Leaderboard

Popular Content

Showing content with the highest reputation on 12/19/16 in all areas

-

Got me a magnetic knife rack from a fleamarket for $1, put it on a stick and sweep my floor with it...works great.2 points

-

What you have described is a typical situation of wear in the holes to the movement, you need to check the wheels to see which ones need to be re-bushed, it could be bent teeth or pivots but I don’t think so because that is mainly caused by a broken spring. These modern movements are poorly made with second rate metal, soft steel and what you think is brass is a made up soft composition installed large powerful springs that will wear the movement in no time. What is also bad is it has a balance wheel which you find in 30-hour alarm clocks, at least you would expect to see a platform escapement. All clocks with springs encased in barrels should be removed in the proper way and that is by a good mainspring winder, removing by hand can and will cause damage to the springs, you end up distorting the spring into a spiral looking spring and it’s out of shape, this can cause the clock to keep bad time because when winding the springs up the coils rise up and rub inside of the barrel caps. From what I can see from your photo, the parts you have numbered are all on the strike side, so the strike having the wear is fouling up the going side, not un-common the strike can jam up causing loss of or no power getting through. Your first step is to let the power down from both springs, you can find how to do this on the net, when let down, I would remove both barrels, make sure you know which barrel goes back in on the side you removed them from, with a pair of tweezers check each wheel for movement in the holes and for end shake, bad teeth and pinons, the bad ones are the ones that need to be fixed wear in the hole will need to be re-bushed. The wheel I would be most interested in is the one you have marked C that is the star wheel and with the star it lifts the hammers and will take most of the wear, but do check them all, you will have to take the whole thing apart to complete a successful repair. If you like to tell me how you are progressing get back and I can help you with this project.2 points

-

When things get really bad for me I scour the floor with a hankie over the end of the vacuum cleaner...2 points

-

No special techniques however If I get a measurement such as 374, I'll be thinking it's probably 375. Most glasses are in increments of .5 in my experience. I also build up a stock of previously used sizes, so if i know that it's a 375 i'll order 2, useful to know I'll have the glasses for any customers returning for the same glass, or that for popular watches I commonly finding myself doing glass replacements on, I know I'm stocked for (helps keep the workload clear if you can do a job as soon as you find yourself with the time) and also in the rare event a glass gets scratched or damaged during fitting, you have a back up. I'm not sure about the whole profit margin thing. I charge enough for glass replacements that ordering an extra glass or two hardly seems worth splitting hairs over. And as you say, they'll get used so it's an investment, not just a simple loss of revenue.2 points

-

Got this very old Elgin Pocket Watch working again by giving it a good cleaning. After assembling it I noticed that the balance was not true to the round so I adjusted it with the truing caliper wrench, without taking the balance off the balance cock. A lot of luck I think. Enjoy. Sent from my iPhone using Tapatalk1 point

-

Hi all, Just a short post to introduce myself, I'm Mark, and i'm currently living and working in Abu Dhabi. I've just recently got into the very addictive hobby of watches, and how they work. Next step dismantling, servicing and putting back together, just getting my tools together at the moment, Wish me luck ;-) Great video's Mark!! I have loads of questions but I'll save them for the future. Thanks for now Mark1 point

-

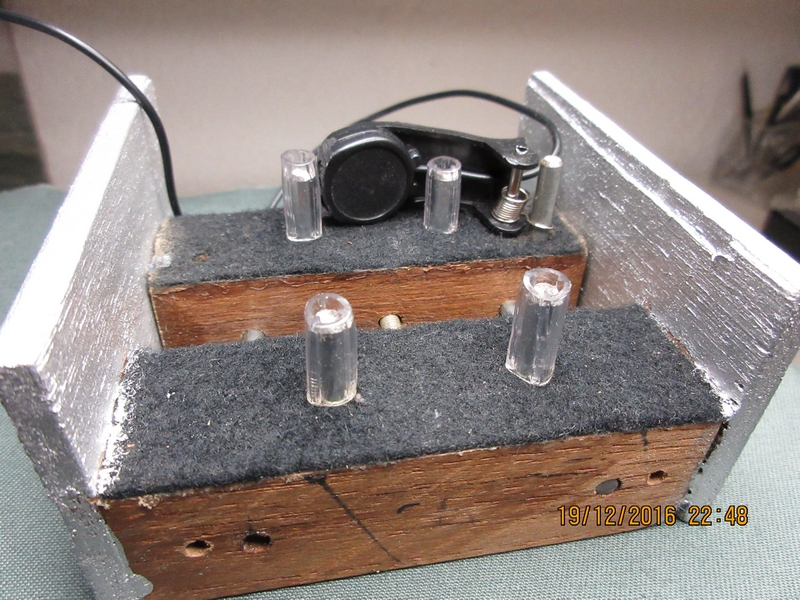

Just for info (probably already known but . . . you never know): the best result are achived when measuring with a laptop running pure on batteries (no connection to mains); this reduced the 50-60Hz noise considerable!. Maybe an SSD helps as well, but can verify that. Futher a picture of my watch-holder; note the mounting of the micro which is pushed with a spring against the crown (constant force) allowing to fix the watch firmly between the four stands. Furthermore two sides which makes it easy to measure the 4 positions Crown up etc. and dialdown while the strap is still mounted. Only dialup required the watch-holder to be put onto two books or so to make space for the strap.1 point

-

Hello SSteel, I don't know if this will help or not, but there's a place here in the US where you can get timing machine repair. As an alternative, if they don't service your model, or it's not worth repairing, they often have refurbished machines for sale. If you want to give it a shot, the website is www.timemachinerepair.com The phone number is on the web site. Hope this helps! Shirley1 point

-

Hi, Mark! Welcome to the most soothing frustration you'll ever experience... lol Shirley1 point

-

Don't even think about going down that route, especially with a good movement. The movement will have to be stripped for any type of cleaning and to do that you really do have to know what you are doing!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Hi fj, generally no. If the spring is manipulated just enough to clear the lip it should not affect its shape. It could be someone forced it to far and bent it back to its proper shape. Once this is done it will break eventually. It quite easy to damage these springs on ladies movement as the gap at the 'waist' is very tiny and you only need a microscopic amount of movement. Personally I think the kif ones are worse Anil1 point

-

I've never seen a clock spring taken out by hand, normally a winder is used. Many years ago they might of. I bet that spring could be very powerful ! Sent from my SM-T585 using Tapatalk1 point

-

Be careful removing the spring they can really hurt and cause damage to you and anything else in its path. Its best to use a designated clock spring winder. If you are going to remove by hand do it inside a clear plastic bag and wear gloves. I used to have a wooden contraption I made for this task but now use a "Oli Baker" winder see below. Clock servicing is much the same as watches. Strip, clean, reassemble.However normally with clocks the pivots are polished.1 point

-

And then, if you're *really* old school, you make them A bit beyond me, though.1 point

-

I don't know anything about clocks really but that mainspring is going to be powerful and "Fly" and could cause you serious grief if you try to take it out by hand without advice. Hopefully "Oldhippy " might see this thread and give some guidance Sent from my SM-G920F using Tapatalk1 point

-

I bought a little box of screws from Ebay some years ago. Have found most of the screws i have lost in that little box. But from time to time i am on the floor seeking and looking for that lost parts. Have updated my little box with screws from Cousinsuk. And bought some old movements at auction sites.1 point

-

My straightening another balance to the flat. Sent from my iPhone using Tapatalk1 point

-

Mineral oil should be ok for 5yrs and synthetic for 10 years providing:- Keep in sealed container, preferably glass. Metal containers may deplete any anti-corrosion, passivating additives in the oil. Plastic maybe ok but some oils will react with plastic so best avoided. Keep stored in cool, dark place which stays fairly constant (heat will oxidise the oil quicker and very cold may cause water crystals as most oils have some very low levels of water in them). Try and keep the container as full as possible to reduce the amount of air (the air will enable oxidation). I always store mine upside down to avoid ingress of air through the cap, (the air could be moist), believe it or not air will get in as the temps change and the air 'pumps' in and out but the oil will not leak out !! As long as the cap is covered internally with oil then this is ok. Pour or drip the oil out when required and avoid putting anything in the oil as this will likely introduce dirt. High quality oils should last longest.1 point

-

@Watchtime Thank you for your nice compliment I'm not sure whether it is going to be this year, but I'll take pictures of my "attempts". I may finish the case with just nickel. I do have a chrome solution, but that's more industrial chrome and not the glossy-chrome. I could do a silver layer over the nickel, but that wouldn't suite a Komandirskie. The back-covers of the Komandirskie's are fine, so when left untouched, there shouldn't be any risk for allergic reactions ....... even though nickel doesn't effect me anyways. To be continued in due time1 point

-

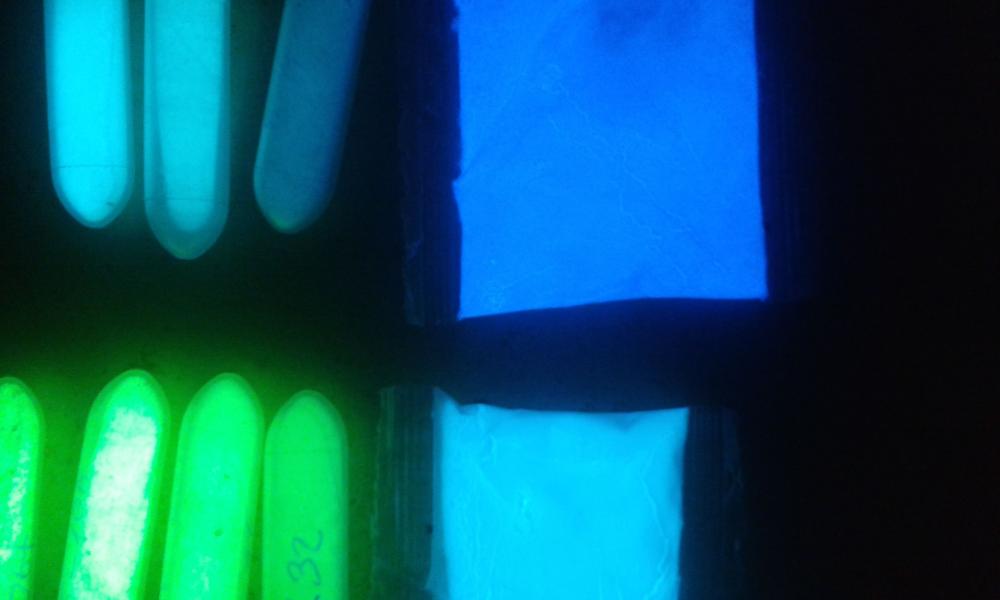

Here is how i do the relume Since i am hobby watchmaker i am using cheap chinese powders. It turned out that they are really good for the price! There are three types that are white in daylight each with different properties (the colored ones are from this 3 type with some paint added, lol). The night green one has the highest initial brightness which goes pale quickly. The turquoise has low initial brightness and loosing it as fast as the green one. And the deep blue has lowest initial brightness but is as bright as the green one in half an hour and much brighter after a night. You can see all of them glowing after a night and even after a day in complete darkness if Your eyes got used to it. Particle size is really important! The bigger the brighter. But bigger ones are harder to apply and looking ugly on the watch. So we have to make a compromise here. There are pigments sold in ~ 1mm particles which need to be grinded and sieved. Used this sieves: http://www.ebay.com/itm/T304-Stainless-Steel-Co**BLEEP**-Dense-Gauze-Woven-Mesh-5-to-500-width-3-to-20-VA-/181505011630?var=&hash=item2a428aafae:m:mr9ZSZ3z9I76O9J31WG9ejA Between 0.03 and 0.07 mm is perfect. It is important to leave out the finest batch since it will fade the lume. The three whites here have a good particle size: http://www.ebay.com/itm/3-Super-Bright-Glow-In-The-Dark-Powder-Luminous-Pigment-Strontium-Aluminate-10g-/222043965311?hash=item33b2da077f:g:PfEAAOSwjVVVr63b Tried acrylic (Tamyia x22), nail polish and UV nail polish up to now. Acrylic is soft if hardened and may be soluble in water and can adsorb it even if cured. You have to exclude water since strontium-aluminate will fade in presence of it. Simple nail polish is excellent, i dilute it with semi-polar solvents like "epamine" solvent (mix of aromatics and alcohols). In particular, You have to use those with high boiling point. Check the composition; look for xylene and n- or iso-butyl alcohol. If toluene and/or iso-propyl alcohol is written on the label then dont buy, it will evaporate quickly. These solvents are also OK for the UV gel. Just deposit the mix on the surface and let it dry, and expose to UV thereafter. Mix the prepared paint every time before taking from it, since the big particles will settle at the bottom and You wont get consistent coating on the different indices or hands. Using dichloromethane for removing the old lume quickly. Using ear cotton buds dipped in this solvent if the hands are painted to scrub down the old lume carefully not to touch the upper side of the hands. Just sanding down the excess if to thick layer is applied with sandpaper after curing. Usually leave 2 days for acrylic and simple nail polish to cure perfectly. The acrylic is much softer. Here is my every day watch with the green on the dial and hands and deep blue on the bezel. And some comparison of the powders. You can compare the lume brightness dependence on the particle size looking at the small vials. First batch is 0.075-0.106 mm and the smallest batch in the middle of the picture (<0.032mm). The blue ones on the right are on their original grain size:1 point

-

1 point