Leaderboard

Popular Content

Showing content with the highest reputation on 09/23/21 in all areas

-

I think we have become overly OCD about beat error. Before the invention of timegraphers, what did watchmakers do? They just line up the balance jewel with the pallet fork by sight and that was it. I think the error could be out by 1.0ms.5 points

-

Google in their infinite wisdom has changed the link format for shared content. As a result the old links that I had shared on Google Drive no longer work correctly. Here is a new link to the Timex Documents collection, hopefully folks will spot this one first when they search. Timex Documents The following is a direct link to the Timex service manuals folder. Timex Service Manuals3 points

-

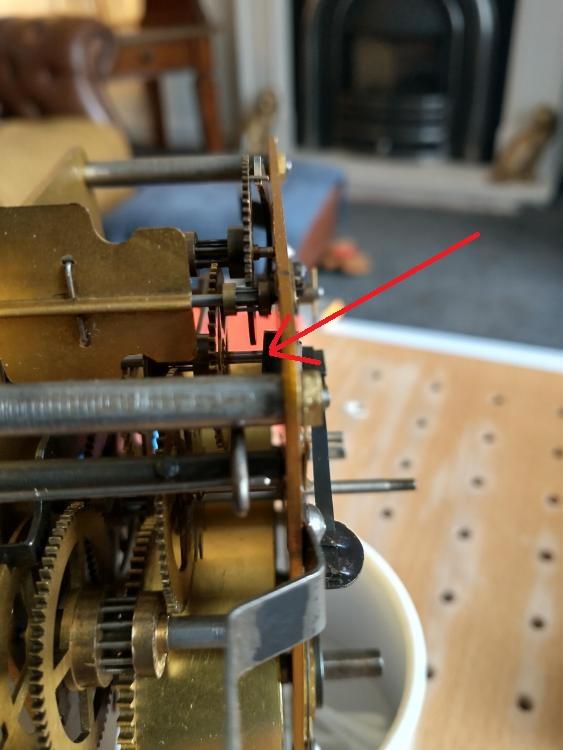

This what I used to adjust the collets on clocks and pocket watches. It's probably too big for a ladies watch. I don't remember where I learnt this from I slip the tool between the hairspring and balance cock and insert the sharp tooth of the tool into the split of the collet. Then I can turn the collet in whatever direction I choose.2 points

-

2 points

-

t's more about "how" things are done rather than going by canned statements. For example, if you mark the balance rim and then clean it with a small brush, the solvent doesn't even get close to where shellac is. Beside, alcohol softening shellac is not instantaneous. Mainly because of the small balance. When a ladies movement is a good timekeeper, that is a manufacturing or adjustment achievement bigger than with a men one. If you go in person to a professional with a ladies watch for service or repair, watch their face and be prepared to hear interesting comments.2 points

-

You can either turn the roller table or hairspring or as said unpin the hairspring and run it through the stud hole. Putting the cock and balance back on the mainplate without anything else gives you a good view of impulse jewel which is to be in midpoint between the banking pins. Turning the hairspring is the riskiest. I turn the roller table instead, I put it on the staff a bit loose so turning be easy, once I call it in beat , I then press the roller table all the way home. Ink marking the balance for a referance point on one edge of the cock is useful.2 points

-

With a fixed stud carrier (and no pics of the movement to refer to) I'm pretty sure you've hit upon the only way. I often work on antiques, and with one little size 0s Swiss cylinder watch - a gift for my wife - to correct the beat error I had to un-pin the pinned hairspring and let it out just a tiny bit, then adjust the collet by teeny tiny increments, repeating this procedure until it was finally in beat and able to be regulated. And it's good to be extremely worried about damaging the hairspring. We all should be. Always. Fragile it is. Take your time on it. Know how much force you are applying, and in what direction. Be mindful and don't go any faster than you are comfortable with. Practice will make you better with time. Good luck. May we see some pictures of the movement please? We always enjoy them.2 points

-

Bulova Seaking Automatic from 1975 I believe. Just restored and serviced this for my next door neighbour. It's 'on test' for the next day. He told me he got it for his tenth wedding anniversary and has been in a drawer for 25 years or so. Going to give it back to him tomorrow evening. I hope he will be pleased to wear it again.2 points

-

Together with the moving piece, which also has an angle, pretty much the same, they will hold the watch in place when turned upside down, for DD position.1 point

-

Yes, it's made from a piece of stainless steel wire. I copied it from a photo I saw of a vintage tool for adjusting beat error.1 point

-

Hi all, I want to recommend this channel, Precision Horology. The producer (Ashton) really knows his stuff and is extremely thorough in his explanations. John1 point

-

Hmmm there's nothing glaringly obvious.....def need a video lol. how about a gif? it may be enough to show us what happens. If levers are jumping then it's worth checking teeth to make sure there's no damaged, bent or even dirt in between them that may be upsetting the movement.1 point

-

1 point

-

I believe so. They will tell you, "it's matter of practice, you can't expect to master it quickly", which is true of course, but the fact is, not everybody gets to the same level, some people is naturally more talented. I'm myself on the mid of the scale at best. Once again the key concept is: practice on something that has zero value, or for which you have replacements at no cost. For me, ruining some of the balances below at Euro 15 a piece was a sobering experience. Which was a good call. Which is what we tell all the time, but some beginners really think they know better. Recently one (not you) attacked a ladies hairloom because "he had reasons to do that". We never heard again how that ended.1 point

-

After all that i hope it's helpful thanks everyone for being patient especial jdm who i think might have been calling me under his breath.1 point

-

I place the complete barrel in a tiny ziplock bag, and use my thumbnails to press down on the rim/teeth of the barrel on a hard flat surface. This allows me to remove the lid from the barrel safely, and the ziplock bag prevents the lid from flying off with too much force and the mainspring uncoiling catastrophically. I find this more controlled than using tweezers to press on the rim/ teeth of the barrel.1 point

-

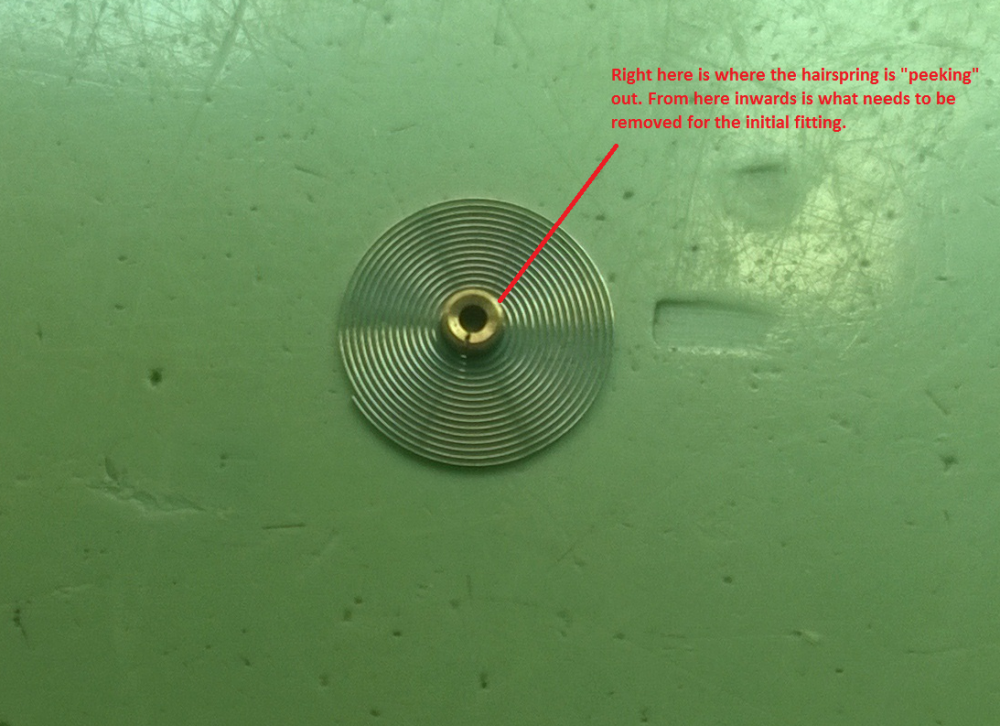

I recommend to let alone the roller table. The normal way to do this is turning the hairspring collet as mentioned above. It should have a cut where you can insert a small screwdriver, which tends to open it a little, and make it a controllable operation. Note, image above is taken from a rare narration of what is actually taught in watchmaking school: https://watchmakingjourney.com/2014/08/16/last-week-final-project-colleting-and-studding-hairsprings/1 point

-

Again: no video of any format can be attached. If you absolutely need to share a video, post on YT or other platform, then post the link.1 point

-

Yeah on further inspection, it is clear that the module is not intended to come apart. It is fastened together by melted plastic pins. I was able to bring this movement alive using my demagnitizer to spin up the rotor and train. That seemed to loosen things up. The watch is assembled...will monitor.1 point

-

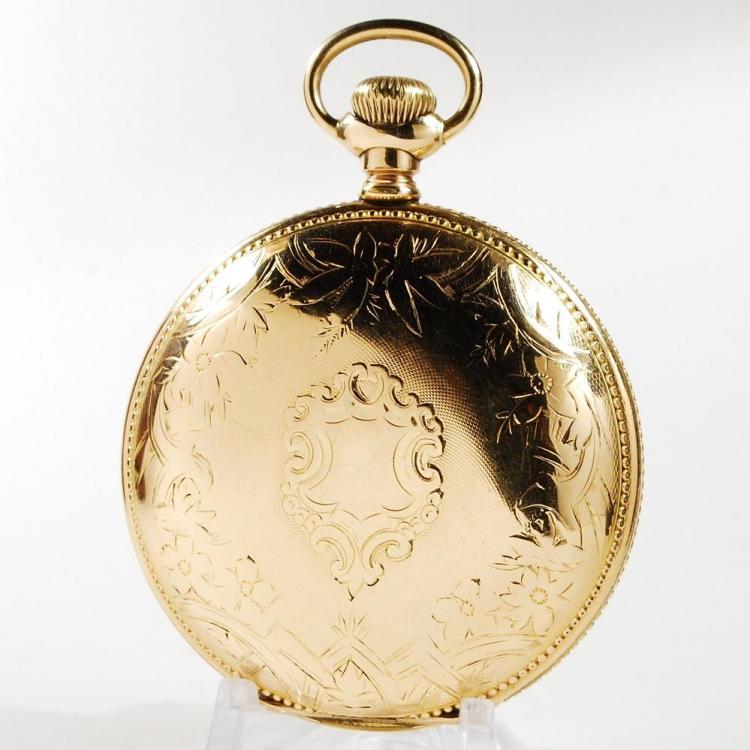

Hi everyone, Im new here Just get back into pocket watches after selling out 5yrs ago. Acquired this nice RR watch a week ago, it is now getting a full cleaning, oil, adjust service in NYC...likely another week till I get this beauty home. 23J Illinois Bunn Special Illinois 18-size 23-jewel Bunn Special w/ DS Montgomery dial. 1913 date 25- year,Gold-filled Keystone re-case, glass crystal. i am now retired and dabbling with Idea of online watch repair training...really to the basic tear down Cleaning adjust, replace spring level.1 point

-

That sounds plausible, and you can always test the watch by wearing it for a month or so. If it performs persistently it's likely nothing wrong with it. Maybe put a Weishi 1900 on your Christmas wish list!? It could also be that the movement is too noisy. I've experienced both scenarios.1 point

-

I have recently used a jacot tool to successfully re-polish a badly worn pivot in a pocket watch the first time in my life. I have watched Richard's videos about it and I also went to a book printed in the same year I was born in 1976. This book is written in Hungarian and was one of the book used by the state sponsored and only one watchmaker school as far as I understand. (To my knowledge you cannot learn watchmaking any longer in Hungary as of now.) I scanned the corresponding pages as how to re-finish a pivot including the usage of a jacot tool. It was a great help to me so I thought I share these pages with you. After scanning the pages i sent the pdf through a pdf to txt engine then sentence by sentence I translated the Hungarian text to English. I learnt watchmaking in English and it might sound strange but the Hungarian name of the parts and methods were unknown to me. This added some more difficulty on top of the fact that my English is far from perfect. I am writing this because I am not sure how good the end result is. If anyone feels that could correct the text so it would be more readable or would make better sense please do so. Enjoy if you can. jacot_tool.pdf jacot_tool_Kopasok_javitasa_magyar.txt jacot_tool_repairing_wear.txt1 point

-

A couple of weeks ago I received my first IOSS purchase, that is a small tool from a reputable Ebay UK seller. The label clearly indicated "VAT Paid IOSS xxxzzz", notwithstanding this my national post charged an accessible €5.90 as customs handling fees - no VAT was charged. That is clearly not in the intent of the program, but unless the EU mandates that no additional fees on IOSS can be charged (and I doubt that will happen), I'm afraid that any postal administration, and private courier will still continue to charge as they please. Their justification is that current regulations state that "any package presented to customs" is charged handling fees. In contrast, the Chinese (AliExpress) already do better than that. They charge VAT at time of purchase, and ship all EU orders to a centralized hub in the Netherlands, where they clear customs and combine multiple packages to a same customer when possible. The shipment is then made from the EU and no charges are due at delivery.1 point

-

1 point

-

I have actually done that repair a few years ago. Trust me it is not an easy repair. However another way is shown here.1 point

-

Hi this book contains a lot of useful material apertaining to clocks and watches. chapter 18 ( page 134 for chiming clocks.) If what you have quoted is one continious chime its not locking and the first quarter is a round of one round 2nd is two rounds 3rd is three hour is four followed by the hour strike as per OH's chart handbook_of_watch_and_clock_repairsa.pdf1 point

-

1 point

-

1 point

-

1 point