Leaderboard

Popular Content

Showing content with the highest reputation on 12/26/17 in all areas

-

Good morning. My suggestion is to power down completely and to remove the balance wheel and pallet fork. Now turn the barrel slowly and if you truly don’t have issues with the train wheel the escape wheel should start spinning rapidly. It shouldn’t take more than half a barrel turn. Caution as too much power can damage the wheels badly. If it doesn’t turn, then you have to find what’s wrong on this side of the movement. If it does spin freely than it’s either the pallet fork or the balance wheel. Good luck and keep us posted [emoji1303] Sent from my iPhone using Tapatalk2 points

-

There’s no section on here for barographs, but I’m going for clock corner and calling it a clock with a complication Santa brought me one of these as another project (because I completed so many of the ones I planned to do last year... honest...). Has anyone here ever worked on the bellows from these? At least one of the capsules in this set needs to be re-vacuumed. It looks like it’s been resoldered but has air in it and makes the stack too high, also it won’t respond correctly to pressure changes like this, but I’m not expecting a perfect calibration here! I’m thinking that I could make up a small brass tube, insert it into the solder joint, suck the air out then crimp it closed before sealing with a blob of solder. It looks like this is how the rest are formed. What I don’t know is how much of a vacuum I need to achieve. Will it be enough to remove as much as I can with a large syringe or am I going to need to acquire a better vacuum pump? It feels as though if these were really pumped out then the plates would collapse? Thoughts welcome, shared wisdom, knowledge or experience very welcome!1 point

-

Continued Creations Art's, Craft's, furniture and construction... I always considered adding watchmaker and jeweler but I lost sight in one eye. But I do have a few tool's that I don't know what they are or how to use them? So, thought I'd share and hopefully gain some knowledge. **** MODERATORS NOTE -> No buying or selling on the forum please **** Or if someone is interested in them?1 point

-

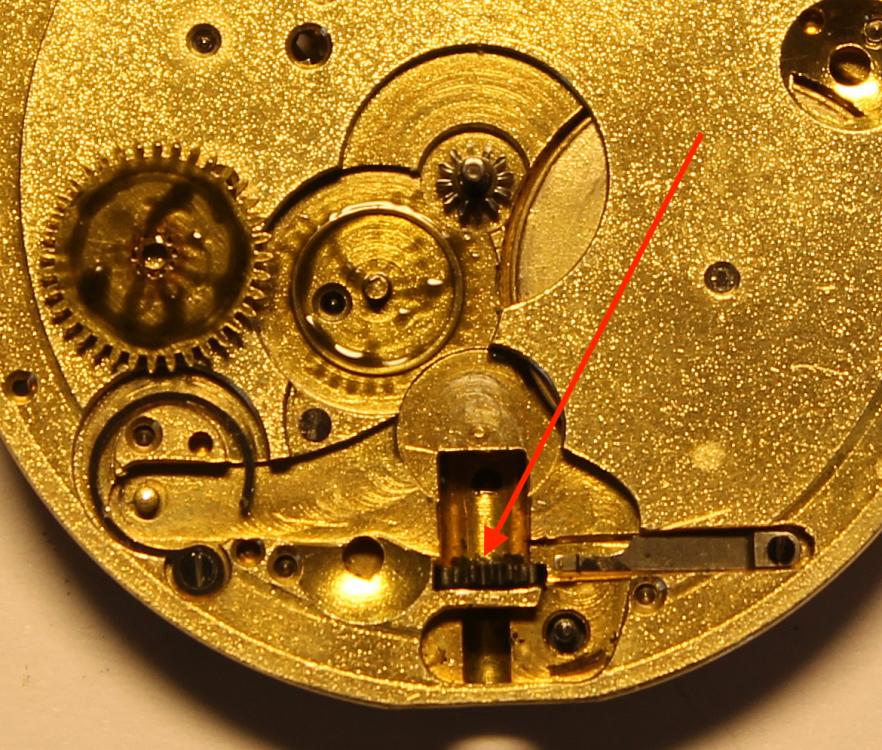

The hi res pic shows that the HS is seriously distorted, I don't think you can get good results with it.1 point

-

Nice! You’re on to something. Sometimes opening the barrel to clean the mainspring will change the endshake so that when you put it back on he bridge it’s caught. I bet that the arbor has a good endshake but the actual barrel rubs on the bridge. I suggest you remove the barrel and look at the arbor shake within it and then look at the lid of the barrel to see if it’s bent outwards. Cheers! Sent from my iPhone using Tapatalk1 point

-

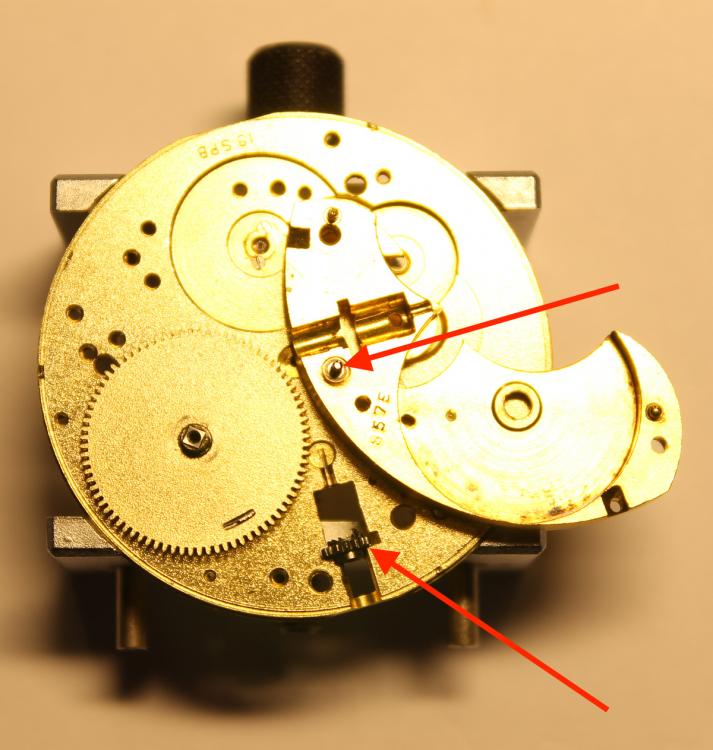

I removed the pallet fork and balance wheel and saw that none of the train wheels were running on full power. I loosed the barrel bridge and suddenly the power was released. It looks like when I screw down the bridge, it jams the barrel somehow and stops the power. After loosing the bridge screws, it started to tick. It looks like the amplitude is pretty low after setting the adjustment lever to something more reasonable. The hairspring seems a bit out of wack. Looking up the serial number, the production date was 1930 and grade 487. It's a really beautiful vintage movement. I hope to collect more of these vintage Elgin wristwatches. It doesn't look like many people care about them since the price is pretty low.1 point

-

Re-shape mine with a diamond file. Brought to cherry red under a gas flame and doused in oil then cleaned off. Seem ok. I haven't come across a stiff Vostok back yet, they seem more awkward than tight. Sent from my SM-T585 using Tapatalk1 point

-

I have M941 but every service sheet I look at seems to recommend pre-treating the stones and escape wheel teeth with epilame (Mobeus Fixodrop) to stop the very thin M941 spreading. This does not seem to be required for M9415 as it is a thixotropic grease type oil (ie is goes very fluid only under pressure). I understand M9451 is now acceptable in low beat escapements. When my M941 is used up I will change to M9415.1 point

-

1 point

-

According to the BHI’s practical guide to lubrication, pallet pivot jewels under 13”’ are never lubricated. There is some debate about wheter to oil them on larger movements, but if you do then it’s the absolute minimum of 9010. If you look around, you will see old moebius oiling charts which recommend 9010 or 8000 on pallet jewels - presumably since 941/9415 didn’t exist then. I have read that 9415 will work perfectly fine on slower escapements and therefore I have only this and not 941. Take your pick if you’d rather use 9010, but I’d use the 9415. Balance jewels is 9010 all the way up to alarm clocks.1 point

-

The other gauge is part of the jacot tool, its for measuring the size of the pivot, I agree that the rubber bands are not for the jaccot tool1 point

-

These are are haute horologerie makers, reviewed by a Wall Street Journal subscribers-only article Finding a Seiko repairer should be less than a elitist's task!1 point

-

I wouldn't know, but wanted to mention that we have a dedicated section where most new members like to introduce themselves even before asking questions.1 point

-

Holiday magic to everyone. And, @SSTEEL, you're not the only one who's been busy. I had to down tools for several weeks just to try and catch my breath after $DAYJOB insanity.1 point

-

Welcome to the forum. If you wish, you can use the dedicated section to introduce yourself in more detail.1 point

-

I treated myself to an early Christmas present of a vintage Junghans stopwatch. Image 26-12-2017 at 9.08 by S STEEL, on Flickr Got it quite cheap due to a crack in the glass, so will be renewing that soon. Perfect working order, apart from the crack, it looks like new.1 point

-

I "bought myself" a pair of no-name vintage swiss watches that need some tlc/servicing but hopefully nothing more... I might get them in a week due to shipping delays.1 point

-

I did.........well sort of. I bght a Citizen Crystal 7 for restore. Wish me luck!1 point

-

1 point

-

Amen brother! Although I have been known to use different words when the part has disappeared... Sent from my iPhone using Tapatalk1 point

-

1 point

-

I think you have missed the thread referenced above: Once again, key points: Benzine (petroleoum ether, and many other names) is NOT benzene and is NOT toxic, at least not more than petrol fuel. It can be purchased anywhere. UK example: http://www.ebay.co.uk/itm/Petroleum-Ether-80-C-100-C-500ml-Petroleum-Spirit-Shipped-Same-Day/1420614068161 point

-

I thought I've give a quick update on this project as tomorrow is the big day and I haven't made a peep since November. In the meantime, I received a replacement 7002 movement for the Seiko 7002-700J which was originally received with an improper 7019 movement inside. I also found a replacement mainspring for the 7019 movement (in Spain) and have cleaned and serviced the it returning it back to good working order. The replacement 7002 movement is the properly marked JAPAN (as opposed to SINGAPORE) version so this will still be a proper 7002-700J watch, but sadly the dial proved to be damaged beyond repair. Both dial feet had fallen off and the paint was ruined by whomever scrapped off the lume. I did manage to clean the oil off though. I cleaned and serviced the movement and found only one bad part- the Pawl Lever for the autowinder which had lost one of its claws. A replacement was readily available from Jules Borel and the movement is again beating away. Interestingly this 7002 movement came equipped with the Day Jumper and Day Finger that you would expect to find on the 7019 movement. I'm not sure why that was the case since the 7002 has no Day Wheel but there you go. Unfortunately one piece the replacement 7002 movement was missing was the Holding Ring for the Dial. This plastic ring sits between the dial and movement and keeps the dial from pressing against the Date Wheel. The holding ring from the 7019 movement had broken into seven pieces and was beyond repair. Replacements are hard to come by but I did manage to secure one just the other day but alas, it will not arrive in time for Christmas. Regardless I powered on and reassembled the case along with a nifty oyster style bracelet. As I've stated before, the bezel ring is an aftermarket replacement but the rest of the case is original. Both cases were the old style with a spring and ball bearing serving as the bezel click. On the 700J case the ball bearing had popped out but I was able to reseat it and the bezel rotates just fine. The 7002-7000 watch came together with a brand new replacement dial and hand set. The dial and hands are aftermarket I believe but look quite good just the same. I have a replacement dial and hand set for the 7002-700J as well and also have a proper original dial that is in route. I haven't decided which will go on the watch as of yet. Although I'm a bit bummed one watch isn't ready yet I'm still pleased with the project. My brother will be getting the 7002-700J when it's all done and I'm sure he'll be fine waiting another few days for the finished product. He will be a bit anxious when he sees the one that is done though. Happy Holidays!1 point

-

A Roger Smith lecture for those that have nothing to do over the next few days [emoji6] Can't see this posted yet....1 point

-

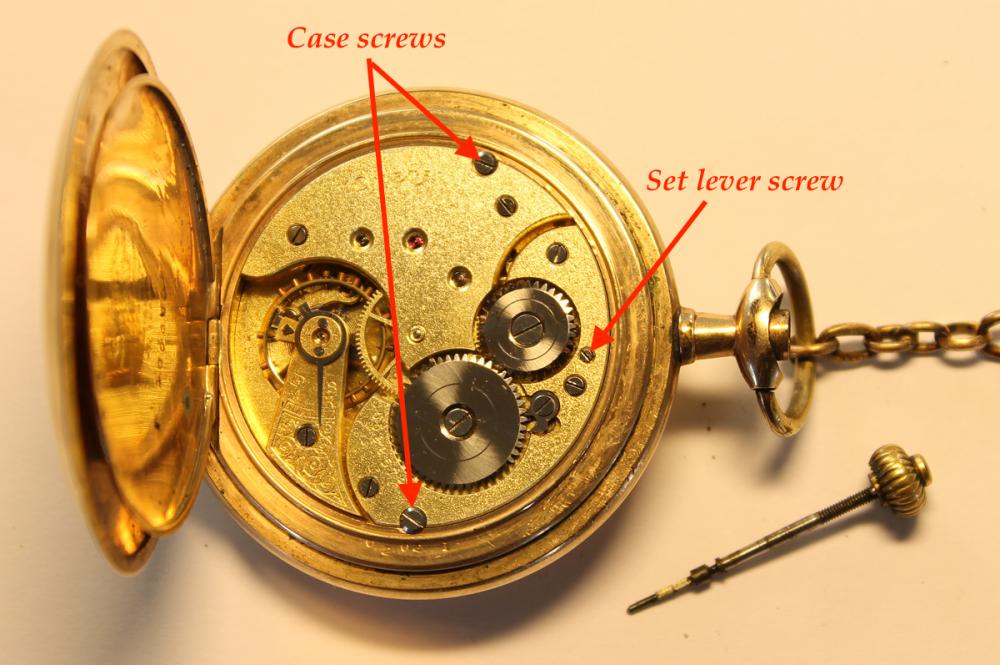

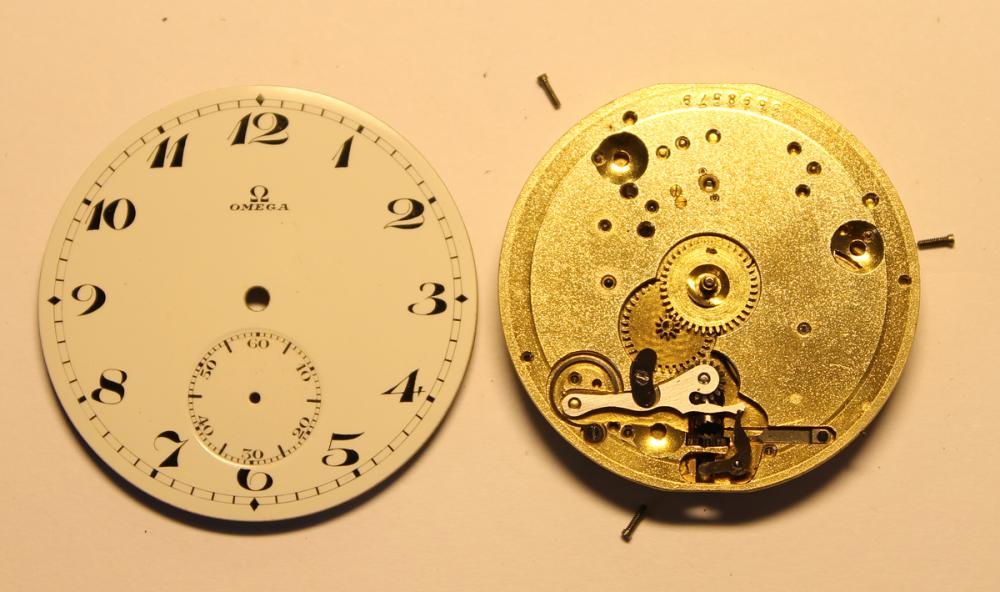

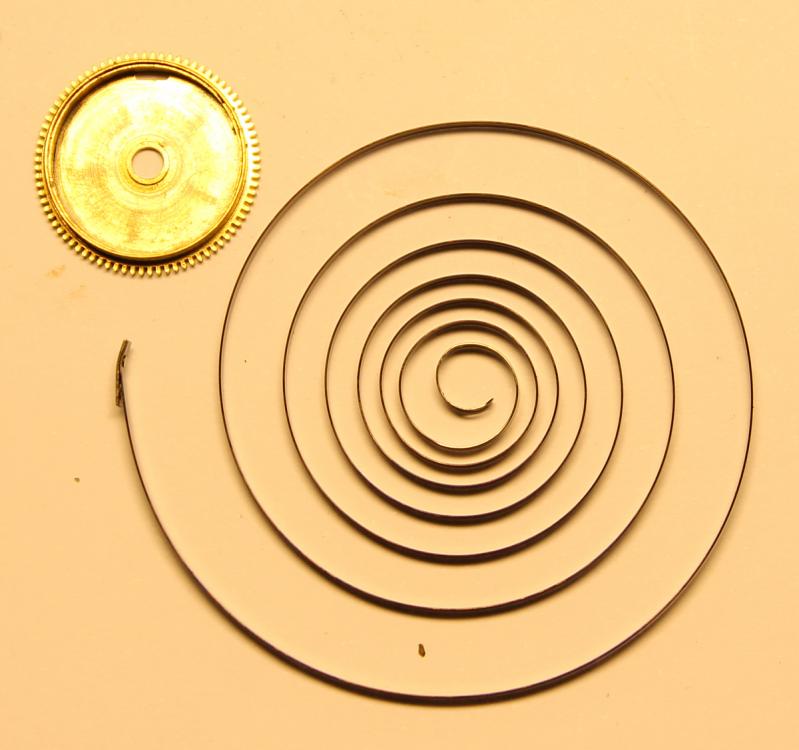

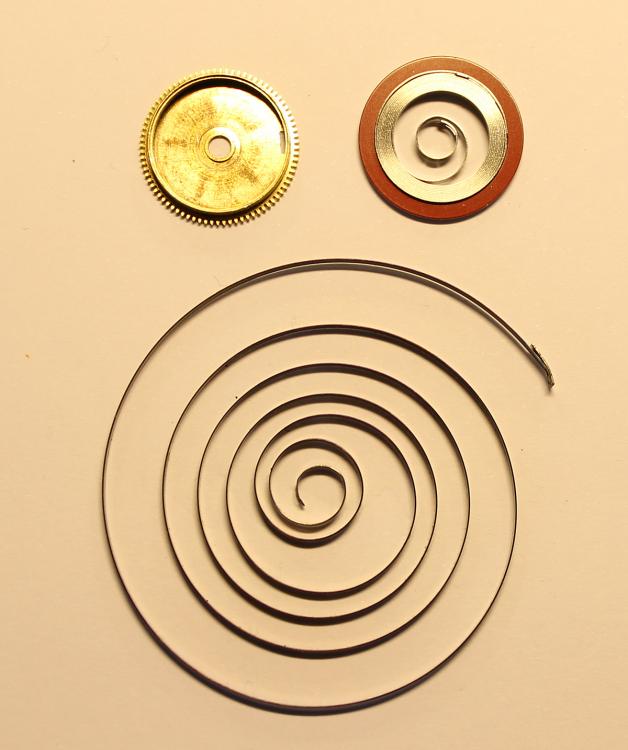

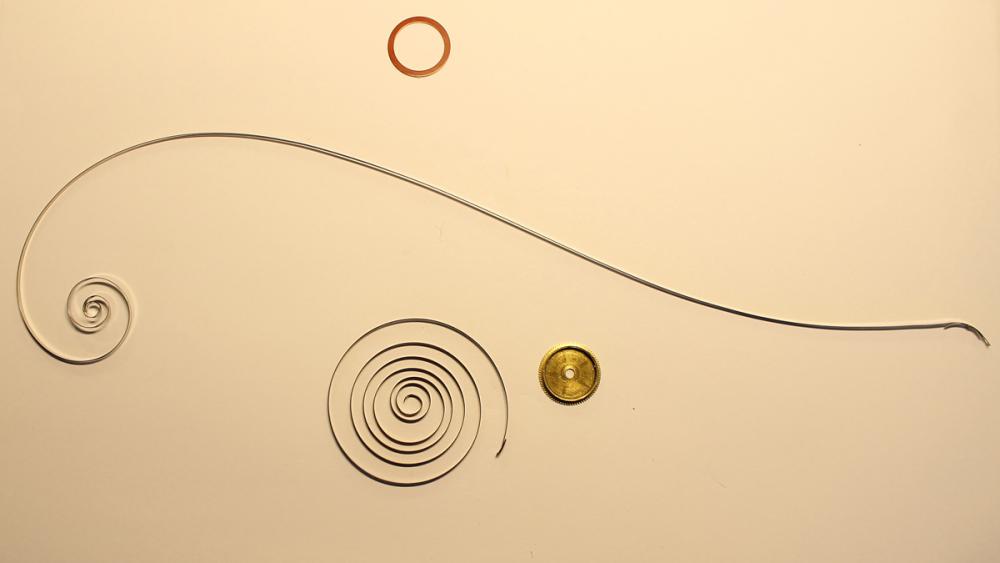

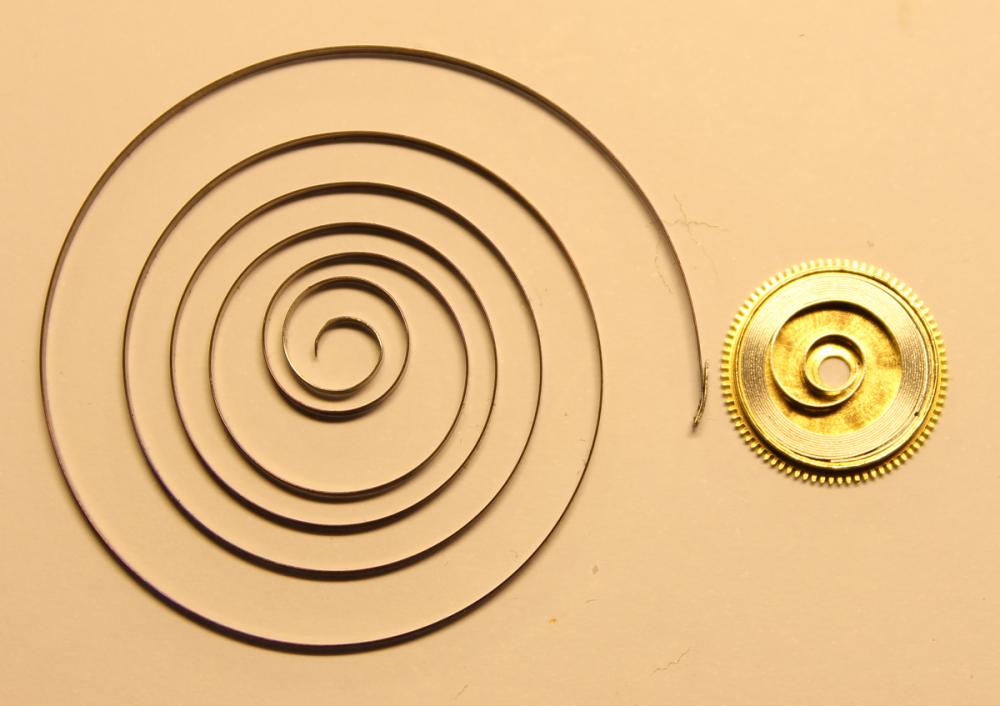

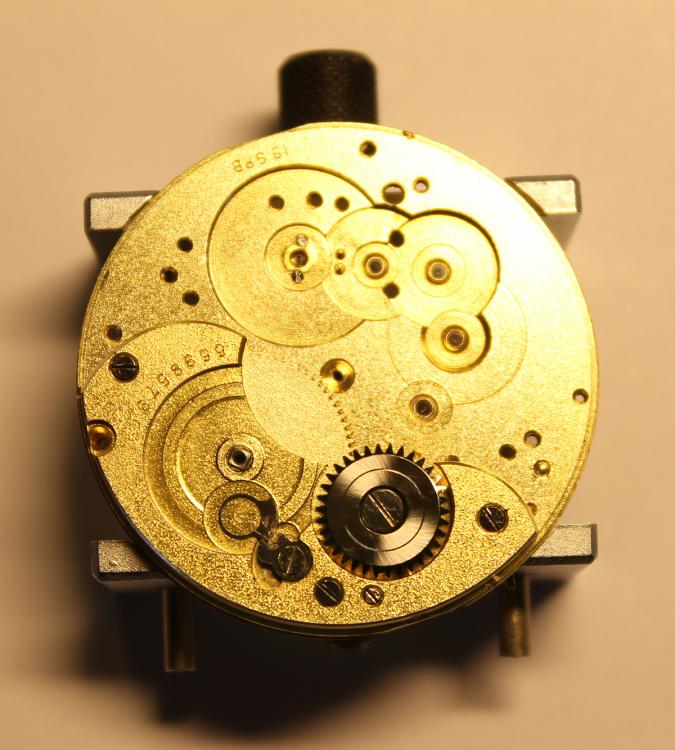

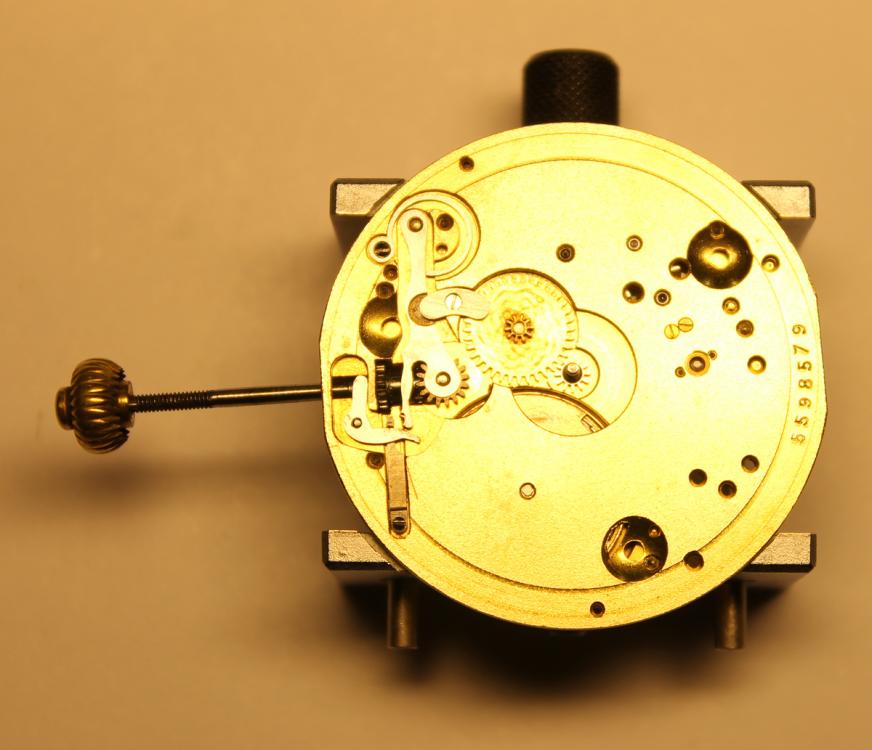

Hello All; I received an Omega 18SPB gold-plated pocket watch, allegedly a non-runner. It was a heirloom item and had to be passed on to the younger generation. Luckily it wasn't a total "non-runner"; after a full wound it ran for 7 hrs. The small seconds-hand was missing and there were visible signs of dirt inside the case & movement. According to bidfun-db ( http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2ustu&1095006620), it is a "Gents Omega Hunter", from the 1924 era and the 18SPB movement has 15-jewels, a bi-metallic screw balance with a Breguet hairspring. Here are some pictures of the watch in the condition I received it; Front cover and dial; Notice the dirt on dial and on the inside of the bottom edge glass ... Rear covers and movement; The 18SPB movement seems pretty straight forwards and judging the case marks / movement-screws-heads; not very often "messed" with. The case numbers did match-up and the gold-plating wear on the case & the chain seem to match up as well. Also the tapered chain seems the original & authentic one; a great bonus ! Before removing the winding stem, remove the residual power in the main-spring; in this case there wasn't any residual power left (?). To pull the winding stem, the set lever screw has to be undone by 1-1/2 to 2 turns; After removing the winding stem, there are two case-screws which have to be taken out. It's a "front loader", the movement is placed inside the casing through the front. Flipped the case over and carefully remove the glass & bezel ...... both the glass and bezel are of very thin material ...... Carefully remove the movement. There is a thin ring around the movement, between the bottom of the movement and the watch case; not shown in the picture. The hands are a straight pull up. The dial is attached to the movement by three (3x) dial-screws, each with a roughly 120 degrees spacing in between; Stripping the keyless works, minute and hour wheel revealed some excessive lubrication; Note; the winding pinion didn't come out at this stage. Pulled the canon-pinion but left both keyless-springs (left and right) in place. Keep an close eye on the minute pinion, which protrude above the main-plate !! Flipped the movement over and removed the balance. Thereafter removed the pallet-bridge, the pallet and the wheel bridge. Note that the crown wheel screw is left-handed, but hasn't got the triple markings some left-hand screws have; Removed ratchet wheel and the crown wheel, also note there is an additional washer underneath the crown wheel; Removed the wheel train, barrel-bridge, spring-barrel, winding pinion and the set lever screw. All items collected in a tray; Opened up the main-spring barrel; Took the old spring out and I have to say that the old spring wasn't eager to get its freedom back ! Before I started on the watch, I asked under the "Watch repairs Help & Advice" the forum for some help. A very educative discussion followed; Luckily I received some excellent help from JohnR725 and StuartBaker104. Both noticed that a wrong main-spring was fitted. The spring fitted had a "normal-bridle", whereas the barrel needed a "DBH" special bridle. This meant that the old spring was not a good reference for a new spring With the help of both forum members above, and the "Spring calculator" on David Boettchers website; http://www.vintagewatchstraps.com/mainsprings.php, we were able to guesstimate which spring was needed. The internal barrel diameter was 14.4mm. Feeding this number in the "Reverse engineering calculator" yielded the follow answer: Spring thickness = 0.177, length = 450, turns = 6.4, area = 55%. From measuring the barrel, the maximum allowable height of the spring was 1.9mm. Scrolling through CousinsUK list for 1.9mm high DBH springs, the closed match was spring GR5617DBH which dimensions were 1.9x0.18x440x14.5 (Height x thickness x length x washer ID). That was the spring which was ordered, pictured below; Even though the spring fitted from the washer inside the barrel, I couldn't engage the hook, so the spring had to be unwound. Note the difference in the amount of "un-cloiling" between the old tired spring and the eager spring. No wonder there was no residual power in the old spring left after 7 hrs running ! Fitted the new spring and it was a perfect fit While this all with the spring was going on, StuartBaker104 made me aware of an eBay auction for a lot of small fusee seconds-hands. The auction ended late in the evening and I throw in a bid, never thought to win it. Lo and behold, I did win !! Whether they fitted had to be seen, but judging the sellers pictures, they had to be close. Thanks again for the tip Stuart ! While the hands were on their way, I thoroughly cleaned and de-magnatized the movement parts. To be continued in part II since I nearly lost all my work above; about 2 hrs of work !! This program doesn't allow intermediate saving, which isn't so good ! @Mark: can that be changed ?1 point

-

I do the same as you, but I'd rather just use a loupe for general work. The microscope is great for inspection, oiling, cleaning, hairspring work etc. I made some extra attachments for the boom to be able to use it with the lathe, but I could not get used to it at all; it seemed to completely screw up my hand-eye coordination and muscle memory.. Some people seem to swear by it, so I may try again sometime in the future.1 point

-

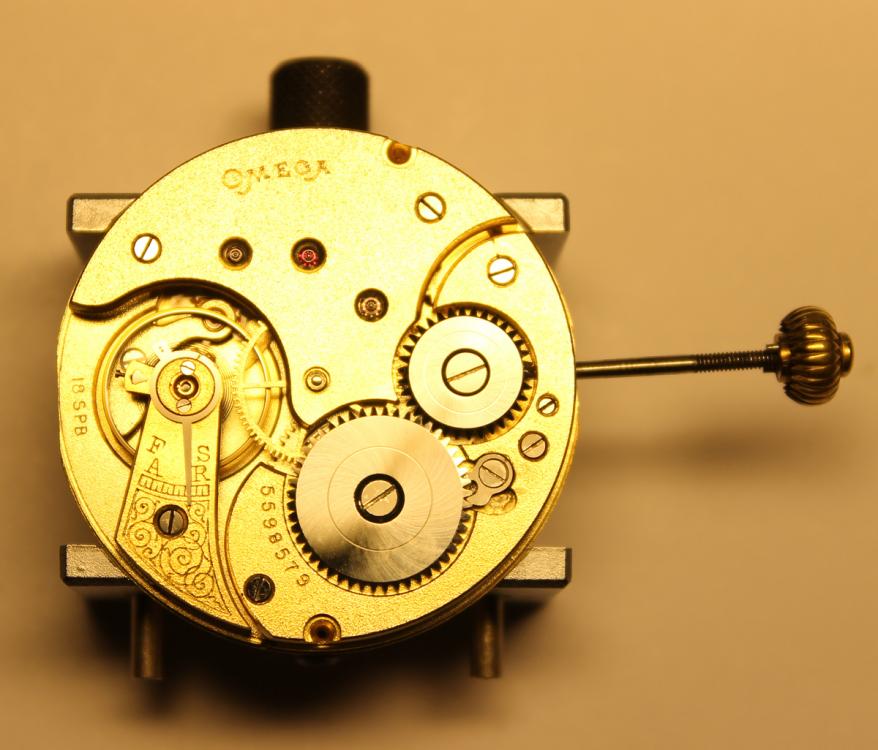

Part II: Assembly and the end result. After cleaning all the jewels, I wasn't able to undo the balance cap-stones. Lubrication was therefor difficult and not optimal. Before placing the barrel bridge, next to the spring barrel, remember to lubricate & place the winding-pinion and the set lever screw; Assembling is the reverse of disassembling; Barrel-bridge, click and crown-wheel lubricated & installed ; The wheel train; Train bridge, pallet fork & bridge Keyless works and winding stem; Installed the balance wheel and ........... a healthy "tick" !! Did some initial checks on the time-grapher and all looked good enough to go ahead and to install the dial and hands. The tubing of the one of the eBay small seconds hand had to be squeezed / pinched with a pin-vice. Luckily I managed to get a nice fit and the hand doesn't look "off" Cleaned the case. It was decided to leave the gold-plating wear of the case and chain as is; the watch was allowed to show its age & previous usage in all its glory To conclude; here are some of the time-graphs. I later adjusted the daily-rate a bit. As for the Beat Error; I decided to leave it as is, too little and not worth the risk. Besides, the watch won't be worn daily, but more to be worn on special occasions. The bench-test showed that the watch ran indeed as accurate as the graphs suggest ....... Dial Down; Dial Up; For some unknown reasons the CU & CD parameters weren't copied to the USB stick, but the amplitude & BE were about the same as dial up & dial down; around 300+ degrees and 2m/s. Crown Up; Crown Down; to me; not too scabby for a nearly 100 years old movement ! I hope the next owner will enjoy & proudly wear this nice watch. For sure, it was for me a privilege to work on it. Thank you Solveig for giving me this opportunity ! Hope that you will enjoy this walk through and that it is of some use to somebody, someday; Roland.1 point