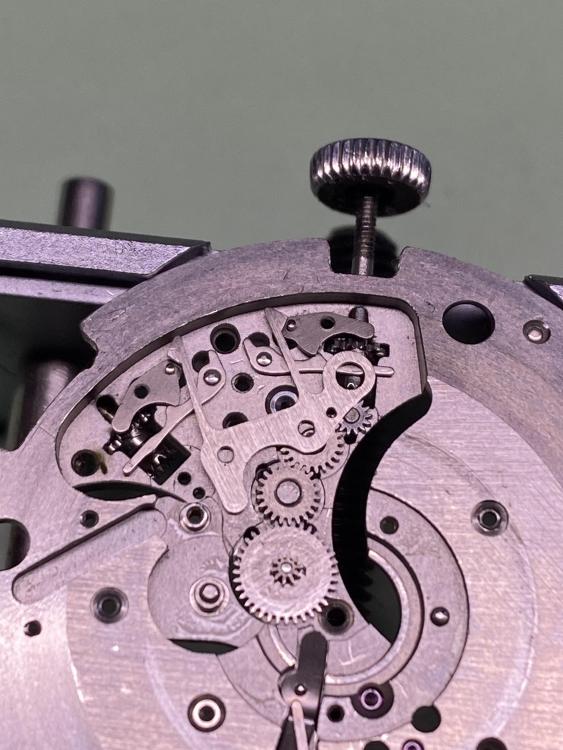

Hello fellow watch repairers, a few days before christmas I scrolled through a website for used stuff and came across an unbelievable offer for a vintage JLC Memovox for just under 1000€. It said that the dial was restored but for this price I just couldn’t say no to it, although I feared that it might be a scam. So on the twenty-third of December I drove four hours to pick it up, still with the feeling that it is to good to be true. But everything worked out well and I bought the watch what makes me the proud owner of my first JLC: And with a new strap it was a really lovely piece: At first everything worked well but after a few days the alarm wasn’t functioning anymore. Diagnosis: broken alarm mainspring. So I had to replace it and give the whole movement a service. The movement itself seemed to be in good condition and marks in the caseback showed that it was at least serviced a couple of times during its lifetime: Here a some impressions from the stripdown: And indeed the alarm mainspring was broken: I cleaned all the parts, replaced the spring and reassembled it. Now the alarm works flawlessly again, it is running nicely and is ready for its next life chapter. I never worked on such a valuable and complicated watch, so I‘m really happy that everything went well and that the watch is working again. I hope you enjoyed this short report!2 points

-

2 points

-

2 points

-

Hey folks, I'd like to share a watch I put together for my Brother's birthday. The movement is a pretty old Unitas 6497 which I picked up from the widow of a watchmaker a year or so back, the plates have been skeletonised and I'm pretty sure this was a once off job by the watchmaker. The mainplate is brass, and the decorated bridge plates appear to have been plated (quite crudely, when inspected under a loupe). The movement is keeping great time now that it is serviced. I made an attempt at a logo using the film-free transfer technique Mark has used in a couple of recent Youtube videos. The logo didn't adhere very well to the dial, not particularly happy with it. In person and to the naked eye it looks pretty good I think. The case is a 41mm case I picked up from Ofrei, who I sourced the dial and hands from also. Hope ye like it!2 points

-

Hi loos a nice clock, does it "stutter " on a regular basis and does it have a cycle (Ie) every min every 30 secs or the like. If so look for a bent tooth or teeth or even broken teeth. If its been away for repair that should not be the case. but a bent tooth/teeth maybe. If its covered in oil that will have to be addressed. Let the movement down and remove the platform escapement. Dismantle the clock and reassemble without the spring reason bring to check the freedom of the train and for any tight spots which may be a bent pivot or faulty wheel. If everything checks out clean the movement and relubricate (Windles oil) and re check the train. check the barrel and spring for being clean and lubricated. if all ok clean the platform and chesk the escate wheel pivots and teeth then lubricate with watch oil and re fit paying attention to the depthing of the ecape pinion and the contrate wheel. once assembled put two or three turns on the spring and observe. all the best.2 points

-

2 points

-

1 point

-

This is something I've been putting off as it seemed like such a daunting task. I needed to make some hands for a design I had been working on, but without access to a lathe, staking set, or infact a lot of the tools I figured I would need, I didn't think It would be possible. I had a go anyway and this is how they turned out. Lots of work left to do (like actually trying to make the round bits round, polishing, plating etc), but here they are. PS please ignore the dial. Its an experiment in engraving a design I'm working on, but ill talk about that in a separate thread.1 point

-

Hey all, I'd like to introduce myself! My name is Jon, and I've been interested in watches and how they function ever since I received my grandfather's 1915-ish Hampden pocket watch after he passed away back in the 90s. He wasn't the original owner of that watch (it having been made about a decade before he was born), but it slotted in nicely with my mechanical interests. Lately I've decided that watch repair would be a fun hobby, partly because I love these things, and partly because it's time for my "daily driver" Seiko SNK809 to have a bit of maintenance. Seiko wants, frankly, more than the watch is worth (excluding sentimentality - my wife got this for me for my first ever father's day, and even had the rear crystal laser-engraved, which I'm told is rather unique) to service this, and after reading a TON and watching a lot of instructional videos on YouTube (shout out to Wristwatch Revival), I've realized that - if you proceed methodically and logically with a good set of screwdrivers and tweezers - these things aren't nearly as scary as they first seem. I mean, until you try and figure out lubricants, that is. To that end, I picked up a few "practice" movements off eBay (a size 12 Locust, a size 10 New York Standard, and an absolutely tiny 16/0 or 7 3/4 linges Peseux 80 ladies wristwatch movement which I'm going to use as my sort of "final exam"). Amazingly, they all work, for varying definitions of "work". The Locust has a broken balance shaft which I'm neither skilled nor equipped to repair, the New York appears to have been recently cleaned and serviced, but the balance spring is disconnected from the balance bridge, and while I haven't taken the Peseux down yet, it looks like it really just needs lubrication. At any rate, I've rambled on long enough. Looking forward to the community here; there's a ton of information out here that have answered some questions I had already.1 point

-

Hi! my name's Kevin and after watching many youtube videos I decided I wanted to get a watch and give it a try. We'll see how it goes.1 point

-

If you are paranoid...as I am often in these situations...use a safety razor to start the process of lifting the bezel. Go around very carefully and "generally" a gap will form. Then you a case knife. It is scary...unless it is a junker.1 point

-

Ok, I thought you wanted to remove an armoured crystal. To remove a bezel, just a regular case knife will do the job. Upload a photo of the watch just in case it's something unusual.1 point

-

This press: https://www.cousinsuk.com/product/press-robur?code=G0728 with this set: https://www.cousinsuk.com/product/die-set-robur?code=D0425 is probably the best, but expensive. They are cheaper second hand on ebay but not by much if two bidders are keen.1 point

-

Just a way to say.. one can't win a this game https://en.wikipedia.org/wiki/Martingale_(probability_theory)1 point

-

Make the measurements turning the spindle by hand, whatever rpm that is. If you see that you have 0.05mm runout, turn the lathe on with the indicator still in contact- it will look way better, haha. Generally you would check the collet taper inside the spindle. The outside front diameter should be as good, but not necessarily (better makes will be great, lesser, less good). Unless a lathe has seen a lot of abuse the collet taper should indicate darn close to zero. My lathe doesn't move an Interapid 0.002mm indicator, so it's quite good. Yes, lots of errors can stack up- but sometimes they cancel out, and a dinged up spindle, with a manky collet, and a workpiece that isn't straight, can end up looking great- until you pull the part out and try to put it back like it was.1 point

-

These are oil sink cutters. They are for countersinking pivot holes to create an oilsink.1 point

-

Thank you for your quick answer and for your help! Would you please check this list for peace of my mind? - second wheel: D5 - third wheel: D5 - fourth wheel: D5 - escape wheel: 9010 - center seconds pinion: a tiny bit of 9010 What do you think about the friction pinion of the second wheel? Should I apply some grease or not?1 point

-

I really wouldn't recommend my method- it involved a fine-ground paring chisel that I was ok re-grinding, a woodworking bench with sacrificial wooden jaws in the vice, and a short sharp shock with a mallet. 30 years of woodworking experience meant I could get away with it, just about. The scratches on the back actually come from failed attempts with various back-opening knives. But here's the watch opened up. The crystal was already damaged, so I decided to make this my first crystal replacement as well.1 point

-

And that is all of my ideas washed away with one stroke. Sigh. I shall now go and sit in the corner.1 point

-

Yes, that's the reason why CAS numbers are used in safety sheets. fwiw, I spent 6 years working on an enterprise-grade cradle-to-grave hazmat tracking application. So what I'm using is 8032-32-4. That should come back as "vm&p naphtha" or "naphtha" in any hazmat database, but searching "naphtha" in the same database is likely to pull up a bunch of other numbers. When i hear "Benzene" i think of the ring-shaped hydrocarbon with CAS number 71-43-2. But that word means a lot of different things around the world. An Italian watchmaker said that where he comes from, people who don't want to buy the commercial solutions mix a little ammonium hydroxide (1336-21-6) and oleic acid (112-80-1) with water, then rinse twice in hexane (110-54-3). Sounds reasonable to me, assuming hexane is really compatible with water, or maybe i understood wrong and they mix it with some hydrocarbon? But hexane isn't something i can buy at a local store, and online it costs twice as much as your average jug of an L&R product. Not that you can buy straight ammonia here in the US without a special license either. I've grown increasingly frustrated with VM&P naphtha. My jug of L&R 111 gets here tomorrow. I'm not sure exactly how it will integrate with my jelly-jars-in-an-ultrasonic method - specifically with the jars, or at least the lids. I might order a sheet of PTFE and cut some discs the same diameter as the standard heat-seal jar lid inserts or whatever they are properly called.1 point

-

1 point

-

Sometimes, even for a small project, I end up spending more time sharpening my gravers than actually cutting metal. I'm really tempted to get a Chinese knock-off of this system.1 point

-

On some movements, you need to screw in to remove the stem. counter intuitive but I've come across it, can't remember what movement though. Anilv1 point

-

1 point

-

You're right not to force things and right that it shouldn't take much force to remove the stem. It's usually one-and-a-something (e.g. 1.5) complete turns of the setting lever screw for the stem to release. Just to check this, screw back up tight then turn one revolution and whilst applying gentle pulling pressure on the crown continue to undo another half revolution or so. Any joy? I've worked on a movement before that visually looked fine and corrosion free but where some small moisture ingress via the case tube had fused stem and clutch wheel together so stem would not release. However this also caused crown in/out (winding position to time change position) to also not be possible. Can you do both? Next question is why you want to remove the stem. If it's to service the watch you've got nothing to lose in removing the barrel bridge etc. to see if you can figure what's going on.1 point

-

1 point

-

In the US, the container I buy is labeled "VM&P Naphtha" - stands for Varnish Makers and Painters. I'm under the impression that the VM&P type is more refined or more pure than other mixtures of light aliphatic petroleum distillates that might also be called "naphtha". I expect that varnish makers and painters have more concerns about the composition of this solvent than people who use it to refill lighters. It's always a mixture, and every facility that makes it produces a little different mixture. I've been frustrated in my attempts to find an obviously trustworthy reference for the solvent resistance of shellac. Closest I have found is an old paper published in India in the 80's, which states: "Shellac is insoluble in water, glycerol, hydrocarbon solvents and esters but dissolves readily in alcohol, aqueous solution of alkalies, organic acids and ketones." https://publications.drdo.gov.in/ojs/index.php/dsj/article/viewFile/6181/3286 At any rate, I've never seen the pallet stone shellac soften after even hours in warm VM&P naphtha here.1 point

-

Almost posted the above. I won't duplicate, but I'll add a bit of context with some alternate imagery/application (usually helps me remember things). Another of my proclivities includes woodworking; specifically luthiery (stringed instrument making, with archtop guitars being my weapon of choice). Shellac is a component of many wood finishes. Specifically for my use, a French polish, where it's the only component and mostly process. I haven't made any up in a while, and it's not at all an exact science, but I usually try to guess how much I'm going to need for a project (it doesn't keep long, and any leftovers are wasted), and pour enough shellac flakes into a little squeeze bottle, then pour in just enough booze to cover, and some for me should I feel like it. Which I never do, because Everclear is gross but I mention this because the potability of it is not at all shared with petroleum distillates and helps with the alternate framing. Shake, wait, and repeat every few hours until it's all dissolved. Takes a solid day to get the flakes fully dissolved. Re: OP, my first thought was pallet jewel depthing, but bouncing hadn't occurred to me. It seems like an easy way to test between the two would be to hold the pallet to one side or the other, give the mainspring a little wind, then let go and see if it'll hold. If the jewels are deep enough, the escape wheel tooth should be on the locking face and not the impulse face, and it won't go anywhere without the balance (or your tweezer tips) to give it a nudge. Do both sides, since either could be too deep, and would be able to kick the whole thing off on its own with the other jewel getting a bounce to keep the it going. If it'll hold when held to start on both sides, it's probably fine and just a function of where the fork was when you initially gave it some wind. If not on both or either, it's the jewels in the pallet fork. Rather than running straight over to the high diving board and attempting to reset the pallet jewels, you might consider dredging up a donor movement. I don't know how common that particular movement is, but Russian watches tend to be plentiful in my 404 hunts, so possibly an inexpensive option. Pallet jewels don't get messed with often, so the odds of getting a good fork seem pretty high.1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

These are so lovely. I dream of owning a memovox like that. With a tuxedo dial they are one of my all time favourite watches.1 point

-

The watchmakers lathe an interesting device that they all look basically the same but? I have a link to an interesting book that you can download from the link below. The book is titled The watchmakers' lathe, its use and abuse. To understand the collet problem you want to look at page 65 in the book. There were unfortunately quite a few different variations and that means you can end up with a lot of collets that may or may not actually fit the Lathe you have. https://archive.org/details/watchmakerslathe00good/page/n1/mode/2up1 point

-

1 point