Leaderboard

Popular Content

Showing content with the highest reputation on 04/10/23 in all areas

-

For those interested, I made a guide for how to use it some years ago. EDIT: Just remembered it. Here's possibly another good source: https://www.emmywatch.com/db/3 points

-

3 points

-

we've discussed this before on the group and I have personal experience with this. Oh and if you really want to do a good job of cleaning elevate the temperature for those 10 minutes. The problem with the cleaning fluids are the ammonia it's wonderful for making things bright and shiny but at a certain point in time it will start to etch the metal if you notice your cleaning fluid turning a blue-green color that's the metal it's been etched out of the watch plate. So it be much better if you can lower your cleaning time down to about five minutes approximately. my experience was at school when the machine had a timer up to a maximum of 10 minutes so of course I sent it for 10 minutes and because the machine used vacuum tubes to generate the ultrasonic energy intended to get warm anyway so I'm sure the solution was warm and it was really a pretty blue color with frosted watch plates. So yes it's a beautiful cleaning product but just be cautious of going over and we don't have an exact time. When I was at school the cleaning machine was taped oversea couldn't go beyond four minutes because every cleaning watches all day long. So I usually try not to go over about five minutes and definitely do not elevate the temperature.2 points

-

It's 100% designed for demagnetizing movements, cased or uncased. Hold it in the gap, zap, then I like to turn it over and 90 degrees and zap again. I've never had it hurt a hairspring (that's installed in a watch), including some very tiny movements. If demagnetizing a bare balance with spring, best to wrap it in tissue paper to keep the coils from jumping all over. In fact, if you get one of those weird watches that just doesn't want to fully demagnetize, (rare to happen if you have a Magnomatic), the balance-out-in-tissue-paper does the trick every time. It's always fun checking the movement on the Greiner Magnotest before and after!2 points

-

On this forum, we have widely differing opinions and experiences letting Shellac get in contact with IPA. In my experience, just a few seconds of exposure to IPA can make the Shellac start to dissolve. Other much respected professional watchmakers report a minute or so is no problem whatsoever. I'm not interested in another debate as I've made up my mind based on previous discussions and experiences. I just felt like sharing my personal point of view. I would personally never let Shellac anywhere near IPA. EDIT: On most modern watches (less than 70 years or so old) the impulse pin is friction-fitted, so no problem soaking it in IPA for however long.2 points

-

I wouldn't do that! A conscientious watchmaker would, as @JohnR725points out, never hand out a repaired/serviced watch without thoroughly testing it for at least a couple of days. Watch movements are complex and extremely sensitive machines of precision and should in my opinion only be worked on by people with a true passion for the subject. In my opinion, a mainspring should always be replaced when professionally serviced (unless it is in flawless condition). Now, a broken mainspring must be replaced as it can't (normally) be repaired. So, assuming it was replaced with a new and unused mainspring the explanation that it broke again is, for lack of a better word, nothing but BS. Braking a new mainspring by winding it too hard is nearly impossible. Before the mainspring breaks it's more likely that something else will give. And mind you, it takes excessive force the destroy or damage something in the movement by winding it. Or you could say, damage to a watch movement by winding it can never occur by accident or "normal carelessness". Take it to a watch repairer with a passion for watches!2 points

-

The Jules Borel database (julesborel.com ) is useful for comparisons. It will tell you which parts are common http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_6349A2 points

-

I've written about this in a different thread, but I feel the topic warrants a thread of its own. I hope no one minds! So... I just re-serviced a movement where I used Moebius 9504 synthetic grease for the keyless works, etc. When inspecting the parts coming out of my cleaning machine I noticed that the parts that had been lubricated with 9504 had a "wax-like" surface, especially in the hard-to-reach sections. The only way I was able to remove this "wax" was to manually soak the parts in a degreaser (Horosolv) and brush them off with a paintbrush. Generally, I feel hand cleaning is too much work for me (unless necessary) so I think I will want to return to either Moebius 9501 or Molykote DX Paste (which I've only heard of) as it's less expensive. I have two questions: Has anyone else noticed this "wax-like" surface on cleaned parts treated with 9504? For cleaning I use my ELMA cleaning machine, with ELMA RED 9:1 (max 10 min) in the 1st jar, demineralized water (approx. 1.5 min) in the 2nd jar, and IPA (approx. 2 min) in the 3rd jar. Finally, I dry the parts in the heating chamber for about two minutes. Would Molykote DX behave the same way as Moebius 9504 in this respect? The reason I'm asking is that I saw the sentence "Very good resistance to the washing out" on Cousins page for this product. I'm not exactly sure about what that sentence means but it makes me associate it with the "wax-like" surface problem.1 point

-

Silly me how come I missed this. I need shooting. This is not the original platform but a replacement. The giveaway is the screw holes that hold the platform to the movement, there are only two in the platform, the movement has 4 screw holes which carriage clocks should have. So you will need a new platform. I see you have done the Math. Meadows & Passmore is the place to go. I have looked on there site and they are closed for Easter but I would think they should be open tomorrow.1 point

-

Hello markr, I had a Samsung tv which did something very similar. I would agree with the others that it's likely to be a capacitor. Though one thing I would try before you start unsoldering things is perhaps giving it a good clean and remove any dust. Though from you're photos it looks clean. I limped along the Samsung for around two years with regular internal cleaning. It used to switch itself on and off when it felt like it. The cause was dust settling and shorting the legs out on the components due to poor design. A combination of badly designed vents to let out heat and poorly oriented components was perfect for dust to settle on shorting out the legs! Good luck and keep safe1 point

-

The problem with moly, graphite, silicone and the like is that they are designed to 'plate out' on the surfaces so that should the oil part of the lubricant break down, then the plated 'dry lubricant' remains to protect the surface from friction damage. As a result they are difficult to remove without 'mechanical means' (ie brushing etc),or aggressive chemicals. In lube manufacturing plants they either avoid using these dry lubes, or have dedicated pipework, tanking etc to avoid cross contamination and cleaning problems. As an aside, similar applies to dyes being used! This maybe why some residue remains after normal cleaning. Also, although the plating is microscopic it can take-up some of the clearance, especially in fine ball/roller bearings and cause problems through the clearance now being too tight and cause skidding wear of the ball/roller or overheating!!! eg autowind rotor ball bearings.1 point

-

Hi all, i have taken the whole clock to pieces and counted all the teeth. Centre 70, 3rd 60-8, contrate 48-7, escape 15-8 i have done the maths and this comes to 13500 bph however if i change the escape wheel pinion to 6 leaves it gives me 18000bph. So am i looking for a new escape wheel and pinion or am i looking for a complete platform?1 point

-

I still think it's a gearing issue. If it's showing a "nice 18,000 per hour" it would be very odd for it to gain 20 minutes per hour; 20 seconds, maybe (but it would still show up as almost +500 seconds/day, more than some timing machines can read). If you get it apart, it would be interesting to see what the calculated BPH should be. 8 leaf pinions are standard, but they can go as low as 6 and as high as 10; and 18,000 BPH is standard, but you can sometimes see lower counts (haven't seen higher yet). I trust OH's judgement, but in the even the platform isn't actually original, it may have had a cylinder escapement before, for example, and those sometimes use a lower beat rate. If it was intended for a 14,400 BPH escapement (just an example), all else the same (escape pinion tooth count), that would already cause a 15 minute gain per hour at 18,000 BPH. To calculate, start at the center wheel (which makes one turn per hour). The calculation is wheels multiplied together, times 2, divided by the pinions multiplied together (not including center pinion). So: center wheel, third wheel, 4th wheel, escape wheel, x 2 / third pinion x 4th pinion x escape pinion. For example: 80 x 75 x 80 x 15 x 2 / 10 x 10 x 8 = 18,000 .1 point

-

That is want I wanted to see. That is the original platform. Poor time keeping will be down to a dirty hairspring or as I said before it could be magnetized. Clean the hairspring in Ronsonol lighter fluid and dry it with your bench blower. Make sure the tools you are using are not magnetized, now use tweezers or an oilier gently push the coils so they touch one another and see if they stick if they do then the hairspring is magnetized and you will need to demagnetize it. I would also put the pallets and escape wheel through. I would also clean all the platform and you will need a Pocket watch oil for the platform.1 point

-

When I come across any stubborn grease or dried lubricants, I use a dental microbrush dipped in Goo-Gone. It has worked like a charm. BTW Horosolv seems to be benzine.1 point

-

yes that is exactly what I mean. Apparently it was recommended by Elma for our very expensive machine at work because the rinse just wasn't drying even with heat which was the same thing I found which is why someone it recommended alcohol I'm just using the inappropriate alcohol but I only have the watch in there for a few seconds and then right onto the dryer it's not an issue. so it is a water base the problem with the material safety sheets are there not a DIY of how to mix up the product and there must be a process because as you found out mixing water in with the solvents it does not this will all go? I believe for Elma for their water-based cleaner there solvent-based rinse is recommended as a rinse for the water base which implies that it must dissolve the water? Or at least the water must go into the solution so maybe you need a different solvent that's more friendly for water.1 point

-

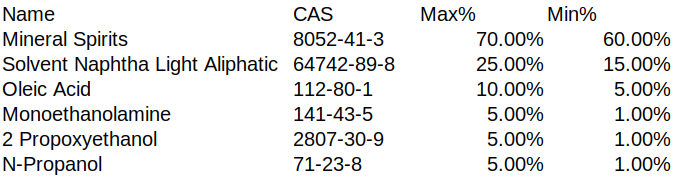

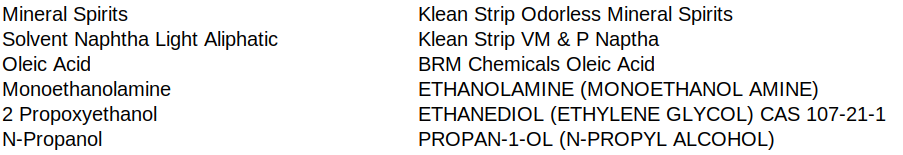

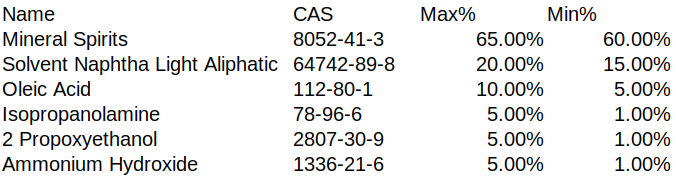

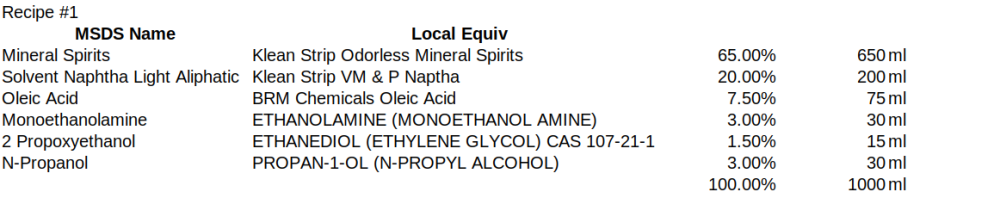

Quick update: Cleaning fluid 111: Fail... this resulted in a cloudy liquid (when I added the 30% amonia solution) which then (after a few days) formed a jelly compound in the bottom 1/3 of the mixture, I mixed and warmed to 60 C but still couldn't get the gel to go back into solution, and after a few mins I again had a gel 1/3 layer in the bottom of the jar - anyone with a chemistry background who can help?? Cleaning fluid 566: Success... this formed a 2 phase solution where about 1/2 of the fluid floated on the other half, but after shaking for a few seconds the mixtures would mix long enough to decant into jars for use in cleaning Rinsing solution: Success... the ingredients easily mixed together to form a clear liquid I used my 566 and rinse solutions above to clean a watch and the parts came out sparkling clean, although the rinse solution took heat to evaporate unlike straight naptha which I had used prior to this. So I'll continue with my home brew 566 and rinse solution unless anyone out there can help to resolve the 111 gel issue.1 point

-

As far as odour is concerned I found the L&R the least pungent compared to Elma. I only wish I had a nice large workspace but I don’t so ventilation is important but items being cleaned must come out grease and dirt free.1 point

-

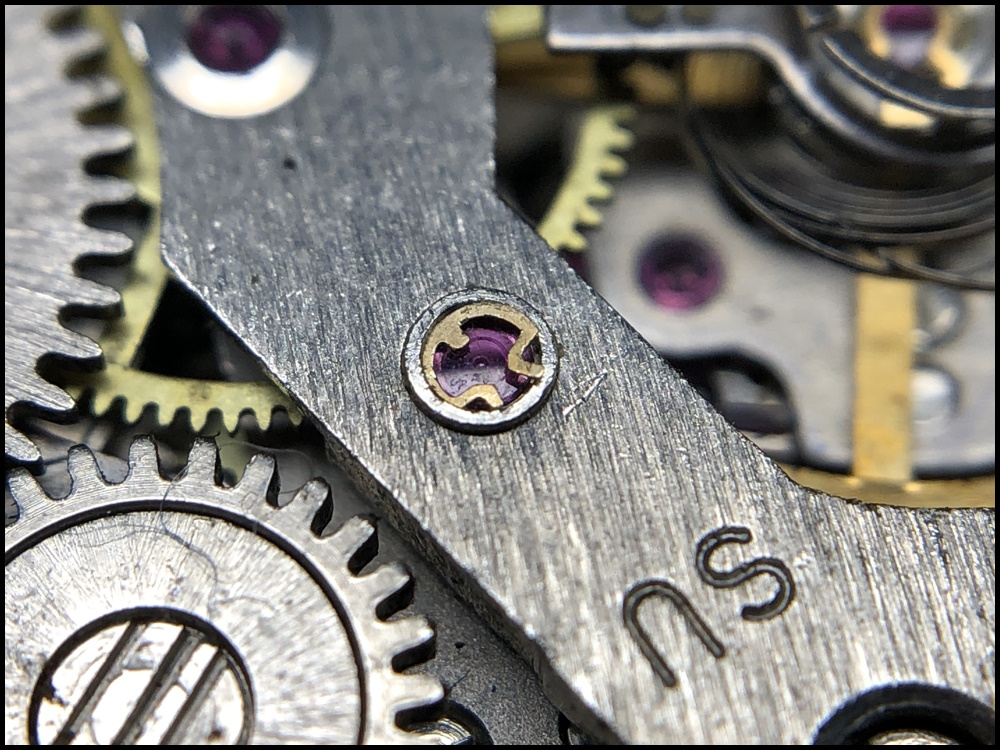

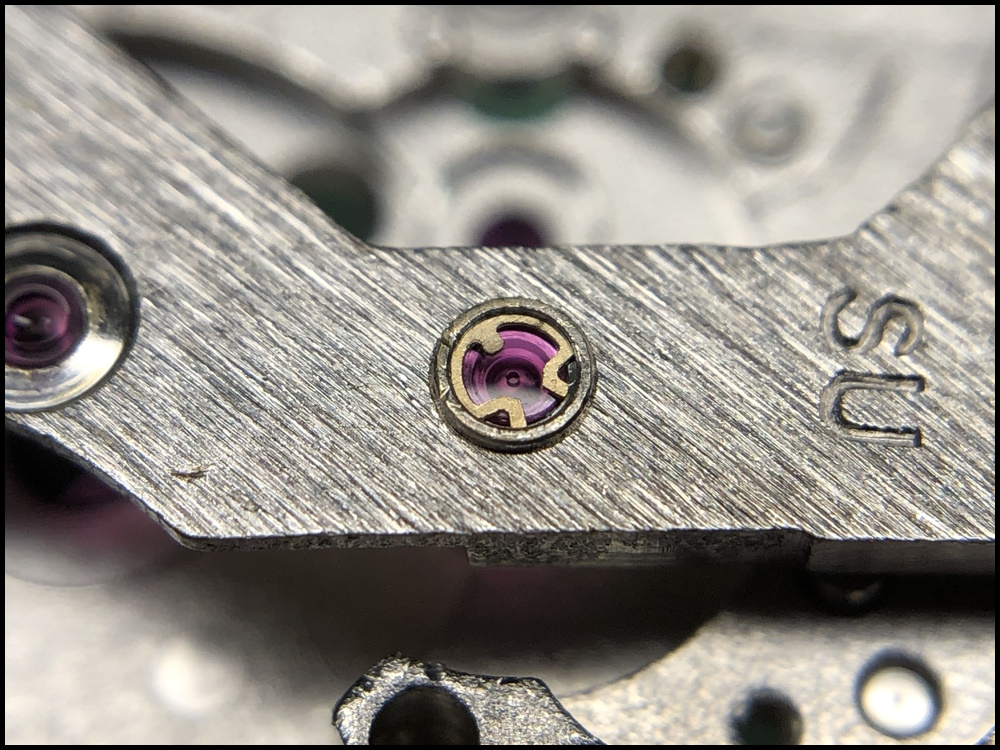

that's not what the title says. so before I spend any more time attempting to find something let's figure out what it is exactly you have. Ideally in my mind when asking a question the title should reflect properly what it is you're looking for so it draws people's attention to helping you with your problem and it's nice if you also put the description in the text itself because sometimes I don't always read the title but here we only have the title and I found the spring for the title. So before I spend any more time looking for anything else I assume from your wording it's a Chinese clone and is it running at 21,600 beats per hour? Because when the Chinese cloned the 6497 they did not they really clone the 6497-2. Which is a slightly different watch than the 6497 specifically the mainspring and there's a few other parts that are different. Then there's the problem of I don't actually remember anymore whether the spring is identical to the Swiss version or not I know they can be purchased because I was at a school where we used them for training purposes and yes we did purchase more of them but conveniently I don't seem to have a listing of what exactly we purchased. then because the Chinese version spring will always fall out even if you're super careful it would be good to practice putting it back in again. Yes it will literally drop in the place if you do it correctly and I'm sure we've discussed it before on the group because I know I posted pictures of why the Chinese version this happens versus the Swiss where it typically does not happen usually. Then when looking at the end stone you look at the reflection. In other words the flat side will reflect a perfect image and the dome side will have a distortion of the reflection that's the easiest way to tell which side is up. in other words if you look at the stone itself it's shiny and if you get a reflection of an overhead light for instance that's the easiest way to tell what you have1 point

-

1 point

-

1 point

-

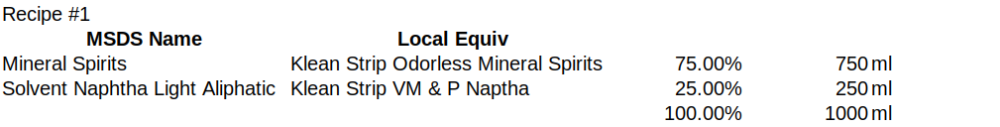

Not sure, but "All American Time Corp." did do this one. Source -> https://peretiredgoodbadugly.blogspot.com/2017/10/just-like-old-days.html Dirty Time corp did this one. I may see if I can rustle up a contemporary "Trump" version. If "The Clan" turns up at my door as a result, you may never hear from me again.1 point

-

1 point

-

even though it's golden color it's not gold. That means you should try a magnet. then I like your title we are searching for the top spring for a very specific caliber as opposed to a cloned caliber? Because with the cloned caliber from the Chinese that will change the spring you're looking for. then based on the page below it looks like you're looking for a incablock 470.13 https://www.ofrei.com/page615.html1 point

-

Before I bought my Elma Solvex SE I emailed the company with questions regarding the warranty and they suggested I contact the Elma lead at Jules Borel (their US distributor) Kyle Woolworth. He answered my warranty questions (2 years coverage), which included asking who does the servicing. They use Electronic Instrument Service for servicing in the US.1 point

-

This is a genuine French carriage clock. It sounds like it has what is known as a sticky hairspring, could be dirt on it or it is magnetized. So that is the first step to take. I notice the back door glass is broken you need to get that sorted as dirt and dust will easily get in. The click spring is not original, I don't think I have ever seen one that big in a small carriage clock. Not sure about the platform. I need to see the movement out of its case, the screws I can see on the platform don't look right they look modern cheese head type which I wouldn't expect to see.1 point

-

Hi with a gain like that on would suspect a sticky balance spring , coils sticking, or running out of flat and again catching. Best to remove the movement from its case and make a close inspection. The pictures are not very clear for diagnostic purposes1 point

-

I've no idea @oldhippyis your man. I have replied because I'm interested to find out.1 point

-

Jonno65 Hello. Like you as a hobbyist I needed spare screws. Usually it was not the plate screws, but the specialist ones, reverse thread crown screw, long threaded barrel spring screw. These I had usually broken at the head as I have been too heavy in my locking. Like Tom I did initially purchase a set of spare screws rom an ebay seller. I have used only 1 since purchase, but it is god to have them in my spares box. Unfortunately the only way I have been able to source the required replacement damaged screws, has been to source the same movement from ebay. Can sometimes take months. As pensioner learning such a brilliant hobby it's problem being at the low end of the wealth ladder for hobbyist. I have £10 a week which I limit my self to use for the hobby. Therefore it can be a few weeks before I can even make an offer for an item. I do look for offers of multiple movements so that I have the opportunity to obtain a special part. Initially I would get 1 movement only to find that the actual part I needed was not actually there, or was damaged. Two things of note. One good, one not so.. Since I started at Christmas 2021 I have noticed that, apart from ladies watches, the price of mechanical watches and movements has nearly doubled. Makes life difficult. However, the price of tools has actually reduced marginally. Tools make the hobby so much easier. The right tools for the job. What has helped, is the Youtube videos of in depth watch restoration. I have learned so much. Know so little. Great fun Ross1 point

-

I got an assortment really cheap from cousinsuk, any material house will stock them. It can be a faff trying to find one to fit but what is watch repair but an exercise in practicing patience? Tom1 point

-

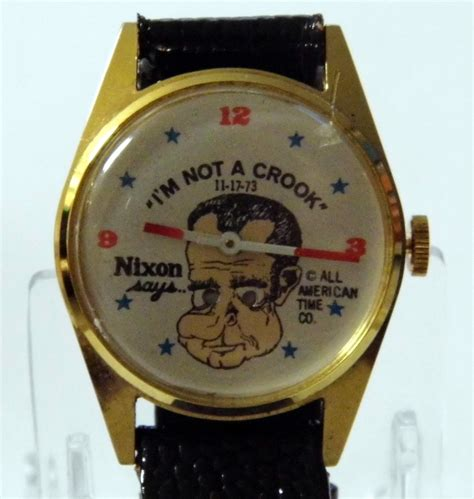

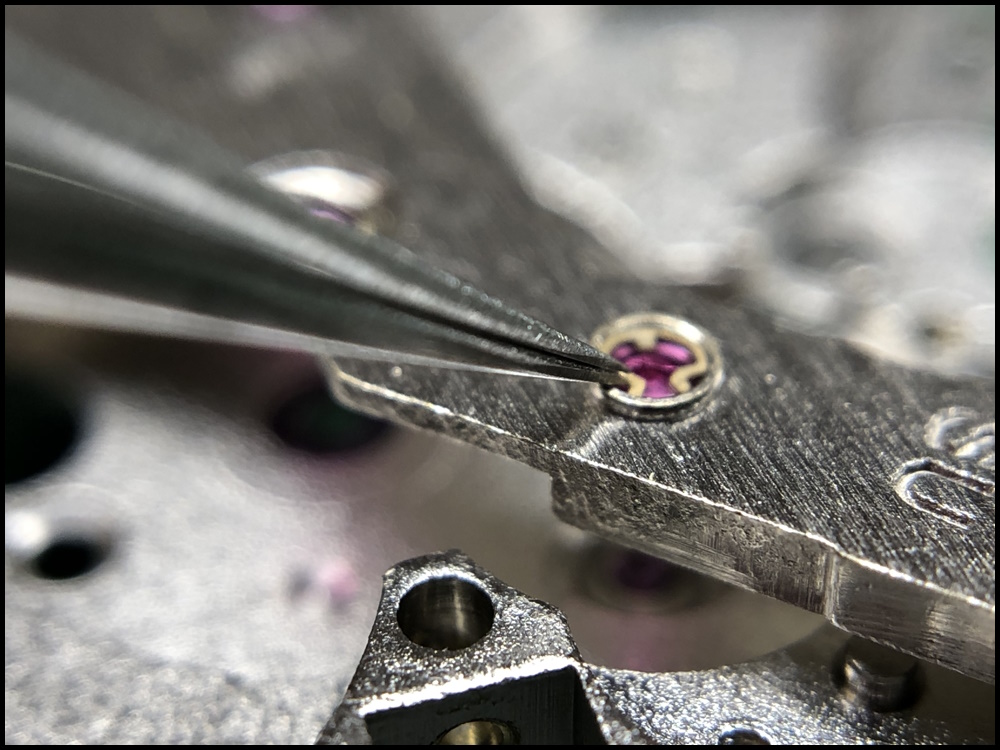

I use a couple of sewing needles pushed into peg wood (point outwards). Having two is useful for two reasons. First, you can use one held between the jewel and the spring so it if tries to fly (and they will) it will be caught between the pin and the jewel and second, it can help spin the spring once you have one or two of the arms in place. I sometimes use one of these with a jewel “picker upper thing” which looks like a pen with a blob on the end which is great for placing / moving the jewel, saving it from springing away instead of using Radico and then picking the spring and the jewel out of the chaton. Picture attached. The main thing though is practice to get a feel for how gentle you need to be and how little pressure is actually required. Get an old movement and spend some time taking out and putting back springs and jewels and then putting them back in. It’s a lot easier to practice when it’s something you don’t care about losing than when it’s the one shot at something you’re scared of damaging / losing.1 point

-

I had no idea. Thanks! Yes, sort of, especially when you succeed. One of the springs I was using for practice was also entangled, but I managed to take care of it after having studied the technique used by Henry B. Fried in the following video. I was actually surprised to see that it was relatively easy.1 point

-

So, yesterday I got my Greiner MagnOmatic, and let me tell you, this is NOT a toy! I tested it by checking the magnetism on my Indian hand levers using the Lepsi app on my iPad, and as soon as I came within a 150mm radius of the sensor point it indicated magnetism. The strong magnetism was also evident when I tried to use these levers to remove the collet from a balance staff. The levers would stick so hard to the hairspring that it was difficult to remove them. So, I placed the levers inside the MagnOmatic, pressed the button, felt a very distinct thump in my fingers, like the machine was trying to yank them away, then rotated the levers about 90 degrees and pressed the button again. The result? Zero magnetism remaining! Even hoovering the levers a millimetre above and in the dead centre of the sensor point on the iPad indicated any magnetism, and when removing the collet the levers felt as magnetic as if they had been made of peg wood. I've tried to demagnetize these levers (and tweezers) on my Elma Antimag many times, but only experienced a very vague difference if any in some cases. I am truly happy I found this machine in the nick of time while only three minutes remaining on the auction and got it for a mere total of £115 including shipping. Had I bought it from Cousins it would have cost me £885 + Shipping + Import fees + VAT totalling approximately £1170. Perhaps a bit of compensation from the watch gods, for some of the many expensive deals I've done on used tools over the years. Anyway, this is without a doubt, a truly professional demagnetizer. If you get the opportunity to acquire one for a reasonable price, do not hesitate to pull the trigger!1 point

-

You have to remove them to properly clean the cap jewel and the jewel hole. If you don't have an automatic oiler, my suggestion would be picking the cap jewel with a jewel picker from the top side, oiling the jewel and putting it back in its place with a help of tweezers. Jewel picker is much safer than tweezers if you don't like flying parts. I also clean cap jewels by picking them with a jewel picker and rubbing against paper with and without IPA. https://www.cousinsuk.com/product/jewel-picker-upper-with-silicone-tips1 point

-

Hi there are several places in th US to get bits, Jules Borel has been mentioned, there is Timesavers, Otto Frei, Esslingers, Perkins in Canada, UK. Cousins, A.G.Thomas, Gleave and co all material houses and suppliers it’s just a case of checking out each. Esslingers is a good site with a wealth of material and tutorials and that’s just one. Cheers1 point

-

You want to narrow down a location in the US as it's a relatively big place do you know the pain spring you're looking for? a lot of it just depends on what mainspring you need there is quite a few online material houses. Depending upon where you live there may be a physical material house That you can actually walk into and buy things from although the quantity of those is decreasing. There is eBay and even though cousins is in the UK a lot of people claimed they can get stuff faster from cousins and they can from the US material houses.1 point

-

I thought some future repairer might find this thread so I will now try to describe how I dealt with the spring that covers the cap jewels for the escape wheel pivots. Thanks for all input which proved very helpful. The diameter of the spring is approximately 1.2 millimetres (the cap jewel diameter is 1.1 mm ) and the spring sits submerged in a hole and the edge of the spring is inserted into a groove that runs around a bit below the hole. It proved difficult to find a tool that was small and flexible enough to hold the spring in the hole while prying it out, so I found an alternative strategy that worked well both for removing the spring and for refitting it. See the below description. To get the spring out I used a sharpened oiler while covering as much of the jewel hole as possible with a piece of peg wood carved like a screwdriver. I jabbed the oiler under the spring and then bent the spring inwards and upwards which caused it to come loose from the groove/lip without putting undue stress on the spring. When the long leg of the spring (the other leg is, yes, shorter) has been freed from the slot in the hole, it is basically just a matter of carefully lifting the spring out of the hole. The cleaned cap jewel was refitted in the hole. To get the spring back in place, I pushed one edge of the spring into the groove of the hole. After that, I again covered as much of the hole as possible with my pegwood screwdriver blade (not visible in the picture). Finally, I gently pushed the other leg of the spring in and down with my tweezers to get it into place in the hole. Hopefully, it is clear from the picture that I pressed onto the edge of the spring between the two closed tweezer blades. Spring is fully seated.1 point