Leaderboard

Popular Content

Showing content with the highest reputation on 11/26/20 in all areas

-

2 points

-

technically this is correct but it's also sort of incorrect? The problem is there's a tiny bit a play of the roller jewel in the fork slot. This means you can have the fork absolute perfect between the banking pins and the timing machine may disagree with your assessment. personally I never hang balance wheels on the balance tack. In the past I found it stretches the hairspring and if you have just the balance with hairspring it makes it easier to see what you're doing as you can see where the stud is in relationship to whatever you are using as a reference.2 points

-

2 points

-

Yes. I have the balance complete with hairspring stud fixed. Then gently rotate the balance with a finger until the jewel is between the banking pins, and note the balance position - against a balance screw, or use a marker pen. If it needs adjustment, I'll remove the balance, hang it on a balance tack, and make an adjustment (as Mark's video shows above). I filed down the end of an old screwdriver so that it will fit in to the slot in the collet. This is the part to practice. It's VERY easy to damage the hairspring. Older 'blue' hairsprings especially are very easy to distort, and when hanging on the tack, I'll try to support them to stop too much stretch. If it's a very small hairspring, or a more valuable movement with no replacement hairsprings likely, I'll reduce the risk by taking the balance off the cock, and adjust as @Jon shows above. There's always the chance of damage either way, so if I get with say, 2ms, I consider that acceptable and stop fiddling. I wanted to know how much I needed to turn the collet to correct the beat error, so did a calculation - I can't find it at the moment, but from what I remember (for a 18,000 bph movement, and 250 deg amplitude) it's about 4 - 5 deg.2 points

-

something that comes up continuously in this discussion group is if the hairspring is a removable component obviously you can remove it and put it on another watch. Physically that is 100% correct but there is a tiny little problem. That is hairsprings are typically vibrated for each balance wheel. I don't know of Seiko actually does it for each one or they do it for a grouping of them traditionally every hairspring only goes on the balance wheel came from. typically with the exception of American pocket watches where the balance wheels had screws that you could interchange to get your balance wheel to match the hairspring. So if you swapped your hairspring from one balance wheel to another and are having a timing issue providing it's not some other problem it's because it's the wrong hairspring for your balance with. Ideally if your watch was running slow then you could take some weight off the balance wheel an attempt to get it to match your hairspring. Unfortunately on these balance wheels it's hard that put weight back on. there here's a link to your balance staff and all the other watches that use the same staff. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=T_[JWD[2 points

-

for the most part balance staffs are considered one time use. then the staff is usually cheap just get a new one. then maybe my confusion when you are busy swapping parts did you swap the hairspring also? In other words a different hairspring is now on a different balance wheel?2 points

-

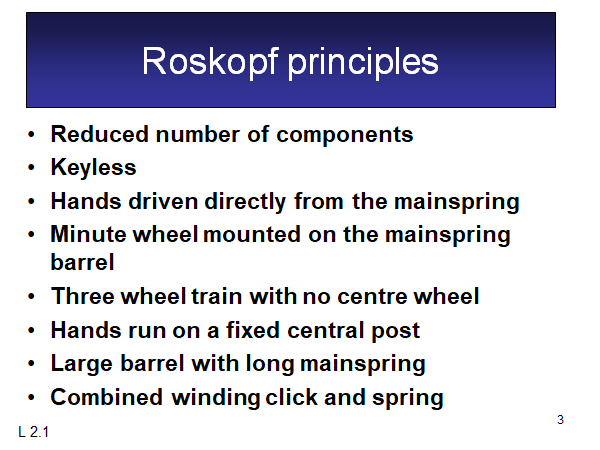

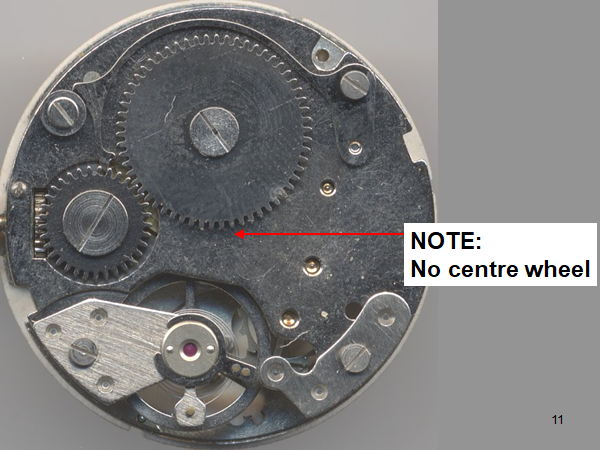

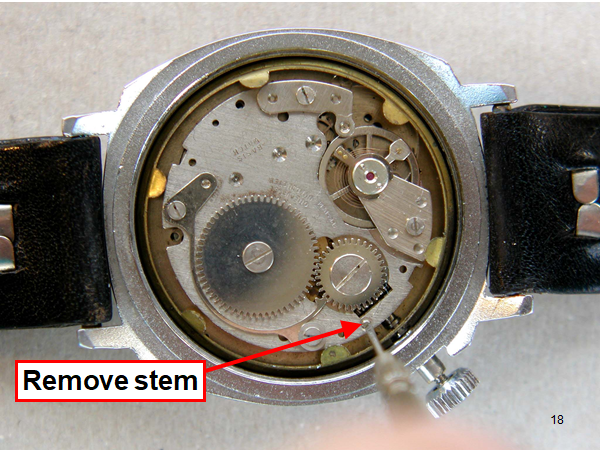

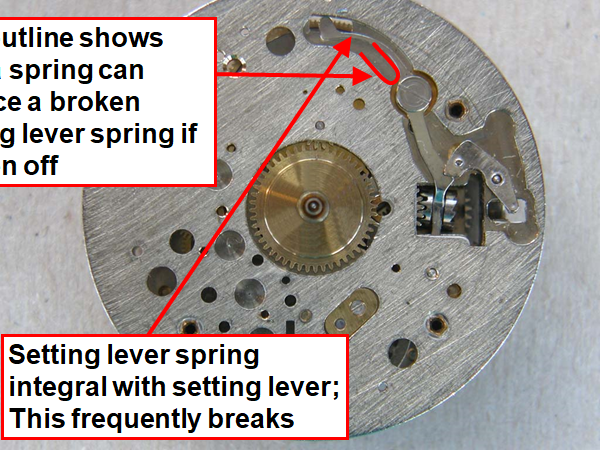

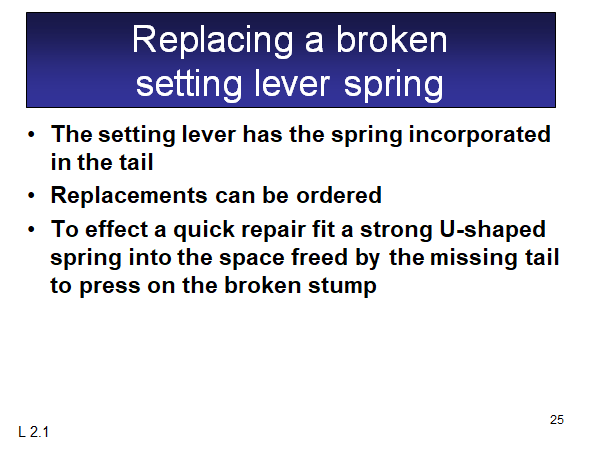

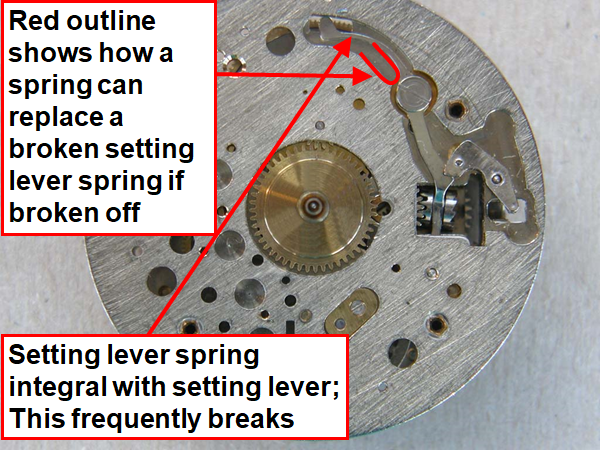

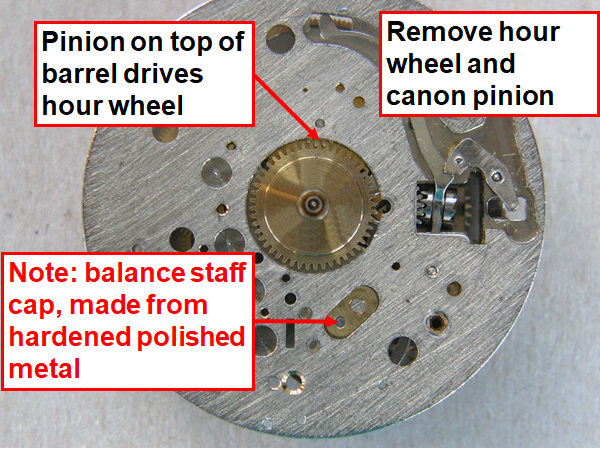

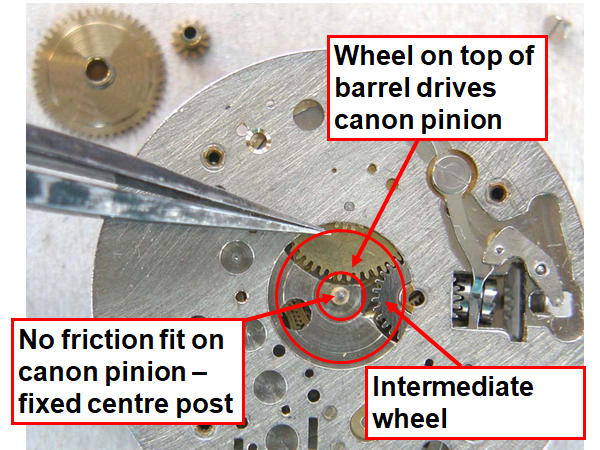

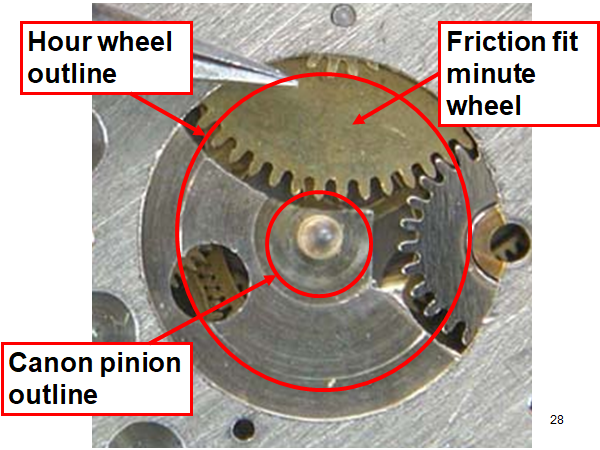

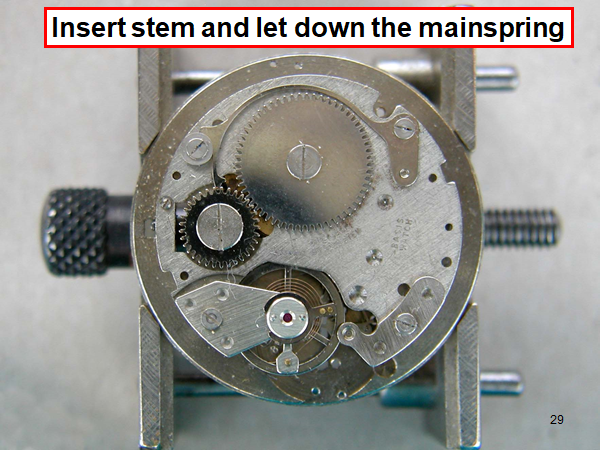

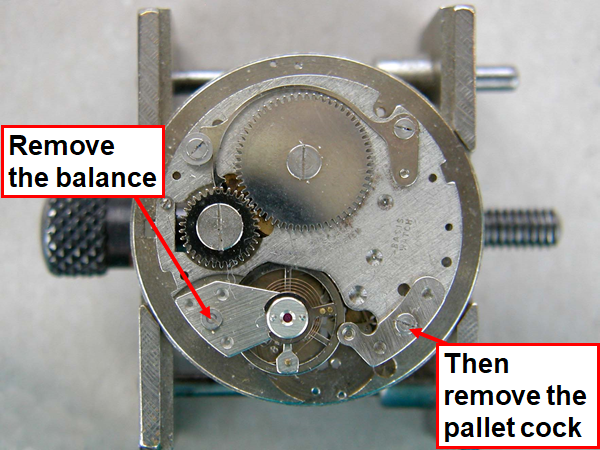

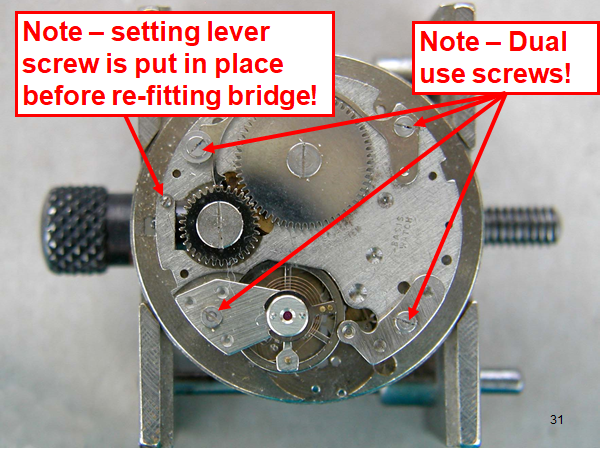

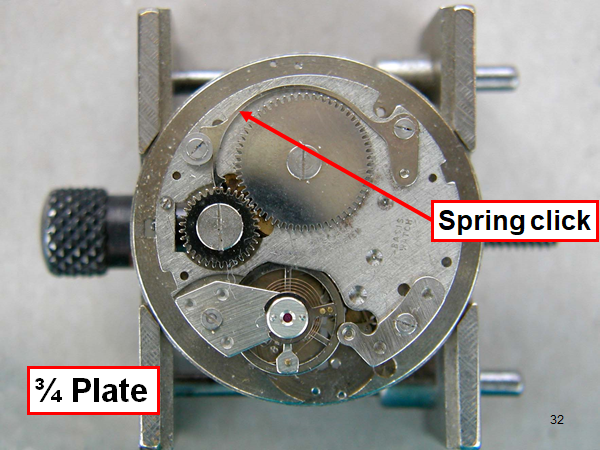

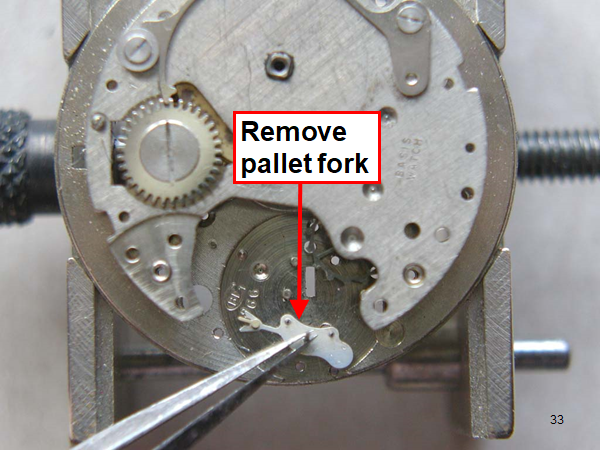

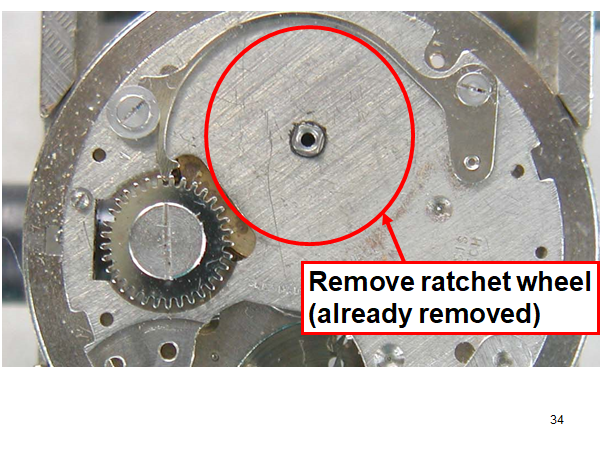

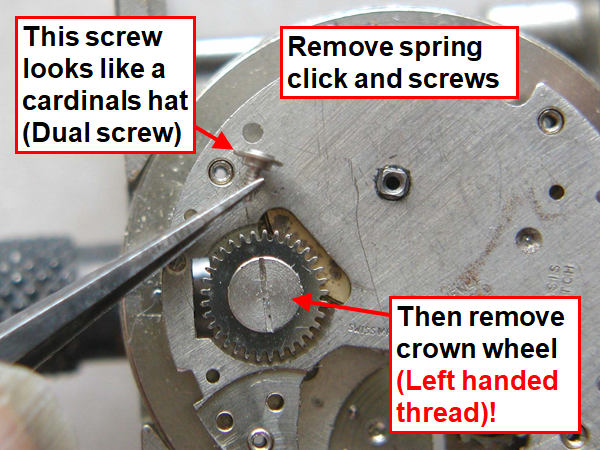

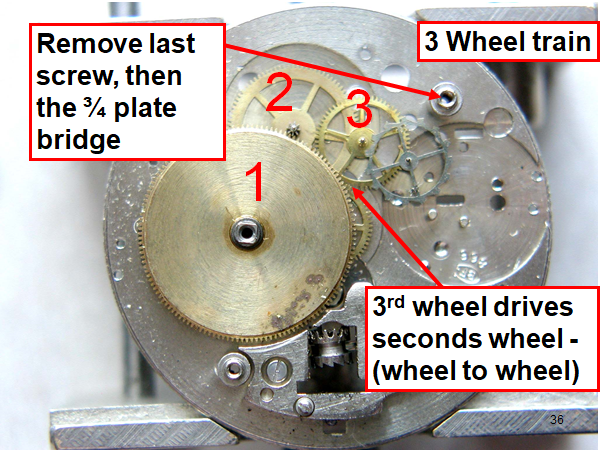

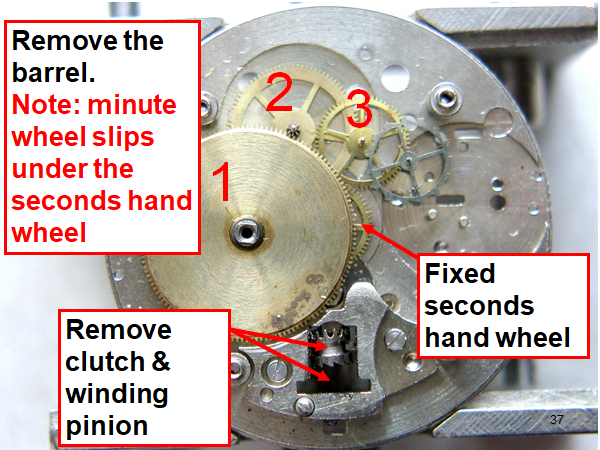

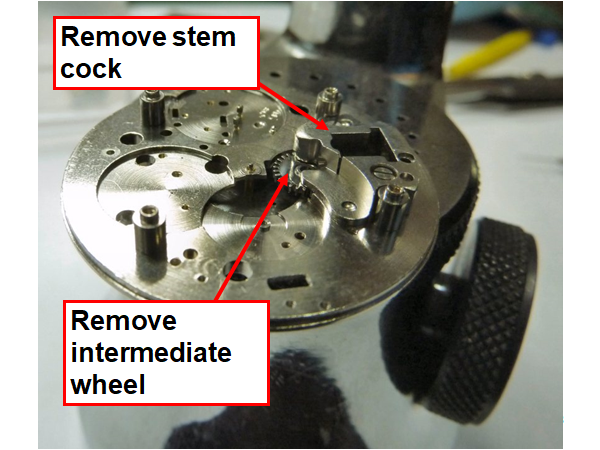

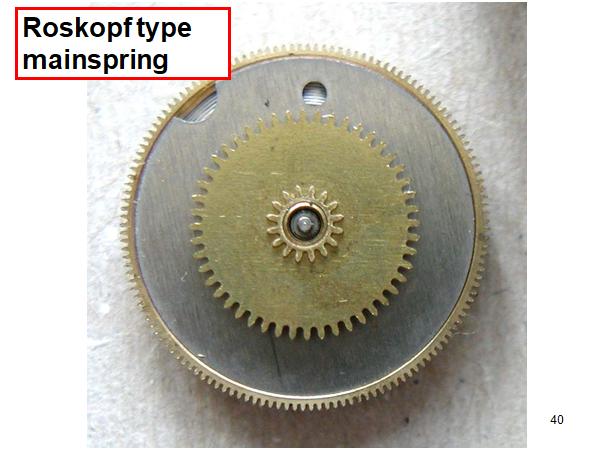

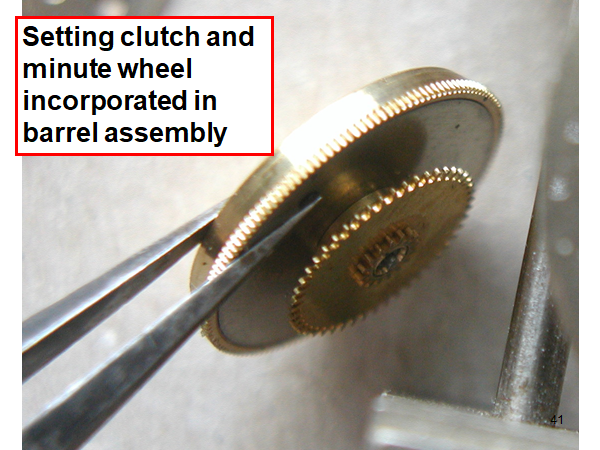

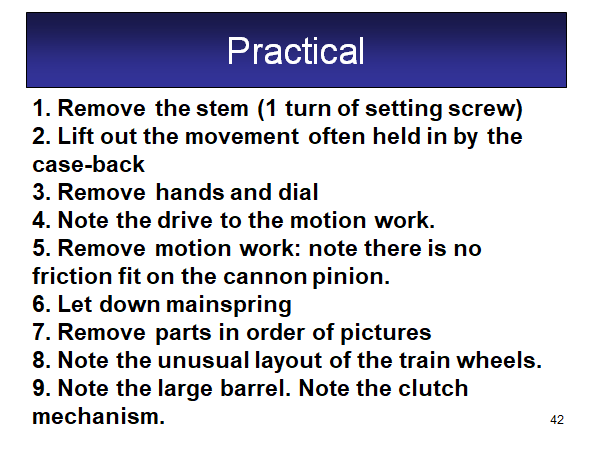

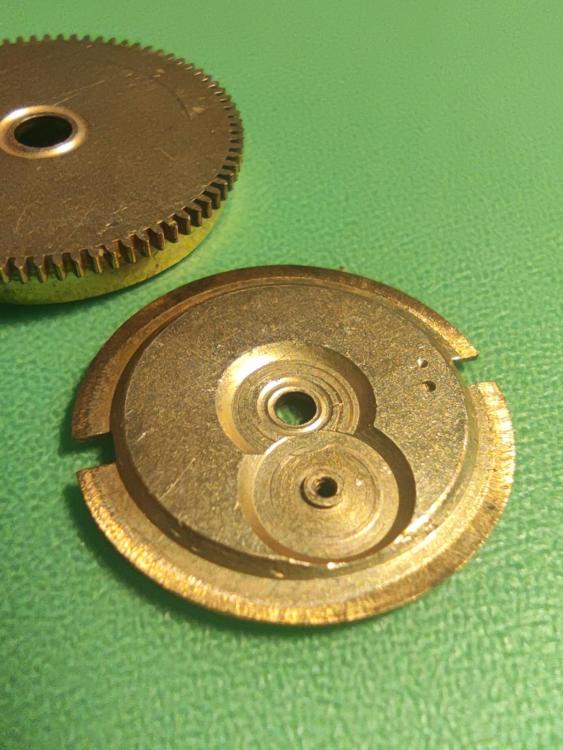

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....1 point

-

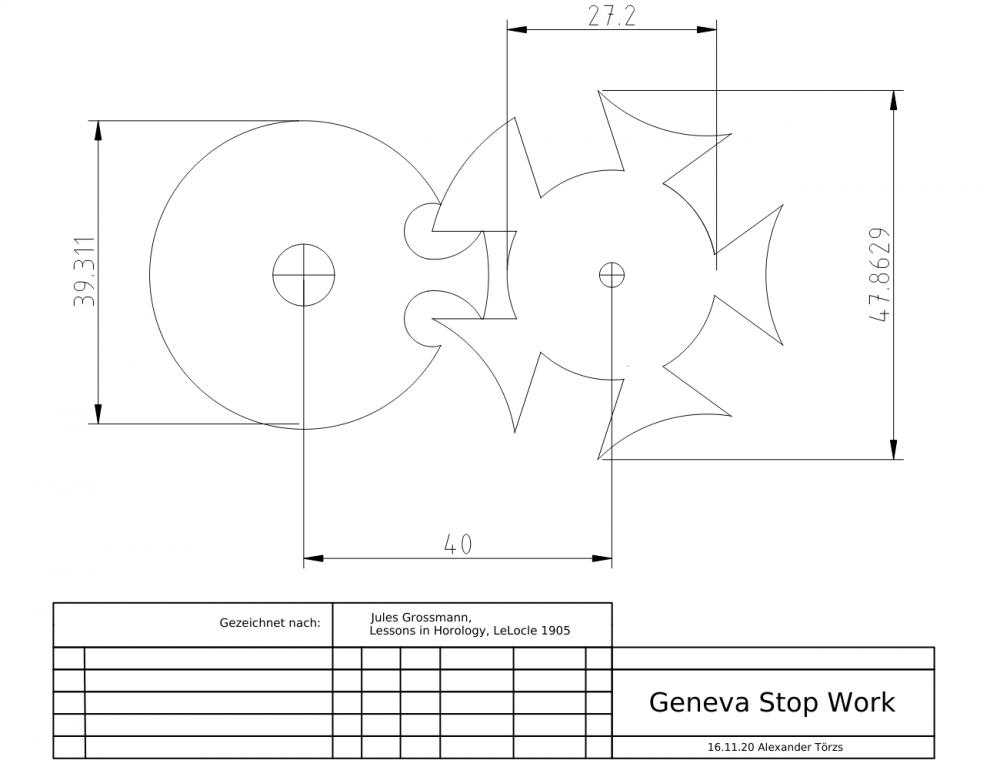

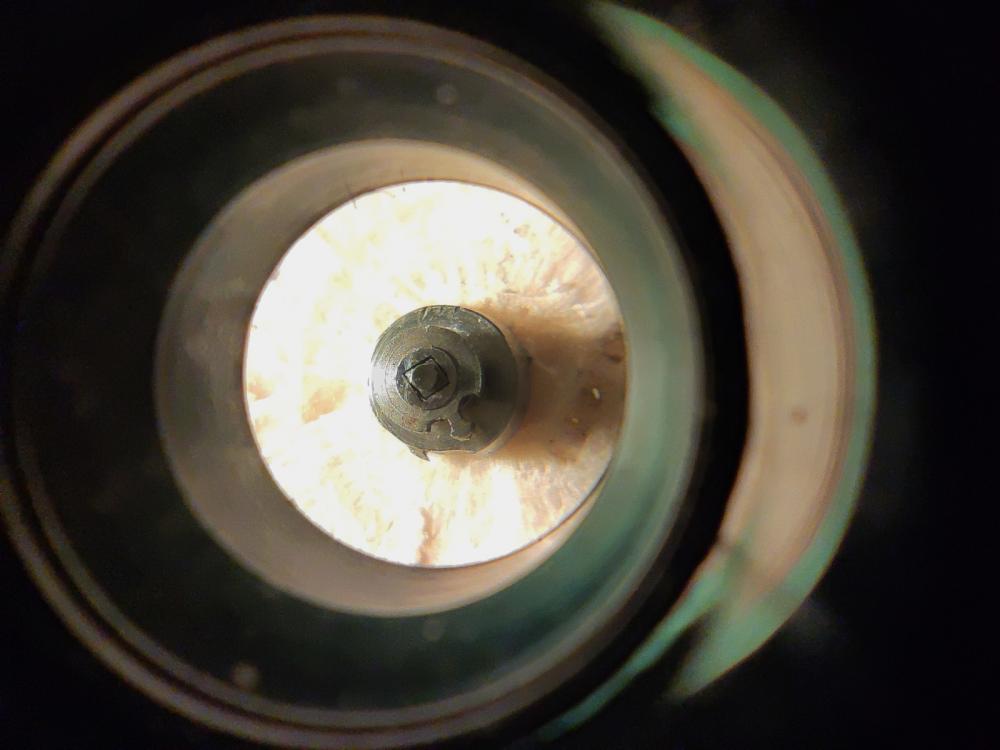

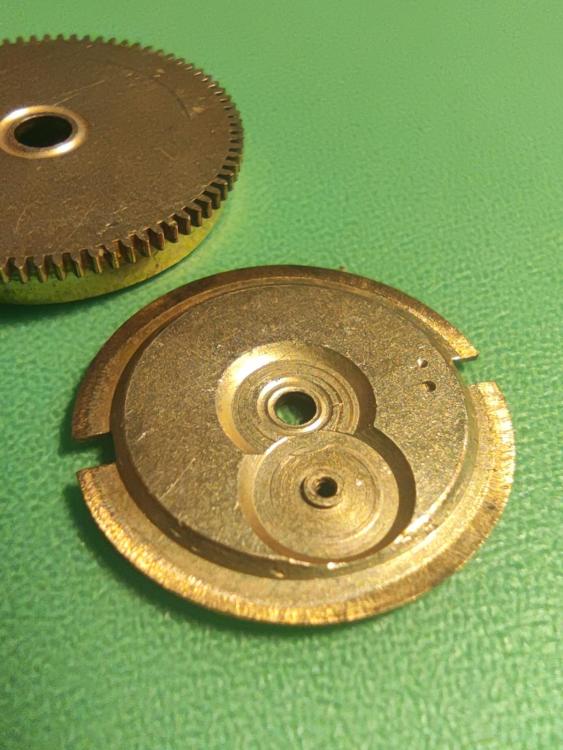

Dear all, my mother gave me a Swiss pocket watch made by Robert, Gerth & Cie in 1889. It belonged to my great-great-grandfather. Wonderful watch - already with a Swiss lever escapement. Unfortunately someone in the past has taken out the the two wheels of the Geneva stop work in the mainspring barrel lid. The distance between the centers of the wheels are 4 mm. I know that it is highly unlikely to find a scrapper movement with exactly the same dimensions for the maltese cross and the finger. However I found an bought a cardboard box on ebay UK with about 100 antique mainspring barrels. And indeed in one of the barrels I found a stop work with exactly 4 mm center to center. A fellow named Jules Grossmann from LeLocle in Switzerland wrote a treatise on watchmaking in 1905 called Lessons in Horology. In there he describes the mathematical construction of the Geneva stop work. If you follow his instructions you can very easily make a drawing. To cut a long story short. All the dimensions fit the wheels I have sourced almost perfectly (give or take a few 1/100th). Now to the problem: The hole in the maltese cross is too small for the seat on the barrel lid. However this can be easily fixed in the lathe. The square hole of the finger wheel (1.3 mm) is too large for the square on the barrel arbour (1.0 mm). Since I am only an amateur I have absolutely no idea how to go from here. What would a watchmaker proper do? Thanks and all the best from Hamburg, Alex 2020_sept_r_g_cie_federhaus_federhausbruecke.bmp1 point

-

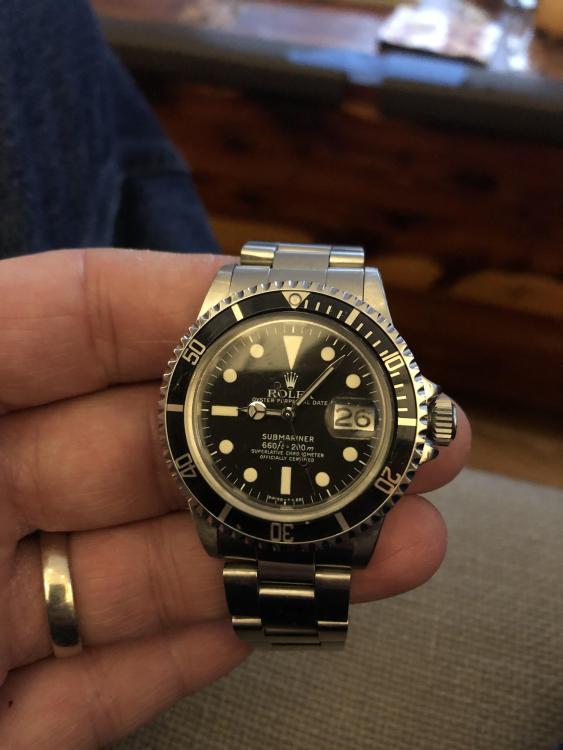

So, this is the watch I always wanted. It was a long road of saving, searching and a bit of swearing and sweating. After the saving, this rough condition 1680 was purchased from an online watch dealer. It’s a 3.9m serial so one that may have originally had a desireable “red” dial. It came with a service dial, so although inconvenient to replace, it reinforced that it MAY have been a red dial when new. It had many service parts, so that’s where the searching comes in. A red dial was several thousand dollars at the time; even more today... so I found a Mk. I white dial- first version of about four all white text dials used on the 1680. The crystal was also service, so I found an original 127 “top hat” with those nice sharp corners. A 702 crown and tube were installed to replace the 703 crown and tube that were on it. Though technically “better” the taller 703 just doesn’t look right on a classic Rolex. Then, the white background date wheel had to go. These early watches used a brushed stainless date wheel, so I found one and took care of that too. The bezel ring was over polished and the insert was a luminova service insert. Those were addressed, but the insert I found did not have a Peal. I installed an NOS tritium Pearl before I installed it in the new bezel ring (I need to get an old stock bezel ring but they are hard to find in good shape). Now, the case was in rough shape, and the bracelet was much newer- probably a service replacement although it did not have the “S” normally next to the date code. Possibly updated by an independent in the 80’s some time. This year was one of the first to use the (then) new 93150 bracelet, which replaced the 9315 folded links with solid ones. But the first couple years they did not get a date code stamped on them. Very rare, but I managed to find a clasp. So, the bracelet parts and mid case went to Michael Young in Hong Kong who rebuilt and reshaped the case, as well as restore the bracelet. (He also did an early ‘68 C&I bracelet for my 5512 at the same time) Now, after more waiting, the parts finally were all on the bench at the same time. Some delicate assembly (and the occasional swearing) and it was finally together. I do wear it, but I am careful with it. Definitely a keeper for sure. I’ll pass it to my Son one day.1 point

-

1 point

-

reading skills are lacking on my part again. Usually people put the pallet fork between the banking pin and as I stated that way works but it's better if you can site through the jewel. But most people don't do that. As it's easier to look at the fork and live with the minor it's not going to be perfect. Or on some rare occasions you have watches were you can't see the jewel at all or for that matter the fork like some American full plate 18 size pocket watches1 point

-

1 point

-

Hi I have one only seldom used as when the balance is removed with the cock it is laid on the bench with the cock on its back and the balance laid on top The spring is relaxed and under no pressure and coverd untill required. There are others who swear by them so you will get some interesting points of view. All valid. Cheers1 point

-

Hi I would agree with that definition. The ones I have seen are mounted on a wooden handle and are hand held.1 point

-

Thanks for the advice everyone. Since I've never done this before I decided to source a replacement staff. I'll be reading "Staking Tools & How to Use Them" in the meantime. I'm sure we will all be talking again in my next "what have I done wrong" thread about broken staffs. ? Thanks again!1 point

-

1 point

-

That is correct, I don't usually have the fork installed. As @JohnR725 mentions, it's won't be exact, but it's close enough for a starting point. After cleaning the main plate + installed balance in the ultrasonic cleaner, I fit the balance jewels, then do the check.1 point

-

I will make a video of the disassembly so we can all see how these watches were made. I read that the swiss called them Boston watches. This one seems like they have a fake movement on the top and the real movement on the bottom. We shall see???1 point

-

I don't suppose you're trying to run the watch like you normally would without the case? This is where it be helpful to have a picture for everybody not familiar with American pocket watches? a problem with American pocket watches is, when the movement is out of the case the case has the crown and stem. The movement then goes into setting and if you try to run the watch out of the case in the setting position it doesn't always run. Sometimes the run fine but they're still driving all the setting mechanism. Later on the watch companies grasping that they had a problem put a variety of ways to put the watch basically into a service mode which is basically put it back into a winding position out of the case. I could make a variety of gases where it is but it be helpful if you give us a picture or several. Like a side picture where the stem goes and would be helpful and the front and the back. then as it's an American pocket watch and they have parts manuals showing all the parts just because they exist swapping them is not a good idea. The catalog may show interchangeability but often times the parts were fit for that particular watch. So if you start swapping parts you can end up with all kinds of interesting and strange issues. Always best if you can keep the original parts with the original watch.1 point

-

Just a passing note, the section dedicated to new members introduction is meant to have that done with few words about oneself. Not to shoot straight questions with incomplete details1 point

-

If you have a collection of hairsprings out of scrap seiko balances, you got a good chance of vibrating a balance. Any member of 7019 family fits your balance. Go to Dr ranfft to see its family generation, Dr ranfft doesn't list 7019, since it itself is a member of 7017, so google seiko 7017 ranfft, Scrol down the calibers to see 7019. All members of same beat listed fit your balance, some of them may turn compatable. if you get a slow rate out of one, your watch is fixed.1 point

-

Thanks @VWatchie for the videos. I have seen Mark's but don't know that I've seen the other. I've been digging around ebay and it turns out there are a handful of these pocket watches available. I found two that were listed for parts and appear to be complete movements so I hope to be able to salvage atleast spring if not a whole balance assembly. If successfully I will work on the original one under the microscope to see what I can do with it. Should be a good learning experience.1 point

-

Looks good. even if incompatable, you sure did a perfect job.1 point

-

Hairpsring out of one might be incompatable with the balance out of the other. But lets get the hairspring sorted out first.1 point

-

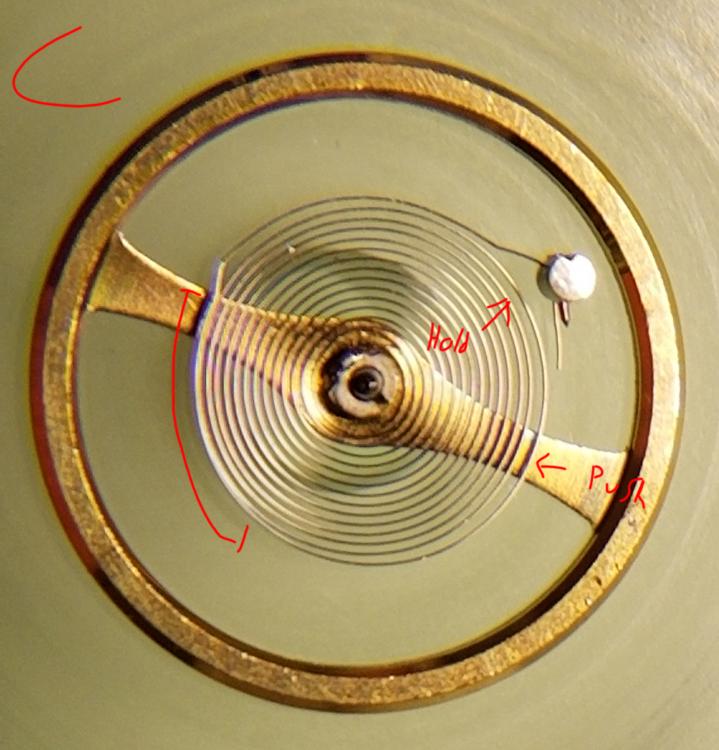

I think I would be inclined to start a bit further around the outer coil, perhaps at about 5 o'clock in your pics, and gently coax the outer coil outwards as you spiral out in a clockwise direction. As it is that outer coil is deviating inwards from about the 5 o'clock position until it is touching the next coil in at about 7 o'clock. It needs to run parallel to the next coil in right up to the dogleg. If you sort that part of the coil out you will probably find that the terminal curve is very much closer to correct than it currently appears.1 point

-

1 point

-

Did you swap the balance or balance complete? Do the number in picture B but aim at about 110 degrees anticlock. Judging by where the stud appear to stand, it too is about 30-45 degrees out of beat.1 point

-

s mentioned above by jdm the clamps are easily made but Cousins do an assortment and the price of a replacement as quoted by Marc Its hardly worth the bother so I would change the movement for new. at least you will have a runner.1 point

-

For those making their own tools, those nuts with the "quick release" are a somewhat standard item at industrial supply places. McMaster is my go-to but MSC and others should also have them. Bridgeport Knee Mills use them (but larger) on the depth stop, so it doesn't take 20 minutes to set the depth...1 point

-

if the case back is not original you're definitely going to have a problem. Usually when ordering components for cases for Seiko watches everything is based on the case back number. It could be a different case back as long as it's the right case back for that case then you could use the number. But if it's totally wrong case back here in trouble sort of? If you look at the dial usually on the bottom there is a dial number it's not exactly the same as the case number. But it helps to narrow down the range of what you're looking for. They is probably I was Seiko is that they've made so many case components. They haven't old it's been discontinued desk of even a bigger problem. I know their sites out there were people are modifying their Seiko watches if you can find one of those sites may be they of something generic.1 point

.thumb.jpg.a474cc252b00d98ed0e30870d586bbdc.jpg)