Leaderboard

Popular Content

Showing content with the highest reputation on 04/12/19 in all areas

-

3 points

-

2 points

-

More blue strap fun. I'm not sure that blue is the perfect colour for the "Mardon", but since it was the only 17mm strap I had that wasn't attached to anything else, and since I can't think what else I would put it on, blue it is. De-gunked, dial cleaned, case polished, movement serviced, new crown and stem fitted and ticking away nicely. It is looking a whole lot better than this..2 points

-

Still i didnt place movement holders into case. Waiting them to arrive from Malasiya. But so far this is how it look like. I have trim the winding steam..hand made leather strap 28 mm on watch and 26 mm on buckle. Overall looknice Послато са SM-J600FN уз помоћ Тапатока2 points

-

2 points

-

I have wanted learn how to assemble a watch from parts for a while now and after recently breaking the second hand stem(is that the right word) on my favorite watch I figured I would give it a go. The watch repairman said that the movement would be expensive to order and that two of the dial post were broken meaning that even if I ordered it in I would not be able to properly attach it to the existing dial. After expressing a desire to learn more about watch repair and mentioning I had recently purchased a repair kit and had been watching videos he went to the back of the store and handed me a bag of vintage watches I could practice on(including a Hamilton) and wished me well. Due to the sentimental value I would love to try and find a movement and dial that will fit inside the existing case. As pictured below I have all of the parts to the watch including the plastic moment ring. I think that the broken movement is a Technotime. Under where the watch battery would go I see numbers that appear to be 71205, but googling that brings nothing up. The watch itself was an alviero martini pc 7030 but google was unable to find any info on the movement. Other than that it just says 7 Jewels and swiss made.The case has a diameter of 38 mm. Ideally I want to be able to find a cheap quartz movement(to learn with) or potentially a small automatic movement if it will fit that has blank dials available for it. Here is a link to the parts I have as well as a picture of the Hamilton I was given if anyone can ID it. If Daniel Wellington can slap a cheap quartz movement into a watch I figured why can't I!1 point

-

Part # of Balance complete with stud for 7S26C is 0310197 and for 7009 is 310 020, so I'm afraid they are not compatible. However the balance in 7S26A is 310 020, so it is the same than in 7009.1 point

-

Once you get the hang of it, hand winding isn't too difficult. It does give your thumbs a good workout though.1 point

-

1 point

-

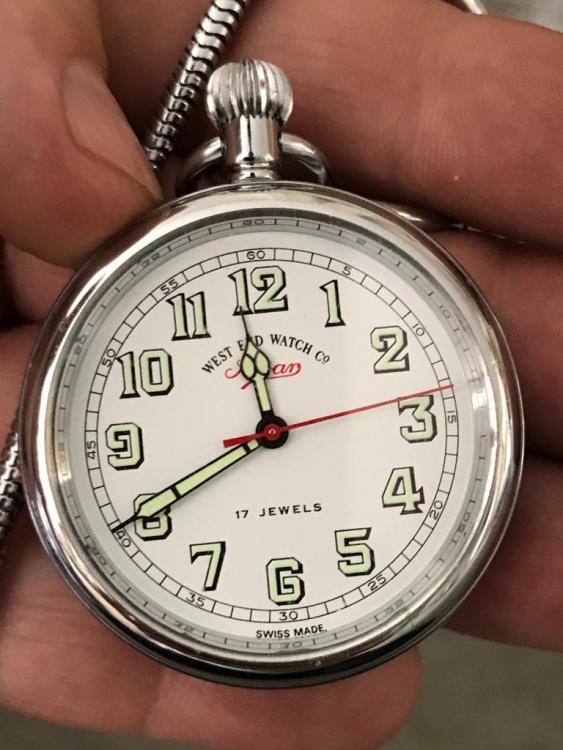

These watches where made in Switzerland they where designed to look like American watches, the claims to be adjusted to 6 positions and heat and cold are spurious, they are "all fur coat and no knickers" as we say in Yorkshire.1 point

-

Thank you so much. It probably opens the same way. I’m away from the shop just now and won’t be back until early next week.1 point

-

Camera books? I have a few, and on old watches, and electronic (like accutron) BUT, " I hate electronics". cheers, vin1 point

-

I'm a self confessed bookaholic, not just Horology books, but books on model engineering, jewellery making,woodworking, restoring classic cameras, gardening, cooking, brewing etc. Basically if its a book on how to make or fix something I probably have atleast 1 book on it. I've even got books on how to make books. (book binding that is not writing a book)1 point

-

Fingers crossed mate, something else learnt today, everyday is a school day you know, if it plays up some more I now know where to look, at least I’ll go for a deep clean/ polish of the escape wheel teeth and try to polish up the pins as best I can. I take it I can do this with a burnishing tool from my lathe kit but done by hand?1 point

-

Hi VWatchie, Great to hear how you're getting on, well done. I'm doing just about exactly what you're doing (close to retirement etc and loving Omegas!) very new to it all but have done Mark's repair course so looking for something to practice on, also struggling a bit to find the 'right' watch to fix up wear for a while then sell, hopefully not at a loss! Graham1 point

-

So annealed O1 needs no further treatment after you carve the part? Sent from my iPhone using Tapatalk Pro1 point

-

Take your pick..... https://www.cousinsuk.com/category/pivot-steel https://www.hswalsh.com/product/blue-pivot-steel-wire http://www.m-p.co.uk/muk/parts/chap10/pivot-steel-0.61mm.-10pcs-no.72-0618007215.htm https://www.esslinger.com/staff-and-pivot-watch-and-clock-wire-rod-assortment-blue-steel-55-1-93mm-12-pieces/ http://timesavers.com/i-24049935-30-pack-3-00mm-3-95mm-blue-wire-assortment.html https://www.amazon.com/Assorted-Tempered-Pivots-repair-pinions/dp/B01N1SOLDF http://redroosteruk.com/11-assorted-tempered-blue-steel-wire-pivots-clock-repair-pivot-pinions-staffs/ https://perrinwatchparts.com/collections/metals/products/pivot_wire_43_2115?variant=37875445135 Google "blue pivot steel" and you will find more. This has been the basic stock for watch and clock pivots and staffs forever. It is a carbon steel that has been hardened and then tempered back to a dark blue so that it can be cut on a lathe. It is still quite hard, try and cut it with snips and it will resist, eventually giving suddenly and breaking rather than cutting. In the lathe though it cuts easily with either a tungsten carbide or HSS graver, although a HSS graver will need frequent touching up to keep it cutting with a good clean finish. Keep a hard Arkansas slip by the lathe for this. Let it get too dull and it will chatter, resulting in a poorer finish, and it will also cause you to apply more pressure to get it to cut. If you're not careful you will break off the work piece by pushing too hard. Don't try to cut it too quickly either, and don't expect long curls of swarf. Take your time and make dust. You will get a better finish and the HSS graver will keep its edge longer, whilst the tungsten carbide will be less likely to chip.It also burnishes well so don't try to cut the pivots to size in the lathe, leave them over size and finish in the Jacot tool. This doesn't need any further heat treating when you're done, it already has the right balance of hardness and strength for pivots and staffs, especially if you burnish the pivots in the Jacot as this locally work hardens the surface giving the correct hardness to resist wear whilst the rest of the staff retains enough strength to cope with a degree of mechanical shock without shattering. Practise and enjoy.1 point

-

First, have it come in, check if pads clean, coil continuity, etc. Then, rhere are 5H23 and 5H23 going cheap on the bay, I guess the difference are not too many to take the needed parts or the entire movement. Technical guide: http://thewatchsite.com/files/Seiko Technical Manuals/5H22A_5H23A.pdf1 point