Leaderboard

Popular Content

Showing content with the highest reputation on 04/14/19 in all areas

-

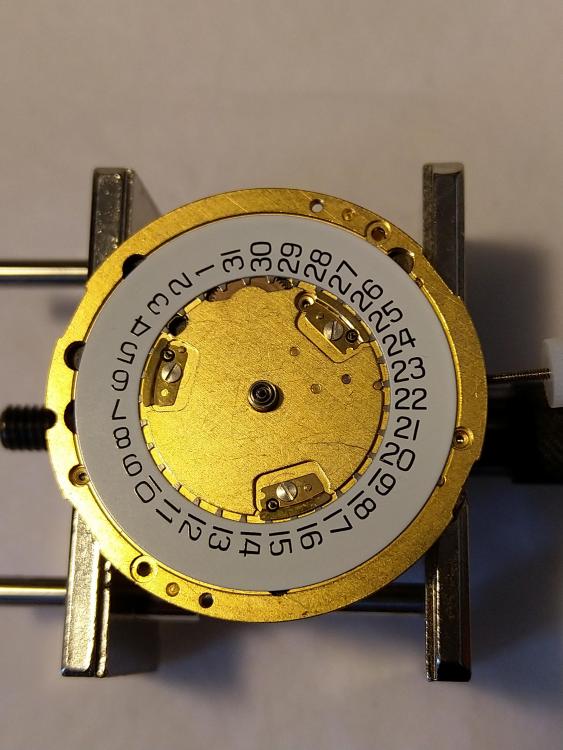

Even though the garden is screaming for attention one has some spare time to continue my magical journey through the heap of quartz movements. This time it is the ETA 251.262 Chronograph which can be found in watches like Breitling Colt Steel, Certina DS FIRST, Longines Hydro Conquest and so on.. I'm quite surprised of the amount of quartz movements which are getting a new life after a good clean and service. As usual all the files are in a PDF format, and all pictures are original. ETA_251_262_Dissasemble.pdf ETA_251_262_Assemble.pdf2 points

-

acetone and alcohol should also be avoided when cleaning pallet and roller jewels. use naphtha (ronsonol lighter fluid) cheap and you dont have to syphon any out of your car lol2 points

-

diesel and kerosene are basically the same ! NOT the best solvent - for cleaning today. BUT, it is CHEAP. VIN2 points

-

2 points

-

I'm considering taking this class. Has anyone here taken it?I'm balking a little at the price tag - $1245.00 US. I'm already comfortable with casing up a naked movement. Will this class get more "under the hood" regarding the movement? Detail disassembly? Will it cover anything more than I could get out of Mark's videos?1 point

-

I follow You. Thanks again for sharing your experience. I'm grateful. It may be relevant to other hobbyists as well. Kind regards1 point

-

Amazing responses! I appreciate your time and effort. I also demounted the Arbor by placing two screwdrivers right below the Arbor on the spring side it popped out. Regarding spring force release, I removed the balance and pallet fork and 'slowly' let the wheels run by controlling with a pegwood (hope it doesn't give wear and tear)..1 point

-

Hello Adam I will give it a try. Thank You very much for advice. And do You have an idea how to release the spring force when fully winded? Kind regards1 point

-

1 point

-

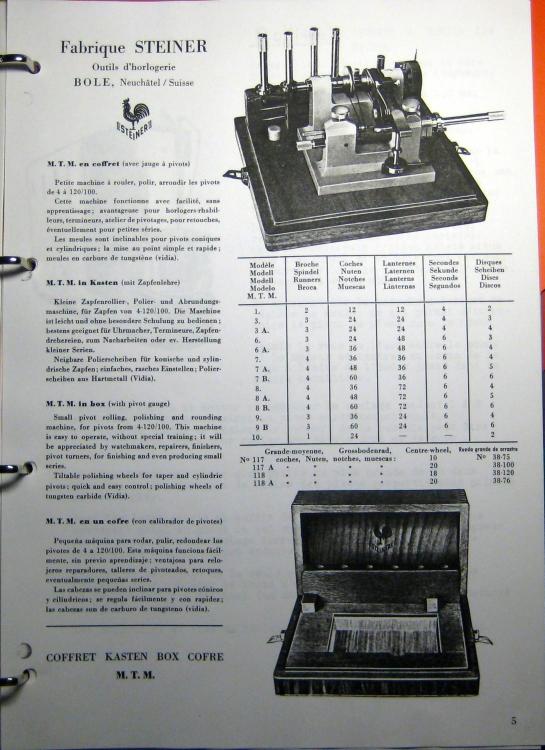

JD Berry, It looks like you hit the mother load. The tool in the first photo is expensive and almost impossible to find. If you watch this video you can see a similar tool in operation: https://youtu.be/mkGygB7BMsQ The tool in the second photo looks like a set of dies and a holding base. It would be used in conjunction with a press for pressing in watch crystals and backs. The tool in the third photo is a small general use drill press. It is good for drilling applications that do not require a high rate of speed. Extremely tiny drill bits will break if turned too slow. I have a Dumore high speed drill press that turns at around 20,000 rpm and is suitable only for extremely small diameter drill bits. david1 point

-

1 point

-

1 point

-

1 point

-

Very true, No matter how hign tech the plating on the base metal, there are pores or scratches, in the palting, through which solvents can penetrate to chew on the base metal. So one should be concerened with long term soaks with reactive solvents. kerosene or Diesel fuel don,t chemically react with the base metal, it dose penetrate through the pores slightly( no reaction), you just remove the penetrated( wetted surface) surface with brush, resoak , brush again, you are cleaning physically, ( no chem reaction) .Solvents chemically reactibe with the base metal, should only be use for very short time and brushed and rinsed immediately. You will see some clean by the first brushing, what news I have , is kerosene works. You are not limited to one clean, no harm with second or more clean, Once visibly clean, time for the final clean in your machine or whatever method you choose. I am staying with yoir thread, I don,t see why this service can be less than percect. How dose the rest of the watch look? Dial, hands and case. Rare piece. Regards1 point

-

Virtually all watch plates are made of brass or similar alloy, then may be plated with different finishing. Anyway petrol and alcohol based solvent are good to clean but will not make it shine the best. For that, if it matters to you, use ammonia based solutions, either off the shelf or you cold make your own with household products, in any case be careful to avoid high concentration or long baths.1 point

-

Diesel fuel would work too, brushing in solvent helps. I use several solvent seperately, each will do some good. Long time soak in paint thinner or carburator cleaner is harmful. Paint brush is suitable for use on gears, pinions. Shellack on pallet jewels and impulse are is susceptible to damage by solvents. I am talking ebauche and gears cleaning only. Picture shows Shock springs on cock and the mainplate diferent, should be the same.1 point

-

1 point

-

I give it numeriois clean. First, Soak in kerosene for several days and brush, kerosene is brass friendly for life, gives off bad oader, dosn,t evaporate but the lid on the jar,, then soak in paint thinner like ten mins and brush after each soak, Every part including the regulator arm is got to come off, I even brush the jewel housing. Keep repeating, three our four good brushing, soak - brush , this brings the shine back, no power drill to brush, just manual. tooth brush would be the roughtest brush you use on plates and bridges. You will start to see clean shiny parts perhaps after three or four clean. Once looks clean, it is ready to go into your cleaning machine or general cleaning so to speak. This jewel is worth it. Best wishes.1 point

-

1 point

-

I did not join Marks course but the feedback I have received is very positive. A price tag of $1245.00 US is way to high IMO.1 point

-

Blue steel can't be cut with a jeweler's saw but can be filed. That used to be how they checked the repivoting exam for clocks back in the day- saw bites, fail, file doesn't bite, fail. The commercially available blue steel bars watch and clockmakers typically use is very hit or miss. The nomial size is often way off (not such a big problem), and the heat treatment can vary between too soft, uneven, or sometimes actually ok. I have some and use it for pins and such. For staffs, stems, pinions- anything from steel- I use oil hardening steel in its annealed state. The standard in Switzerland is Sandvik 20AP, probably not so easy to find in small quantities elsewhere. In the U.S. O1 would be the closest thing (and is a fine steel for watch parts). Parts get hardened and tempered after machining, with generally the last 0.01mm or removed in finishing for bearing surfaces. For a staff I cut everything right to size except the pivots which are a good 0.10mm oversized, and I leave the taper for the roller table straight and oversized. After heat treatment, holding on the now straight roller diameter the top pivot is brought to 0.01mm over final size, the surfaces polished, rivet formed. Flip around and do lower pivot, roller taper, polish. Finally finish pivots in jacot. Heat treatment is a little different than most books or schools teach. I use an iron tube welded to a long thin bar. These are actually CO2 or N2O cartridges from selzer or whipped cream bottles with the neck cut off (about the size of the first two digits of an index finger). This gets filled about 1/3 with fine wood charcoal powder, parts go in, filled the rest of the way. The whole thing is torch heated until glowing orange, then the contents dumped in oil. The parts fished out with a magnet, and they are a nice grey color and very clean. After cleaning off the oil they are blued in a pan of fine brass filings over an alcohol lamp. With the above method there is rarely any deformation of even long thin parts, and no pitting.1 point

-

1 point