Leaderboard

Popular Content

Showing content with the highest reputation on 09/20/21 in all areas

-

5 points

-

3 points

-

Finally got around to install the Indian vice on my new bench. Turns out that the base is actually chromed brass. I used wood inserts and SS socket screws. There weren't many choices but right above the drawer has the advantage that all I need to do is to open it and place a plastic bag to catch filings. After use it stays put in the same cardboard it came in. The red "visette" is another handy Cousins cheapie which I have already corrected for jaws and slide alignment, but I still have to find a way to fix on the thick bench.3 points

-

Recently retired and inherited a large collection of clocks and watches together with horological tools. My parents - Alan and Rita Shenton were legends in the electric clock world and horological books - back in the day. Looking forward to honing my amateur skills skills to renovate and learn more form like minded enthusiasts2 points

-

I just finished a similar project, and wanted to put an update here on the crystal, to help future searchers. The Sternkreuz FBA 321.701 is also a good replacement for this watch. The GS CY 934-17 is not. I was able to source the Sternkreuz through Cousins. Here's a photo of the completed watch. Happy jumping! Dave2 points

-

I think you have reached the point of thinking out side the box and rigging a device to apply downward pressure whilst being able the turn the screw driver, Ie a modifed G clamp. the main points being that the driver has to be a good fit and the watch held securely. prior to this soak the screws with acetone as jdm recomends.1 point

-

It's still tripping so check the lever and the pin in the wheel and make sure the lever holds the wheel and pin. As it's a count wheel strike are you sure the lever that drops into the count drops right down in the slots and lines up with the wheel with the pin.1 point

-

1 point

-

Unless you suspect it is causing an issue then no. Removing involves removing the friction fitted parts and replacing back to the correct depth.1 point

-

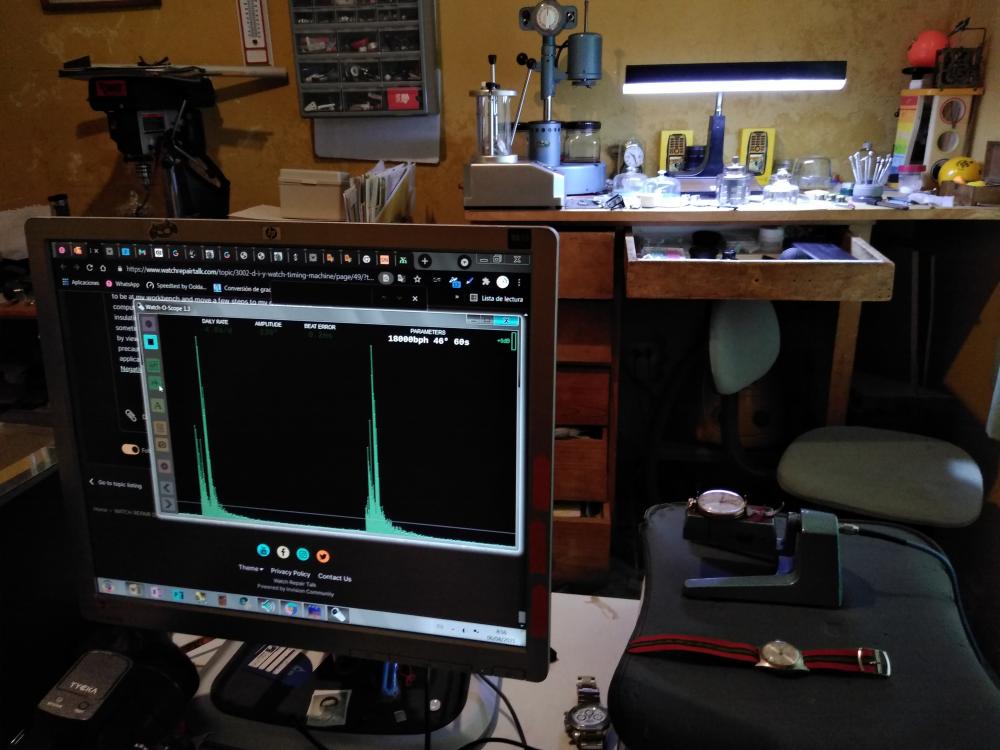

Don't assume that closer is necessarily better. There are situations in which a minor noise gets amplified too much and fools the software in detecting it instead to the actual impulse, that is why gain control is present on the other models. The machine is designed to work well even not only with the bare mov.t sitting 2cm far from the microphone with the metallic mov.t holder transmitting sound as a vibration, but as well with it in a closed case and other noises in the room.1 point

-

If you're in the US, there is a product called Evaporust. It is safe to use with brass, and very effective. It's gentle, and even non-toxic IIRC. Can be had pretty readily at hardware stores.1 point

-

I don't think that Rotary makes parts available. Maybe generic pushers can be fitted, had you posted a picture one could get an idea of what we're talking about.1 point

-

Phenix https://www.mikrolisk.de/show.php?site=280 Type in Phenix into the above link1 point

-

Not sure about the Coca‑Cola of today but back in the 70's & 80's that stuff would make brass shine, the same with farmhouse cider. Just imagine what it does to one's insides.1 point

-

I would add to this: remove any brass parts wherever possible. I was schooled about using vinegar around brass, by a few veterans on this very forum in the recent past. I did my own testing on old, broken watch wheels. Using white distilled vinegar, and a third wheel from an old wrist watch, I discovered that soaking it no longer than 30 minutes is still safe - but I would not go past that. And it's likely safer not to do it at all. I keep reading how vinegar has a cumulative effect on brass, and can weaken it. And I know that the brass parts of watches can be very fine and delicate, not much thickness to the brass, so it wouldn't take very long to destroy them I imagine. But I think OH and other experienced folks here could recommend a safe rust remover if you need assistance there. That said, I have not yet tested Coke on brass. I will need to do that and record my findings.1 point

-

A Raketa CCCP mystery watch - possibly a 2609HA - The Dial reads CCCP - гласность This translates to USSR - Glasnost. The crystal looks cracked, and it is missing its crown, and possibly its stem, but hopefully I have suitable replacements. It should look a bit like this. It should also make a fine 404 club member and a good companion piece for the Slava 21 jewel 2414 - Перестройка (Perestroika) mechanical above.1 point

-

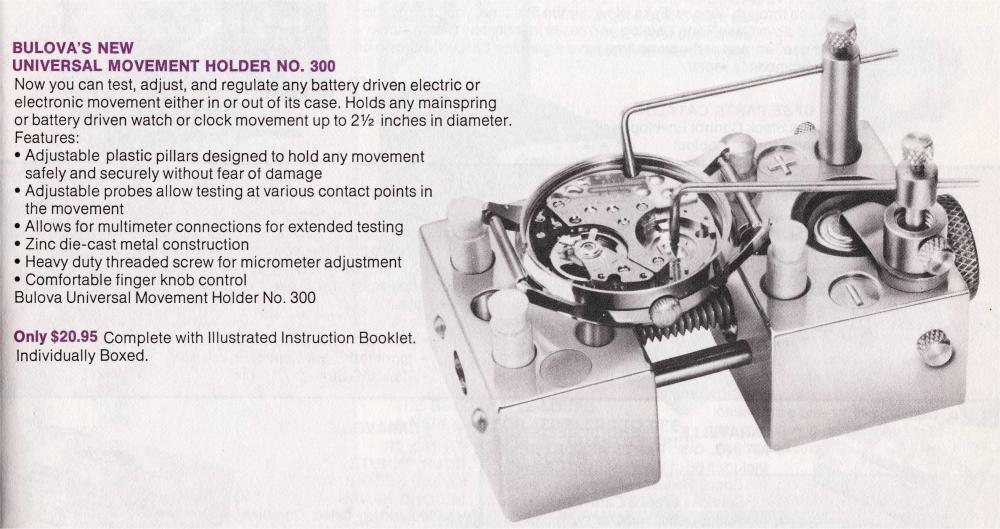

I noticed on eBay sometimes they'll sell the microphones separate and claim their new and improved but conveniently they never said what they improved. Yours definitely looks improved as that would hold the movement without it falling out.1 point

-

If all parts are shaped and sized correctly, you would get from 3 bar to 20 depending on crystal thickness.1 point

-

So glad you were able to find the issue. I think it's @HectorLooi who is also the dentist; he must feel right at home when encountering broken teeth. I see a few of those now and then too. The first time I had a jammed up watch, and saw the second wheel had a broken tooth, I later found that tooth wedged in a pinion, held in there by another wheel's tooth. Being as paranoid as I am, any time I see a broken tooth now, I will search the whole movement as I strip it down, looking for the tooth and giving it no unsearched crevasse to hide in. I wish I knew when my mother will be sending over my aunt's nurse's-watch. I'd only seen it a couple times when I was little, upon getting injured or sick. She only wore it at work, and when I got older, healthier, and less clumsy, I never saw her at work after a certain time. But I think the watch looked very much like the one in your pictures, though I do not know what maker.1 point

-

Just curious... did you lubricate the pallet jewels or the escape wheel teeth?1 point

-

Power off, stud cap screws loose, insert stud. HS in pins, wiggle watch a little so everything settles. Screw down stud cap screws. From there, if you need to adjust anything adjust- beat error, move the hs collet. HS not centered in regulator pins, adjust. HS not flat, centered overall, adjust. Ideally with everything "relaxed" and snugging up the stud cap it should all be good. But a watch this age has seen many watchmakers and probably needs some loving.1 point

-

Welcome to the forum. Oh what a beautiful workbench! Just lovely. I seriously doubt I could speculate how much money you could get from selling it. I know hand-crafted furniture is not cheap stuff, especially these days. And I'm sure that bench is worth more than I could afford. But then, I'm the sort to encourage the owner to keep it rather than sell it. It looks like something you'd miss later. And if not used for watches, it would make a fine desk. Thanks for sharing the pictures.1 point

-

If you look in old books about watchmaking and the tools they used, you will see pictures of workbenches in the style of the one you have, some even include the foot wheel inside to operate the lathe which would be screwed on the bench.1 point

-

I think jdm is spot on . a lot of these benches were custom build to order by local craftsmen and as such have no makers plates. You could pull the drawers and have a close look at them. Some furniture that was hand made, the underside of a drawer was marked but not always the case.1 point

-

1 point

-

I've hoped so. I once broke a pivot while trying to true a wheel, and had to purchase a new wheel at my expense (which was probably a better idea anyway, considering how warped the original was). Ever since, any truing I do is in the staking set with the staff protected by a stake and a stump*. It was all I could come up with, but it feels more steady and secure than in the calipers, and I can work at the wheel's deviation more slowly and carefully. It just feels easier to be more precise like this. I could see where some might find it cumbersome or inconvenient, but I find it more steady, and I can measure my progress against the die plate as a reference. *Addendum: when truing a wheel, one must still use the other hand to apply slight pressure to the punch to hold the wheel steady, but the wheel can't go anywhere and the staff cannot be harmed, and the pivots are not in contact with anything.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

You are right @LittleWatchShop And it is understood that in some parts the problem of space is very complicated. In my case the problem would be the cost of buying a Weishi. Although it is one of the cheapest. But with the modest investment that goes into building the preamp and an acceptable mic I am very satisfied with the W-O-S software. It's everything a watchmaker could even dream of in the golden years of watchmaking let's call the 60s 70s. There were tools in those years. But compared to what WOS can do, they look like toys. Here I share a photograph of my workspace. I will apologize for the mess that is appreciated. It is the entropy related to the precision of the clocks. This configuration allows me to be at my workbench and move a few steps to my desk with the computer where I have the microphone stand with a padded insulating support and from there make the readings and sometimes taking my magnifying glass and a tool, do the settings by viewing my computer screen. It is not ideal, but taking precautions is functional. And I explain the black screen, I use an application to be able to invert the colors of the monitor. NegativeScreen.1 point