Leaderboard

Popular Content

Showing content with the highest reputation on 03/20/19 in all areas

-

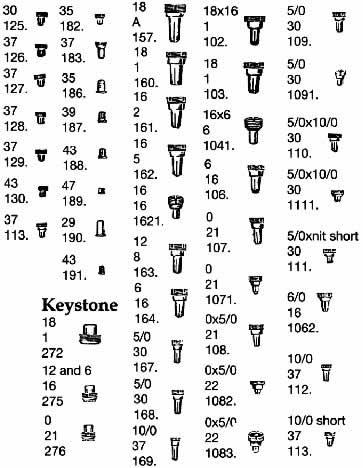

Waltham pocket watch stems are not like normal stems. One part is in the movement, the other part is held in the neck by a sleeve, inside the neck the sleeve which most of them screw inside, holds the other piece, this determines the depth by its screw adjustment to wind the spring, then pull to adjust the hands. Here is a picture of the types of sleeves for watches with this type of winding and hand setting.2 points

-

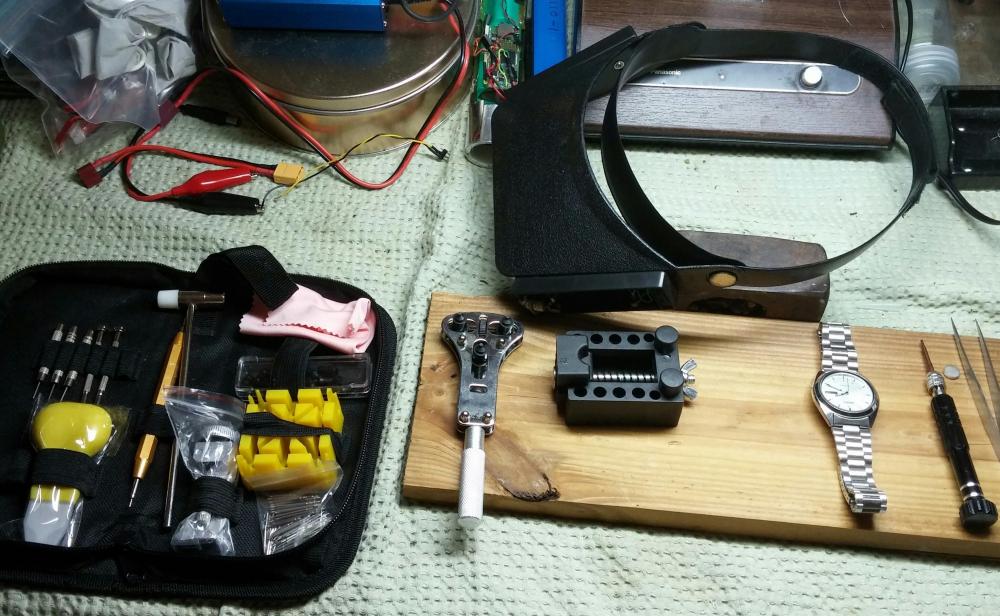

Howdy, Well, this is my first effort of a watch repair. I have been fascinated with watches, clocks and all kinds of mechanical things since a young age. I decided at this time that working on watches would be a great hobby/interest to take up in my later years. I have already spent some time learning to refurbish and repair fishing reels in the last few years. So here is my first repair attempt. Interest in tinkering watches started when I dropped my Seiko SKX009KD diver to the tile floor in the bathroom. Was not too good an idea to put a watch on there with a towel thrown over it, pulled the towel and down comes the watch, face down on the tile floor. Needless to say, I picked it up and took a look, nothing seen. Then I shake it and hear a rattle. Not too good! So I did some research on the 7S26C movements. Read a lot of information and watched a lot of videos. Thanks to all that makes this information available. So I purchased a cheap watch tool kit from Amazon. I had other watches that needed batteries and some strap work anyway. I knew the kit would not be 'pro' grade, but it was a nice kit with all the basic tools needed. Back to the rattle, I figured the Oscillating Weight (OW) had become separated from the bearing. So I used the case back wrench in the kit and opened the back, and sure enough that was the problem. I looked on-line for a replacement OW but could not find any except one on Ebay for $35! So I decided, what the heck, I'll try to repair this one. So, here is what I did being a little mechanically inclined but never at this small a scale, I performed the following: 1) remove case back. 2) examine the OW, it was dislodged/loose from the bearing. 3) remove center OW bearing from center post. 4) place OW on a small anvil, then use a small pin punch from the kit as to carefully work the metal around the OW's hole as to make the bearing hole smaller. 6) After enough working with the punch, I took a smooth round stone and gently kept working the ID of the OW hole until it just would friction fit to the surface of the OW bearing. 7) carefully press fit the bearing into the OW, I knew too much pressure would ruin the small bearing races and ball bearings. 8) finalized fitting of the bearing to the OW by applying a very small amount of red Locktite thread locker using the end of a pin as an 'oiler'. 9) I then let the OW set for a day to cure the Locktite 10) install OW per alignment instructions in the 7S26C technical guide. At this time I also wound the mainspring up 8 turns to check the power, it ran for about 40 hours. 11) did not have any watch oil, so I used a very small amount of some 10W synthetic engine oil using a small pin as the oiler to lubricate the OW bearing ONLY. It appears to be a successful repair for now, watch been running great and keeping good time for about 2 months. I'm sure something else might have gotten damaged during the fall, especially the balance assembly, but then again the watch is working fine for now. I might use this particular watch to dive deeper into the 7S26 movement at a later time. Kind of happy for now. Got 2 other watches running with new batteries, fitted some straps and having fun with my new hobby. Look forward to learning some more. Now to find a 'bag o watches at a flea market and get busy. I know I'm going to need more and quality tools down the road, that's OK with me. Cheers, Chip ---1 point

-

Hey fold, I picked up this 1885 lever set, Waltham pocket watch with a Hillside 1884 cal movement ( I think). The watch is missing a stem and crown, I should be able to find a suitable crown handy. I have two questions: I am planning to turn a stem to fit the watch, I'm wondering what size and cut of file is best to use to form the square on the stem? Also, the case tube has a thread inside it, any ideas why? Thanks in advance!1 point

-

Wow! They all look so nice and shiney too! Are you selling any or are they collection peices? [emoji16] Sent from my SM-G950F using Tapatalk1 point

-

I do have a few lathes. Sent from my iPhone using Tapatalk Pro1 point

-

No i dont JD, looks like an awesome setup you have there. If i require delicate machine work ill know who to pm though [emoji1360] Sent from my SM-G950F using Tapatalk1 point

-

Please allow me to add my voice to the chorus of congratulations. Regardless of your motivation, as we say here in Texas, "If you can actually do it, then it ain't bragging to say so". Your posts are always a welcome read.1 point

-

Oh ok i didnt consider lathe work, i knew you guys all wear spectical type magnification for a reason. Sent from my SM-G950F using Tapatalk1 point

-

Hello, I'm just starting out in watch repair, hopefully to be able to maintain my own watches as there are not many repair places left here in Saskatchewan and those that do exist have very long wait times. I'm also really into vintage watches, especially anything to do with art deco. To that end I'm trying to repair two watches right now: An A. Schild 341 movement with face labelled PAL (I'll post a picture later, it's in pieces right now) A Pierce 103SC movement (again with the later pictures) I've found some information on both on Dr. Roland Ranfft's website, but what I'm really interested in is how to service vintage swiss watches (which oils to use). If anyone has more information on these watches I would very much appreciate it. So far I've been unable to find service manuals for either. Thanks!1 point

-

1 point

-

Thank you both for your input. I will check the hairspring again. It was messed up and I had to untangle it but it was flat, evenly spaced and centred on the balance cock before I put it back on the balance staff. I'll check it again but i really hope it's OK. Working on it under a microscope with fine tweezers isn't my favourite thing to do.1 point

-

The red dial works very well. You are correct, they don't really produce them in volume any more, however they do produce the odd batch now and then. Keep checking their website from time to time, HMT are in my opinion one of the most undervalued brands. https://www.hmtwatches.in/18/products/eco-frnd-mechl-gents.htm The quality is up to the standard of Citizen, since they were tied in with Citizen for their technology, and their mechanicals have the advantage of nearly all featuring stainless steel cases. I have a couple of very nice examples, which I picked up for pocket money prices on ebay.1 point

-

1 point

-

What can I say. It is orange. Very, very orange... and black of course. Where the no name white dial above, was brand free, this one screams its brand at you from the caseback and the dial. A fun watch, but not one for the big formal occasions I would suggest.. Its just a shame that the lumed hands are fake. Oh.. and I've just spotted. I've set the wrong date.1 point

-

Hi JD, Congratulations on your outstanding work AND special thanks for exercising patience with me, Needless to say OH is special, his approval is a gold medal. Best wishes.1 point

-

1 point

-

looks like an A. Schild. Need a pic of dial side. there will be a logo stamped somewhere. but thats half the battle. as far as finding caliber you first need to get the ligne size and general idea of date range, and number of jewels. then go on Dr. Ranfft's advanced search type in those specs and go through each pic of the results. some will look very similar but the keyless works is where you will tell the difference. edit: its an 8.75 Ligne size movement1 point

-

http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_922 Check ranfft link above, usually he will list all other calibers in the family but doesnt seem like there is any for this movement. Normally you want to swap a balance wheel from the same caliber movement but in this case you may have to look at another AS. I would be sticking within the pre 1945 date range and look for AS that is 10.5 ligne, most likely balances could be the same. There is a link to all AS calibers below and there are others like the cal 912 for example that may work. You can search ebay for a schild movements and find one. or search 10.5 ligne movements. I work on old swiss trench watches so sometimes Iam in the same boat as you. Thats why now i prefer american movements, 100 year old parts can still be sourced. Swiss had wayyy too much going on during the ASAUG Ebauches days, and finding parts are extremely difficult. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk1 point

-

1 point

-

Here's a fresh upload on Thingiverse for 3D printing. A simplemovement holder for Miyota 8215, Clones and other variants. https://www.thingiverse.com/thing:35018431 point

-

Thank you very much, guys. I actually assembled it back together on Friday night. Now everything works like a dream. Delgetti, you were right, the lever was upside down so it could not push the castle wheel all the way to the intermediate wheel. Soon I turned that, I could see that such a silly mistake I made and did not spot it for so long. Special thanks for you HSL for the great pictures and explanation. You must have some serious skills if you got it working after five beers. Sometimes I feel that my hands are not steady enough even without beer. All your information will be even more useful when I strip the whole movement again for cleaning and lubricating soon.1 point

-

1 point

-

Hi the answer is yes greasing the gasket makes a water/moisture tight seal keeping the water/ moisture out. all it needs is a smear on the gasket. there are recommended greases for the job I use silicone grease rubbed on the fingers to warm it up then put it on the gasket had no problems with that over many years.1 point

-

1 point

-

Thin aluminum foil, sourced from chocolate, candy, medicarions wrap like tablets, come in various thinkness. I rins, cut a piece into shapes I need, like a cm long a mm wide. The cock need not be removed, just loosen the screw two turns, wigle the cock loose to get a gap between cock- mainplate about .5 mm , insert the foil, thighten, check the end shake. Alter the length of foil you inset in/out and its position under the cock to lower or raise the cock as you wish. Choose a position where, the BW is tight, just about to be let free by half turn more of the cock screw. Mark shows the final screw tightening in a video. Advantages are, incredibly high percision results. No gouge ing, Regards1 point

-

Hi , 5am here, need some rest and I,ll be as good as new. Regards1 point

-

Ok, why don,t you just loosen the cock screw in fourth of a turn incerments up to a full turn even a bit more, The tight balance should loosen and run. You always have the shimming option.please don,t dig a canion under the balance bridge. Now that you have rolled up sleeves, I get one going. Rubbed in jewels are not so neat to replace. I best go hide myself Joe1 point

-

I have made a video on tools and a boat load of videos on repair JD Richard on YouTube. Just trying to help. Sent from my iPhone using Tapatalk Pro1 point