Leaderboard

Popular Content

Showing content with the highest reputation on 01/03/23 in all areas

-

This reminds me of the following quote: "I'm afraid one day I will die and my wife will sell my watches for what I told her I paid for them."4 points

-

Good news! I just heard back from "perplxr" with the following message: "Hi, we are working on that. Please stay posted for further information about our videos - we are currently revamping our social media. Thank you so much for your interest and concern!"4 points

-

I take some thin metal wire and bend a small loop in the end with pliers, clean it and dip in oil bottle.3 points

-

FU face up is also same as DU dial up. FD face down is also DD dial down ( not a bra size, well not in this case anyway ) . If the balance installed with the pallet fork is only oscillating for 5 -10 seconds after a good puffer blow. Then there is some friction or obstruction somewhere. Could be anything on the balance. Frequently hairspring or staff pivot issue. Have a close inspection of these two things first. I was going to suggest before you removed the pallet fork for testing the balance, that the impulse jewel may not be entering the pallet fork as you install the balance. Or the impulse is not on the open side of the fork ready to enter when starting. This is easily determined by the lack of any movement from the balance as the impulse hits the outside of the fork horn.2 points

-

The hs has what is called an active length, this is the point at which the hs is beating at its required bph to give the watch accurate time keeping. The active length providing the hs has been vibrated and formed correctly would be found somewhere along the terminal curve. Ideally midway, that active length is held at the point of the regulator pins. So when adjusting the regulator arm that active length moves to become longer thereby lowering the rate and slowing the timekeeping or becomes shorter thereby increasing its bph and speeding up the timekeeping. When the pins are too wide and not touching or rarely touching the hs, then what ? The active length is extended back to the stud, so it is now at its furthest point and the slowest it can go at its current ampitude.2 points

-

This has been on ebay for awhile. It is on my watch list just for fun.1 point

-

Here's a guy in Arkansas putting an estate he acquired on ebay. Curious I was. He shows you the stuff with a series of terrible videos. This kind of stuff intrigues me, but this guy is whistling Dixie, IMHO. I tried to find a reason to go buy it but failed.1 point

-

I printed this up over the weekend and got a chance to sit & try it out a couple times now. I knew I needed something, but holy cow, it really helps me find what I need easily and keeps me way more organized while I'm working... Duh. Also, behold the dirt cheap collection of (mostly) junky tools this beginner is working with here! The screwdrivers are better than they look. I have some titanium rod and I was thinking of machining my own screwdrivers from some of that, just to be different. I figure just delrin for the heads, which seems common. Anyways, I'm guessing most of these tools will be upgraded over time, but enough about the future. This uses a lot of plastic and of course it fits my tools and maybe not yours, but I uploaded a "step" file in case you know how to customize it for yourself. Yeah, tool blocks baby! We expect them for our screwdrivers, why not everything else? https://www.thingiverse.com/thing:57618301 point

-

Interesting..... I have a late 1960's Elliott desk/mantle clock which has a 7 jewel french platform escapement but without any of the spring work on the escape wheel, and it is really loud!! I have to agree with OH on the build quality, it is very much a notch or two above the average fare...1 point

-

Hello and welcome to the forum Benji, Regarding the Marvin you might try ebay for a donor or these, speedtimerkollection.com Europe or welwynwatchparts.co.uk both second user parts suppliers. getting a hairspring will be difficult as each spring is vibrated / tuned to the balance wheel as a matched pair. you may be lucky and pick up a balance complete (balance wheel and spring attached) all the best1 point

-

1 point

-

Egad! Well, I saw some watches, watch parts, and pliers near the end. But mostly I saw a whole lot of boxes and cases, with the implication that there were vintage watchmaking tools in them. There's no way I'd spend $40,000 or more on implications. (That, and I don't presently have $40,000 to spend.) That man has big dreams, but I'm afraid I cannot bring myself to be all that optimistic for him.1 point

-

1 point

-

You'll notice your stud holder looks like it's made out of a different material Then the rest the balance bridge. It probably can be pushed and used to put the watch in beat usually when there a different Material that's what happens. It just happens to be a strange design.1 point

-

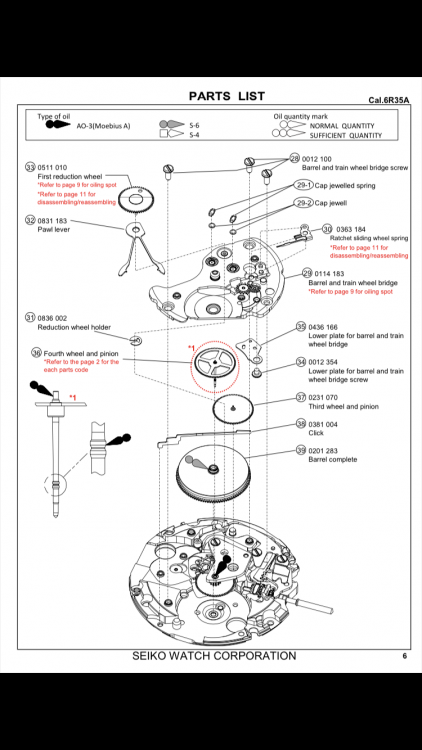

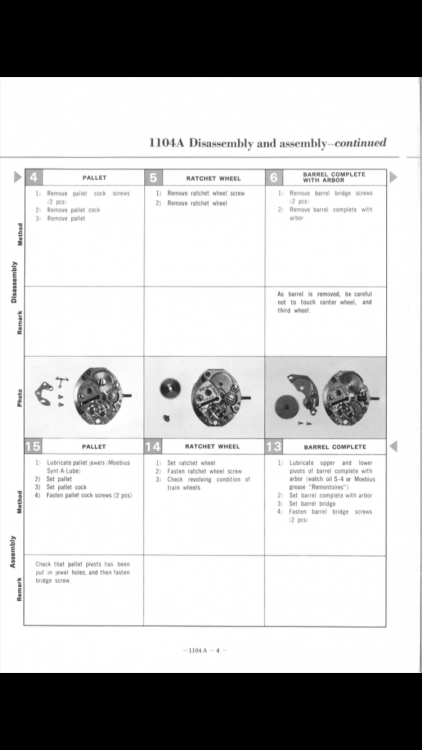

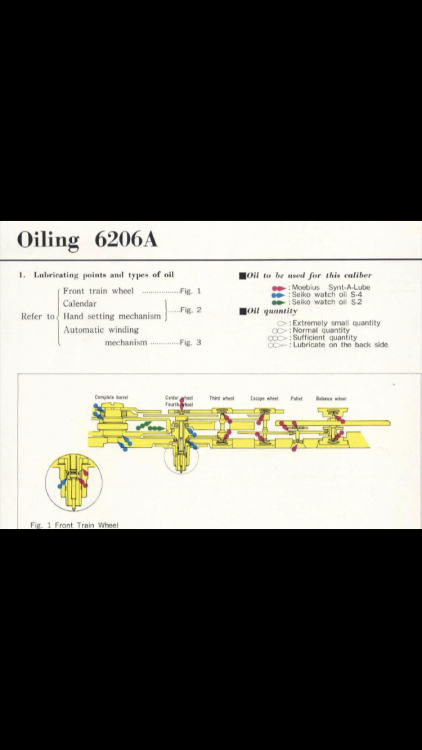

Yes because the exact same thing. I'm also attaching a PDF of a slightly different Seiko showing how to lubricated and their lubrication choices. The other thing to do you find a really new Seiko watch and see what their lubrication choices are just because people like to change especially watch companies. Here's a recent discussion on Seiko lubricants https://www.watchrepairtalk.com/topic/23122-does-anyone-actually-use-the-seiko-lubricants/#comment-206985 Here's a much older discussion with interesting images that might give us some helpful ideas. Then for the S6 I'm guessing from your list D5 would work fine. https://www.watchrepairtalk.com/topic/5407-seiko-oiling-instructions/ Seiko-Oil-7005A.PDF1 point

-

Saw that Stephen and also confused me. Hence my post.1 point

-

Where did you get this information, and can you please link to the video? In any case, that isn't what the graphics posted by John are describing.1 point

-

Elliot clocks are English I have many ranging from time pieces to Chiming all with platform escapements they are very well made clocks from the movement to the cases. The coiled spring on the escape wheel should act as a silent tick, that is if it is working correctly. You need to make sure the balance is in beat, if you stop the balance and you have power on the spring the balance should start up on its own. You need to check the balance and the depth of the contrite wheel making sure the teeth engage correctly. No matter what position the movement is in it should work, if it stops the depth will be wrong.1 point

-

I like the sound of friction have you tried whacking it with a big hammer? It would've been nice to have a side view picture as something doesn't quite look right? Waltham mainspring barrels I really despise. They come apart a variety of ways unscrewing is a pain. Putting it back together is also a pain sometimes helps the whole part of it in a watchmaker's lathe. Okay I'm trying to find you a picture. If I'm guessing right temporarily take the ratchet wheel and put it on top of the barrel arbor and then you can unscrew the arbor it screws together. I'm trying to find an image does I know I had images of all this in the past just where did they go to? Then yes we have discussed it on the group somewhere before Okay founded I ask you have three images. One of the images talks about what I said putting the ratchet wheel back on using that to unscrew. But just in case of the give you all three images. Oh and as a reminder you have issues with putting the mainspring back in and unless you get a real Waltham mainspring or modify the end and I will let you be surprised on that one when you get there.1 point

-

Yes. The most important part of the hairspring. It has to follow the arc of the regulator precisely, so that when the regulator arm is moved, the regulator must not touch the hairspring throughout the entire travel. Not an easy thing to achieve.1 point

-

Very good explanation. I sorta new what some things did but not why they did them and that clarified quite a few things. Appreciate ya bud! So the terminal curve is just the part from the stud to the first kink then?1 point

-

This evening I decided to take a look at a remarkably slim cylinder movement of unknown origin, with an engine turned silver dial, possibly from 1892, possibly considerably earlier, and maybe French. Any experts please chime in and let me know your thoughts. I picket this up for a few pennies, because I liked the look of the dial, and the blued screw construction. I have it working, but don't have any suitable hands for it yet. I presume it has had its original spring replaced, as the Maltese cross works are missing. There are a couple of inscriptions on the back of the dial, one from 1892, and a couple of others that are less distinct, one may say 1820. If anybody has any ideas about what they say, let me know. ... and the star of the show, the Guilloché dial. .. and a few more pictures for completeness.1 point

-

If this was an over coil hairspring then the rule is as tight as possible as long as they hairspring can still slide between the pins. On a flat hairspring you have to have a tiny bit of breathing room but not very much. I think the suggestion might have been if you had a another piece of hairspring and shoved it in so basically at half of the new hairspring on either side that would be the most but I suspect that this number can vary. And yes you definitely need to follow the terminal curve that was last week's fun at work. My boss likes to have a service of regulating watches to being just like Rolex watches at least to please the timing machine. So he had played with the Seiko hairspring everything was perfect except the raids and then when he move the regulator it was all screwed up because? This is what happens when you don't follow and have a terminal curve Then I've attached an image the importance of things being right. So yes if you open up the pins too much in the amplitude drops at some point in time you get some really bizarre timekeeping. This also becomes very obvious on an over quill watch for that spacing is even more critical you'll see the watch being really slow as the amplitude drops you might even think you have some other problem and it's just a regulator pin problem.1 point

-

Hi. With power on the mainspring the watch should run without the automatic assy on .What’s the problem fitting the balance, dont force anything, once the balance cock is in position put the screw in for a couple of turns just to steady it then jiggle the balance wheel into position,once in position using a fine brush start the balance and slowley screw the cock down all the while keep the balance swinging. If it stops as the screw is tightened stop and back off as its not in position correctly and reasses the problem.1 point

-

Thank you so much for documenting this!!! I inherited my grandfather's nearly identical grandfather clock a few years ago, and I'm fairly certain it's never been serviced. It runs just fine, and keeps decent enough time, but I stopped winding it a while ago (once I knew it didn't have any issues) because I wanted to not add to the decades of wear unnecessarily. I poked around in it to try to figure out how to get the movement out, but it was not immediately obvious. The manual, as you stated, is less than helpful, or even accurate. This just moved way up the to-do list thanks to your fine work!1 point

-

Yes, and if you have family and friends, don't forget about them or else they will "forget" you!1 point

-

Have a read of this thread messed-up-a-seiko-6r35-regulation There's a video which explains removal and adjustment https://youtu.be/ExfFlYFAffg1 point

-

1 point

-

That one is a lot nicer than the one I had in my office For the OP, I don't think there is a need to put a movement inside of a plastic bag. You can get the same benefit by just laying a thin piece of plastic on top of the movement and working through it like the below. It works for all the movement springs like this click spring, shock springs, etc. Same when putting the springs back:1 point

-

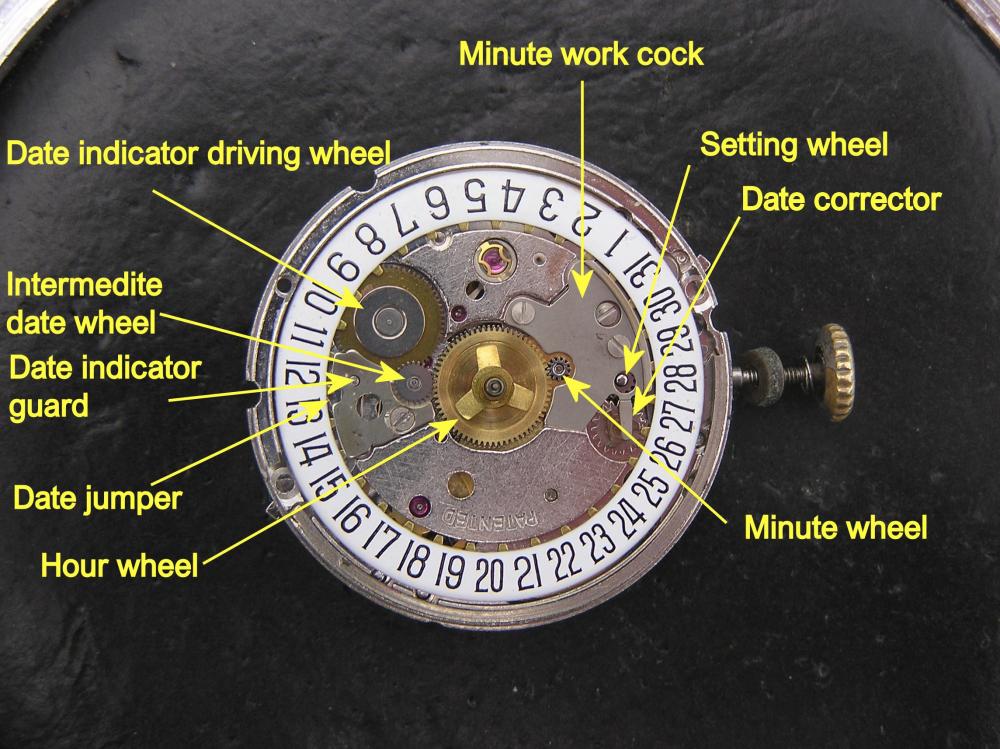

Well lets try to explain the function... There use to be three positions on the setting lever. 1. Winding 2. Date setting 3. Time setting In position 2 the setting lever pushes (the date corrector lever) the setting wheel onto the date corrector. The date corrector has three paddles that will turn the date ring in one direction. Due to it's design you cant switch the date backwards. In position 3 the setting wheel will engage the minute wheel . The minute wheel drives the Hour wheel. The hour wheel drives the intemediate date wheel, this is held in place by the date indicator guard . On the date indicator driving wheel there should be a smaller wheel which drives the date indicator driving wheel. the intermediate wheel must turn free in the guard . On the date indicator driving wheel there should be a spring loaded pin which allows for date shift in one direction (clockwise) but not in the other. Sometimes this springloaded pin is to worn or dirty so it will not grabb onto the date ring. The date jumper will ensure you get a snappy dateswitch and later on keep the ring in position. The dial is held in place by the date indicator guard and the minute work cock. These two must be exactly flat or the datering will not move. So in this picture the date indicator guard looks beaten up and as previously said the date jumper is out of position.1 point

-

Last century when I was in school I was alerted that a well known watchmaker and author was selling off all his stuff as one lot. It was a couple hours drive, so talked to him on the phone first, "there's no cherry-picking, it's all or nothing"; OK. Went down, he had a couple of nice lathes, but from his writing I was expecting one set up for milling and dividing... "no, sold that to another guy", what about that rounding up tool? "sold to another guy", and so forth. So it was the dregs, already been cherry-picked. A sad thing that happens is when a watchmaker passes and folks come in and pick off the good stuff for nothing from the unknowing widow, leaving the cigar boxes full of random junk and a few forlorn 3/4 empty assortments, or a lathe which magically is missing all its accessories.0 points