Leaderboard

Popular Content

Showing content with the highest reputation on 03/31/19 in all areas

-

1 point

-

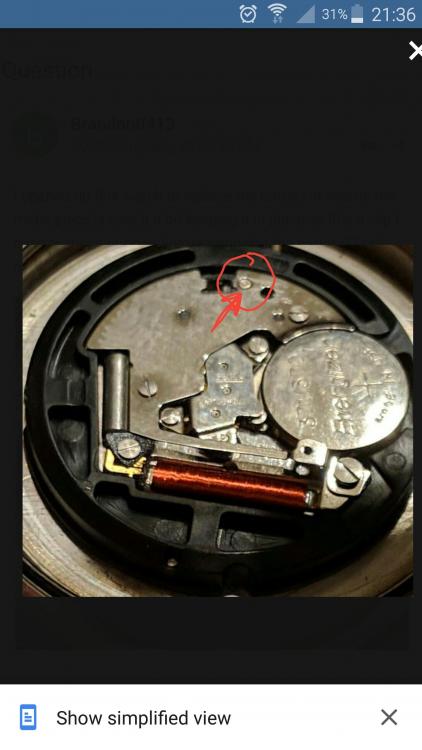

So I needed to remove a broken screw from the bridge, the one that locks in the Hairspring stud. I first tried drilling it out with small bits from China and this resulted in a peek in the hole. Then I got a great idea and took a bit that broke and filed it down to a wedge,like a screwdriver bit. This got rid in the peek and allowed me to use another bit with cutting oil. And it worked. Used a lathe for this with a collet holding tail stock. Here are are the pictures. Sent from my iPhone using Tapatalk Pro1 point

-

Thanks to strings here, I am about to buy some Dumont #2 tweezers. I figure I'll go with Dumoxel alloy. As I am a light-use hobbyist, I think would be a good crossover between maintenance (non rusting), price, and function. If I made my living with a set, I'd go carbon or Dumostar. It's clear Dumont is the best maker and that a #2 is a good jumping-off place, followed by a #5 later. Opinions? Also, as I seem to do a lot of quartz battery replacements for friends, family and myself, a gasket lubricator would be great. Otto Frei has a reasonable looking one for not too much, which carries Silicon 747 grease. The same lube is available in a syringe, which would work for stems, and other uses. Don't mind spending more if needed but if it is a good product, why do so? Has anyone used this greaser and lube? The balance between cost and performance of tools is important. Like with the tweezers, a more expensive tool has been reported to be very much worth the money. Sometimes however, the more modestly priced item can be as good, or better, than a higher cost item. I can think of some of my automotive tools which fall into that bucket. It's all about value for money spent, and this is where forums are GREAT! New here, and am enjoying reading and learning. Thanks!1 point

-

1 point

-

The latest addition to the $40.40 club with appropriate apologies to Andy. I can't explain the logic behind purchasing a great watch, only to let it lie new and unworn in a safe until the battery dies. Then sell it at a huge loss. I'm grateful for such individuals but unable to understand them. This is still available new and the least expensive one I could locate on-line was from a dealer in Taiwan for $75 with a 3 week wait. Stateside, the cost was closer to $125. I paid $20 delivered to my door. I removed the hang tag as it was still attached to the watch. The second hand was advancing two seconds at a time which is the indicator for this model that the battery is on its last legs. One SR920SW battery later, it's off and running normally, keeping accurate time. So far, it's gained 1 second over a week. I can also recall a time when I referred to watches of this size as salad plates strapped to someone's arm. Not any longer. At 45mm diameter, this is just about perfect for my eyesight now. Welcome to the rotation.1 point

-

Glad to see you are making progress. There is probably a build up of gunk in the stem tube. If WD40 is doing the job, then if you take it slowly and gently, you should get it free. If you post a couple of clear pictures of the mechanism, we can probably figure out how to release the stem completely to allow you to drop the mechanism out of the case and clean the tube and the stem more thoroughly. I suspect you simply press the little circle next to the stem with a pin or tweezers, but a better picture of that area would confirm that.1 point

-

Hi Davey If you have a time grapher put it on that and check the beat error and amplitude. If not remove balance and check the action of the pallet is it crisp when moved banking pin to pin, also you can remove the esc wheel and put a little power on the watch the wheels run down there should be a bit of backrun as the power runs out. If you have no timegrapher have a look at Watch-O Scope the lite version is free to use but you need to build a small amp there are diagrams on the site. I use it in conjunction with the Horotec unit to double check.1 point

-

Looks sluggish. If you didn't replace the mainspring when you took it apart, I'd replace it. When did you last give it an overhaul? It is probably dry and running with considerable drag on the drive train. Also, It looks like the entry stroke of the pallet is occuring a little fast, so the beat is probably off. Balance wheel looks a tiny bit wobbly. Give it an overhaul, replace mainspring, and put it on a time grapher to correct the beat error--that should improve things dramatically. J1 point

-

1 point

-

I've got one of those, this is just for those cases you can't open with the rubber ball1 point

-

1 point

-

If the machine doesn't display rate, something is very wrong. like the dots are too much spaced even when the line is almost horizontal, as in the last picture. A 3ms beat error would not cause that. I would record sound and post it here, so it can diagnosed by ear and software in "scope" mode.1 point

-

I switched from watches to manly high-grade clocks. Partly due to there being a demand for such a person and the area in which I lived was very full in such clocks. I also had a very well equipped workshop, which was handed down to me when my master retired. Experience plays a big part and the right equipment. Each clock was worked on in turn to its arrival. I never did part jobs such as replacing a mainspring spring it was never worth it. The clocks would be completely repaired or restored; I would always give an estimate and stick to that. Every repair had a 1 years guarantee and I always preferred to set the clock up at its home, that way you can be sure it will be correct. My waiting time for repairing would run into months because of the workload, I wold have about 5 Longcase clocks at any given time waiting for repair. You will have to work out what you want to do and how you go about running your workshop. The only work that I would farm out would be case repairs, dial repainting and some wheel cutting. It can be long hours even after closing you have all the paper work, estimates, martial to order. If you are successful, the rewards are big and you can make a decent living. I served a 7 year apprenticeship two of those years was as an improver to become a watch & clockmaker. This included making certain parts for watches and parts for clocks.1 point

-

First of all we need to id the movement. Could you tell me the size of it and could I have a close up photo of the movement both sides, dial off so I can see the keyless work. Sorry but my eye sight is not so good.1 point

-

I presume you checked that the crown is not a screw down type, and simply needs unscrewed before you can pull it out.1 point

-

Elgin model 111 New Old Stock case with its original grosgrain ribbon and clasp I have a movement with a NOS dial waiting1 point

-

Hello. Cannot identify it myself.... But check out the advanced research on the Ranfft database. It should help you. http://www.ranfft.de/cgi-bin/bidfun-2uswk.cgi?1&ranfft Sorry I cannot make the research myself now.... But I am looking forward to reading more.1 point