Leaderboard

Popular Content

Showing content with the highest reputation on 08/26/19 in all areas

-

If you’re like me, taking apart you first ETA calibre 2472 and feeling somewhat intimidated after having removed the case back lid looking down on the automatic works, then you will likely appreciate this post. By the way, except for the oscillating weight itself, the automatic winding device is identical for the following calibres: ETA 2450, ETA 2451, ETA 2452, ETA 2453, ETA 2454, ETA 2472, and ETA 2474. My only other experience of ETA’s automatic winding devices comes from calibre 2824-2. So, looking down on the oscillating weight of the ETA 2472 and not seeing a screw holding it attached to the automatic device framework, made me think the parts had somehow been riveted together and probably were inseparable. Having removed and looked at the back of the automatic device framework I could see that the oscillating weight was indeed attached with a screw or at least something that reminded me of a screw. Its slot was very thin, and it sat in a large jewel! No way I was going to try to remove it without knowing for sure it could be done and how it should be done, especially as this watch wasn’t mine but my brother’s who’d trusted it to me for an overhaul. My first thought then was to try to remove all wheels without touching the oscillating weight. After having looked at the device for a good long while, I realized I wouldn’t be able to remove a single wheel before separating the oscillating weight from the framework. So, I decided to be patient (hardest part of watch repairing), put the parts away for now and research the Internet. I Googled “eta 2472 how to remove oscillating weight”. The first hit was “Untitled - OM-Mechanics”, a PDF document. Well, I wasn’t feeling very optimistic but lo and behold, there it was, in full detail! Anyway, the PDF is pretty poorly scanned, and it isn’t all that easy to read the part numbers, so I decided to make my own picture guide for disassembling the automatic device of this ETA calibre 2472, and that’s what follows next: (Eventually, I’ll publish a complete ETA calibre 2472 service picture walkthrough. If interested, you’ll find a link to it in a future post in this thread.)3 points

-

2 points

-

So I have this watch that I like, and I have clean/oiled it and it's keeping very good time. It's a blue Seiko 6119-8083, but although I have it's original case, the case you're seeing is a different one because I do not have the crown/stem for the 8083 case. I have just order a new AM stem and a NOS crown to take it to his own case, and yes it's been more expensive than the hole watch! Anyway, I want to also change the crystal of it's original case, and that's something I've never done so far, so I don't feel confident at all. I know that the (discontinued) Seiko crystal code is 310T10ANS0. So here are my questions: 1.- Would any 31,0 mm generic crystal fit in the case? 2.- Shoud I buy plexi or mineral, or it doesn't matter in terms of fitting it into the case? 3.- Do I have to remove the bezel before pressing the crystal in? (I have one of those manual cheap chinese crystal press, I know I should buy a better threaded one, but for now I have to try this one) 4.- I have no more questions, but I bet you have more answers for an absolute newbie like me Oh, btw! I'm attaching also pics of the 8083 case (not cleaned yet) just in case you need to take a look at it. Thank you for any comment and/or advise!1 point

-

You don't need to hang the movement 7 foot off the ground just 4 foot is plenty as this would give you about 4 days of running time, then just wind it up again for another 4 days. The movements are simple so you should be able to ID the issue.1 point

-

Get all the barrel greasing done, place the ring on barrel, rightly position the spring coil to enter the barrel ( nearly 0.75 mm of the coil enters the barrel) push the spring home, preferably sandwich the barrel and coil between two prongs of your tweezers to push on top of the spring. Next you insert the arbor in center of the coil.1 point

-

1 point

-

think I will use this phase next time my colleagues in our London office make a difficult request.1 point

-

Nivada chrono GMT,s are rare and expensive pieces. Be careful with it. Perhaps should get all set up for pix and read up on them. Get data sheet.1 point

-

Hi Jdm, Thanks for your kind offer to send me oil. I discovered this company maltina.com an affiliate of Amazon, through whom I can order general goods offered by amazon. Thanks again for your offer. Regards joe1 point

-

From what I see the existing crystal can be polished to a satisfying level. No parts needed, no disassembly and you learn an useful and rewarding skill. Many threads on the subject, just use the search function.1 point

-

1 point

-

1 point

-

Generally a well serviced watch will have negligible wear at the balance pivots. If its worn you have to change. You can get away with changing the depth of the mainplate jewel to address slightly worn pivots but this can cause other problems like harispring touching the balance cock or balance, the rolller jewel not making proper contact with the pallet fork. Also a worn pivot will usually mark the cap jewel as well as wearing the edges of the pivot (not only the tip) so anything other than replacing a balance staff will be a bodge. Having said that in my neck of the woods (Malaysia) changing a balance staff and service will set you back USD70-100 (unless a balance can be harvested from another movement) so its not really an option for a USD50 watch. I have guys come in with their fathers watch which they want to keep running for occasional use so its not surprising that they opt for a bodge. As it will see minimal use I usually oblige by cleaning the pivots up and try to get the endshake in spec. Anilv1 point

-

To be on the safe side always keep them separate, that way you can't go wrong.1 point

-

1 point

-

I let the screw find a strong magnet. You are sure to get some bonus too, other screws, washers ...1 point

-

1 point

-

1 point

-

You need to have the piece at least at neck's height with the elbows resting on the bench while you work. And use a good loupe with the support wire. Doing without that means wasting time, getting aggravated and breaking or losing parts.1 point

-

1 point

-

I also have an old Elma, which I got at an Ebay Auction. I use the machine to clean the movements. I bought the fluids from elma. 1st Jar for a cleaning solution and the 2 others for the rinse. The parts come out if the machine really clean and shinning. Its beautiful! I'll try to post a pic tomorrow.1 point

-

1 point

-

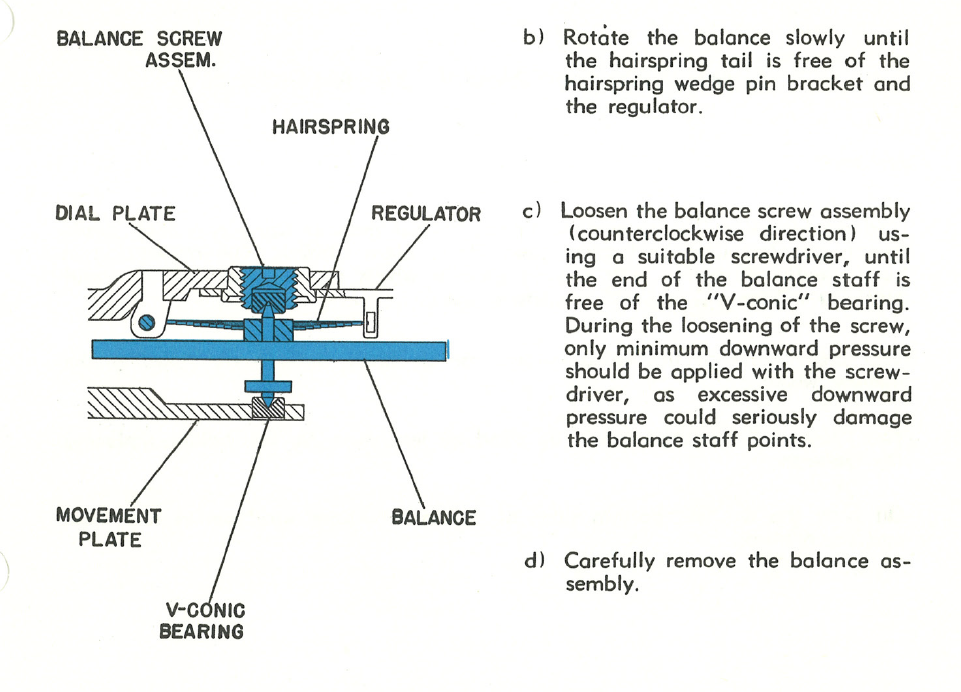

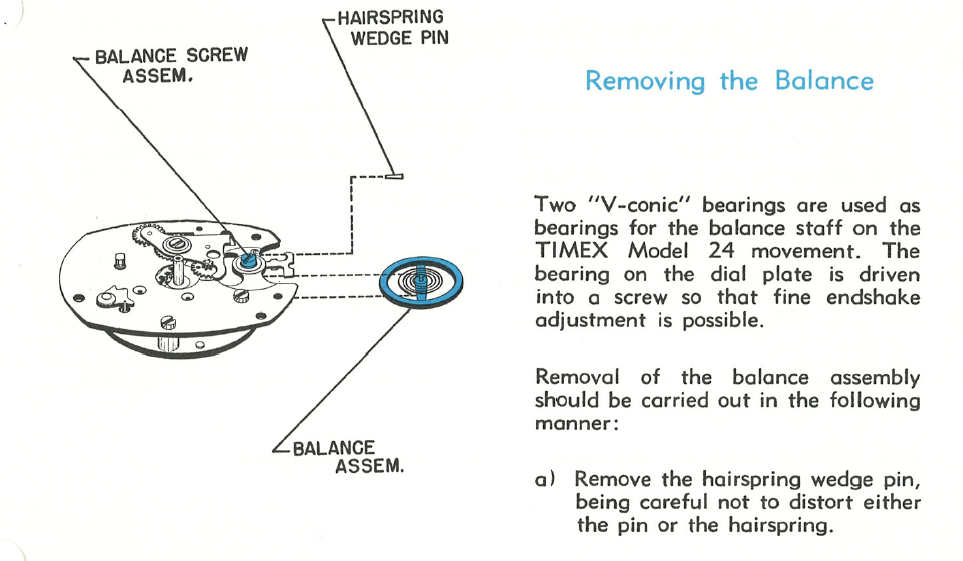

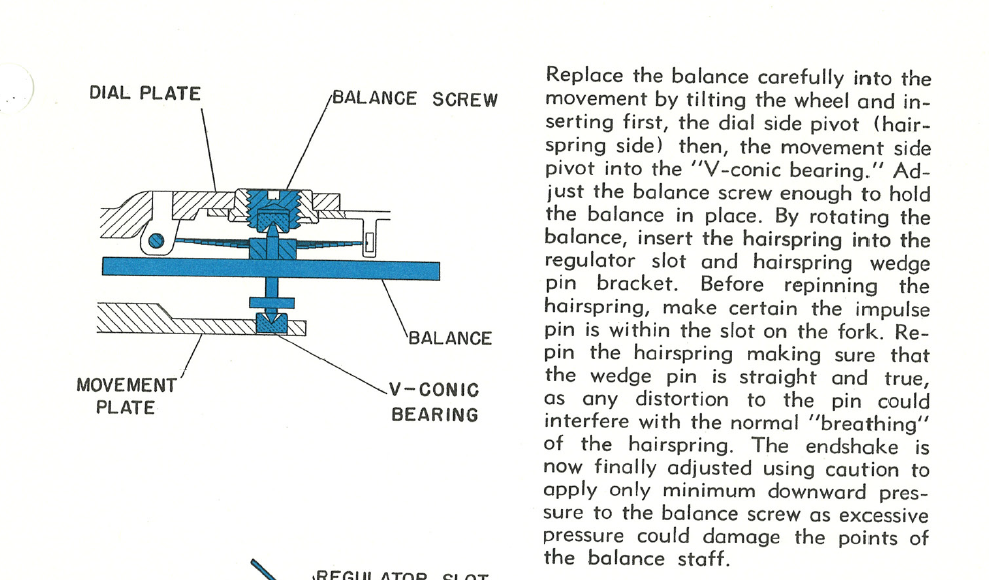

Hi ITProDad - Thanks for the input, all good advice for most movements. What I'm working with is a different kind of balance assembly. I'm attaching some diagrams from the Timex service sheets. Had no trouble with the hairspring, which should be the touchiest part. It's the balance screw - it's made of butter-soft brass, and it's a tight fit. Trying to avoid carving out the slot without putting too much downward pressure on the screw - which can damage the cone tips of the balance staff - has proven to be beyond my current level of expertise. All I know to do now is close it up and move on. Maybe look for a donor in my "morgue". But I need to know how to approach this from the start the next time I run into one of these.1 point

-

If you over oil, not good: use rodico to remove and start again. Sent from my iPhone using Tapatalk Pro1 point

-

You need to be good with lhe piercing saw and micro files. Try on scrap dial to get an idea.1 point

-

Looking at your pictures I found what I was looking for so I've snipped out the interesting ones. Looking at the images attached you'll notice that your hairspring is touching the backside of the regulator pin. It also looks like your terminal curve is distorted. In the video I gave you he clearly shows how to make the terminal curve but you have to be careful in that each watch is different. So for that I went looking on eBay to see if anyone had nice picture is of a balance complete. Currently on eBay there are quite a few balance completes a couple have pictures this one was the nicest picture. Personally for fixing this I would do it in the watch. That's because the problem is in the watch. Looks like the balance complete has a nice gradual terminal curve which I think yours still has. The typical problem and it's the most common problem for watchmakers is distortion in the around the stud. The preferred method of practicing with the hairspring would be to practice on a disposable watch. Practice distorting the hairspring bending it then fixing the problem until you get good at it. But as there are replacement balance completes on eBay you can practice with this watch what's the worst you're going to do? I notice they even have movements on eBay.1 point

-

How does the ultrasonic screw up the spring? I would imagine the average old school machine that swishes the parts around a jillion times would be more of an issue (and it isn't). Is there something particular about Timex stuff?1 point