Leaderboard

Popular Content

Showing content with the highest reputation on 12/05/20 in all areas

-

2 points

-

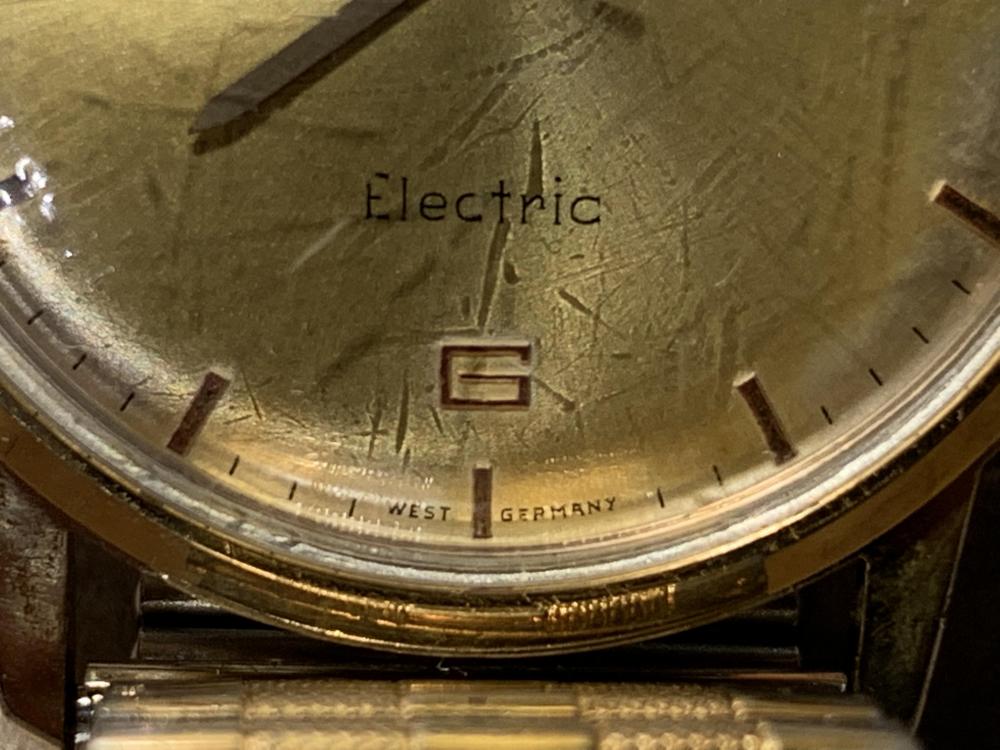

This was sitting in my junk pile for some time. I was looking for a spare contact wire for one of my Timex Electrics, and I remembered that the Timex Electronic has a contact wire. But when I opened it up, it was a totally different beast inside. The movement number on the dial plate is 882, which I checked up is a M87. The balance appeared fine. So I put a battery in to see if it would fire up. And it does! After cleaning it up, it doesn't look half bad. And now I have to continue searching for a contact wire....1 point

-

I think this top has been covered in great depth already. As a bare minimum, I would say you could get away with using a light oil like 9010 and a heavy oil like D5. And you’d need at least one fine oiler and preferably also a thicker one.1 point

-

Hi Gary, Go to www.balancestaffs.com , scrol the of calibers down to landeron, find these calibers you want, it also shows all dimensions of staff on a diagram . No need to measure the broken ones.1 point

-

Thank you very much everyone, you've been very helpful. I contacted the seller on ebay that Marc suggested and he says it should fit ok so I'll try that.1 point

-

1 point

-

That is right, just like on the NH35 you've handled before and pretty much any other.1 point

-

Ranfft has an OK advanced search feature, but it's very manual and leaves a lot to be desired. With a bit of practice, it'll give you a good list of candidates which will include your answer or at least a similar movement from the same design, if it's in his database. You can limit your search based on the bridge layout details and some features. You can't, for example, limit your search by size or by approximate year even though this info is in the db. Sometimes this can be an advantage, if for example you've got an unspecified model that is based on an earlier or different sized design. It also seems to not work well if you input too many parameters. If you could take his database and improve the search querying and the sorting, plus add some image recognition to the movement ID scheme, it would be fun to try.1 point

-

You know, I rather like the look of that watch. It's pretty cool. For all that I love my pocket watches, I would wear that one.1 point

-

You could glue them together with shellac and then heat them up to separate them when you're done. Or use a CA glue (super glue) and soak in acetone to separate them. GS hypo cement might even work in which case use IPA to dissolve the glue.1 point

-

Forgot to mention that no timegrapher is required during disassembly, visual inspection, cleaning, drying, re-assembling, oiling, winding... what else... oh yes, during attaching the watch strap or bracelet, balance staff replacement, crystal replacement, hydrostatic pressure test ?and it's definitely not needed for taking photographs... I think ??1 point

-

1 point

-

1 point

-

1 point

-

Reviews? Mine works just fine. Do not assume that a price difference means a quality difference when it's about Chinese mass produced objects. If you want to be a bit different and not dependent on batteries and Electronics, get a vernier or dial caliper.1 point

-

Today’s watch is my longtime owned Timex Sprite. I have no idea where I got it but it’s been in my dresser drawer of treasures since I was a boy. The original plastic strap hardened and cracked into pieces years ago so it was just a case until I recently decided to bring it back from the dead. I put on this lovely black leather Bulova strap I had from another watch and think it looks sharp. The movement was bound likely from overzealous winding and would only run for a few minutes at a time. Thanks to eBay I was able to find a trashed but running case to serve as a movement donor.1 point

-

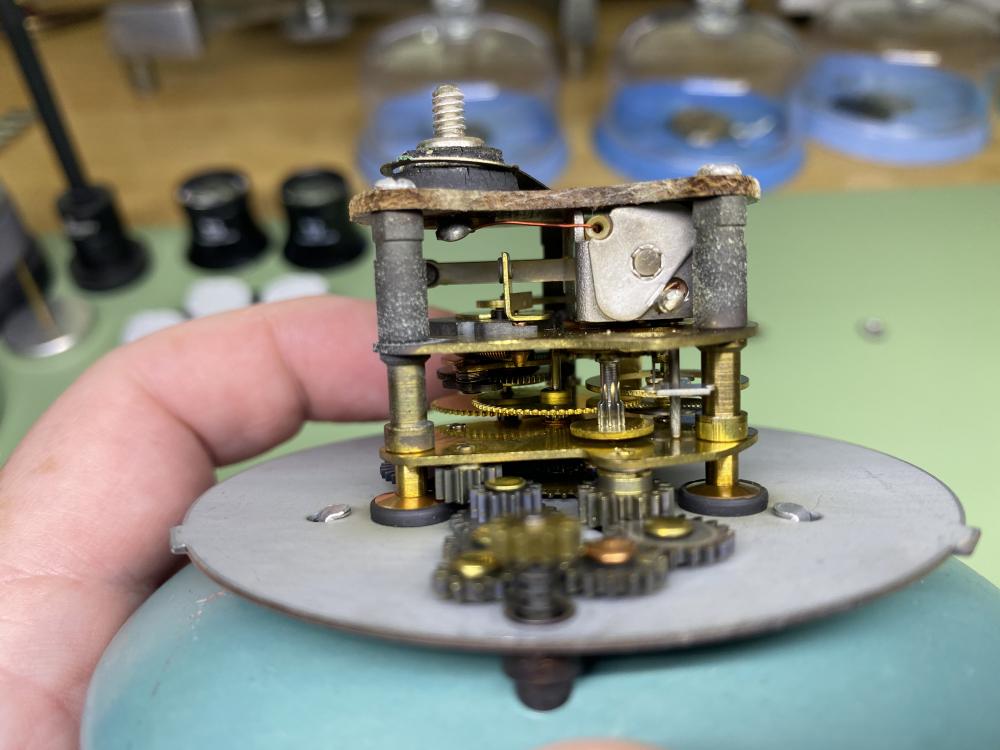

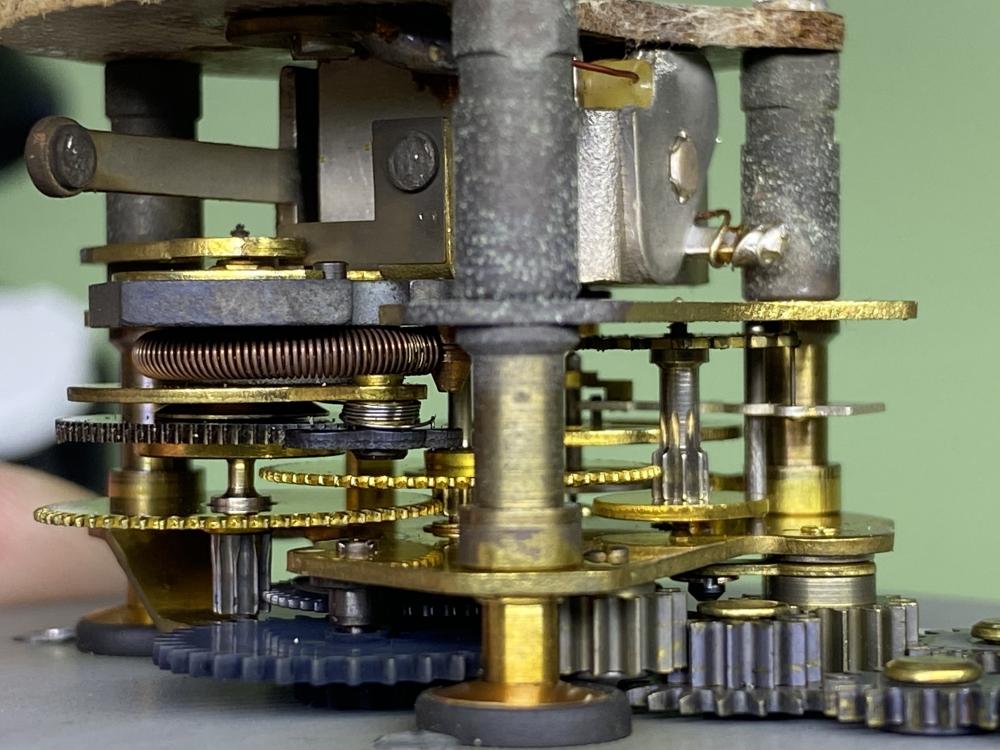

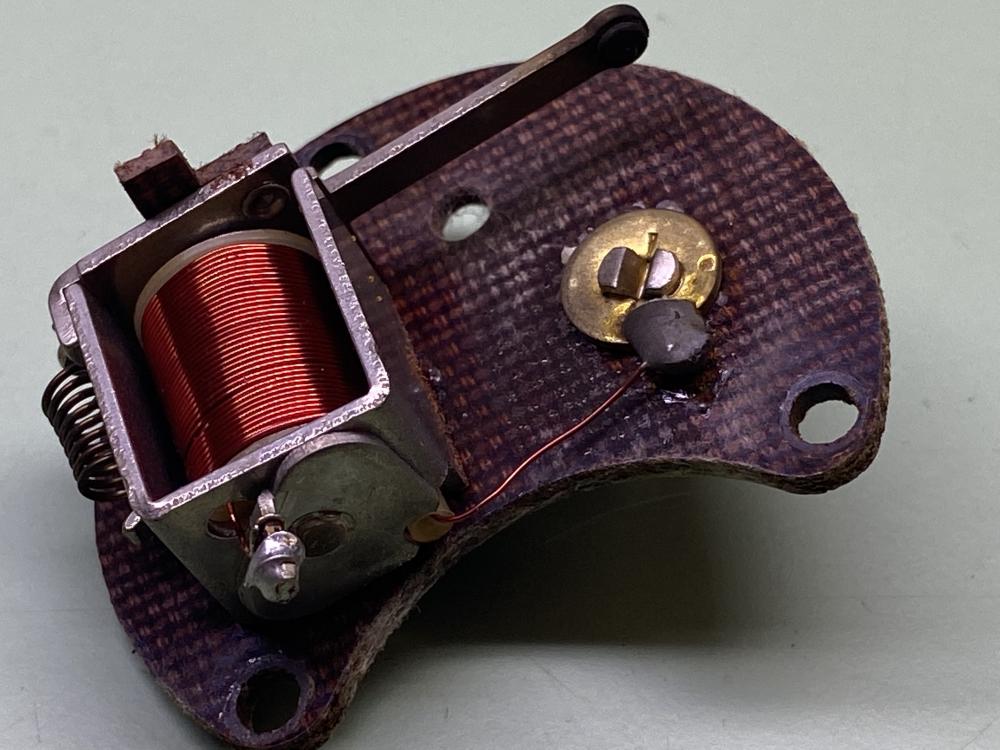

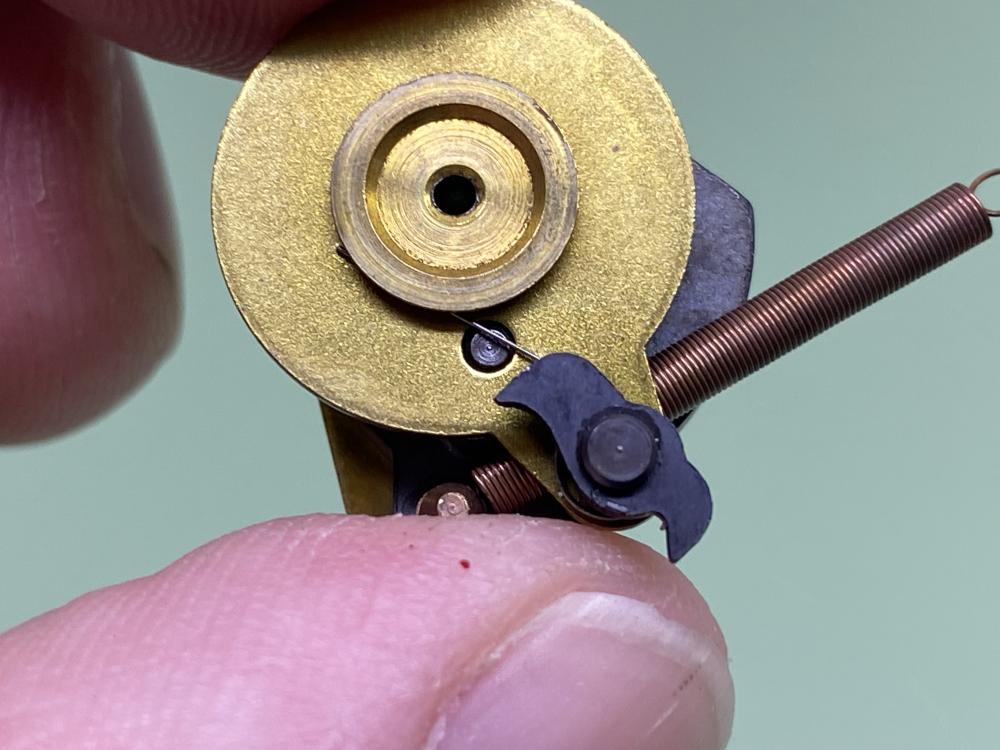

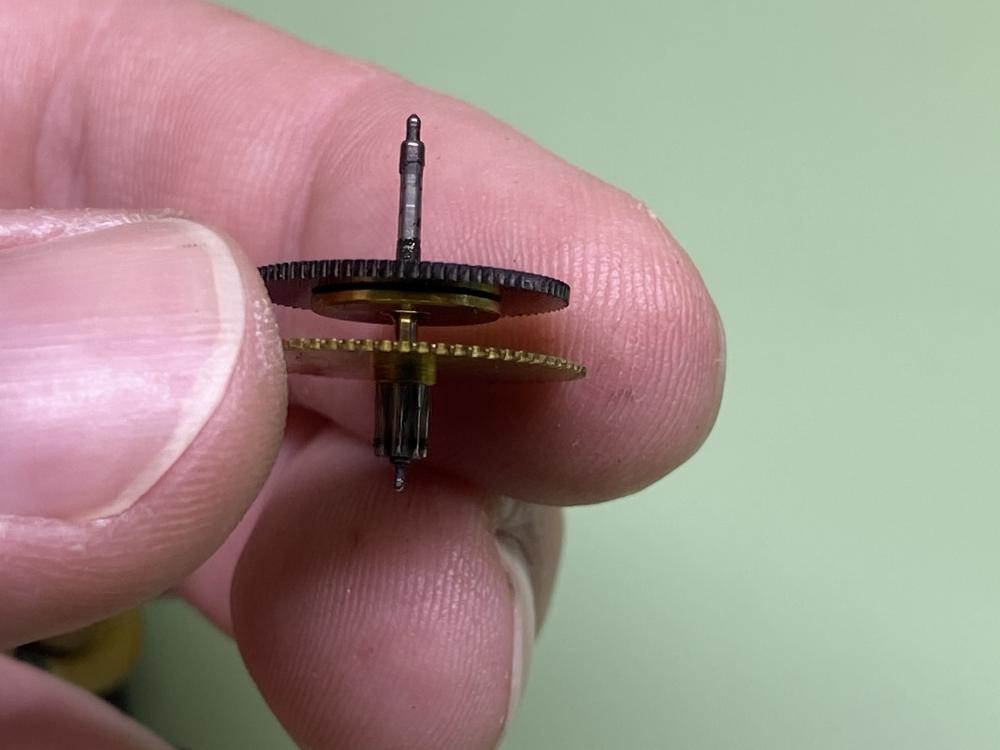

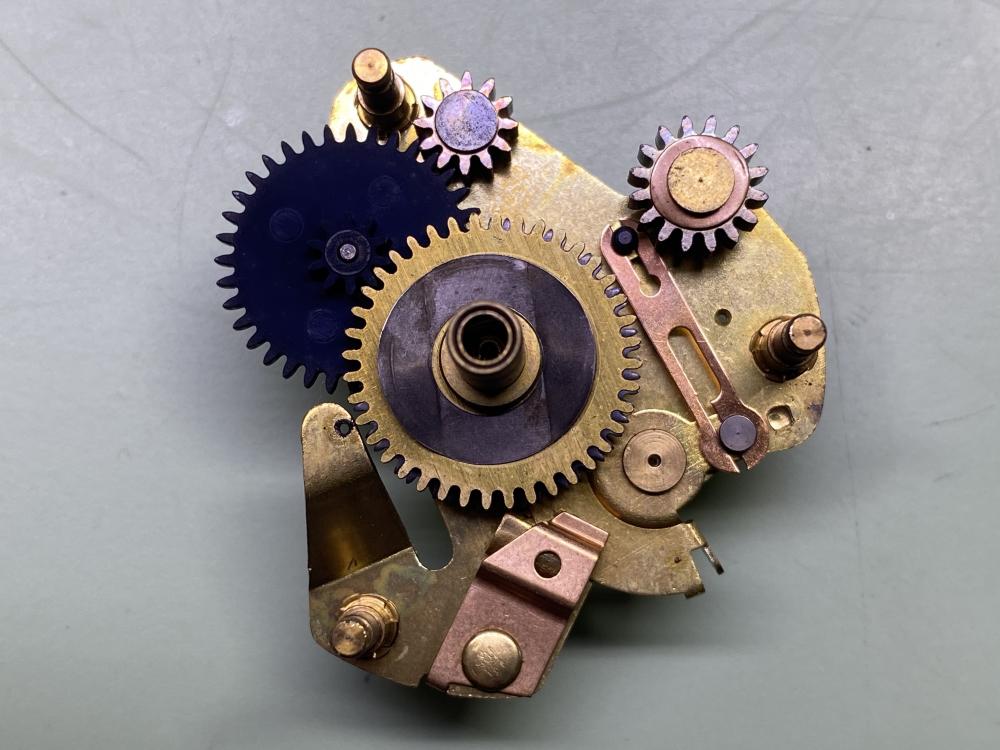

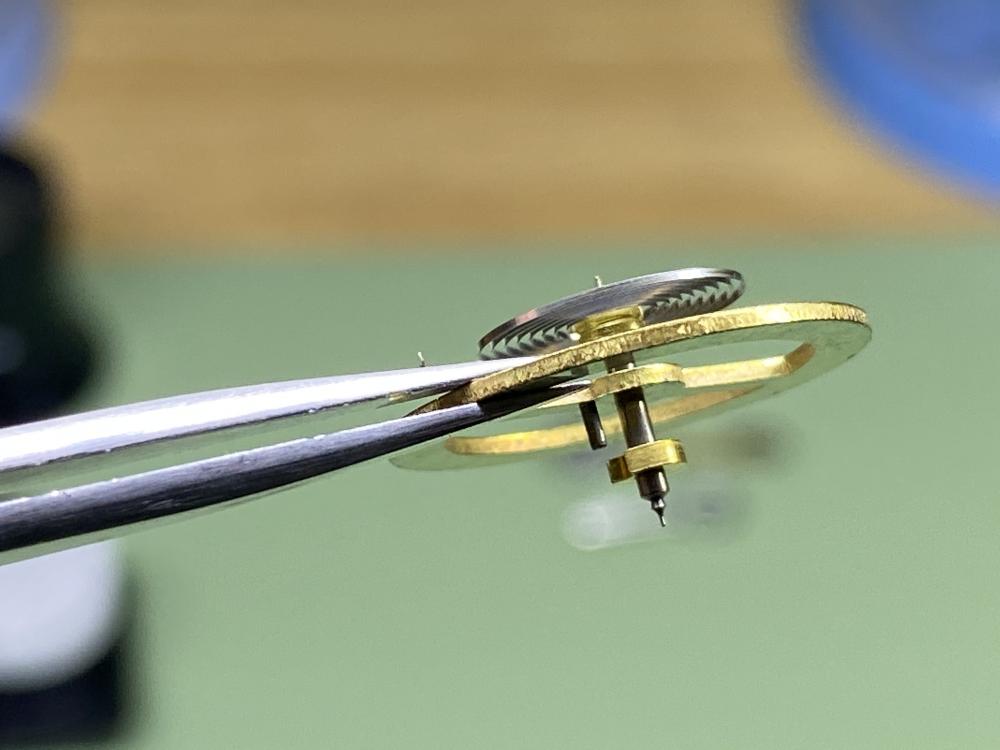

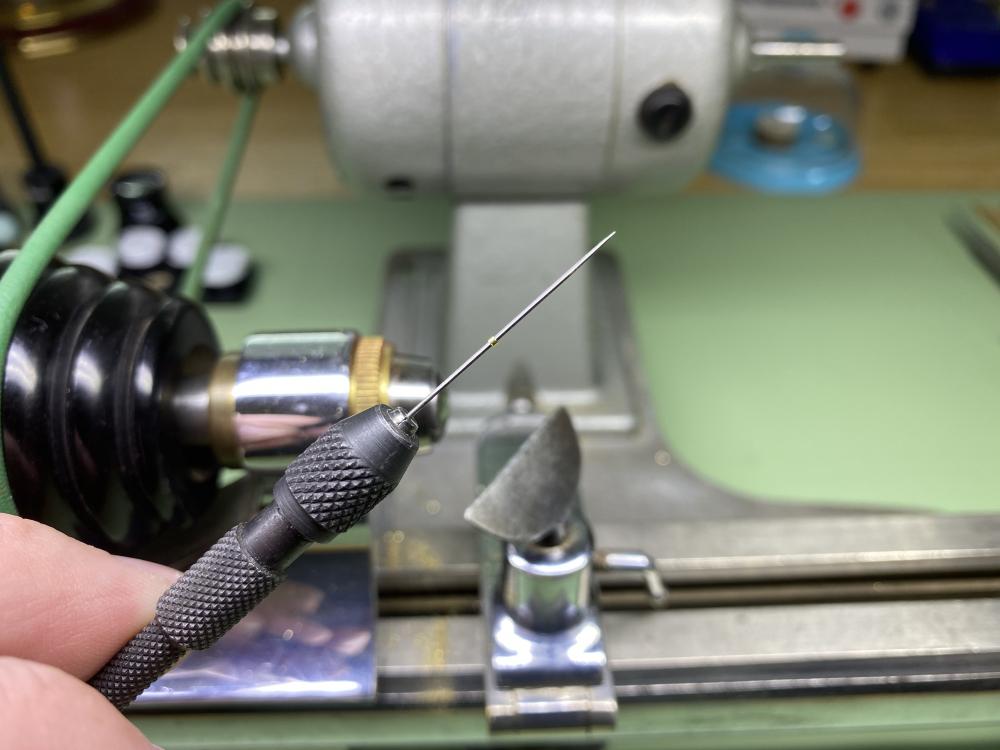

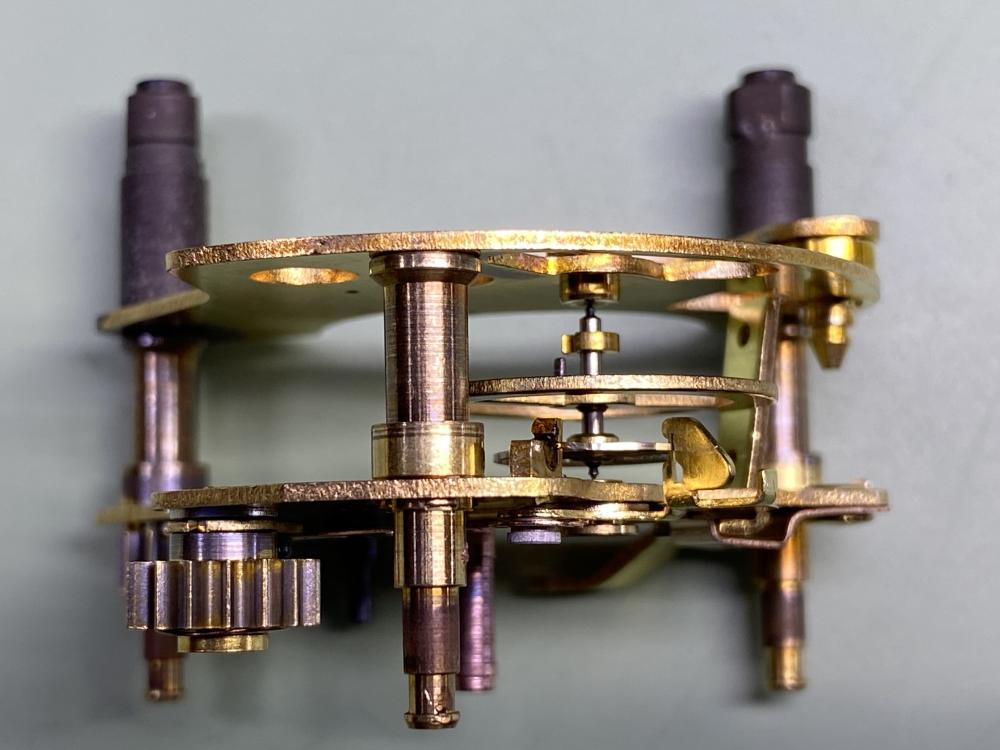

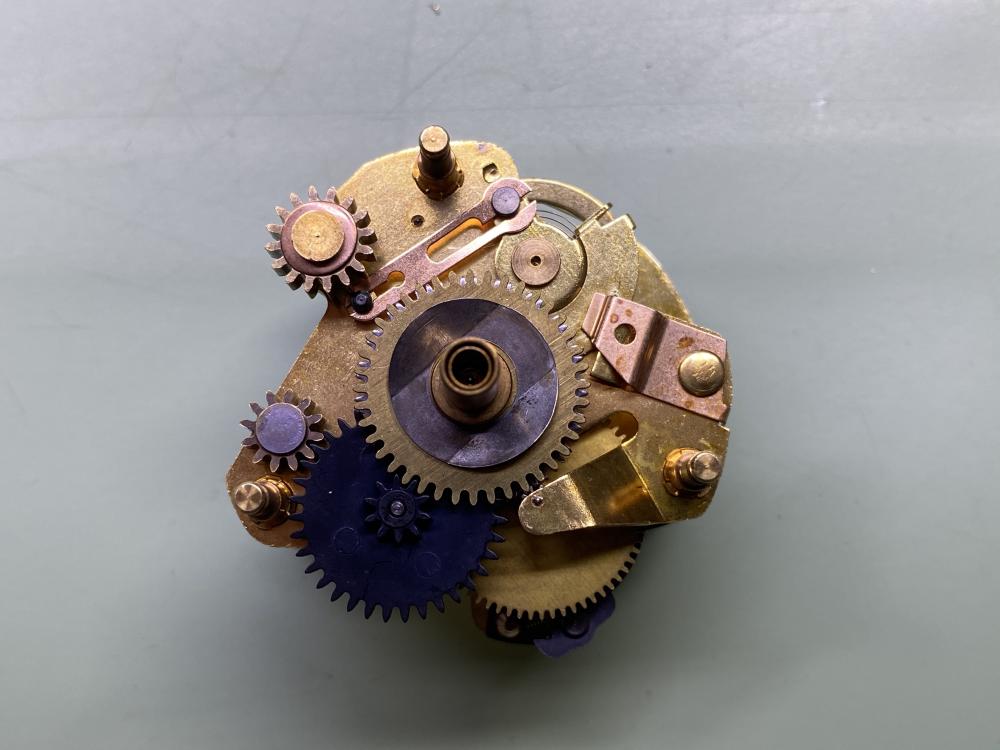

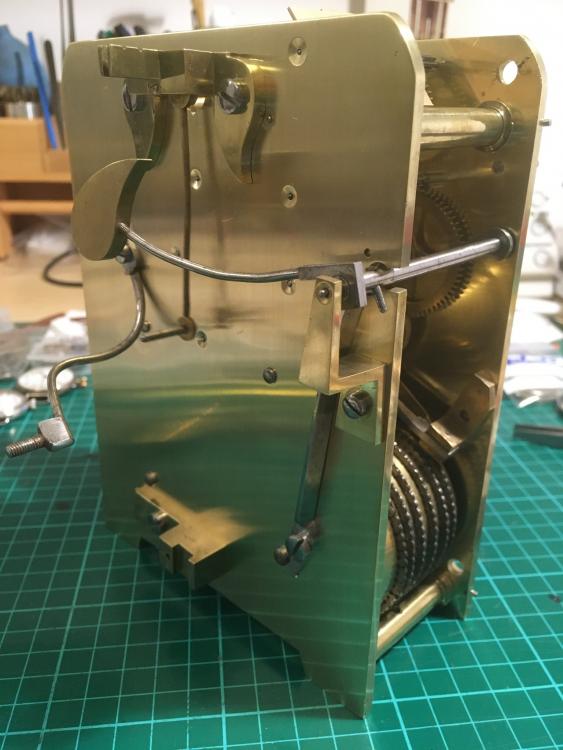

This is the dashboard clock my father pulled from his 1966 Chevrolet El Camino earlier this year. The clock didn't run at all and he asked me to take a look at it. Knowing nothing about automotive clocks I was intrigued and rushed over to pick it up. It's a simple affair with just two hands and a knob to adjust the time. No winding is necessary. On the back of the clock housing is a single 12 volt connection- the housing itself must ground the clock when installed in the dash. Stamped on the rear housing are the words Borg Instruments, Delavan Wis. The housing is removed by bending the three sheet metal tabs that run the circumference of the clock. Inside is a delicious stack of gears and a solenoid which winds the clock. A coil spring serves as the mainspring in this clock and it holds just about two minutes of power in it. When the coil spring is completely relaxed the two electrical contact points come together and are energized via the 12v connection. This causes the solenoid to act snapping the contacts away from each other and putting energy back into the spring. This action repeats itself every two minutes until the car battery is dead. Judging from the YouTube videos I watched before tackling this project- the typical failure point is the electrical contacts which wear out over time and fail to connect when the mainspring winds down. This wasn't the problem in my father's clock though. Most of the bearings in his clock had worn pear shaped and needed to be replaced. I broke down the clock for a good cleaning before turning new bearing on the lathe. The movement only has two jewels (for the balance wheel) so it's not surprising that the bearings would give out eventually. Some of the pivots were worn too and needed cleaning up as well. One of the cool things about this clock is that adjusting the time also regulates the speed of the clock. The setting knob is geared to make adjustment to the regulator and in this way whenever you make an adjustment 9adding or removing time) you are also adjusting the speed of the escapement. Everything was giving a nice scrub before reassembly. I removed the balance wheel in order to clean the plates and the hairspring is attached using shellac. This worried me a little bit but I found a narrow tip on the soldering iron was just perfect for softening the shellac and re-securing the hairspring. In the end I think I replaced five bushings in all. My father and I tested the clock by attaching it to the battery and letting it run for twenty-four hours; we found it to be a couple minutes slow the next day. I made an adjustment to the regulator before final installation in the dash and it seemed to be a bit better. Time will tell if it was a proper repair though. It was a fun little side project. I always assumed those dashboard clocks were entirely electrical but never bothered to considered how they worked. Now I know. ?1 point

-

Initially I had it on a fairly boring tan leather strap, which sort of worked with the red, but then I grabbed this midnight blue one with red stitching. It actually echoes my ThinkPad laptop's styling pretty closely too. I'll leave you to decide if Timex were ahead of their time, or Lenovo are harking back to a different era.1 point

-

1 point

-

Just for the record, if the fork and balance aren’t installed and I slightly wind the watch, EVERYTHING spins freely and when the power is out of the mainspring, the gears also continue to spin for a bit as inertia winds down. I’d also considered the fork as the issue. Cleaned the jewels and made sure that it would easily flick back and forth when the end was tapped and there was power in the mainspring. When everything is installed and I encourage the balance to spin, everything works. The fork ticks back and forth a few times, the train of wheels all turn. The balance just stops after a few ticks.1 point

-

@Bradders recently posted, looking for information about the venerable Baumgartner BFG866, and as a result I had a trawl through my spares to see if I had the makings of a complete movement. I wasn't quite there, however today while tidying up and organising things I came across this Buler 17 jewel 866(CLD) sweep second, date version. It had a smashed crystal and the balance was loose, but surprisingly when I inspected it, far from being damaged, the only issue with the balance was a loose balance cock screw, and a slight kink in the hairspring, no doubt due to be balance rattling about loose over the years. So unable to resist a challenge I cleaned lubricated and polished the thing, and off it went. There is some obvious damage to the dial, and it originally had a Cyclops date magnifier crystal, which I didn't have, so I substituted a standard high dome. It is also sporting rather annoying 17mm lugs. I had 17mm pins, but the only strap I had that wasn't glaringly obviously the wrong size was this slightly scruffy looking number. It wont win any beauty contests, but it does have a certain late fifties looking charm.1 point

-

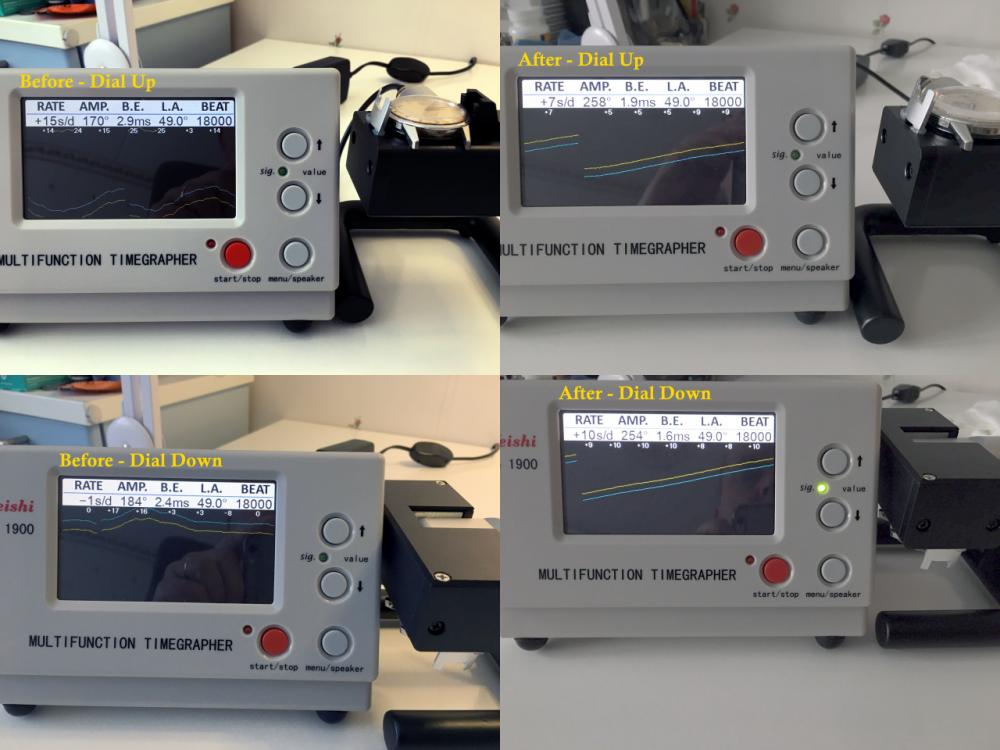

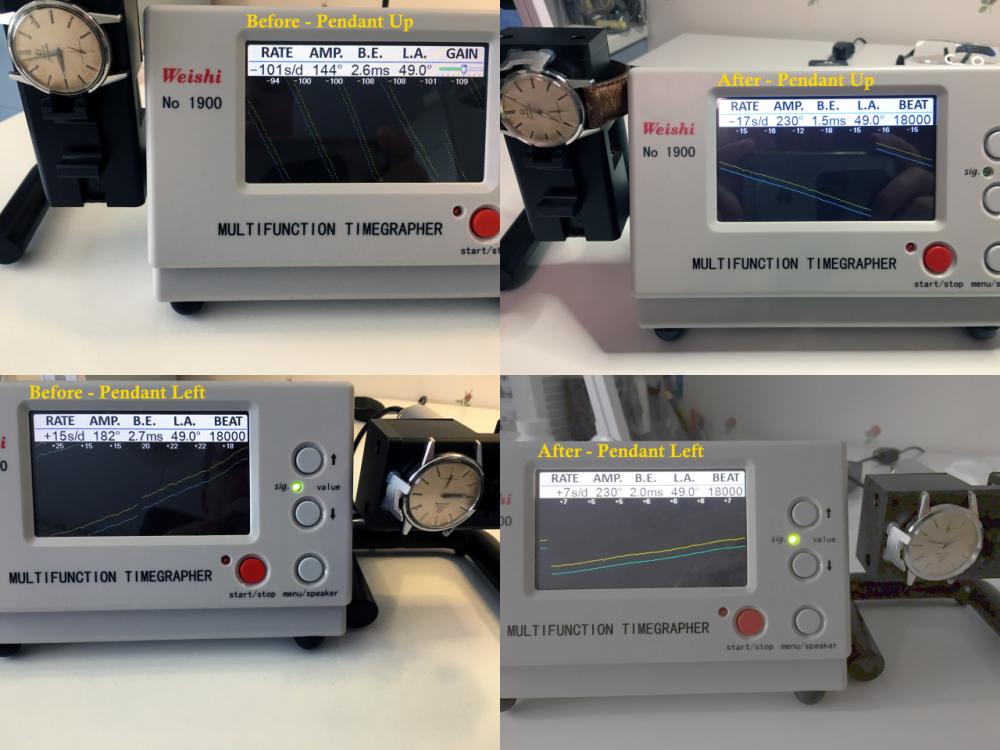

@Poljot I like you member name. Here's a beautiful Poljot I serviced a year or so ago! No, I didn't measure the ID of the mainspring barrel or the old mainspring. I simply trusted the GR4186 and fortunately it seems to be working well (as stated by the owner). However, as I fell in in love with this type of watch and movement I picked one up on Swedish local eBay (tradera.se) and it's in the pipe for an overhaul. As I have several other projects and ideas going I'm not sure when it is going to be, but I'll try to remember to measure and take some photos then. Anyway, the old MS was S-shaped, but it was obvious the movement had been serviced a couple of times before my service of it, so I don't think it was the original spring. My guess is that it had probably been serviced last two to three decades before my service it. Yes, I've heard other WR-talkers mention that GR springs sometimes are dud ?, but I've been lucky so far. Yes, I did apply the white lume as the original lume simply fell out of the hands as soon as I touched them, and white was the only color at hand. I guess a "retro"-color would have been better...1 point

-

Some more photos, including the dial-side striking work. I only cleaned the dial-side components since they are not normally visible and I didn’t want to remove any material. I did however dress the screw heads as some of them were very marred. I’ve cased it now, but may take it back out to adjust the exact time of striking - it strikes at 5 minutes past, so I may un-mesh and slip the motion works slightly to bring it forward.1 point

-

I have cleaned and repaired thousands of watches. All the complete balances and pallets have all been cleaned in Ronsonol also my master who taught me watchmaking who had already be a watchmaker for over 40 years. As far as I know never had a a single repair back due to trouble caused by Ronsonol lighter fluid. I'm sure if he did he would not want me to use it or recommend it to me.1 point

-

In my experience, and I suppose it could matter what brand of isopropanol, make that a very quick rinse. Absolutely make sure you do not rinse for more than a minute (60 seconds). Already after two minutes the shellac starts to soften and after a one or two more minutes the shellac will be in a state of dissolution.1 point