Leaderboard

Popular Content

Showing content with the highest reputation on 07/31/20 in all areas

-

3 points

-

Just to continue the point that Frank is describing, the thickness is your more likely issue here, as the difference between 0.11 and 0.10 is 10%...... and that difference is effectively cubed when it comes to calculating force. 1 cubed = 1 1.1 cubed = 1.331 That’s an increase of 33%2 points

-

@AdamC considering age and possible wear of your movement, your choice of a slightly thicker spring is intelligible. For a more modern, less wear movement I 'd chosen 0.10 rather and is what my calculator recommends. Nivarox/steel: strength changes in 3rd power with thickness, not linear. I suspect, needed decrease of thickness will be much less. @nickelsilver I buy from GR, too, but mostly the Inox variant. They have the same S-form as Nivarox springs. Frank2 points

-

As for differences in strength between steel and modern alloys, there are a few things to consider. Elgin was the first to offer a modern alloy as a mainspring, Elgiloy, which is still used extensively in industry. Others followed, and nowadays we have most new springs coming from Generale Ressorts. They offer springs in two grades, stainless, or Nivaflex. There are a few properties that one would look for in a spring, first being "springiness" or strength, which boils down to Young's Modulus. Another would be durability, and another ease of manufacture. To see the differences of the common mainspring materials we have: Carbon steel- Young's modulus of 206, fairly durable Stainless steel- Young's modulus of around 190, quite durable Elgiloy- Young's modulus of 211, very durable Nivaflex- Young's modulus 221, very durable While Elgiloy is still used in industrial applications I don't think anyone is making watch mainsprings from it anymore. One of its particular qualities is that its point of plastic deformation is very good compared to other similar alloys. So you can have a spring that can be pushed further without deforming or breaking- no doubt one reason it was such a good mainspring. I don't think anyone makes carbon steel watch springs anymore, nor have for some time. Nivaflex is the #1 choice of manufacturers for new pieces. As seen above, it is significantly stronger than carbon steel, and even more so than stainless. I have noticed that replacing a carbon steel spring with a stainless spring of the same thickness is indeed a step back in power. Likewise, replacing a carbon steel or stainless spring with Nivaflex offers a boost in power. I order directly from GR, and always request Nivaflex specifically. In some cases if they only have stainless in stock I will look elsewhere for old stock. Bottom line is Nivaflex is stronger than carbon steel, stainless is weaker (as springs). Stainless springs will not have the reverse curve at the hook end like Nivaflex does, it will open up like a regular steel spring.2 points

-

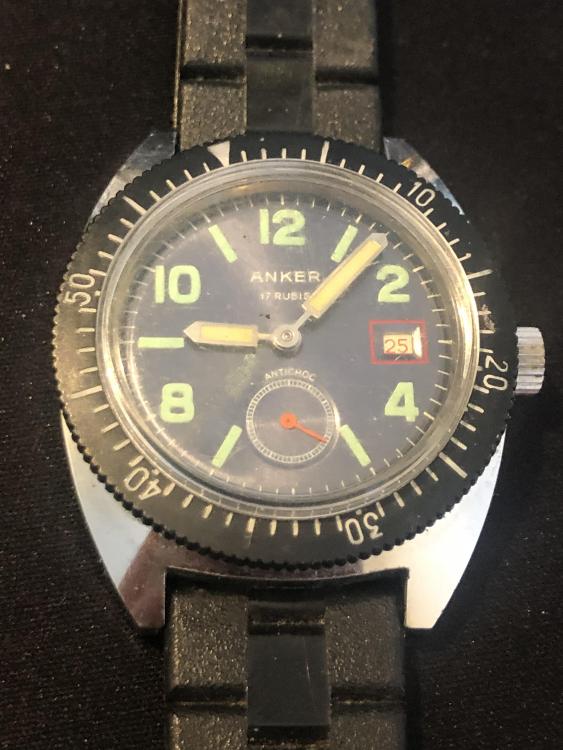

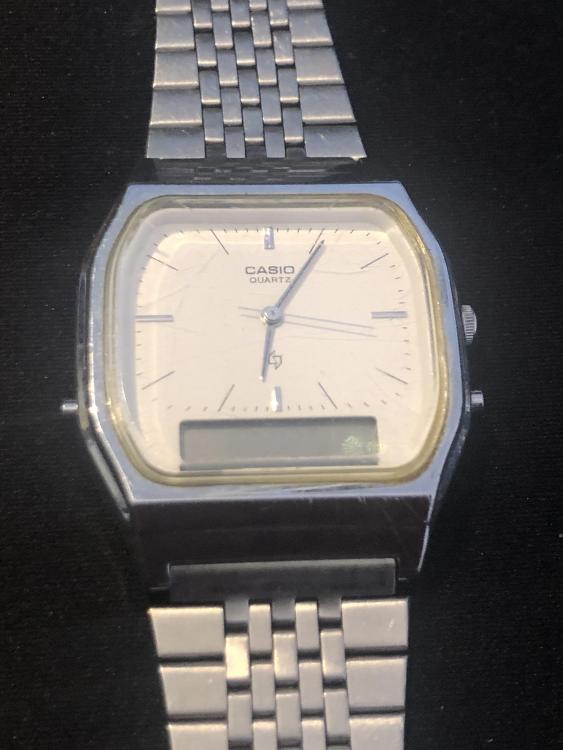

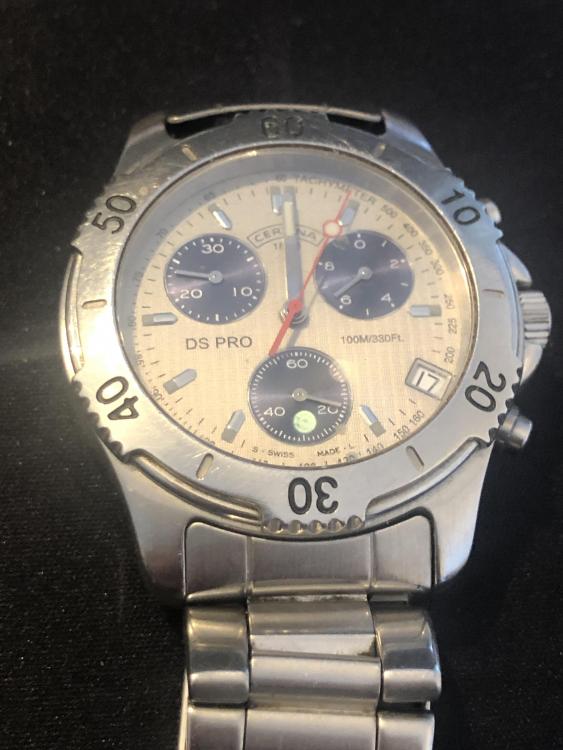

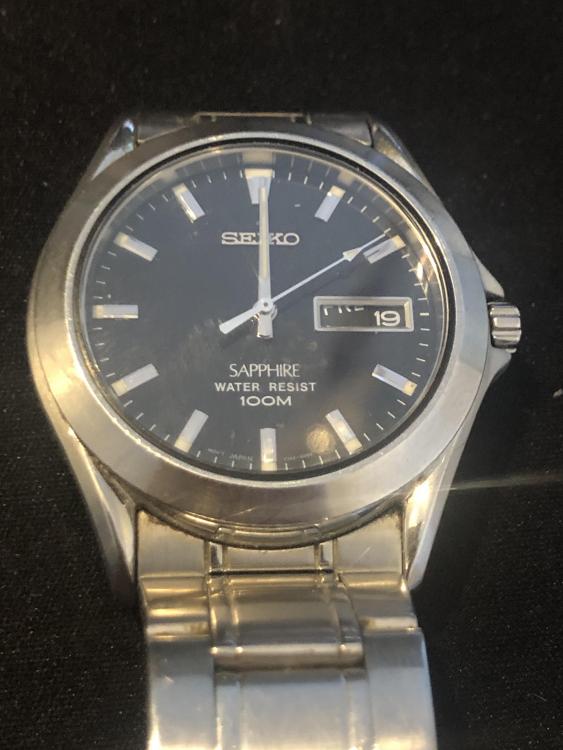

This is my personal watches. I got the as birthdays presents over the years. The blue Seiko I got from a work project as thanks you. They were daily use and abuse. Except the Anker. Im not in to quartz. But I will change batteries, service, and and buff them up. Not in picture. But daytime I use a Applewatch. Hopefully it will soon change to a pure mechanical watch. That I have restored my self. The Anker is a very beloved watch. As a kid, I got it new from my father in 1978. A year later he passed away suddenly. It is totally original, plastic bracelet and all. I pretty much never wore it, because it was too big at the time. He was a sports diver, and of coarse. He got me a divers watch. I remember trying to punch a new hole, to get it to fit it to my wrist. But was still to big. And when I grew up. It wasn't cool anymore. So it is pretty much scratch free. It has a problem that I need to look in to later, when Im much more experienced. I remember many years ago. I tried to wind it up. But something broke. And it now only moves the hands. Even in winding position. I will look in to this with great care! I have recently searched high and low about this particular model. But came up with nothing. I find models with the same bezel, and hands. But no one with a separate second "bullseye?" if anyone have info where to find Anker info. I would be much appreciated! In the near future, I hope to find a cpl of pocket watches. Also find my self starring at Landeron movements. Cheers!1 point

-

Ok, So the screwdrivers, tweezers ect arrived today. Could not wait to start! Have got a Fortis as first project, that seems to come from a lot of sparepart watches. It has the FHF 96ST movement. Looks brand new, and was sold as a non runner. It is missing the stem. And the dial looked loose. Pried up the case lid. And the movment fell out. So, I tried to wind the barrel a little with a screwdriver. No surplice there, It didn't run. After a little closer look. I saw the balance jewel is missing. Also looked like the pivot might be broken. Bit exited, I started with removing the hands. Had little trouble there. The houerhand was pried to dial face. But after a little more fiddling than expected. I got it off. For my life. I couldn't find the screws to the dial. Turns out it was glued on to the movement.. Even more intresting! But got that off too, with little "fiddling" Tried to get it running again. But noticed that the balance looked out of alignment. Time to bring out the new "chunky" Bergeon screwdrivers! (love them already) With a "some" intresting trying out different work positions, shifting between 4x and 10x loupe. Half scared to mess up the balance, possibly even more. Still exited. But with some fueling with the tweezers. Tha balance came out in one piece with the hair spring. Im not sure why its called hairspring. It sure is thinner than a hair.. After som try and tribulations with the loupe. I managed to notice that the lower pivot on the balance staff is ok. Had hard time to see if the upper pivot was existing. The hairspring is in the way. Im not sure how you guys do it? Im sure scared to mess up the hairspring! But eventually, I got a glimpse of it. Looked at the fork and timing wheel. It seemd to want to "tick". So I decided to remount the balance again. Well..That took some time. Again very fiddly! First time, I got the impulse jewel out of alignment. Took me a while to figure out. And even more time to reassemble with it in alignment. But got it there on the second try. Im not telling you about how long it took.. With everything back. I I tried to "kick" the balance. Veeerrry carefully. It wanted to go! With the missing to jewel in mind. I decided to give it "some" oil. Since it never has been up and running. It is probably very gummed up. So disassembly, cleaning and oiling have to be done anyway. So I thought it is the perfect first oiling effort, as I can clean upp my mess, anyway. Oiling. Jeez.. Those jewels is tiny!! Let say.. Comparing on what Ive seen on turitorials ect. My jewels isn't missing any lube.. But it started ticking!!! It definitely isn't strong ticking. But an houer later, writing this. It is still ticking! Mezmerasing! I call this evening a success! Some notes to self: 1. Im getting a bit shakier over the years. Loupes magnifies that too.. LOL! 2. Improve working position. Sitting on the floor isn't an option. So raising the office table some how, is needed. 3. I did like to use the loupe better without the head band. It was quicker to change between magnification. (have only 4x and 10x) 4. Amongst many other things. A microscope is now on the wishlist for the future wallet enlightener list. 4. When doing close up work. Don´t poke the nose with the screwdrivers.(unintentional, or not). The new Bergeon screwdrivers will be offended!! 5. Somehow, I need to find a correct jewel, spring ect. Find out if a jewel press is needed?. Hm. have to get a stem and crown too. 6. The only thing I got top quality tool to start with. Was the Bergeon screwdrivers. As the first set "stuff" needed. Didn't come cheap any way. But Im happy I got quality screwdrivers. So Im pondering if the wife get upset if I have them on the night table! Hm! 7. Today was a great day! lets make tomorrow even better! 8. Tomorrow is disassembly day. Remember to take maaany pictures!! 9. Get some sleep! /Johan1 point

-

£20.00 I think is the going rate with some carriers they get a bit shirty about carrying liquids if you live any where near they have a trade counter.1 point

-

That's 100% approved A-OK especially when needing to part something that's challenging the rigidity of a machine. If on a larger lathe best to put a block of wood under the cut or the saw can surprise you when it gets through and nick the bed (I do the saw trick with the lathe running). Just remember to reverse the spindle direction id using a jeweler's saw where the cut direction is opposite.1 point

-

a couple of minor problems with this. Mineral oils are still available so they haven't gone away we could conceivably still use them or are still using them. then organic or animal-based oils as the reference am currently looking at calls them were supposed to be much better than the mineral oils.1 point

-

Today's watch is my grandads old Roamer which I acquired in 1986. It had been sat in the cupboard all this time but finally I have had it repaired and serviced. It required a new main spring. It keeps great time although I only wear it when sat in the office. I don't know its age but I do know that the movement is an MST 430.1 point

-

From experience, I've been able to open all "do not open" barrels and close them except Zodiac. The ones I've seen are truly crimped/burnished such that the cap is destroyed in removal. Last one I did I made a new cap.1 point

-

Yankeedog is right on with the plastic bag trick, can save hours scraping round the floor. A usefull tool for finding errant parts is a long magnetic knife holder covers a lot of ground with one sweep. You have the right attitude to succeed, dont get frustated just walk away have a beer then start again you are doing ok.1 point

-

When working on the dial side I like to work on the movement inside a clear plastic bag.It keeps the Jesus springs from flying off to heaven.working on a clean white surface such as a piece of printer/copy paper helps you to see small parts.1 point

-

Ok, I had to look it up: Torque of the barrel M ~ E x I E= E or Young's modulus I= moment of inertia (with physical dimensions of spring, e.g. s^3) Means, influence of E is direct (linear), influence of thickness s is with 3rd power. My source (Prof. Glaser: Uhrentechnik) mentiones: E, springsteel, texture rolled: 225 E, Inox: 190 - 210 E, Nivaflex: 225 About the same as above. Frank1 point

-

I would regard this as nonsense, I am sorry. Old neatsfoot oil (when fresh) had better lubricating properties than modern oil. But wear of teeth and bearings (if not jewelled) gives more loss in power transmission. Hence imho the opposite is true. Frank1 point

-

Hi Johnnie If when the insulator is re fitted it still not going Hattori VX11 and VX51 etc depending on the ligne size of movement. Most will need the dial feet moving or removing and resort to stickers. And possible hand sets . Attached two docs which might be usefull if you have to on the search. cheers List of WATCH MOVEMENTS J Borel.pdf Watch Movement Catalog (1).pdf1 point

-

Hi and welcome to the forum as a first attempt you deserve a pat on the back. Getting it to work brilliant, long my your hobby continue and long may you enjoy it.1 point

-

I see you might have been at Tradera and looked for treasures. That glue what looks like the Swedish specialty "Karlssons klister" might be tough to get off but a good rub with pure acetone on a cotton Topps would do it. Since the dial lacks feet you shouldn't glue it back on, I recommend you begin with dial feet stickers and take it from there, when you get a bit experienced swap them to dial feet’s. Unfortunately I don’t have that kind of cap jewels for the FHF (ST) 96 at home, if you don't find it I have a replacement movement which I can donate for free. Just pop me a PM.1 point

-

I think twice and examine pix from a digital microscope before wasting money on one. To put the jewel, end stone and spring on the cock, I detach balance, stud and regulator arm off the cock, makes the task a lot easier. Needs three cleans. Good luck1 point

-

1 point

-

Not much in ebay UK at the moment , just a few odd parts. There may be nothing wrong with the movement other than gummed up 'works', I find this a lot with 40 year old quartz watches. I do have the advantage of a Seiko Quartz tester though and can quickly confirm if the electronics are running despite no movement of the hands....1 point

-

1 point

-

Oils? Talk about opening a can of worms! Strictly speaking you SHOULD use a proper oil. Loosely speaking that bottle might set you back more than the watch...now granted so little oil is needed that bottle will oil dozens of watches. You could also use 0w20 synthetic motor oil. But that would be improper.1 point

-

The movement is a cal.53530. search 'Orient 53530' in ebay and with a bit of luck you will find a working watch 'cosmetically challenged' with movement that you can swap out...1 point

-

My amphibia does the same. Every time I change the dial and hands it throws a hissy fit for a few days and needs to be wound manually. Always works perfectly after that. It's still one of the most accurate watches I own. I think they built gremlins into the design. Sent from my SM-G973F using Tapatalk1 point

-

1 point

-

I do take them apart, but they're tricky. I have a special tool made by Star decades ago but alas 19/20 it doesn't fit. I slide nickel tweezers between the upper and lower pinion, and push on the pivot with the tail end of another nickel tweezer. A Platax tool would work too (about the only good it's for in my opinion). If you clean it assembled, put some good thick oil like HP1300 at the seam, hold the upper pinion with nickel or brass tweezers and turn the wheel so it works in. Do it a couple of times, then remove any remaining oil with pithwood. If it's not lubricated it will fail and then you have a bigger job on your hands.1 point

-

Almost all complete. Everything dry fit, nothing fastened together. As mentioned above, I’ll have to re-contour the retaining walls. I’ll also finish the top so it somewhat matches the drawers. When it’s complete I’ll post the last picture. I’m happy with the semi-finished product. I certainly learned a lot. In case it went unread, look up a few posts about the free work surface.1 point

-

1 point

-

I've had very good consistent results using the Quadralene fine instrument cleaner which is a non ammonia based cleaner, although it does have a very slight ammonia type smell to it but certainly not enough to be a nuisance in a small room , I also use the Quadralene fine rinse, both these are solvent based but are safe to use with shellac, I do though pre clean some parts if heavily soiled in dried gummy oil with lighter fluid, the cleaner is used neat and not watered down it is cheaper than other brand name cleaners. Some people use isopropanol rinse, which will degrade shellac I personally would not use it, if you do be sure to clean the pallets and balance separately, it does have the advantage of being cheap and evaporating very quickly and leaves no drying marks, the Quadralene rinse is slower to dry but also leaves no surface marks. The Quadralene web site is a bit poor and does not as far as I have seen list individual products, but the sales team offer good advice if you tell them what you need a product for, so ring them up and ask if you need to buy. I am lucky in that I have two sets of jars for my National so do use a product similar to Horolene for some clock parts and distilled water for rinsing, it is always handy to have a spare set of jars for these machines. I can't comment on other cleaners because I've never used them.1 point

-

1 point

-

Hi I got another Wag on the Wall Clock (postmans clock) in a box its had a hard life. Its been duly cleaned and in doing so on of the pivots was almost gone, So out comes the lathe and after making a pivoting flag to fit the tool rest post, down to work drilling the arbour and fitting a new pivot. The end result was a working clock again now on the test stand awaiting the dial and surround fitting. I thought I had better post something in case you all think I dont do anything1 point

-

Finally got round to sporting my Soviet era “Polarski” Elektronika 1 today. Wife hates pretty much all of my collection, but out with her friends last night - they are both into 60s and 70s retro furniture and design. They loved it! The husband especially got a kick out it being stamped in Cyrillic “made in CCCP” Her female friend wants any ladies LED I can find for her - I just happen to have few kicking around1 point