Leaderboard

Popular Content

Showing content with the highest reputation on 08/15/20 in all areas

-

Notice how your timing machine microphone has notches on the holder? You're supposed beholding the movement farther up rather than resting it where you have it. Also according to the link down below you have a subsecond spit one of the problems with resting the movement down is the subsecond bit shouldn't be pushing against anything besides upsetting the timing machine you risk bending that which is why the holder is meant the hold watches farther up. Notice how your amplitude is 184°? The timing procedure would be to wind the watch up let it run about 15 minutes time at preferably dial-up and dial down and as it's a wristwatch crown down we need to see all of that. Fully wound up that number should be just a tiny bit higher like 250 heading towards 300°. Out of curiosity did you take the mainspring out and replace it or even clean it? Then your grossly out of beat except until you get the amplitude up to 200° we can't tell because when you go past 200° problems get magnified considerably. Also did you demagnetized the watch? http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Universal_2623 points

-

In case anyone is having trouble curing their UV cure products, check the UV curing light. Most nail curing lights are using UVA leds with a wavelength of 365 to 405nm. These tend to have a low output and some manufacturers apply higher currents than recommended to increase output. This unfortunately will shorten the lifespan of the LED. The bad news is it will still lights up but the useful UVA part of the spectrum is gone. Hence your varnish or glue won't cure properly. Another problem is using a dental curing light for curing UV gels. Our dental curing lights are actually using blue light with a wavelength of 450nm. There is absolutely no no UVA. It is designed to be safer for eyes. Hope this info helps.2 points

-

My Breitling Airwolf A78363: My Seiko 6139-6011 which needs service and a new crystal. This won't be my only 6139-601x, I'm way too addicted to that absolutely gorgeous blue dial: My Seiko 6139-6020 (the red hue on the dial and hands is because of a red parasol). Hardly worn by the original owner: My Seiko SARB017: My Seiko SNA411: My Seiko Recraft Series SSC667 'Gulf': My Seiko SRP731K1 (NOS): I hope you enjoyed the post. Walter1 point

-

All of above are excellent points. Your mainspring appears to be the original mainspring it's a blued steel spring. On the modern White Springs you can get by without lubrication either because they have an invisible lubrication or because the steel itself doesn't need lubrication. But this is a blued steel spring some lubrication is required. When I look at the timing machine I still see what looks like power fluctuations Which unfortunately could come from a whole variety of things all the way for the mainspring to the balance wheel. If you manually rotate the balance wheel all the way until the roller jewel touches the fork on the backside and you let go how long does it take for the balance wheel to come to stop swinging back and forth? Then it does not appear that this watch has a jewel for the center wheel you want to look really carefully at the hot. Seeing as how that's the wheel driven by the mainspring that's the most likely place you could have a out around whole which would cause issues. The scratches on the pallet fork bridge look like sloppy watch work. But if you see anything that looks like the balance wheel was rubbing that is 100% unacceptable. One of the features unfortunately missing from that timing machine is the ability to listen to the watch ticking. Hold the watch up to your ear and listen to it really carefully and see if you hear anything beyond ticking noises like you actually hear it scraping or rubbing your hitting her bumping. Which would be so much nicer if the timing machine actually had audio. On the other hand was rubbing on the pallet fork bridge and turn it upside down that problem should go away.1 point

-

End shake on staff is ideally .01 to .02 mm. To test for lack of end shake, loosening cock screw like you did is enough, you would notice the oscilator set free to turn. You have an issue at the barrel though, Check, if barrel rubs on the bridge, barrel lid should drop in barrel and sit flush level with barrel wall, not push on mainspring ? worn holes in barrel or its lid or bent bridge, worn barrel arbour. Is this a fresh mainspring? old one might be dead. Goid luck1 point

-

1 point

-

I managed to find a piece if plastic pipe with a decent wall thickness that just happened to fit over the screw thread on the case-back (of my Omega Seamaster vintage 1967) and which also fitted over the outside of a small chuck for an electric drill. Ran the drill at its slow speed and used dialux compounds (can't remember which !!) on a cloth backed by a wooden spatula. This gave a good polished finish with no lining/marks.1 point

-

With Elgin being one of the biggest watch companies on the planet at least for a while they did make a lot of components and watches so their spare parts out there you just have to give it some time. Although changing the balance wheel complete from another watch is sometimes problematic. There was variations the balance staff pivots had variations then the escapement was set up for the balance wheel currently in the watch. Although we will hope that's the original balance wheel and somebody just didn't swap that. Fortunately most of the time on American balance wheels the serial number has been inscribed. So even though it's on a parts list it's interchangeable like the balance wheel I would try not to change that but the hairspring is another matter. Then why were waiting for the original posting person to come back tell us what's going on in the world I'm attached some more Images of the hairspring and the timing screws that would need possibly. Then looking at all the usual sources I didn't see any hairsprings but that just means you have to have patience and wait on eBay one will show up sooner or later or a scrap watch it could Get a hairspring from.1 point

-

Maybe the bushing could be moved in a touch to take up the shake. Although a replacement would be best sometimes one has to improvise when parts are not available.1 point

-

Even though I have the Chinese 1000 machine to play with I keep forgetting about his nasty killer spring. I'm not sure if I'd want to put an 18 size pocket watch in because if you were to ever let go of the spring it probably take a finger off If that was in the way. It's a shame they didn't copy the witschi microphones but they're considerably more complicated inside. They have a really nice even pressure plus the jaws are just slightly bigger you can hold a 36 size watch. But in any case you do want to get it up off the base especially with little seconds shaft sticking down because it's really easy to have accidents and break that off. Even if you know what you're doing it's all too easy to have an accident and I'll skip over how I know about that one.1 point

-

Having had the week to mull the clock over, I gave a lot of thought to the gilding the clock has, on close inspection it was obvious the clock had been gilded around the dial but the varnish covering the gilding has deteriorated and gone a mucky brown colour through the years, cleaning this with nothing more than a cotton bud and distilled water did bring some of this off but was also removing gilding, In order to return some of the victorian splendor to the clock, I decided to renew the gilding with 23k gold leaf around the dial i am part way through the process, I have dulled the gold down some what using a gold, brown varnish so it matches the gilded area with the writing on1 point

-

Andy Hull, wait 'till you see my old "Corona Virus lockdown watch". First *wrist* watch that I bought with my own money. It's the one I wear when I'm working on the van, or doing outdoor work late into the night, banging about with tools and whatnot. It's a Walmart brand called Eagle Ridge. It has a thick, heavy case, and a crystal that for its price has defied getting chipped or scratched somehow. Its a beater watch that won't die. And it does decently with accuracy, being quartz. As a bonus, it has "DiaLight"; a sort of tribute to Indiglo. If I'm going to be *seen* with a wrist watch I'd rather it were my Citizen or my Bulova. But if I want to *see* the time in dark places I just wear this.1 point

-

For lubrication nothing on the teeth or the pinions typically. Use the 9504 on anything that is a high friction typically metal on metal will work fine. Technically for the plastic wheels they actually do make a lubrication for plastic. Then the HP oil should work fine on the balance pivots it's a really big heavy balance wheel in any way. I'm just not sure if you want to put anything on the plastic because I don't know if it's going to react with the plastic Or not.1 point

-

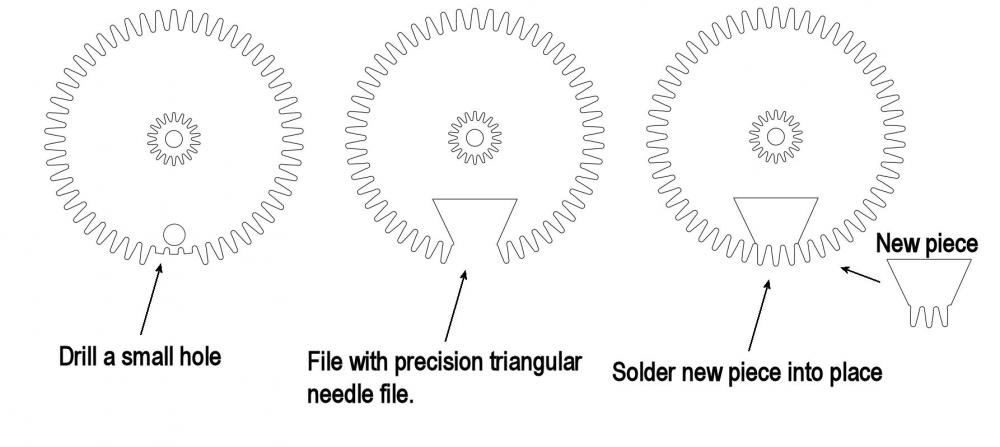

I think @oldhippy is right. From wrestling with hairsprings this is one of the trickiest repairs to do, and when doing it one whish one saved the previous discarded part in the “good to have in the future box”. When it comes to replacing the teeth the donor piece has to come from a wheel not only with the same diameter but also the same type of teeth and depth on them, this is so you will get the correct amount of freedom for the wheels to rotate in a correct way. Even small differences like these ones will make the wheels not to run correctly in the length. Another thing to consider is how to put the new piece in place. One should avoid making a rectangular shape to fit with and instead make a “dove tail” shape with a precision triangular file. Since the teeth on the wheel is subjected to lateral driving pressures a rectangular shape will eventually cause it to wriggle free and fall out, the solder hasn’t a very good mechanical resistance. This is just some small tips and tricks to think of when repairing wheels.1 point

-

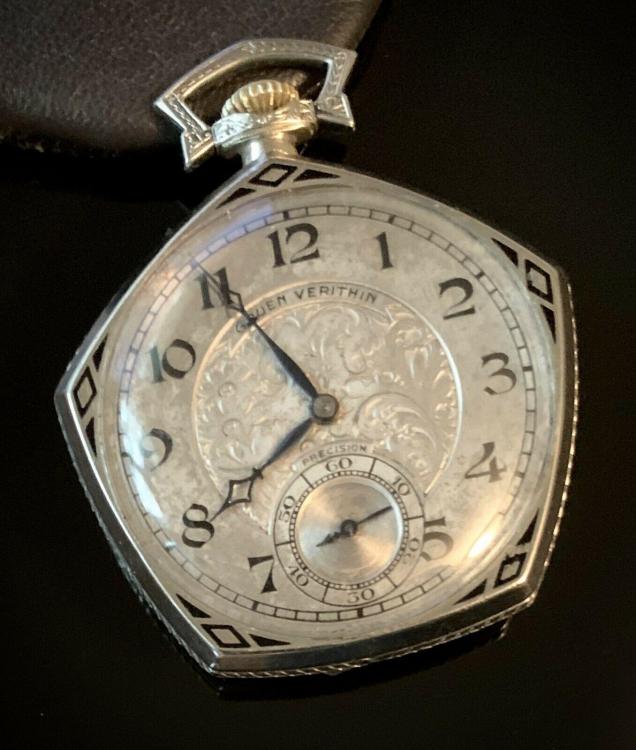

So, here's kind of a fun story: A few weeks ago, I purchased a Gruen Verithin Pentagon pocket watch in filled white gold. It had a distinctive engraving inside of its caseback that read "Leland S. Offer, Los Angeles, Calif." Based on the serial number of its case and movement, and with the assistance of some Gruen experts, I was able to date this watch to 1922 or 1923. Because I was curious and like a good story, I researched the original owner, one Leland Stanford Offer, who was a successful salesman living near Los Angeles at the time he purchased the Pentagon. Using Ancestry.com, I was able to learn the names of Leland S. Offer's living descendants. With the help of Google and some paid people searches, I was able to get in contact with Leland S. Offer's living grandson and one of Leland S. Offer's living great-grandnephews. I mailed the great-grandnephew Leland S. Offer's Gruen Pentagon, and the current plan is for the great-grandnephew and I to surprise Leland S. Offer's living grandson with his grandfather's watch on a Zoom videoconference later this week. I was happy to reunite this family with the pocketwatch free of charge, but the great-grandnephew insisted on covering my expenses. Because of this, I've been on the lookout for a nice replacement Gruen Pentagon pocketwatch. I had been lusting after a 14k or filled green gold Pentagon, but earlier today I found a really nice solid 14k white gold specimen that was nicely engraved and featured pretty black enamel painting on its case. Here's the replacement Gruen Pentagon that is on its way to me now: I plan on polishing and heat bluing the hands from this watch. I would like to overhaul it myself, but I don't know if I have the skills to attempt this yet. I've been practicing on Seiko NH36A movements and the experience has, to say the least, been humbling. There's something about the super thin and delicate layers of aluminum in the NH36A movement that I can't help but destroy.1 point

-

If bikes of all kinds are your thing, and you find yourself in Glasgow then I highly recommend the Riverside Museum (actually even if bikes are not your thing). Click the links for a little more of a flavour of the place. https://www.tripadvisor.co.uk/Attraction_Review-g186534-d214166-Reviews-The_Riverside_Museum_of_Transport_and_Travel-Glasgow_Scotland.html#photos;aggregationId=101&albumid=101&filter=7&ff=390872885 You can easily spend a day in the place. The Riverside is second (in my opinion) only to the National Museum of Scotland in Edinburgh as must see museums round here. The NMS also has some interesting cycling exhibits. https://www.nms.ac.uk/explore-our-collections/stories/science-and-technology/bicycles-at-national-museums-scotland/1 point

-

1 point

-

To answer the original question - the ring is to put the handle into to protect it so you don't press the plunger accidentally while fooling with the spring. You can sit the handle into it so you can work on the with the handle upright and the plunger protected.1 point

-

I've had another look at the movement, the chime and strike are flirt release they use a system that operates without warning, it use a large sprung flirt that is tripped by a pin on the hour wheel knocking the rack hook upwards and allowing the rack to fall, I'll take some pictures and post when I clean it. but the following picture is of another clock I own that uses the same type of chime strike mechanism1 point

-

The Limit almost certainly will contain an AS2066 movement Andy....1 point

-

1 point

-

1 point

-

Buying new, the most likely candidate is the "sincere" Chinese lathe mentioned and pictured above.1 point

-

This should put your mind at rest. Click on this link. http://members.iinet.net.au/~fotoplot/sdriver/sdriver.html1 point

-

Well, I suppose it depends on what you define as “perfect”. I don’t think you could easily achieve a flat/even polish using a Dremel in that way, and the photos posted above show why. You could possibly buff, but in this case significant material needs to be cut, assuming the intention is to remove the printed text. I do own the same Dremel as shown above, but I always mount cases and case backs on a lathe to get results which I would expect from a watch leaving the factory.0 points