Leaderboard

Popular Content

Showing content with the highest reputation on 03/17/21 in Posts

-

3 points

-

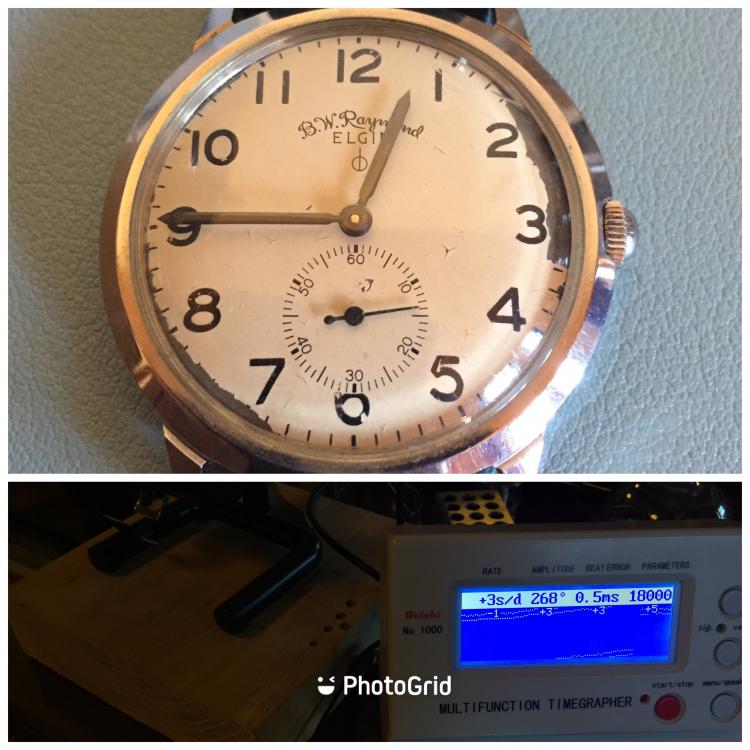

It was productive week with these 3 watches and getting them in working order. The Bancor AS1187/94 was the only one received that was running but needed a new mainspring and cleaning. The Elgin 730A wristwatch stopped and started and the pocket watch had a broken staff. The PW, Elgin grade 96, was a gift for my father. All running well now. Lastly, I made some cosmetic improvements to my staking set last month. The tools inside needed minor refreshing but the box had seen better days. Scraped to bare wood - poplar - stained and finished. before: after:3 points

-

I think it needs to be demagnetized.2 points

-

2 points

-

Here's a PowerPoint of removing a refitting the so called 'fixed' centre seconds wheel, which should be removed, cleaned and properly lubricated. Enjoy Lesson 21. Baumgartner 866 Removing centre second wheel and oiling movement.pptx1 point

-

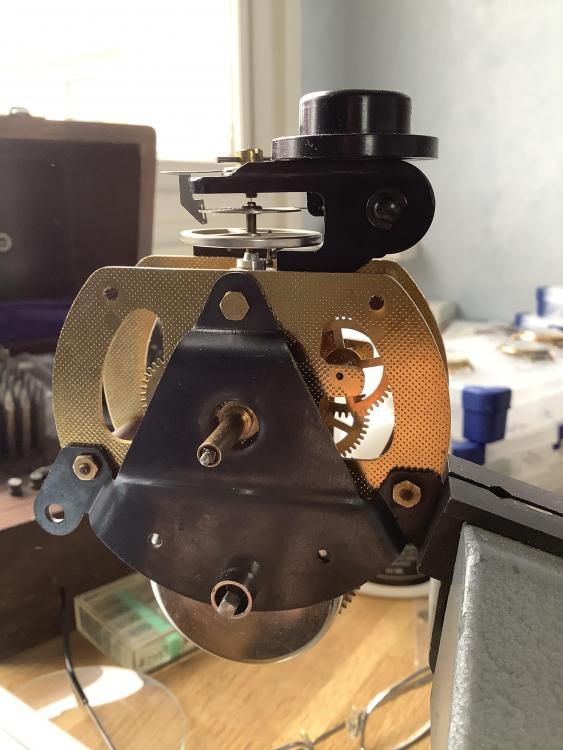

Hi all, I got another 60’s kitchen clock to work on. Movement photos are attached. one of the wheels needed a bit of attention and I got that fixed and after some basic cleaning and oiling, the movement runs. The overall design is however new to me and I would appreciate any advice on service and lubrication ”specials” as I’m a newbie on these ”big things”. Fundamentally I guess it’s a pin lever design? The balance wheel appears to be ”floating” by using what I suppose are two opposite mounted magnets and there’s a thin metal wire going through the ”staff” to keep things in place. Should end with really low friction but obviously only works when the movement is correctly placed. Curious to hear if this needs any special consideration or just leave as is? Thanks!1 point

-

That's the perfect oil for this machine. It's normal for plain bearing machines to get warm*, if it's not getting warm the bearings are too loose. If it's too hot to hold your hand on for 5 seconds after 30 minutes running the bearings are too tight. But ISO 10 is just right. *When doing very high precision work it's good to let the machine run for a half hour first. A watchmaker friend who worked in the gear department at Mcdonell Douglass told me it was protocol to turn on all the machines 30 minutes at least before making parts. Another friend who was well known for handmade watches had thermometer strips on the heads of certain machines to know when they were warm enough.1 point

-

Somebody beat me to the question did you demagnetized it? Dial-up and dial down should be almost identical if not identical. Definitely should be identical for amplitude. As soon as you go the crown positions you lose amplitude and depending upon the poise of the balance wheel you will have timing variations. It would be nice if you would time the watch in all six positions and give us the numbers. Another thing that happens is how close together are your regulator pins. If there are too far apart or far apart at all when you lose amplitude the watch will slow down. The farther apart they are the worst is going to be. But it should be stable at whatever amplitude whether it's slow or fast it shouldn't have slow variations. That's hard to tell from your timing machine but it doesn't look like it's a repeating pattern? In other words if it is a particular wheel then it would occur at whatever the rate of that wheels issue issue is. This is where it be nice to have access to the timing machine with time plot capability. Another way to look at your watch where you can see things like we'll variations show up very very clearly versus the normal graphical display. Looking at the pictures below and the text it is a railroad watch it should be keeping really good time. It looks like a really nice movement that definitely should be doing much much better than what we're seeing now What was the watch doing before you serviced it? No words did you put her on the timing machine what was going on? http://forumamontres.forumactif.com/t167485-universal-geneve-cal-64-chemins-de-fer-italiens-ferrovie-dello-stato1 point

-

I don't think the latest PLA ones I created are leaking, I have checked many times. I did the lids at 50% fill. Matt1 point

-

Interesting. Could be static electricity? If you do get charged and are holding a very fine wire, all the charge will try and earth through the end of the oiler. It's like a lightning conductor in reverse! Is the weather dry, and are you sitting on a synthetic seat ? If so, every time you slide about you could be charging up. My seat is nylon, If I slide off and touch the bathroom tap I can feel a slight spark as I earth. Shocking1 point

-

A 60 second wave would generally be the 4th wheel being out of round. Not much can be done to correct the out of round. You should see a shifting amplitude as well. If the regulator pins are a little too open then changes in amplitude will have a direct effect on the rate, imagining that the hairspring is well adjusted between the two pins (or pin and boot). The two images I am guessing are dial down and some vertical position? This would go along with the pins being too open, especially if all the vertical positions show a losing rate like that. Universal made very good stuff, and you should be able to get a good rate across 6 positions even with an out of round 4th wheel.1 point

-

Dr ranfft reffers to this as " independently driven minute wheel". Following the tear down, I put the train bridge ( with this wheel attached) back on the mainplate, give it four cleans in ultrasonic and call it cleaned. I do not remove this wheel unless there is a need to replace a faulty part. what kinda side shake on the driver arbour do you feel? Do you have a staking set?1 point

-

1 point

-

I think this is the driving wheel for the center second. It is friction fitted to the third wheel and can best be removed with a special Bergeon tool: https://www.bergeon.swiss/outil-presto-1857.html1 point

-

1 point

-

On these Seiko all calendar moving parts are made of plastic, on which due to its self lubrication properties no additional oiling is needed or desireable. A tiny adjustment on the date jumper may be needed after observation with the dial removed.1 point

-

1 point

-

There is so much wrong in this video his rough handling of the clock is a disgrace, knocking the ends of the barrel arbors on a vice and pulling the springs out by hand gives exactly what you would expect a pair of coned springs and probably a nasty dent on the arbor ends. His choice of tools is extraordinary the largest pair of pliers in the tool box. I would be very surprised if this guy has never broken a pivot on a French clock the way he separates the plates and holds the movement.1 point

-

wlysenko, I am very thankful for your work and your schematic. Also for all the help you and others have given. I read your article and very much enjoyed it. I will try the AD797 in place of the LT1115 and see what change it makes, I will also change the capacitors as you stated above. This amp I built from your schematic is not much noisier than my factory built machine. I am using a vibrograf pickup instead of just a piezo disc and it works FAR better with much less background noise, it also has a much cleaner signal. I didn't think it would work based on what I have read but to my surprise it works very well. As I have stated I am new to all this, but I am learning though. I am sure I will be building several more amplifiers as time passes. My quest for a good amp is the first step in building a special purpose machine with a few specific capabilities that will make diagnosing and building escapements much easier as well as preforming the typical timing functions. As I go along and learn I will incorporate the knowledge gained into a design all my own. I am trying to design a better microphone also, and a couple other pickup devices that do not involve a traditional microphone to produce a signal. These will be for use with some of my other manufacturing and testing machines. Many of the machines and tools I use in my shop are purpose built by me, to solve various problems and limitations. I enjoy the process and am able to get my work done quicker with higher quality and better repeatability. I need to create several types of triggering devices and associated peripherals. It will be a long process for sure. Being able to both hear and see various mechanisms in action during testing, design, and manufacturing is very helpful. Being able to incorporate electronics, optics, and mechanics into usable devices, for my shop is my aim. With the knowledge I have gained I have been able to build a few devices and repair some of my equipment. My laser welder, heat treat oven, CNC mill, and CNC lathe all had issues that needed attention, all are working great now and have better reliability. So this new dive into electronics has brought some successes for which I am grateful.......1 point

-

I have three staking sets and one empty box. You inspired me to refinish the empty box. Then move one of the sets into it! Damn! Another shiny object!1 point

-

I was recovering from my second covid shot and did not participate in the recent activity on this thread. I am sorry about CWRNH's problems with the preamp he built, which are now resolved it appears. Thanks to those who helped to solve the problems. CWRNH's circuit is based on my circuit, which is based on svorkoetter's original design. My circuit is described in the preamp noise article at wlysenko.blogspot.com (click on link at the bottom of the page). The schematic in my article is for my version 15 of the preamp. The latest version (no. 16) is the same except that C3 and C5 are now 0.1 uF instead of 0.47 uF and C7 is now 0.03 uF instead of 0.1 uF. These changes improve the frequency response and lower the noise a bit. Question for CWRNH: Why are you using an LT1115 for the buffer stage? The data sheet says this part has the lowest voltage noise, which is good, of course, but this device is not recommended for use as a voltage follower. LittleWatchShop questioned the need for the 680 ohm resistor in the buffer stage (the data sheet uses 600 ohm in their example). It seems the AD797 opamp, which is what I used, likes to run at a high current. At high current, the voltage noise is lower, which is what we want, at the expense of some current noise. I hope people continue to look at improving the microphone. My microphone is nearly identical to the original svorkoetter design. I found that it picks up sounds in the room all too well. If I listen to the output with headphones, I can hear my own breathing! I think we want something that is sensitive to watch vibrations but not to sounds in the air.1 point

-

1 point

-

oh back in my old shop we would call that a "goes-in-ta". ? as in that goes into the pile of stuff we have no idea what it is.1 point

-

I use my wife whenever I've lost a part and I'm devastated. She has the eyes of a hawk and has an eerie ability to find any part no matter how small in minutes. She definitely gets a kick out of it. The record is a cap jewel anti-shock spring for the escape wheel pivot of a Seiko cal. 7S36B. It is smaller than a spec of dust. I think she was sent to me for this very reason. Bless her and I try to treat her really well so that she won't get any second thoughts about me. Couldn't do watches without her! She has a sister who's single if anyone is interested ?1 point

-

1 point

-

I use a magnetic sweeper too, but I wrap mine in masking tape. They have a habit of picking up random stuff on the one hand, and the chrome housing would like to mar the bottoms of furniture legs. Additionally, masking tape comes in colors other than metal which makes finding other metal colored parts easier to see. My best into-the-ether part story so far is a missing shock spring. Sproinged off, as is their wont, and I spent an entire evening looking for it. My wife got involved. Many swearings. I eventually worked up a bit of a sweat moving furniture or whatever, and took my glasses off to rub my eyes or something. There it was, statically clinging to the lower inside of my left lens the entire time. Talk about being right in front of you the whole time!1 point

-

I have been known to get my 1 meter steel ruler from my outside workshop and put rare earth magnets on it every 10cm and then wave it over everything. I've found more than 1 click spring with that method, once I even found 2 click springs and I was only looking for 1 at the time. ?1 point

-

Looks like you have had all the good advise except on the hosiery front 1. make sure they are not the wife's best tights 2, she is not wearing them at the time . Try putting out some bait it might get hungry.1 point

-

Wow, did you see how 'coned' those mainsprings were when sitting on the bench by being pulled out like that! I do hope those long nose pliers were not the serrated type, but I'm guessing they are.0 points