Leaderboard

Popular Content

Showing content with the highest reputation on 04/04/20 in Posts

-

This image from the Dundee based Evening Telegraph, of an assembly worker at the Timex plant suggests that it is probably a bit of both. Skill and custom tooling I suspect there was a knack to the various tasks, and specialists in each task. Furthermore there were probably teams performing each task, to keep things flowing along, rather than one individual performing multiple assembly tasks. So you would have a bunch of machinists on multiple similar machines producing batches of parts, another team producing the plates, another team of assemblers, another team doing the casing, a team lathe turning screws, others still machining the cases, fitting crystals, pins, straps and so forth. The trick with this kind of work, is to keep things flowing as smoothly and as quickly as possible. Any major bottle necks and potentially the whole plant grinds to a halt, and that costs money. I once got called out to the Schweppes plant (now called Coca-Cola European Partners or some such) in East Kilbride, to a failed custom branded industrial PC computer. Their maintenance team couldn't fix it so they called round all of the local computer companies until they found someone that said "aye, nae bother, we can fix anything", so I was duly dispatched to fix the thing with a bunch of random spares and a completely different PC. An entire bottling plant line was controlled by one PC (this was a long time back when computers were expensive), and therefore the whole place had ground to a halt. No pressure. I replaced the motherboard with my random spare, and off it went. As soon as it started back up the first task was to dump all of the contents of the various huge vats of ingredients into a skip as they had been sitting longer than their food hygiene policy permitted. Several thousand pounds worth of sugar syrup, tomato paste, vinegar, flavourings, spices and other consumable went straight into the waste bins, and the whole thing got scrubbed down and off it went, back to bottling thousands of bottles per hour. I can't remember the exact figure they quoted for the cost of the place sitting idle per hour, but it was of the order of tens of thousands of pounds. A few thousands worth of ingredients was small beer compared with the down time cost. The "Aye we can fix anything" attitude has stuck. You can fix anything, well almost anything if you are prepared to throw enough skilled people and enough money at the problem. Sadly the demise of Timex Dundee was not down to the failings of the skilled workforce, but rather the short sited attitudes of managers and politicians. Ever was it thus.3 points

-

Hi all, very very new to this is go gentle. I am starting to get into watches and have just purchased my first omega speedmaster. As my interest has grown I have got a bit of a bug for watch repairs and am currently scouring eBay for some budget watches to practice on. However rummaging through my wardrobe I came across the timex below. I appreciate it's worth about a fiver, but it was my grandads watch and I want to give it to my dad for Christmas . however a few issues... the crystal is scratched and I am struggling to find one on eBay any ideas where I can source one It won't wind, I can set the date, time, and spin the hands, but as soon as I try to wind it locks up solid, I am presuming as people say these are hard to repair it would be easier and cheaper to change the whole movement , I have seen some on eBay ( glass cracked) that will do but I have heard the hands can be hard to remove, is this true, any tips. Any other thoughts on this or starter watches thanks1 point

-

Distance between upper and lower end stones is less than the length of balance staff, whereas if should exceed it by .02 mm. this .02 is called the end shake. there are many ways to adjust for decent end shake. Shimming, whereby you put a shim of say aluminum foil underneath the balance cock then go on with tightening the cock screw. you can also move the lower jewel assembly outward, if it is movable.1 point

-

1 point

-

The 1918 epidemic killed 50 million out of a population of about 1 billion. In today's numbers that would translate into 450 million , or roughly the whole population of North America. it was a VERY NASTY BUG. . Let us not forget a virus is a living thing, which must mutate in order to survive, because as we become immune it dies.Every so often it mutates in a very pernicious way. As for the Donald ,I used to work in the cemetery where his parents are buried.I locked him in several times, after he came to visit their graves. He was always a gentleman. However, if you step on his toes, he will not say thank you.1 point

-

I don't agree that a "natural" lubricant is ever preferable to a synthetic one. Of course this being a lubrication topic will expose the widest latitude of opinions in horologerie. So if one believes to know the best answer already, what's the point of asking.1 point

-

I would lubricate with a tiny bit of Moebius 9501. I am sure others will have other preferred lubricants but thats what I would use.1 point

-

The Mrs has asked around the people she knows who worked there and the answers we got back suggest that it was all done on a jig of some description. The movement was put in the centre of the jig and small metal arms would fit into place and screw the plates down, the arms would then retract and the process would start again. I hope this helps to answer the question, I might have some better info as the day goes on as the Mrs has asked quite a few people that worked on the lines in the Harrison Rd Plant.1 point

-

Yes. Next question is what sort of oil to use. There are a couple of Bulova service manuals around for similar watches. The first one also gives some information on checking the tension spring, but neither tell you what oil to use. https://www.buzzufy.com/ebooks/11AOACDB.pdf http://www.phfactor.net/wtf/Bulova and Caravelle/Bulova 11ANAC, D, B.pdf This shows what happens if you don’t oil them https://onatelier.co.uk/bulova-automatic-divers-watch-666-feet-m7-calibre-11alac-service#more-2183 Let me know how you get on. I have one of these in my project box waiting attention.1 point

-

Try this link -> https://drive.google.com/open?id=1XbRtG03Bx-nqcfHBpHDVcTQcoN94HefM Let me know if you have any problems downloading, or if I have managed to screw up the zip file again.1 point

-

Nowhere to go, nothing to do, get yourself a blank dial watch. .. or maybe one with GPS, so you can track your toilet rolls if someone steals them. .. or maybe something to help us go back in time and sort out the problem before it started.1 point

-

Can't help Identify the movement, but the first watch I ever owned was a "Nidor vibraflex" 17 jewels. I was 13 and the year was 1966 !1 point

-

I blame the idiot who created the zip file. In my defence I was sitting in the supermarket car park at the time waiting for my wife to emerge with the groceries. Apparently I'm not to be trusted with that task either. Give me a few mins and I'll update the file with the correct two parts. EDIT: Actually give me about an hour or so, my uplink speed has dropped into the glacially slow bracket. I suspect there are too may other self isolating people interwebbing at the moment. I'll post a revised link once it has uploaded.1 point

-

I have successfully managed to replace these in the past using the ball from the nib of a ballpoint pen and a section of spring scavenged from a spring bar.1 point

-

1 point

-

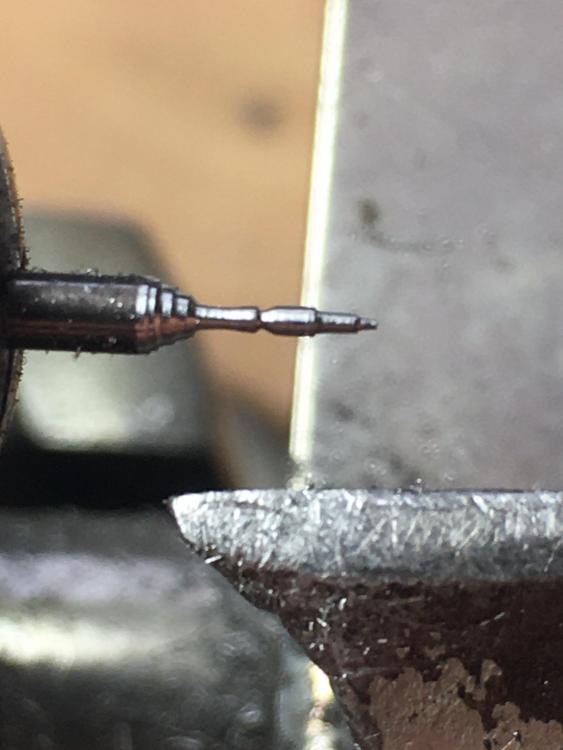

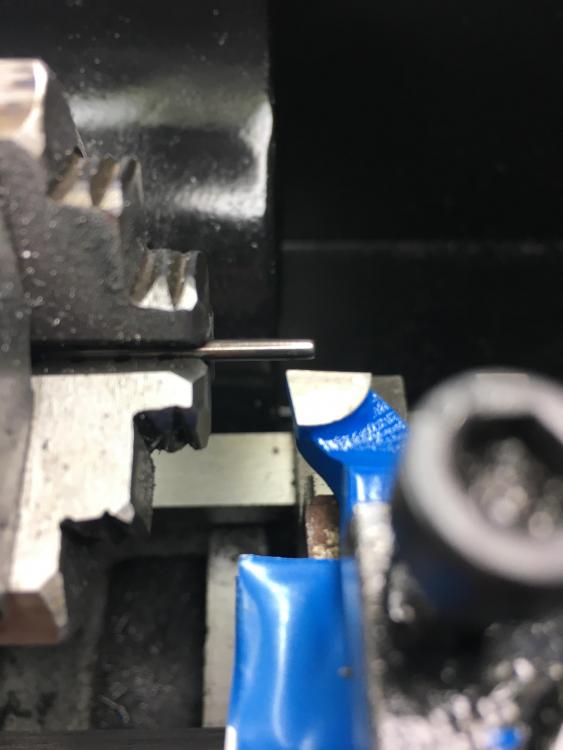

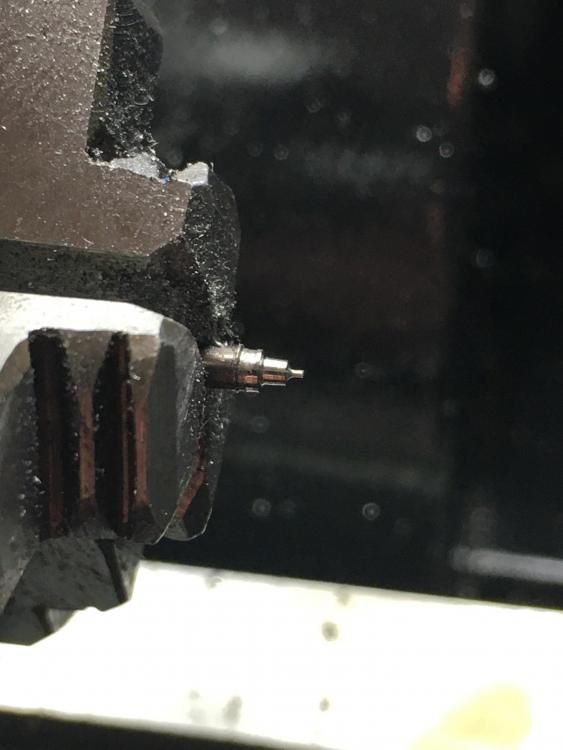

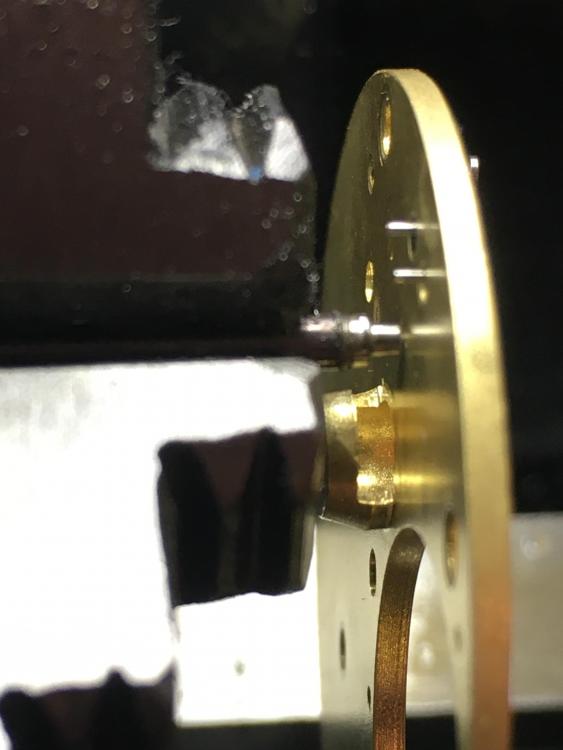

Ok none of that worked very well so back to the drawing board, the problem is I’ve not got a full set up for turning between centres on my Lorch lathe, so I went ahead and cracked on if only for practice with the gravers and sharpening them. What I can say is that I can turn faster by hand than I can on my Axminster engineers lathe!! the only thing is I can’t seem to get absolutely straight edges yet, again it’s down to practice. So how have I got on, well I’ve had 3 attempts all with varying success but none up to the standard that is required, what I need is a few more collets of smaller sizes, my smallest is 1.4mm so i need to go under 1mm and I’ll have this arbor smashed. The largest diameter on this job is 0.73mm, if i can get a collet to fit that then I can turn rhe job around and finish the pivots much better. So bearing that I’m mind when you look at the pictures these have been turned from right to left in a single collet starting with 2mm blues pivot rod. Will start again next week after the weekend Open to comments, hints, tips etc etc1 point

-

Well I started on my larger lathe and was going fine but my 3 jaw Chuck doesn’t close enough to allow me to turn the job and do the other end, so I had to leave that one. I then decided that I could put my drill chuck from the tail stock into the chuck as that closes enough to accept the job, had Wayne too much wobble, it just wouldn’t sit right. turn between centres next, was going ok but took bits just too big so could get proper shoulders etc so again left that idea. finally got my Lorch 6mm lathe our and started turning by hand, just can’t seem to get a good straight edge by hand so finished off with file, even got the pivots to fit the plates. then disaster, I snapped a pivot whilst finishing it off with the pivot file, so I’ll start again tomorrow and see how I get on.1 point

-

@jdrichard my apologies for the delayed response, I somehow missed your question. That spring is the tension spring for the seconds hand pinion and is there to prevent the seconds hand jittering due to the back lash between the pinion leaves and the teeth on the wheel that drives it (the pinion). If you try to install the seconds hand without supporting the other end of the pinion (or the spring) all that happens is the spring will flex allowing the seconds hand pinion to move down into the watch as you try to push the hand onto it, and the hand won't install properly. If I remember correctly the trick with this movement is to install the autowind bridge and the axial rotor retaining screw without the rotor. If you do this the end of the screw can reach the end of the seconds hand pinion, so tightening up the rotor screw until it just makes contact with the spring supports the pinion while you install the hand allowing the hand to be pressed fully home.1 point

-

watch making in Seattle; could be brought home for the virus duration ? i feal sorry for anyone in Seattle. the governer and his lawer ( Side show bob ) are outstanding "nut cases". if there is to be a vote this year they will be gone. Trump will help that along. later vin1 point

-

"Zen" hairspring adjustment technique. No. I'm saying, watch the hairspring coiling and uncoiling. Make sure that nothing rubs against the hairspring. And using a technique that I learnt from you, JD, use the slow motion capture of yr phone camera. The camera can see things that the naked eye can't. Like this short video of the watch I was working on last night. Watch the hairspring.... It's so hypnotic.... Zen.... Oooommm.... 20200401_201404_002.mp41 point

-

The Spanish flu killed 50 Million People in 1918. That fact just floored me. I have been lucky to be able to continue to work as our company, aerospace defense, is considered to be an essential business. That said, we have deployed everyone to their homes to work; except manufacturing. Working from home with FaceTime, Google Duo and RDP or VPN is not really an issue. It’s the idea generation that is caused by random interaction with people. Also, I am a social animal, so not seeing people is hard for me; but I do have a very understanding wife. I have an HDML splitter for my iPhone and can push my FaceTime video to a 72” screen and have virtual coffee with my best friend and family members...kind of cool. I also purchased a desk tripod and a iPhone holder, knowing that we will be at this for months. Cleaned the crap out of my office and now can do work and watch repair in the same space. I also put a non-watch repair video of me playing Europa by Santana on YouTube. So everything is relative. working from home and self-isolating is not as bad as: 1) 55 days in a submarine without surfacing (a friend) 2) fighting in a tank in Afghanistan (son) 3) in the North Pole research facility 4) stranded on Gillians Island (humor) 5) lost at sea (many stories) 6) prison camp (WW1, WW2, Vietnam, etc. 7) sick from C19 ( this should be #1 ) All just my opinion. I did go shopping the other day and wanted to be safe...more humor. Sent from my iPhone using Tapatalk Pro1 point

-

You might like this. The gunfight took place on Wednesday, October 26, 1881, the above watch serial number is from 1882, but that model was first produced in 1880. So this is the kind of watch that you would have been looking at in the window of the watch shops that year. http://elginwatches.org/cgi-bin/elgin_sn?sn=1178868&action=search Summary.. Serial Number SN Range Quanty Name Year grade size code jewels Adj/reg/etc. -------------- -------- ------ ---- ---- ----- ---- ------ ------ ------------ 1178868 1175001 5000 1882 87 18s hfn1k 11j grade total runs first yr last yr class size code jewels Adj/name ----- ----- ----- -------- ------- ----- ---- ------ ------ ---------- 87 33000 8 1880 1883 5 18s hfn1k 11j The Elgin in the previous posts is from 1881. http://elginwatches.org/cgi-bin/elgin_sn?sn=805552&action=search Summary. Serial Number SN Range Quanty Name Year grade size code jewels Adj/reg/etc. -------------- -------- ------ ---- ---- ----- ---- ------ ------ ------------ 805552 805001 1000 1881 3* 16s h3g3l 15j Adj ? grade total runs first yr last yr class size code jewels Adj/name ----- ----- ----- -------- ------- ----- ---- ------ ------ ---------- 3 24800 24 1879 1895 24 16s h3g3l 15j Adj (*) notes on grade 3: # Elgin MCs say a few were 14s # SN>1,600,000 have REG_OLD_RR_PAT SN<700,000 have a steel barrel washer Class 24: 16s HC 3/4 lever model 3 3 24800 made 15j Adj gilded Elgin MCs say a few were 14s # SN>1,600,000 have REG_OLD_RR_PAT SN<700,000 have a steel barrel washer 4 31000 made 15j Adj Elgin MCs say a few were 14s # SN>1,600,000 have REG_OLD_RR_PAT SN<1,300,000 have a steel barrel washer1 point

-

1 point

-

1 point

-

as an alternative I have worked with Greg Ward from Woodland Tech - He is located in Lincolnshire. does great restores on all type of time pieces.1 point

-

you can save the one you have! - use very fine sand paper and rub against the scratches until they fad - use wet extra fine sand paper and rub in circles until you see a milky slur - wipe off and use a dremel felt wheel charged with Crystal bright. <<< find this on EBay use the dremel on low speed and go again in cirlcles. be sure to keep the felt charged with poilsh as to not burn the plastic. It will come out great. I've done hundreds this way. Poly watch? use it as the final polish to bring out the gloss. That is about all it is good for. Toothpaste? - well it is good for your teeth1 point

-

1 point

-

JerseyMo, wow that's a spares collection you have there mate, atleast you seem to have concentrated on one make, ive got bits and bobs from so many, drivers the wife mad1 point

-

I have a soft spot for Timex as well. If you need any parts I may have one or two here somewhere1 point

-

Mate the timex movements are pretty easy to work on, the hardest part is putting the plates together, unlike other movements that have bridges, one for the barreL one for the train a cock for the balance and a tiny bridge for the fork, on these timex movements you have two plates and you have to line up the train the barrel the balance and the fork all at once. The way to do it is to start with the furthest wheel away from you and with seriously light pressure to hold the plates together between your finger and thumb use an oiler to manipulate each wheel in turn into their respective jewels. When you get to the hairspring you will have unpinned it during the strip down, now you will have to re pin the hairspring, beware you will ping the small brass taper pin into another universe to begin with until you get the hang of it. As for the hands, all watch hands can be a bit of a pain until you have done a few, but with the correct tools it's pretty easy ok. Also the tabs you mention are I believe dial tabs, theses are holding the dial on, the movement is held together by 4 screws, which screw into 4 pillars that hold the plates the correct width apart. Your symptoms are to me that the watch needs to be let down and a service given, basically the mainspring is fully wound but something is stopping the power from the mainspring to be transmitted through the train to the balance, so a little detective work into required to find out what! I know you can get another movementer for a few quid but then the watch won't be original when you give it to your father, its one of the things I like to try and do is keep original movements and cases together. Your crystal as has been said before is acrylic and can if not cracked be polished to near as dam it new condition. A watchsmith probably won't work on it or if they do the cost to you might make you baulk, I have no idea just how much one would charge but wether one would work on it I don't know. These timex movements were designed to be throw away, or at the very most the whole movement complete would be stuck in a cleaning machine then rinsed and dried and then oiled and put back in the case, the mainsprings have a coating on them that doesn't need lubing and can be cleaned in situ. There are tech sheets for Timex movements on the Web as there is a timex forum, which has the whole lot ready for download, they are very handy. I have are soft spot for the old timex movements as it was the first ever movement that I fully stripped and serviced when I took up this hobby. Have fun what ever you decide to do and don't be afraid to aressk questions that's what we are here for ok1 point

-

1 point

-

1 point

-

You can look up the movement it has and buy an identical one and have it replaced if you're keen on originality. You can't replace it with any kind of movement. It's not just the dimensions but also the hands which won't fit any movement.1 point

-

Cheers Chopin, never though of polishing it, I will give it a go. with regards to the movement It is mechanical however it's very very basic, it's held together with tabs, I think a watch maker would laugh at me, I am comfortable with replacing the movement I can pick a watch up for five pounds, if I have a spare I will try and get this one working with no risk if I can't repair it .1 point

-

The glass is, I'm assuming, acrylic crystal which is basically a thick transparent plastic. If it has no cracks and the scratches aren't very deep you can actually polish it yourself. You can use Polywatch which is a substance made specially for this (costs 5-6$) or you can use toothpaste which apparently acts the same thing. Never used toothpaste so far. You simply put some polywatch on the crystal and then with a small piece of rag or a tissue you have to do circular and even motions (in both directions). One thing you have to be careful is that you'll have to put some tape on the face of the watch so as not to polish the case as that might make the finish uneven. For your second issue. Is your watch mechanical ? If yes then you can simply take it to a watchmaker and get it serviced. I think it most likely just needs a cleaning of the inner components and re-lubricating.1 point

-

Apprentices and hobbyists can practise on these movements because the balance staffs just knock out and push back in no riveting required.1 point