Leaderboard

Popular Content

Showing content with the highest reputation on 03/19/24 in all areas

-

4 points

-

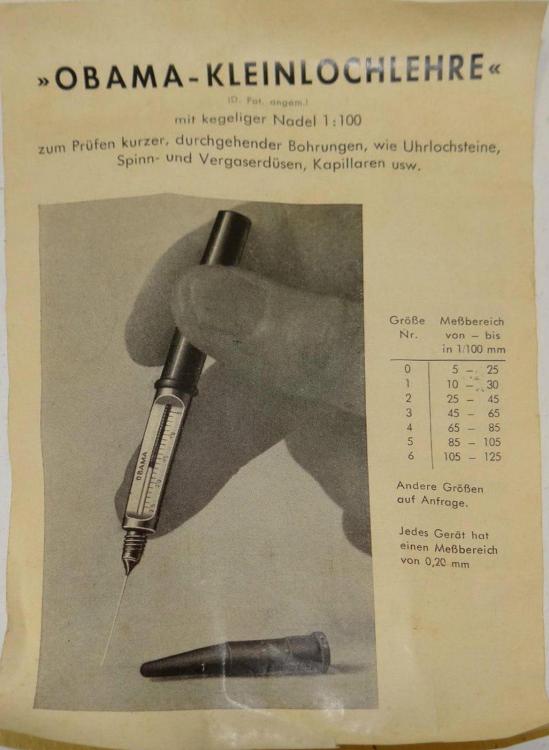

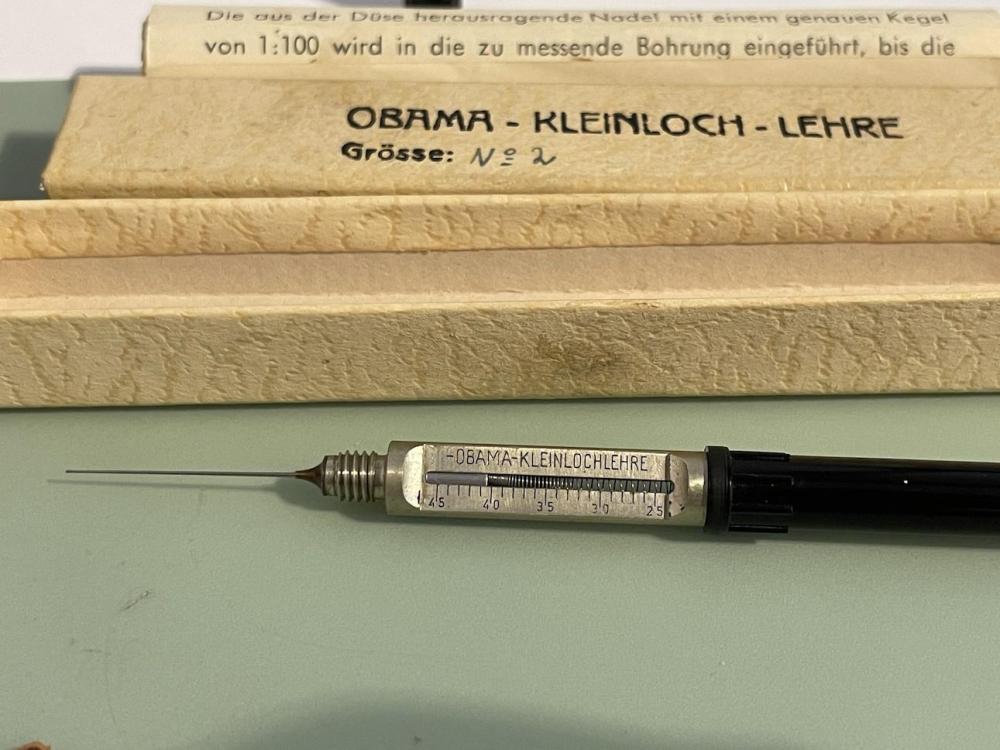

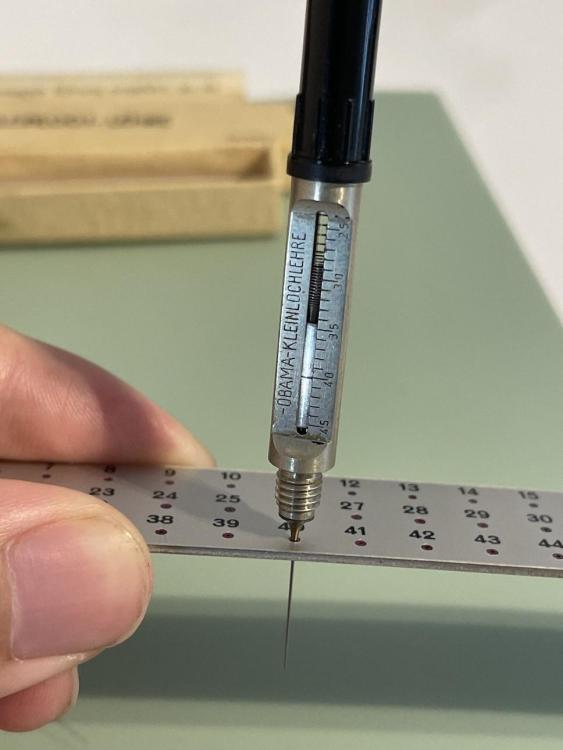

There is a tool for this, if you can find one. It's called an Obama Jewel Hole Gauge. It consists of a finely tapered pin which you push into the hole as far as it will go. The pin then pushes back into the body of the instrument until the jewel is against the tip. The hole diameter can then be read off the scale in 0.01mm increments down to 0.05mm. If you could find a suitably fine tapered pin there's no reason why you couldn't improvise by marking where the jewel sits on the taper and then measuring it with a micrometer. In practice though if you are replacing a jewel you could always just measure the pivot that is going to run in it.4 points

-

Welcome Jeff. As a newbie, you are bound to drop things and launch things across the room. We all went through that phase. It gets less frequent as time goes by though, trust me. In the meantime, get yourself good, comfy knee pads, a headlight and a magnetic sweeper. Enjoy.3 points

-

Re. rust removal: I'm using a formula created by one of the science channels on youtube (Elementalmaker). It's cheap, not acidic and works in a similar way to evaporust, but seems milder. It has worked well on everything I've tried it with so far, with no detrimental effects. The formula is: Per 100ml deionised water; 5g Tetrasodium EDTA [from amazon or ebay etc] then enough citric acid to bring it to ~6.5ph, testing with ph paper, plus a few drops of washing up liquid / dish soap. I've only made one, 100ml batch so far and it shows no signs of stopping working, though it is starting to look a bit murky! These spring winding arbours were the worst rusted items I've put in it - they had quite heavy scaled rust patches; you can see the darker grey areas where the rust ate in to the metal, compared to the untouched areas. The small clock parts are unaffected by the solution, other than the rust having gone. (I've also used it on such as setting levers & other keyless components, that had quite significant rust from water ingress).3 points

-

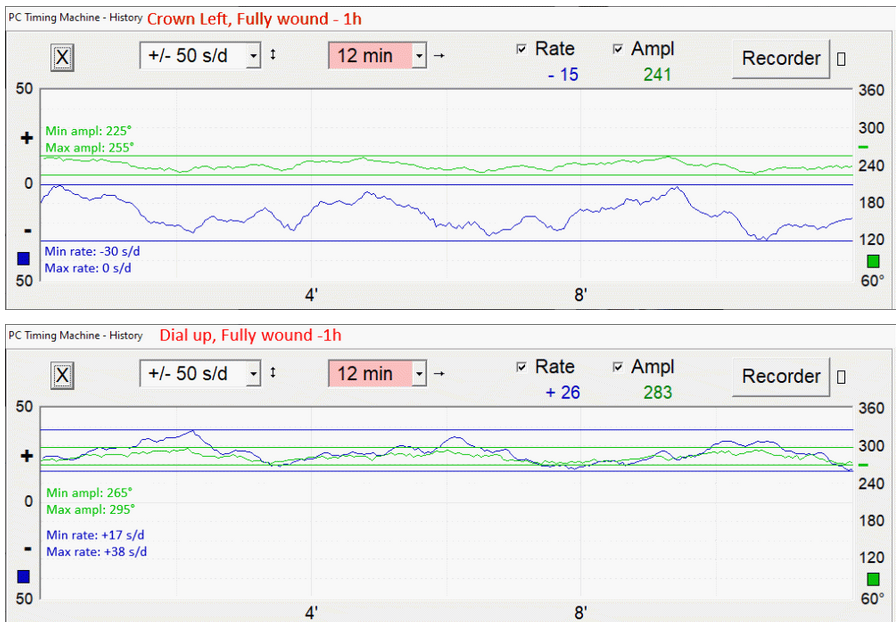

This seems to be complicated case... We have many variables here and we need to exclude some of them to make some progress. We have plots that show amplitude variations, but we don't know if this variations are significant, as they can be 'amplified' or 'smoothed' by the software. So, some observation of the amplitude by eye will be of help. Then, if we really have not isochronical work, then the main reason for this would be the hairspring being not 'linear'. And not linear may be sometimes not only because 'touching', but because bad hairsping material structure. Some of the advanced watchmakers claim that repairing badly bent hairspring is useless, because this springs will never be isochronic again. Well, my own observations are that such thing happens, but not in all the cases and it depends on the case if the result is acceptable or not. I will not suppose here that this spring has been repaired, but it has some strange behavior watching at it's work. It will be good if it is possible to test the movement with another balance or thest the balance on another movement...3 points

-

OK, several things to say here. The thought thay if with the old spring the movement works 16 hours, then replacing the spring will solve that - is totally wrong. With a new spring the movement probably will work for 17 hours. The power reserve is practically not reduced when the spring gets weak with the age. It is rather something wrong with the movement. As You worked on the hairspring, we need to confirm that it is OK now before everything else. So, thake the lever out and do the free oscillations test. What is the result? I expect numbers, not only 'it is good' or 'it is not good'. Then, this is no jewels pin lever movement, so this is not unusual to have not well regulated or even worn escapement, this is the main reason that this kind of watches doesn't work as long and reliable as the jeweled escapement ones. You can find many of them with no wear at the crown and case, and this is because they stopped working normally pritty soon after purchase.3 points

-

Thanks guys. It's a Seawolf 10ATM pre spring bezel. The case knife stressed me a bit, but eventually got it off and cleaned - nearly seventy years of grime. Thanks. Cheers John3 points

-

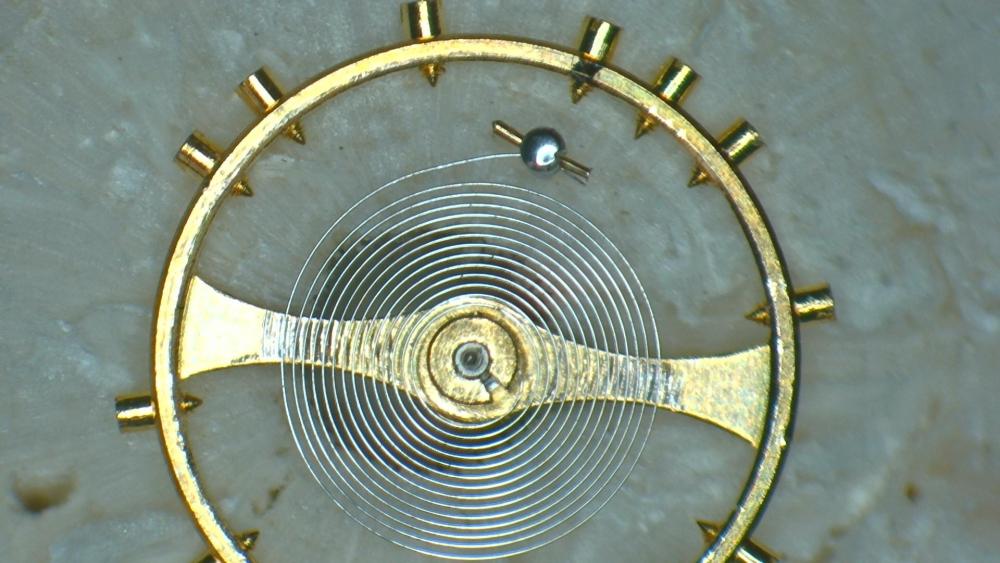

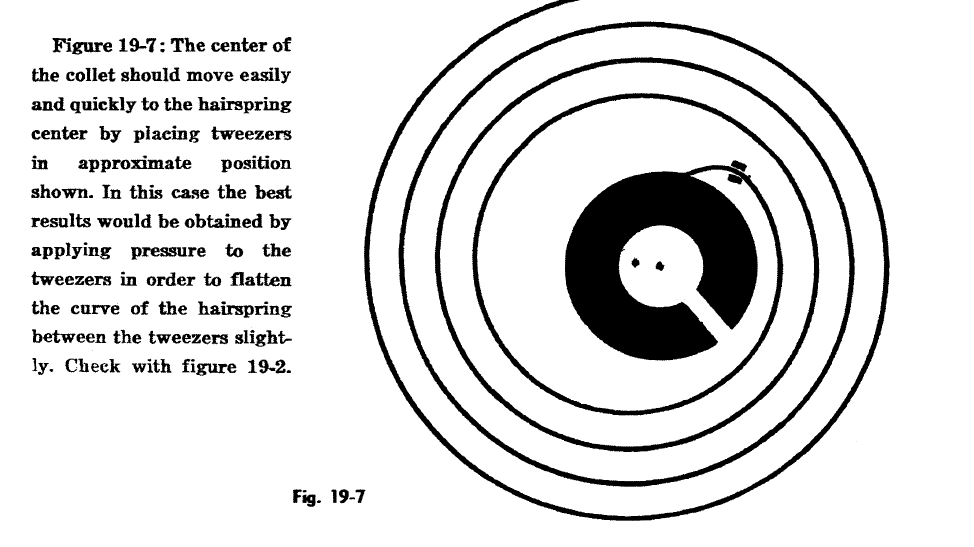

Exactly. This is a pic of the hairspring I'm working on. My horizontal v vertical rates are all over the place. There is no discernible terminal curve. My problem is that the outer coil is (possibly) hitting the regulator pin. It's hard to tell but it looks to be getting very close. Also getting close to the stud, which could be @VWatchie's problem. You can see that I need to adjust the inner coil to centre the collet. That will hopefully solve the problem. But then I'll take the spring off and attach it to the cock to see how it looks. I don't know if it's causing your problem @VWatchie, but I would say your inner coil looks like this3 points

-

As @rossjackson01says, "good this hobby, isn't it " or words to that effect. I'm not sure that I do learn daily but no matter how much I do learn, there's always something new and I'm constantly learning. So yes, since I love learning, this is a brilliant hobby or profession.2 points

-

2 points

-

From everything I have read, I believe the terms are interchangeable. Hair, due to the thinness of the spring and balance for obvious reasons.2 points

-

The problem (as I see it) is not amplitude fluctuations, they can be normal if the readings are correct. The real problem is that the rate changes much from horizontal to verical positions and from fully wound to unwound spring. In other words, the rate strongly depends on amplitude. In this situation (where amlitude increase leads to rare increase), the first thing to do is to close the regulator pins as much as possible to avoid the free play of hairspring and see if this will affect the rate change enough. I don't believe it will be enough, but at least a slight improvement is expected. The thing that would be interesting (if the software can do it) is to show a graph of rate versus amplitude. It will be interesting to see if the graph is calm or there is a 'break point' in it2 points

-

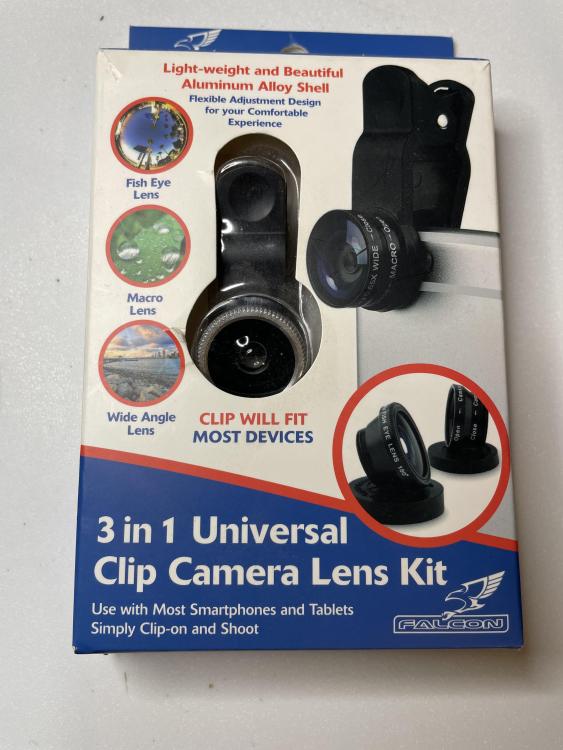

Hi Jeff. Welcome to WRT. For a moment there I thought i was reading my own biography. I too work in IT, have a degree in art and love all things mechanical. If you're left-handed too, then I'll have to check Ancestry.com to see if I have any relatives in TN. I've found the best solution for me was to get a set of these and clamp them to a pair of readers. If you stick with it, you'll want to get a microsocpe, but that's a ways down the road. BTW, in order to not frustrate yourself in the beginning, You'll need to get some decent screwdrivers and tweezers, and learn to dress them properly to keep those tiny parts from flying all over the place.2 points

-

Yes, you'll have to be extremely careful with pivot diameters less than about 0.12mm. They are all too easy to dent even with a very, very light hand. I have the Bergeon version with the adjustable table too but I must say I prefer the JKA Feintaster. Also, the JKA has a dial that I find to be very pleasing, both from an aesthetic and practical perspective. I always feel a little extra happy when I get the chance to use it. I'm not being nerdy now, am I!? There's a Swedish watch that reminds me of the JKA named Strayer. I love its dial but way, way too expensive for me. We'll all soon be there!2 points

-

I'm presently using a cheap supermarket ultrasonic cleaner, with L&R #111 cleaner and #3 rinse solutions. I cut a bit off the bottom of an appropriate size plastic sports drink bottle, which is a perfect fit around the mesh basket I use (~65mm diameter). That allows me to use mostly water in the machine tub and cleaner or rinse only in the small plastic container. I keep the solutions that are still fit for use in small glass jam jars. I use the cleaner then two rinses, then the mesh basket balances on my bathroom radiator (once it stops dripping) to dry the parts with moderate warmth. Prior to that I tried just lighter fluid (eg. generic zippo fluid) and just soaking / swirling parts in the glass jars, but the movements did not run at all well afterwards, they were still acting gummed up. The proper solutions make a world of difference & the watches now work as they should!2 points

-

Have to agree with you. Will not do another. Did not enjoy the time spent. However, it was worth it to know that I understood how to disassemble, look for defects, repair and then assemble. Timegrapher? No facility to alter anything other than the stud. Everything is metal to metal.2 points

-

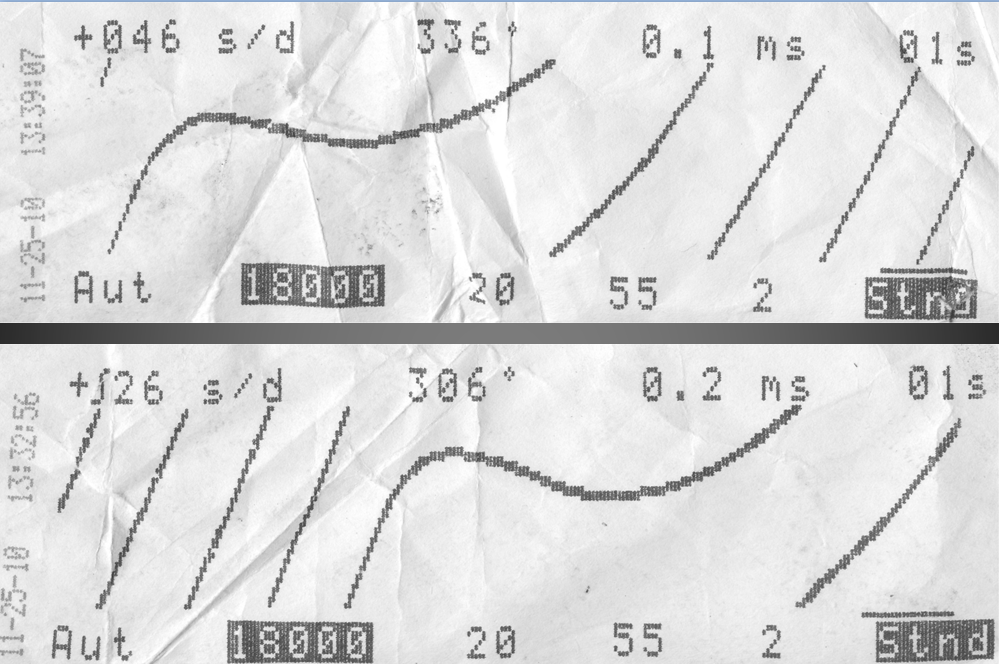

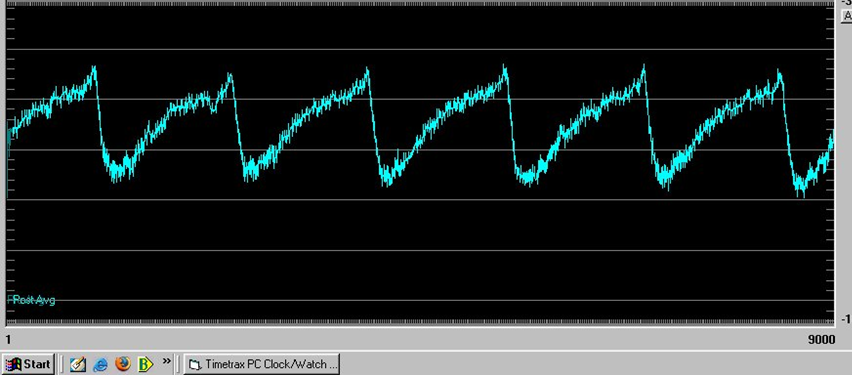

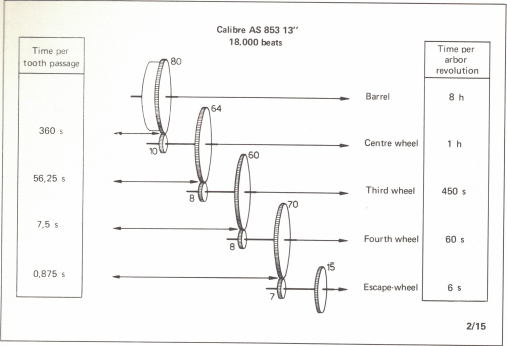

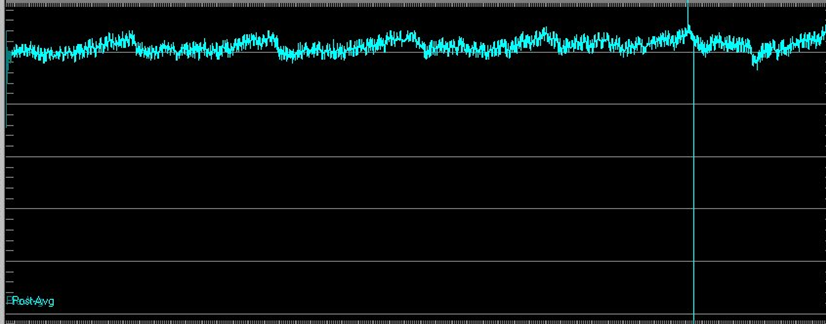

somewhere in the universe although as I'm answering this I remembered which discussion group. Somebody had a similar question loss basically expanded it to the watch would totally disintegrate in my think like 30 years. I'd have to go back and find the original discussion if I can the person seem to think that they hairspring would disintegrate like you describe and just metal on metal wearing out the entire watch. Except of course we all work on watches over 30 years and they obviously do not disintegrate. Plus somebody came along and explained why hairsprings do not have the same issues as mainsprings. Although hairsprings do end up with watchmakers insisting on bending and playing with them and torturing them etc. and that obviously is not good for the metal at all. one of the problems that you're having here it is what is the purpose of the test that started this discussion? Let me go and snip out the original image as you can see from images above this watch is horrible. Or is it? What is the purpose of the images up above in other words what exactly would use this test for? The real purpose this test is show the effect of amplitude on timekeeping. Or specifically you're looking for mechanical issues that are causing fluctuations in amplitude which unfortunately shows up with timekeeping. or basically everything affects timekeeping but amplitude is affected by the mechanical characteristics of the watch from the mainspring to the balance wheel and unfortunately as it's a mechanical watch your always going to have power fluctuations. so how do we rule out unacceptable fluctuations versus the natural characteristic of the watch? Usually if you can find a repeating pattern you can narrow it down to the offending components for instance I'm attaching a PDF. on the second page of the PDF it talks about 21st-century equipment versus paper tape timing machines. Then they give an example of timing problems solely caused by a faulty component. although off you have a user's manual for a paper tape machine it does explain that you can find faulty components by looking at the variations on your paper tape seeing how often they repeat and do the same thing without the fancy software. Even though it was claimed that you couldn't do that in other words you couldn't find a pattern? One of the problems that comes up with modern LCD-based timing machines versus software is limited screen size. In other words it makes it very hard to look for patterns you'll see variations in numbers but it's hard to tell what's going on which is why the display above is really nice to see if there is a problem. for instance here's a paper printout from a witschi timing machine it does look distorted because I changed the speed at which the image would move across the screen. In other words I was trying to figure out a way to extend the screen to being much longer as I was looking for a pattern as you can see there doesn't appear to be a pattern at all so basically we end up with a watch that I cannot time at all they cannot really figure out what the problem is and I actually cannot find a pattern even begin the figure out where the problem might be. Plus I agreed to service this watch for free as I was going to use it for the purposes of a lecture. In other words it's a nice railroad grade pocket watch and I wanted to show before how horrible amplitude is and how wonderful it looks after serviced and after servicing it looked exactly the same still horrible. Then I used software for a clock timing machine and came up with this interesting image one a minor problems we have with time plots and how they look is that they all do things a little bit differently. So this was occurring approximately every five minutes. Then we need another chart then I replaced something in the watch and we now get this one of the things that I was always bothered with was if I had put the hands on after servicing would the watch have Time? Because the pattern was repeating the watch would average that out may it would have Time. Oh and what did I change somebody had swapped the mainspring barrel for something different were getting a binding between the mainspring in the center wheel pinion. so the problem you're having is what exactly is the problem? the purpose of the test image is to look for mechanical problems causing amplitude problems. Because it's a mechanical watch your always going to have variations so are the variations in this watch abnormal or normal for this watch? Once we eliminate the mechanical issues beyond it's a mechanical watch then you can work on timing issues. for timing issues I recommend going back to the normal display that were used to and make sure you have your averaging times set correctly. In other words while the graphical display is basically real time years of the numbers are averaged over time. Anywhere from 20 to 40 seconds depending upon whose specs you're looking at. So basically they will average out the problems were seeing on this time plot. one of my amusements with students that go to the same school is that you have different instructors. So this gives you different experiences like what exactly is tight anyway as I don't remember any thing like this? Then did you know that Rolex at least in Geneva as I visited their service center replace all the screws in the watch every time they service the watch. then why did they do that because they use power screwdrivers and tighten those things down as tight as you can get them which has a problem. How many times can you tighten screw down really tight before the hints break off. So they replace the screws every single time. So personally I don't think they have to be so tight that you're in danger snapping head off that's too tight in my opinion. but the screws definitely shouldn't be falling out either which I've occasionally see and where people just don't tighten their screws tight enough. Horologica Times -- May 2004 From the Workshop witschi time plot.pdf2 points

-

Yes, I do have the Seitz pivot gauge which is worth a small fortune these days. Got mine for about £200 which I thought to be crazy expensive at the time, but I've now seen asking prices over twice that. And no, I do not have the scaled pin gauge, but it would be convenient. Let me know if you find them! Anyway, the Seitz pivot gauge is in my opinion not really necessary if you have the JKA Feintaster. It can measure even the very small pivots w/o making any dents. One will have to be a lot more careful when using the Bergeon micrometres.2 points

-

2 points

-

Yep seen this tool before but never for sale. I bet there aren't many that aren't broken.2 points

-

I saw a mention in one thread with the OP saying they could not take good photos of a watch movement they were asking about, so I thought I'd post my ultra-cheapo method: A local second hand shop had a stack of the nasty looking "clip on" lens kits for smartphones; they were priced at 50p so I got one out of curiosity. I didn't even try they for weeks, until I was struggling to take a high enough magnification of a damaged piece of jewellery, for a friend. The "macro" lens in these kits is actually amazing, it's very effective - and the full kits around only around £3 to £4 on ebay. The first photos are the particular 50p lens kit I got, and the lens I'm using from that, then examples photos, using my iphone with the macro lens in the clip and approximately centred over the camera lens. It does need a good light, and finding the exact height for best focus can be tricky sometimes, but the results are worth it. The movement is a Junghans calibre 73 from ebay:1 point

-

I had a cabinet with a few draws, I had wooden trays fitted for the insides and small transparent plastic boxes that would take a watch movement and its parts all the boxes had small labels with the cal on them. I called it my A to Z of watch parts. This you might like to think of.1 point

-

Hi Kim a read through the attached document may be of help to you. 1982.03 Seiko Case Servicing Guide.pdf1 point

-

1 point

-

No problem i have a four poster bed to make for my daughter this week. Where am i sending the sawdust to ? Aw Joe thats my second favourite thing to do,in cherrywood shavings hmmmm ❤1 point

-

Yes, it does not seem at all sticky and is water-thin. Things may need a wipe down (with a cloth or fingertips) after rinsing to remove rust residue, but that appears to be the remains of the degraded rust rather than the solution itself. That may break down further if left longer? I usually submerse things from between 2 - 6 hours, depending how thick the rust looks.1 point

-

To save time , Neverenough should be the first to volunteerly jump in the sawdust box. lol1 point

-

1 point

-

I have to agree with your numbers, it is centred. The shape of the first coil makes it look off centre. I too had not thought about the direction of the springs. It depends on which way the balance cock points. Yours points clockwise, hence the spring must be anti-clock for the stud to be on the outside. Mine is the other way1 point

-

Yes, the hairspring is not perfrctly centered. But it is not enough to cause 'touching' to the collet. It makes the hairspring center move in circle and this movement is partly transmitted to the outer coil, making it's distance to the studd to change in odd manner. But if You don't see any touching to the studd (this distance never gets dangerously close to 0), then no problem from that. But for the sport, You can try to center the spring at the collet. There are left hand and right nand wound springs, this is normal. The layout of the movements are different. I meen graph that has amplitude for one axis and rate for the other. May be the graph then will be not line, but something like cloud of dots.1 point

-

1 point

-

He talked about the balance cock screw but it may be also applied to the plate screws as well. Anyway rodico tight is definitely not good enough and there is a chance that this contributed to your readings. Open your sawdust box please!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

From what I’ve seen Rich below 0.1mm aren’t available unless maybe from a Swiss manufacturer I don’t know and I can easily imagine the price for 1 to be more than that whole Aliexpress set my next thought is that the really small sizes would be more likely found in ladies movements which we do less often? Maybe one of the professional guys we are so lucky to have here can help educate us? Tom1 point

-

Hello from the Mid-Atlantic United States. I've been in the hobby for a few months and have concluded that I will be staying in it for a while. I've started to get some proper tools and I am looking forward to developing some skills. My current goal is to get comfortable enough to service / repair some watches I've inherited from family members. My current project is a Mentor pendent watch with a BF866 movement that belonged to my great aunt.1 point

-

I have always had it in my mind that hairsprings can fatigue in just the same way as mainsprings can. If a hairspring has gone through a rough process of repair then its structure will have changed ( bending any metal backwards and forwards will cause micro fractures and eventually breakage ) in those areas of heavy manipulation. Its strength and elasticity is no longer linear over its full length so no longer isochronical.1 point

-

The more common Jewel hole diameters are from about 0.07mm to 0.50mm. Those are the sizes in the Seitz jewel gauge tool.1 point

-

Having recently acquired a JKA Feintaster myself I ordered a set of pin guages from Aliexpress. Randomly measuring them they look good. I am planning to get some jewels now to experiment with. https://www.aliexpress.com/item/1005003664177054.html?spm=a2g0o.order_list.order_list_main.29.550018027e4OVW these are the ones I ordered, I also bought 100 plastic sample vials from amazon to organise jewels Tom1 point

-

Pin levers, you gotta hate em to love em. Big Friendly Giants - lotsa wierd bits and pieces floating around making the job interesting . Great pictures Ross, you did well to ignore your timegrapher and showed great restraint not pebble dashing the wall behind you with its innards.1 point

-

as you're grasping you want to be very careful what the definition of? in other words you can have the collet centered over the jewel hole and not actually have the hairspring centered.1 point

-

Thank you ALL for your great information. Clearly, I have a lot to learn, which is exactly why I am so thankful for this forum! Best, Corky Update. I've ordered a "blue box with the red button" demagnetizer. and we'll see if this improves my results. It's clearly a low cost option, and a good start for this point in my journey.1 point

-

@Qutadah, see, You first need to have the watch in You hands, or at least to have good pictures of the movement. What the seller says is useless, as if He understands enough of watchmaking, He would repair the watch. We need to see this hairspring, as it may be really bad, but it may be quite easily repairable too. And it concerns not only the hairspring, but all the other parts... The main problem that I see is that You intend to repair this small and fragile calibre without having any experience. Such attempts usually end up with ruined hairspring and/or broken pivots. Actually, the hairsprings end up ruined never by themselves, but only because someone did'nt handle them properly.1 point

-

I've just posted this on the forum to help understand the theory in conjunction with the practical aspects of end-shake. Unfortunately the videos won't play because of the conversion to PDF. Enjoy!1 point

-

Back in the day you would always dry parts in sawdust; it soaks off the solvent (benzine, maybe alcohol) and avoids condensation. There were little boxes with a layer of sawdust at every bench. The "dust" part is misleading- more like dust-free micro wood chips. This was still common, at least in the restoration end of things, when I was in school. If you brought something to the teacher to check that was clearly wrong, you might get away with it once, but after that your movement went in the sawdust. Meaning you got to take it all apart and reclean and oil it... so you got good at bringing things up that were worth the teacher's time, haha!. I still use sawdust sometimes, but I didn't drop student's movements in it when I was teaching, and don't do it to the new guys at the workshop- though I have been pretty tempted.1 point

-

1 point

-

1 point