Leaderboard

Popular Content

Showing content with the highest reputation on 08/19/22 in all areas

-

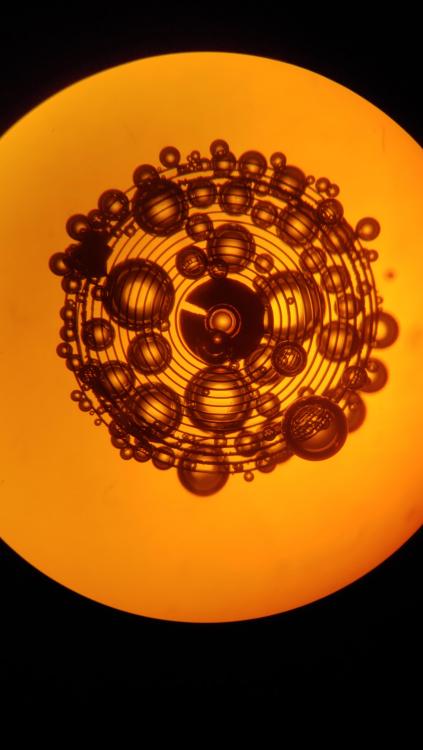

yes that's one of the amusements with this group an obsession with amplitude. obviously nobody from Seiko factories ever on this group they would be so unhappy their watches totally suck for amplitude at least according to group specifications. Notice how normally and never find a Seiko referenced amplitude except the 4006 a manual specifies fully wound up you should have a minimum of what? typically for the watch companies if they have specifications are concerned if they have too much amplitude like over 300+ degrees otherwise they could care less until 24 hours later. Then it's supposed to have a minimum but the big thing they want is time keeping. So while Omega specifications are almost everything they have a section on vintage watches not found in the normal specifications and I snipped out that image. Notice the minimum amplitudes I'm not sure I want to say what those minimums are because somebody's go find some tar and feather and track me down for daring to suggest a watch could even run at those amplitudes. On the other hand these are Omega watches which are usually really really nice other watches probably would keep horrible time of those amplitudes but still it tells us that they don't care about amplitude wound up the only care about timekeeping amplitude at 24 hours then taking a quick look at the rest the Omega timing sheets looks like the highest of the low amplitude is 200° and the low as 160 and then it just depends on the watch it could be as I said 160, 170, 180, 190 and then 200 But there's no specification that says you've done a good job if you watch is doing 271.9° I'm just joking about that particular number but that's not in the specifications. Realistically it seems to me that if the watch was running before you cleaned that if you ran a timing profile and if afterwords it was doing better amplitude and preferably better timekeeping you did good enough at the end of 24 hours it still running and keeping reasonable time than you did outstanding.4 points

-

Thanks for the replies and advice @JohnR725 and @VWatchie and also for the charts. Happily, this particular movement falls within the above specification as it was running pretty awful prior to a service. I've also had to poise the balance to stop some horrendous rate changes and all is a lot better now. I agree with @gbyleveldtabout the Seiko's. I've never been able to get my 6309's to run much above 230. I've had to learn to be happy with that.3 points

-

Trying to find answers most of us new enthusiasts have. I’m not new in age, just the enthusiasm. Love any kind of time keeping mechanism but genuinely love wristwatches. Pocket watches are a close second. Vintage divers is what I will eventually collect, but for now, entry level, nicer Swiss made, Swiss movement watches. I own a plain Swiss made Swiss movement Invicta pro diver, A 1960 Bulova RGP Thin 17j hand wind. This one is amazing. I honestly believe it’s been serviced maybe once. All original as far as I can tell. A friend gave it to me. It was their fathers. Looks like it may have been worn a couple dozen times on special occasions over 60 years. It stayed in a box somewhere safe when it wasent being worn. Accurate time for almost 34 hours on a wind.3 points

-

2 points

-

Heh, till you work on Seiko 6309's where you're considered a master of the art if you get 230deg amplitude. It really depends on the piece and how it was designed2 points

-

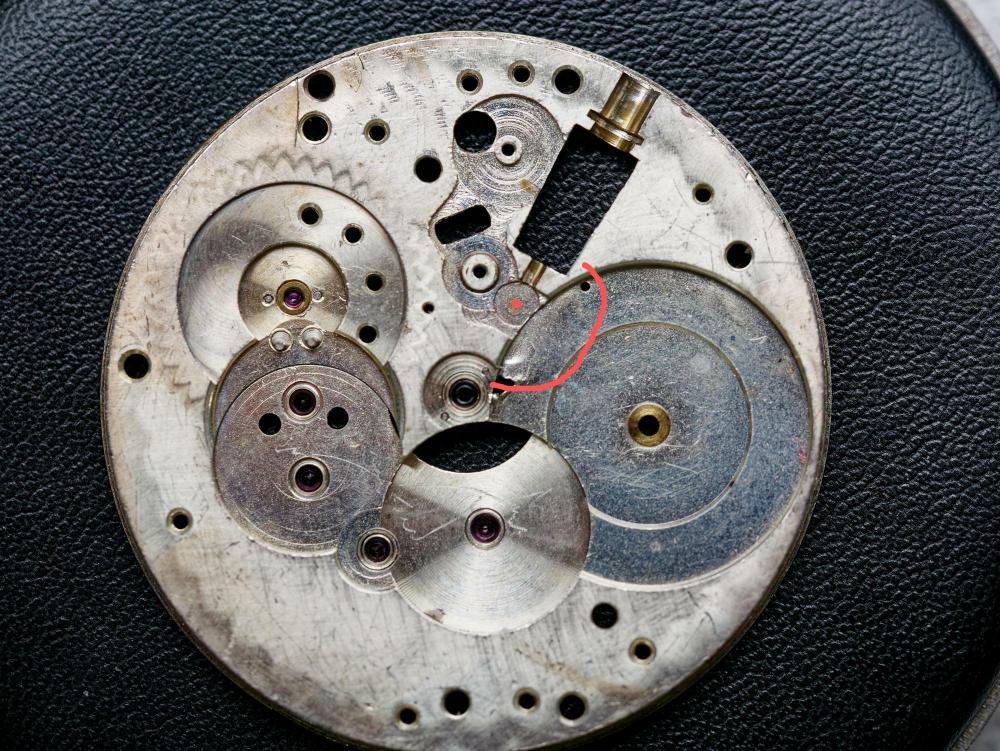

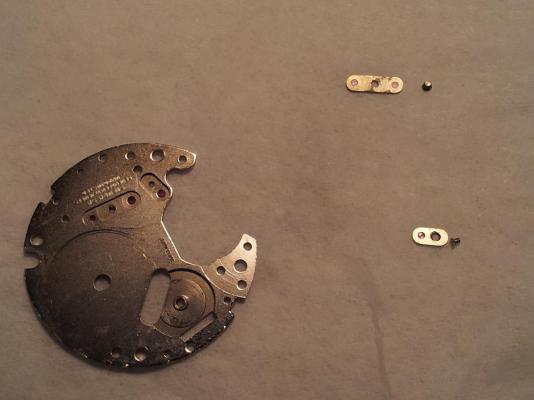

It does look like a very small diameter rotating cutter was used to address that screw head coming in from this direction. As the cutter continually climbed across the brass doing more harm then good. It chewed through the thin brass in that spot, grabbed and quickly dug in, folding that detail towards the barrel (probably snapping the tool in the process). That screw was probably interfering with the minute wheel after an attempted repair and this felt like their best course of action. They probably sat shaking their head for a while and never tried that again. If it worked for the last fifty years in that condition, there's no reason why it shouldn't continue to work and replacing it won't magically add an otherwise complete serialized watch movement back into the world. I'd put it back together unless I had an another complete serialized movements that just happened to need everything else transferred over. If you have the complete serial number from the nice side of a bride plates (the number on the main plate is often abbreviated) we can look it up and I will look and see what I have to offer. Shane2 points

-

Even with the recent trend in oversized "quartz copper frying pans" masquerading as wrist watches, at almost 50mm this thing would be over-oversized as a wristwatch. It might look OK if I went completely steampunk. I'll need to think about that.2 points

-

way too many variables here to even make a guess. size the watch will make a difference ladies watch pocket watch for instance. Condition of the watch has it ever been serviced what is its current amplitude so in other words adapted really sucks need to serviced then it would be much greater. Quality the watch modern versus vintage. A whole bunch of things can make it a challenge to have an absolute this is good versus bad situation. than usually if you're looking at technical specs from watch companies they are more concerned about timekeeping in various positions. they're usually not obsessed with amplitude other than at 24 hours and if the watch still keeps time. I snipped out something from the witschi technical PDF which I attached there is what they think should happen. But they sometimes tend to have a more idealized world of things average modern watches in good condition not vintage watches for instance. Witschi Training Course.pdf2 points

-

Thanks to the stocking distributor model, we have NOS items appearing on eBay all the time. If the entire world shifts to the just-in-time model or the indent-order model, there wouldn't be any hidden stashes waiting to be discovered.2 points

-

this is where on a practice watch acquired cheap where you make a decision as to how far you want to go. Also as a practice watch have you been practicing with it? Like how many times have you taken apart and put it back together how good are you at putting it together without breaking the pivots off. When people learn watch repair at least in school they practice a lot at doing tasks they don't just do a one time it's done multiple of times. If you decide that replacing the staff and actually making this watch run is almost impossible it still has value as a watch to practice taking apart putting back together and getting familiar with everything. It's also a good lesson to learn that unfortunately every single watch cannot be restored and made the run again at least not in a practical sense.2 points

-

It certainly has that vibe about it. I'm trying to find something similar, but so far I've drawn a blank. I may just make a simple wooden stand for it. I'll see how creative I am feeling.2 points

-

Hot on the heels of the cylinder pocket watch, I also picked up a pocket watch sized cylinder clock movement. I'm not sure what exactly this was part of, but it has no alarm or chime, so it was presumably some kind of small decorative clock. It was absolutely filthy, and not running when it arrived, and the case has some evidence of being modified (or perhaps butchered might be slightly more accurate). It needs a new main spring which I may have in the stash, and it gives every sign that it should run fine once that has been replaced. It still needs a little more cleaning, and I'm tempted to re-plate the rear of the case ... and possibly the front bezel... maybe. It seems to be nickel plated which shouldn't be beyond my skill set. I'm not sure exactly what I am going to do with it once I get it running. Any suggestions? The outer bezel is 49.5 mm wide, and the inner case back is around 46, so roughly the size of a pocket watch.2 points

-

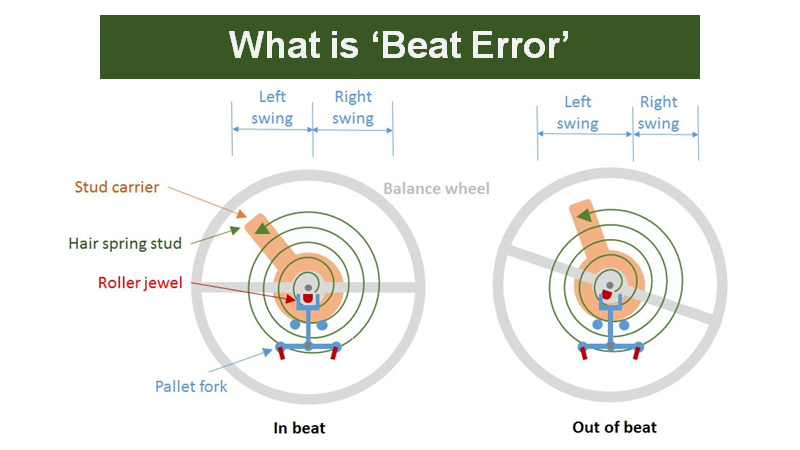

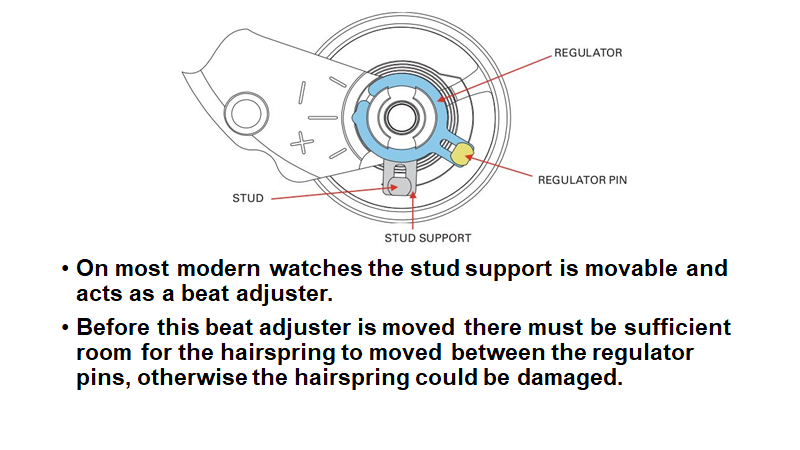

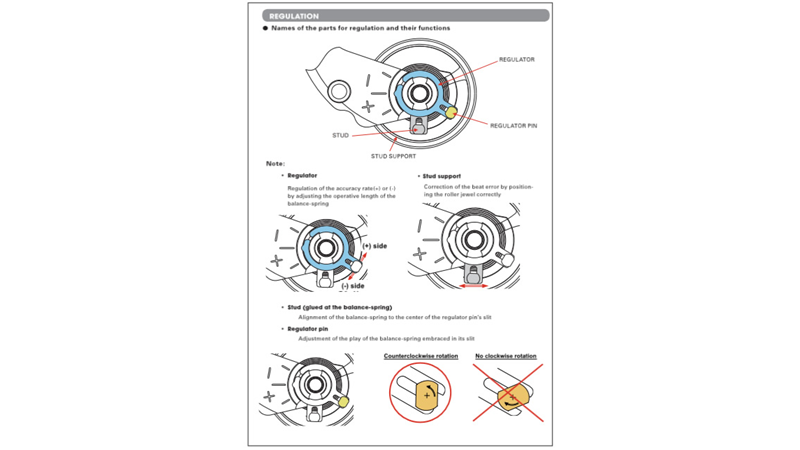

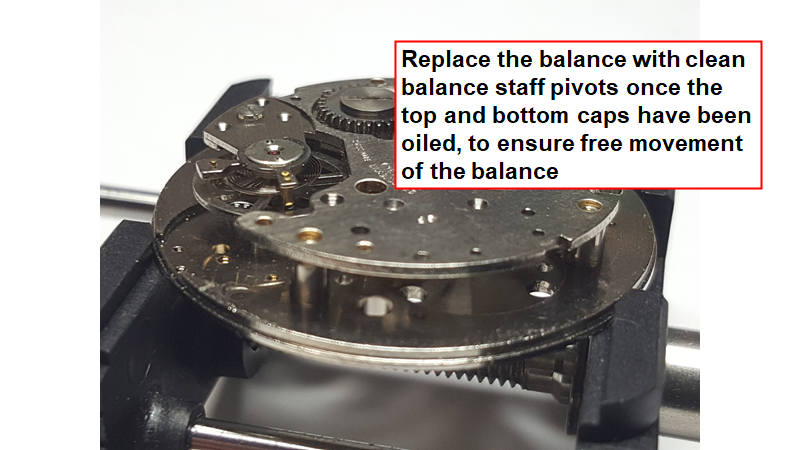

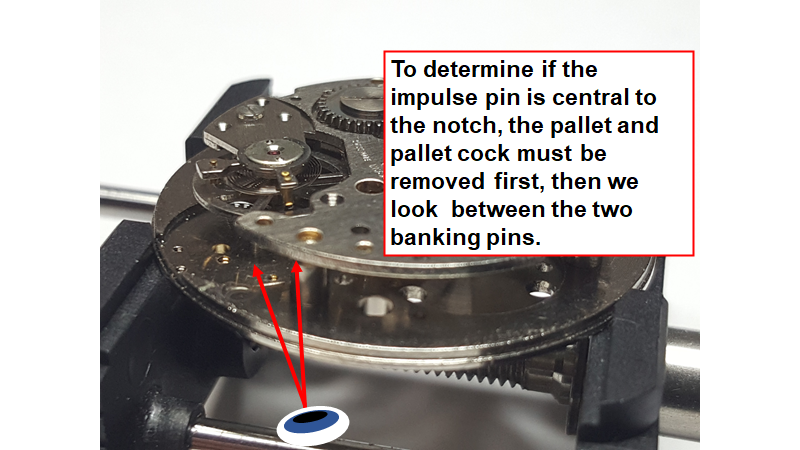

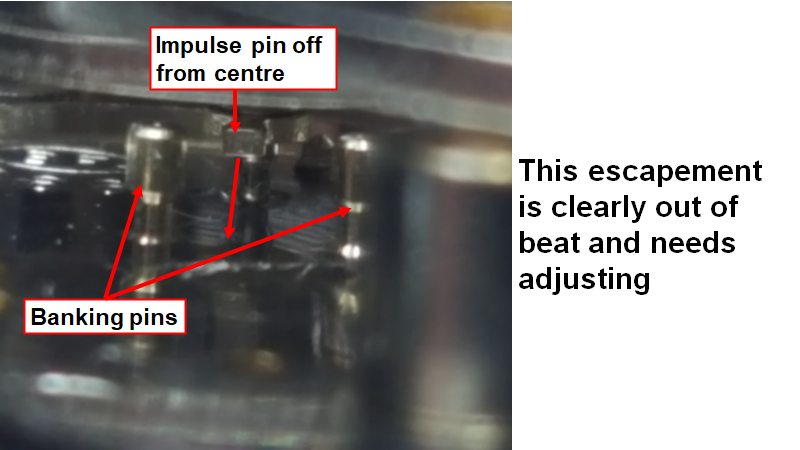

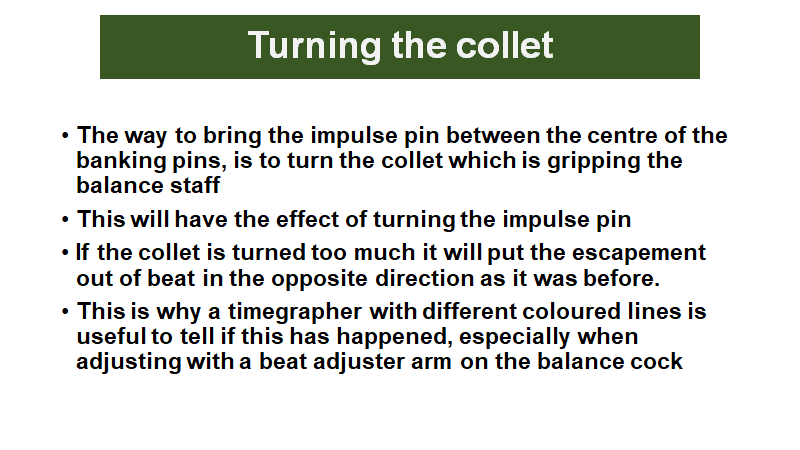

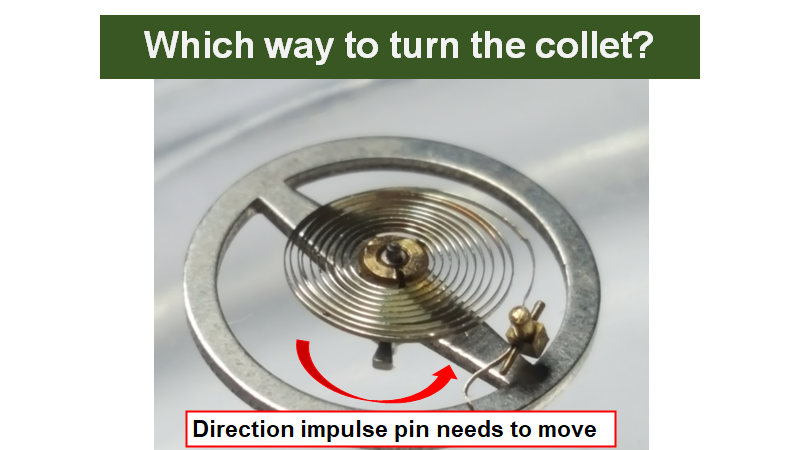

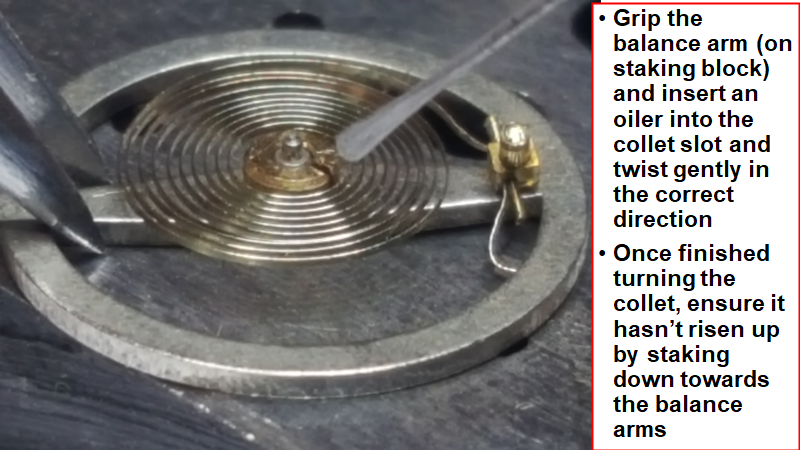

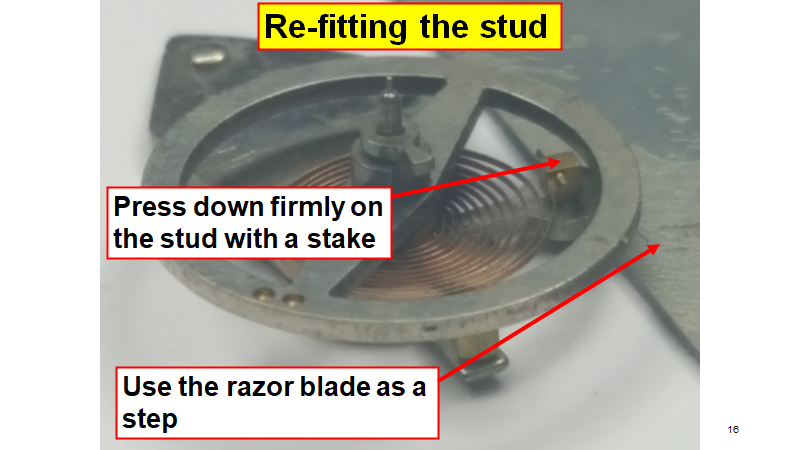

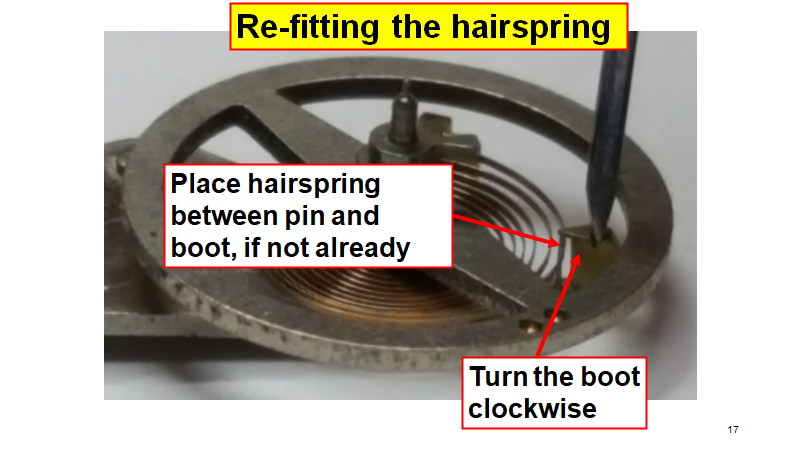

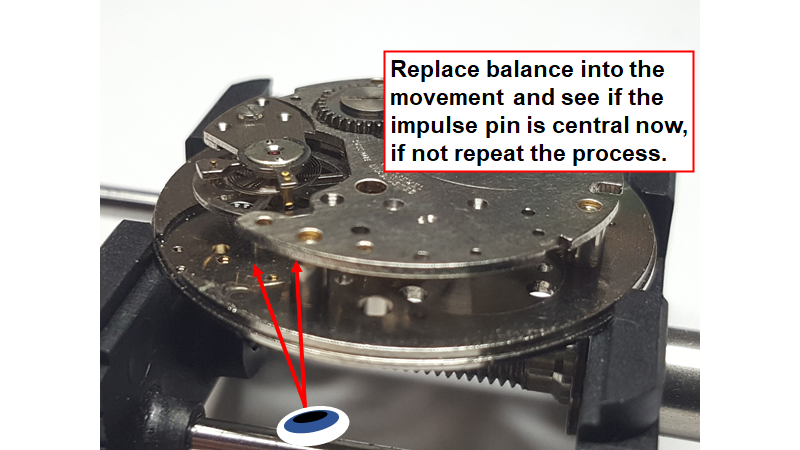

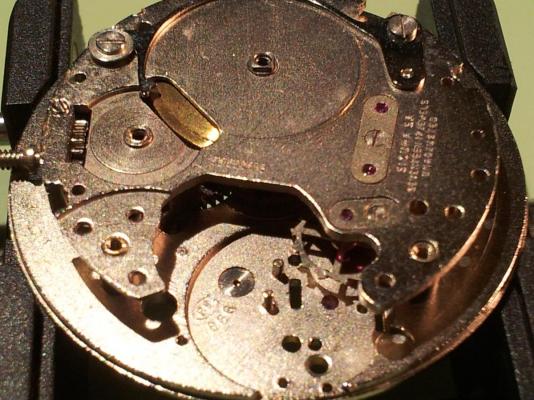

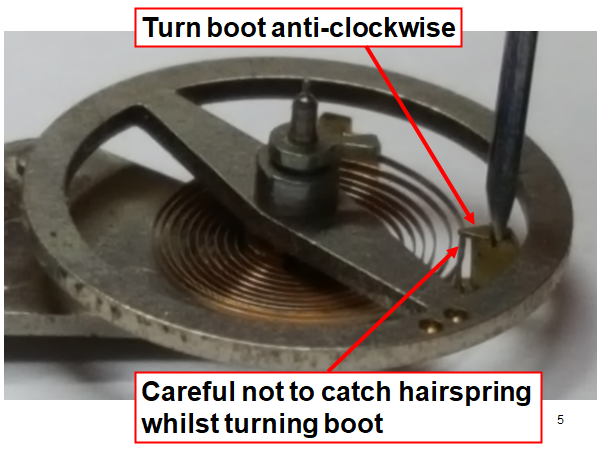

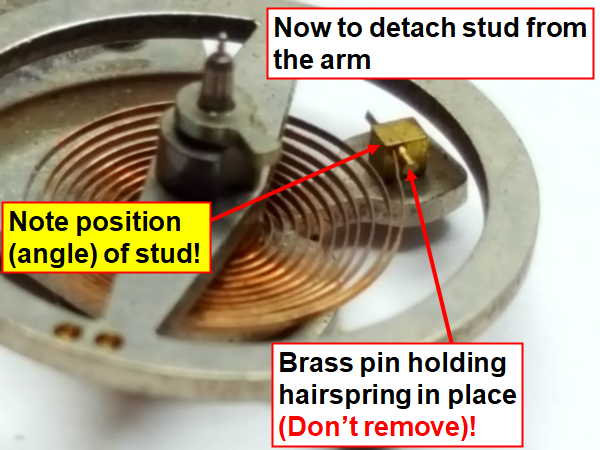

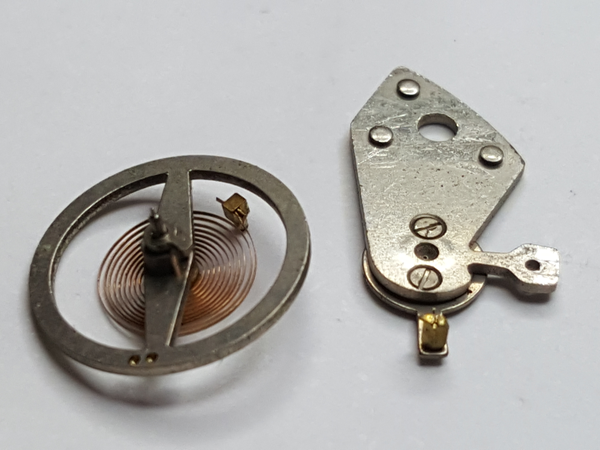

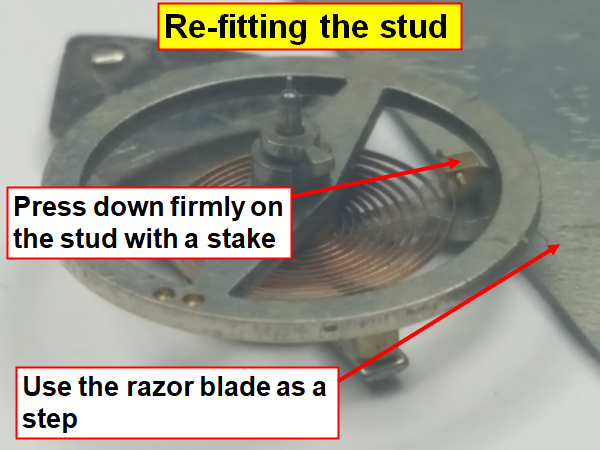

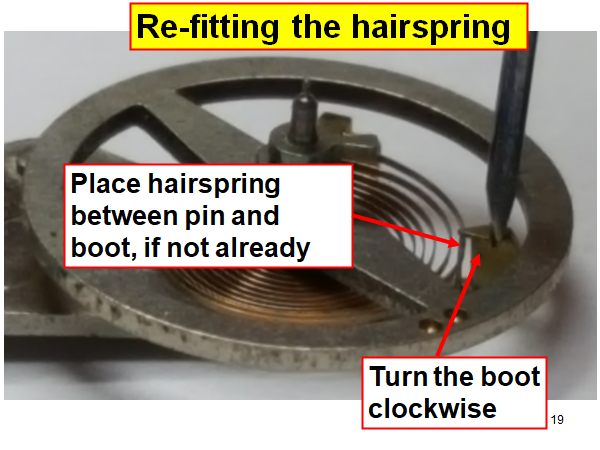

Hi, This is the third instalment on the Baumgartner BFG 866. I wanted to show how to bring the watch into beat On a previous walk-through of the BFG 866, I have described in detail how to remove the balance and hairspring to be able to oil the cap jewels As you look between the banking pins, the impulse pin is off to the left side slightly, putting the watch out of beat. The collet is turned in the opposite direction to the direction the impulse pin needs to move. So if in this case the impulse pin needs to move anti-clockwise to get it perfectly between the two banking pins, then the collet needs to be twisted in a clockwise direction You can attempt to turn the collet whilst fixed to the balance cock, but there is a much greater risk of damaging components, especially the hairspring. This is the way I teach my students, as it gives them the skills and confidence to remove the hairspring and balance from the balance cock and while removed they can oil the cap jewels as I've shown in this other walk-through on the BFG 866. I've got two more walk-through's on the BFG 866 that I'll post on the subject of adjusting the friction fitted minute wheel that is on the barrel and removing/re-fitting the centre seconds wheel and oiling the movement...1 point

-

Hello and welcome to the forum down the rabbit hole we go enjoy the experience.1 point

-

Hello and welcome to the forum, If you are really keen to follow the path, have a look at the site "watchFix.com " for the online courses set up and administered by Mark Lovick, these are online self paced and give you a good grounding in watch repair and diagnosis.1 point

-

1 point

-

I notice that the shield seems to align perfectly with the lugs. This leads me to believe that it is not a screw back (never seen a screw back that seated perfectly to align a logo--but it could happen). Are you sure that it is not a front-loader? I would first remove the crystal to see if it is a front-loader (please post a picture of the dial side). It would be obvious if it were because you would see at least some forward movement of the dial side outward from the case. EDIT--on second thought, since it is electronic, I seriously doubt it is a front-loader. If it is clear that it cannot be a front-loader, I would use a safety razor to slip between the (what appears to be) back...working around the circumference. Exercise caution and don't cut yourself.1 point

-

A common sense approach by John and what he says is well justified. Just the process of discussing of the problem and the advice given has been a lesson and some thing has been gleaned from it. You now understand the the mechanics of a watch and the diagnostic approach and the dificulties encountered in working with Vintage/Antique watches. I believe that is Johns forte as he works on them most of all. As a practice piece it is priceless. good luck and all the best.1 point

-

That chart is very interesting @JohnR725 in the respect that reading many posts on this forum you get the impression that an amplitude below about 270 degrees in the horizontal position (fully wound) should be considered a failure. I've serviced a few watches now since I started this hobby some five years ago. Very often I have found the amplitude to be somewhat below 270 degrees and I have always thought of that as a failure (which has been very disappointing at times). Still, many of those watches have proved to be excellent timekeepers despite not being able to reach an amplitude above 270 degrees. So, through practical experience, I have learned not to overestimate the importance of high amplitude. If you think that amplitude is all-important, you probably get tired of repairing and servicing watches pretty quickly.1 point

-

always nice with questions like this if you would give us pictures so we can see what you're seeing.1 point

-

if you assemble the mainspring barrel and rotate it does it stick up far enough to touch the barrel? Does it affect anything at all other than making for an interesting conversation piece? then are a lot of times with the watch companies especially the early watches they didn't come with the case. The cases were in one display in the store the movements for another they were assembled at the time. I don't suppose you have a serial number for the watch?1 point

-

@Neverenoughwatches, Hahahahaha - of course you have my permission to use any and all of my confabulated, archaic, obscure and otherwise (to me at least) neat-o terminology! g. -----1 point

-

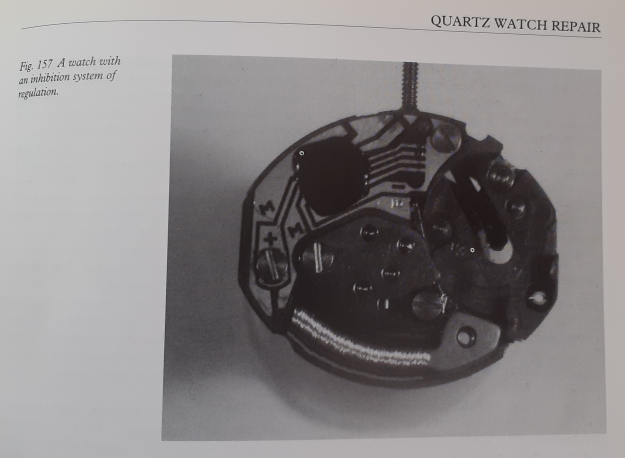

Hello Everyone, One of the more interesting sections of one of the books I am reading at the moment... ...is the section that discusses how manufacturers have to compensate for errors in the quartz oscillators they rely on to provide accurate timing signals to the rest of the quartz circuit. As almost every quartzophile (is that a word?) knows, the quartz crystal package is supposed to oscillate at 32,768 vibrations per second: https://en.wikipedia.org/wiki/Quartz_clock#:~:text=Most such quartz clock crystals,frequency of 32768 Hz. What's interesting (and what I didn't know, but made sense as soon as I read it) was the fact that this isn't always true, and a certain amount of compensation (or regulation) must be performed by the movement manufacturer, sometimes by by cutting certain traces on the circuit board: After that, the rate of the crystal was then more or less assumed to be stable over time. But that's not true. Apparently, the timing of quartz crystals degrades over time according to a well-known equation (Arrhenius Equation). https://www.allaboutcircuits.com/technical-articles/using-the-arrhenius-equation-to-predict-aging-of-electronic-components/ I am now quite curious to know if dynamic compensation was implemented (perhaps using a second crystal) to help account for "drift" in the primary crystal. One could imagine very highly demanding timing environments requiring three crystals and some form of polling system to converge on an "agreed upon" rate of oscillation. Wow. Cool! I am very quickly finding quartz movements ultra, ultra nifty as I learn more about how they work. Revolutionary is not too strong a word. (Aside: One of our sister institutions, MIT at their Media Lab (the parallel to my Department at PolyU) has recently showcased a sculpture that attempts to make what's going on in a quartz movement more accessible to people. It's called "32,768 Times Per Second" and a small write-up appears on the MIT Media Lab website at: https://www.media.mit.edu/projects/32768-times-per-second). Sadly, I cannot find any photos of the installation g. ----1 point

-

I hold the basket with the parts in it in my hand. If the heat from the heat gun is cool enough for my hand, it's cool enough for the watch parts. The heat gun I have was originally purchased years ago for shrinking balsa wood model airplane covering material, but I'm sure similar is available today. If you happen to have access to an industrial one, it would work, just have to be carefull with the settings. Not the soldering station kind, this kind, my setup is below too.1 point

-

Hello Everyone, One can certainly see the appeal (and power) of the "Internet Catalog" in action when looking over Amazon or Alibaba. I myself recently benefited from the extremely powerful Amazon model - especially while buying a single generic item from quasi-anonymous sellers exclusively on the basis of price. Here's what happened. As an example of Watchmaking (can I even call it that?) low-hanging fruit, I determined that I would attempt to do a "Hydro Mod" on a Casio Marlin MDV-106B. This modification is a well-trodden path and I thought that even at this stage of my supposed development as a Watchmaker (can I even call myself that?) I would be able to perform this simple modification. I figured I'd: 1) Buy a Casio Marlin 2) Buy a sapphire crystal 3) Buy extremely low cTs oil 4) Buy a replacement rubber strap 5) Integrate all of the above in a video Problem was, the watch arrived with heavily damaged packaging, as I have documented on this forum: Naturally I complained (almost ZERO cost to me, so why not?). After some consideration, Amazon came back with a significant refund, making the watch even less expensive. In my case, Amazon acted as a Retailer, Logistics Provider and Insurer. They did not inhabit the role of Manufacturer, or even the (hated) Distributor. g. ----1 point

-

1 point

-

What ever happened, I don't think it happened from this side. The plating under the barrel isn't even scuffed. What does the other side look like? It might have been caused by Elgin themselves when they machined the pocket for the minute wheel on the other side. If that's true, I don't think it's very common. Shane1 point

-

Well, I can give you a concrete example from personal experience. I spent the last years of my career at a small US Midwest manufacturer. Speco, Inc. , which makes meat grinder plates and knives. Family business, 5th generation now operating the company, been around since the Chicago Stockyard days, about 100 years. Sells internationally, and has customers on every continent except Antarctica Speco uses the stocking distributor model. Only three inside sales people, including the company President. When I left revenue was about 10 million per year. Now, is the stocking distributor model now the most efficient way of doing things? Maybe 50 years ago, but I don't think so anymore. In fact, most of the distributors, except the largest, and this even includes some catalog houses, no longer actually stock products. It has become a drop ship model,with Speco doing the fulfillment. Way back when sales was very personal, it was about the relationships between the salesperson and the buyer. Not any longer. Speco's closest competitor in terms of product and market is Thomas Precision, and they use a completely different model. They have a direct sales force, and sell directly to the customer, and by all accounts are doing a gangbuster business. They are a much newer company than Speco, have have grown quite quickly in the past two decades. I don't know what their financials look like, but they are certainly able to compete with Speco in every market that both are in. If Speco has an advantage here, and perhaps one of the reasons that it is still in business, is that it is not a financially driven business, being a private company. It just has to make enough money to keep the family happy. I tried to plant the suggestion that that instead of keeping the "stocking distributor" model that at least the company could move to a "factory representative" model, independent outside sales people based on commision, which is closer to current reality, but there was no stomach for change. Speco is somewhat trapped in a web of individually negotiated discounts with distributors that would be difficult to untangle, even if the result would be significantly more money flowing to Speco, and no price increase or service reduction to the customer. The principals are simply not interested in that kind of disruptive change. Speco's website was always built with the potential for direct to customer sales, but see above. It would take a commitment to an expansion of customer service, but not on any huge scale. Again, no one was ready to deal with the disruption that that would entail. In the past, manufacturer's often found that fulfillment and end customer service was too far away from their core competencies, and farmed those functions out to distributors. With modern logistics companies able to handle warehousing and fulfillment, and an internet based "catalog" within the reach of even the smallest concern, I don't think this is as true anymore. The only place where Speco's current setup is probably the best is in their international markets. There, barriers like distance, language, and culture mean that it can be advantageous to have "boots on the ground" that handle more than just sales, that are involved in logistics too. Even still, Speco's international distributors don't stock very much inventory, but they do provide an order consolidation service that reduces the cost of shipping. Significant inventories means significant risk of getting stuck with obsolete inventory as customers change equipment. So, as I said, there are roles for people to grease the wheels, but only in certain circumstances. Mostly in international business, not so much in domestic US business. From my personal experience, the state of most distribution networks is driven mostly by history, personal relationships, and emotion. Not economic efficiency. Another example, the automotive semiconductor debacle. Rote implementation of the "just in time" model, cancelling orders, which meant that when the market roared back the capacity had been scooped up by other customers, which meant that auto manufacturers left huge piles of money on the table. A rational actor would not have done that. Sheer inertia and the inability to manage supply chain disruption. As inefficient as it gets. Cheers!1 point

-

1 point

-

A couple of youtubers have recommended a food dehydrator for drying parts.1 point

-

the only problem with the bestfit books are the only cover a specific time spanned and even over that time span they do not cover every single watch. I looked in a different book that goes back much farther and does have some stems like this one as in other words the lack of a stamp and I saw zero reference to this watch which is not unexpected there were a heck of a lot of watches of this type made that there is no identification for this means of the absolutely had to have a staff you have to take it out disassemble measure everything and we do a search to see if we can find a staff if you're really lucky we would find one. Or the likely we might find one that's close and with your lathe that typically people new to watch repair don't have because they become expensive with all the bits and pieces and they require skill set. But if you had the lathe you could either modify existing staff or just make a new one which would solve your problem. But if you still have pivots on that staff then we should find out what the problem really is as opposed to attempting to replace the staff with very likely a custom-made staff either you will spend the hundreds probably thousands of dollars to acquire the tools or you could send it out to have some a custom make staff which is definitely not justified for a watch of this quality unless this was some family heirloom where money is no object.1 point

-

Hello Bruno, I've recently got a Junghans working again. A 620. Mine was missing the stem and crown. Your best bet is likely ebay. That's where I got my new old stock stem from. The crown I salvaged from an old quartz watch. Fitted a treat. If your stem is serviceable you should be able to get crown fairly easily. Do you have any pictures? Good luck1 point

-

Ditto jdm's post, Timex are made now in the Phillipines and as far as I know there is very little technical information in the public domain.1 point

-

Just FYI, we have a dedicated section where it's considered polite for new members to introduce themselves.1 point

-

1 point

-

Hi Find attached the service/parts sheet for the BFG 866. It would be helpful if you could post some pictures of the watch indicating your problem, pictures accompanying any query are always a great help to members. thanks. 2529_BFG 866,866.31.7 (2).pdf1 point

-

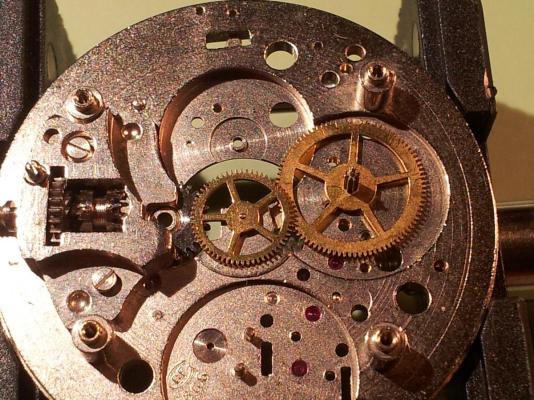

Hi friends, I could finally finished the elgin pocket watch. It took me many many days between sourcing the parts and working on the watch jjj. But it's finally done. I put a video together wrapping up the process. Here I'm posting the video and link. Thank you so much to every single one of you who tolerated me along the way. Without your advices I wouldn't have done it.1 point

-

Hi, this a short update about the hairspring experiment. I had the hairspring in naptha for more than 48hs. It did not remove the rust. Then, I placed it in coca-cola for about 12hs and it improved a little bit. Finally, I placed it in lemon juice for a couple hours and it began breaking the rust out of the spring. Now I have it in 99% isopropyl alcohol. Another question (sorry to bother you so much) Should the balance pivots be a little bit thinner than the hole jewel (ex. staff pivots .10 & hole jewel .11)? Or, should balance pivots be same as hole jewel (pivots .10 & hole jewel .10)? What would happen if the balance pivots are .1 thinner than hole jewel? Thank you guys.1 point

-

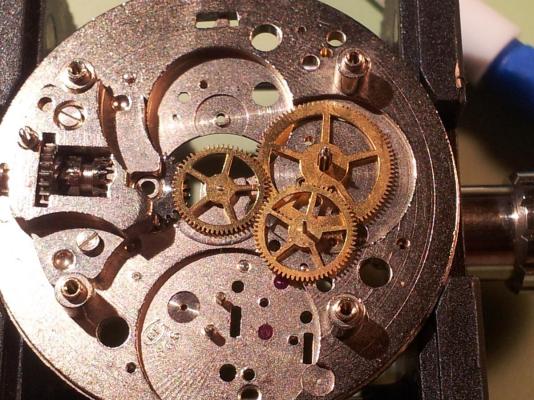

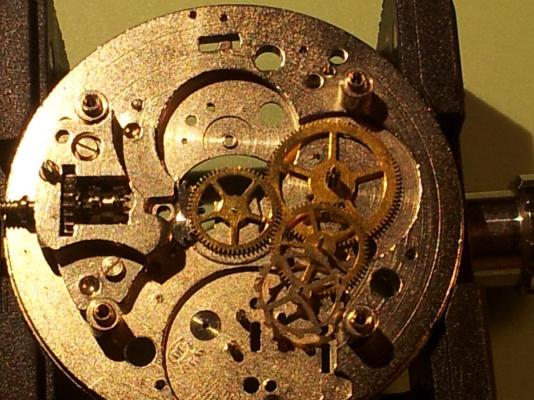

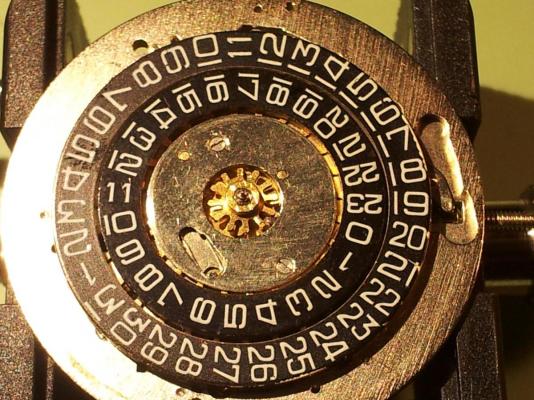

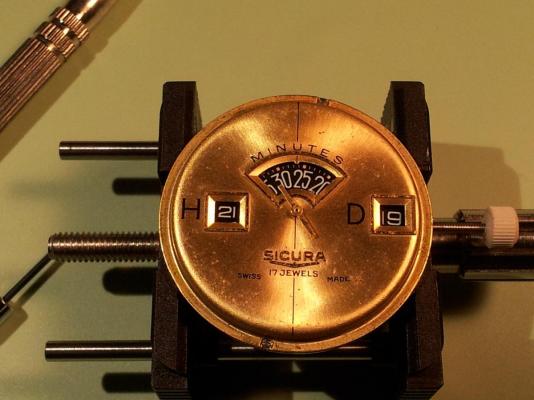

Hello my fellow horologica aficionados...I've had a long day as usual, but couldn't wait to get the hour/minute/seconds dials on the baumgartner 866 and finish putting it together. The result is better than I could have hoped. This is my very first movement I've ever torn down, cleaned and re-assembled! Everything came out great! The watch is working and keeping good time (so far) the hour minutes and seconds are all turing over as they should. It took 3 times putting in the dials in and then removing and adjusting them until I got the hour wheel to turn right on the mark (i.e. XX:00). I am going to start another movement right away! I have posted pictures and I again want to thank Mark for his excellent video and running commentary and insights as he did the work--I wouldn't have been able to do it without that specific video as my template guide.. I've watched the AS1900 overhaul about 10 times! Oh yeah, the case is being replated so stay tuned for a "what's on your wrist" post. P.S. I wanted to post a little video of the movement working but I haven't figured out how to do it yet. Regards, JC1 point

-

1 point

-

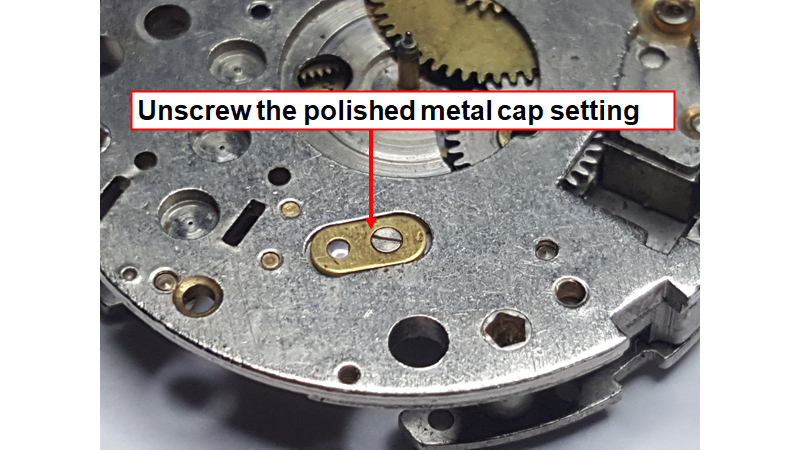

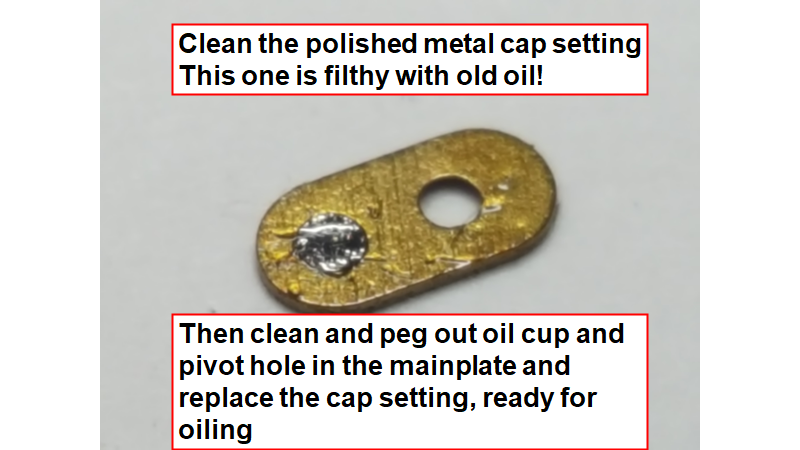

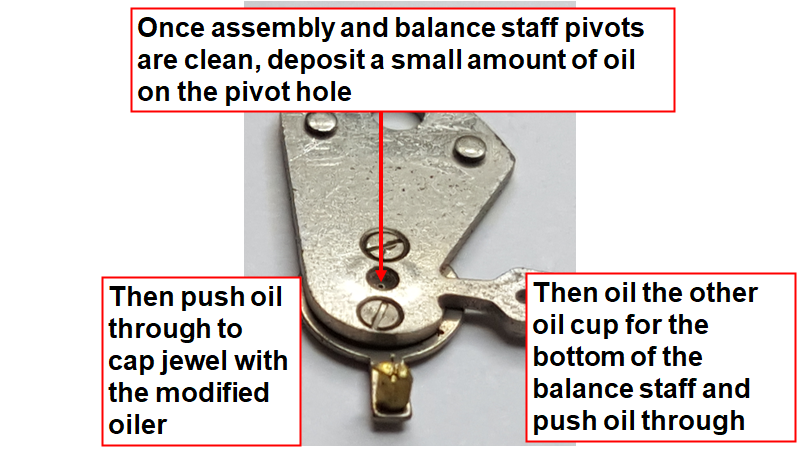

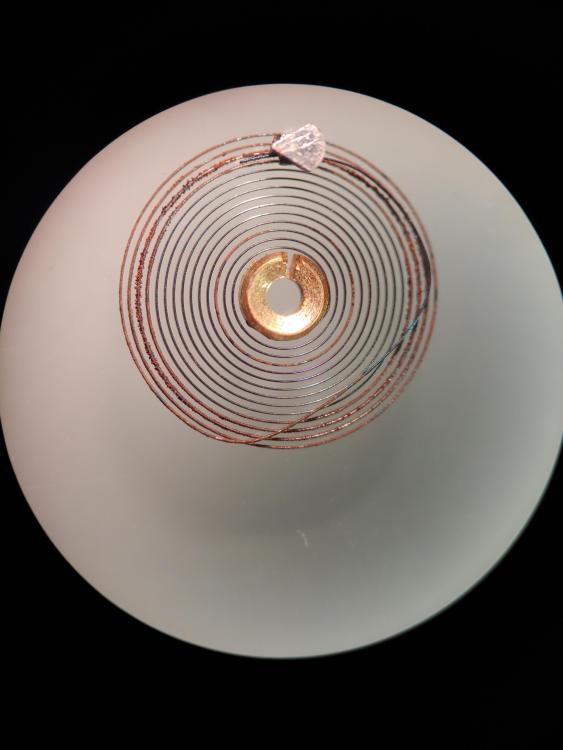

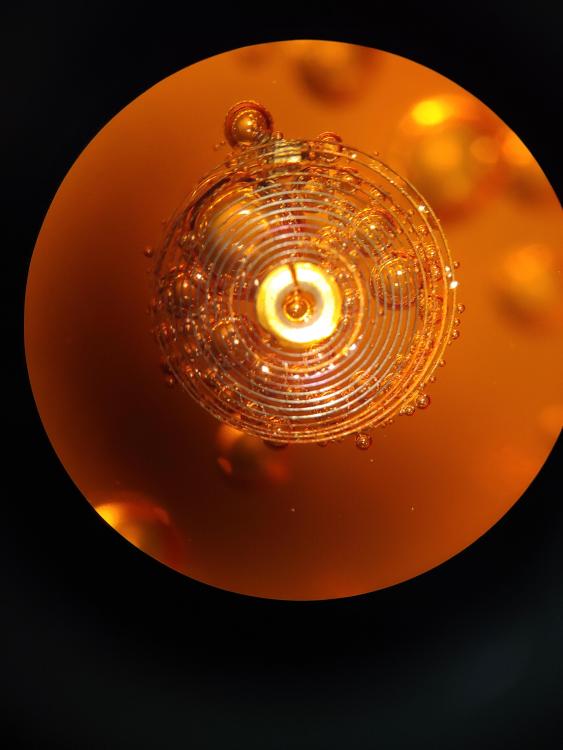

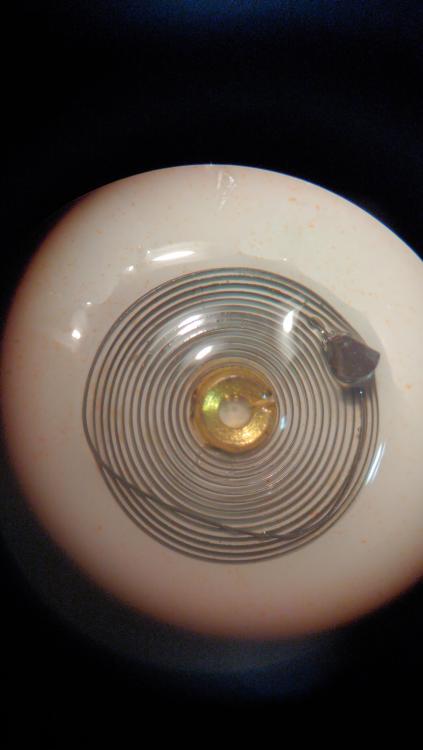

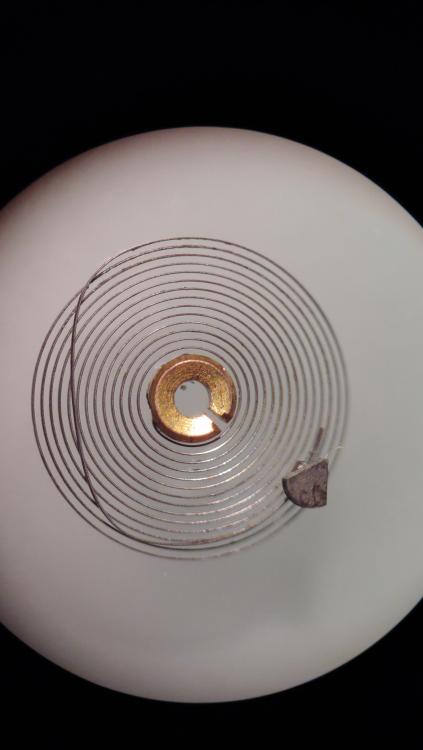

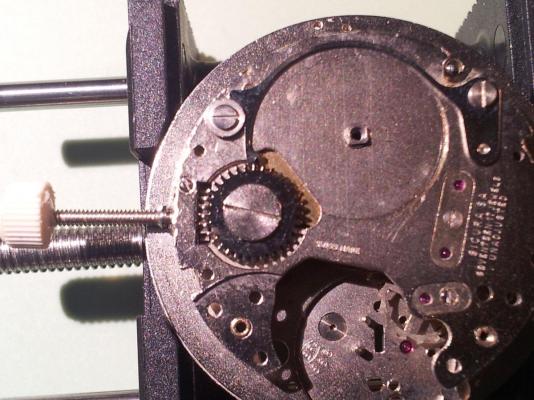

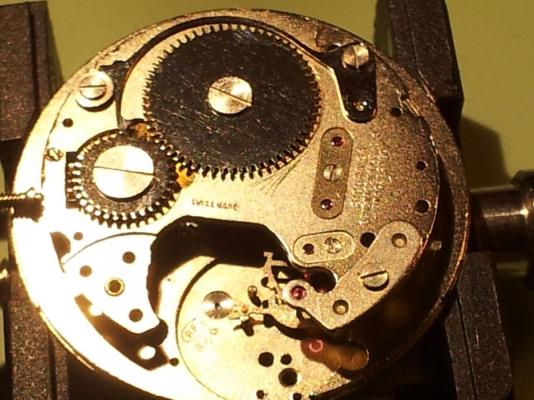

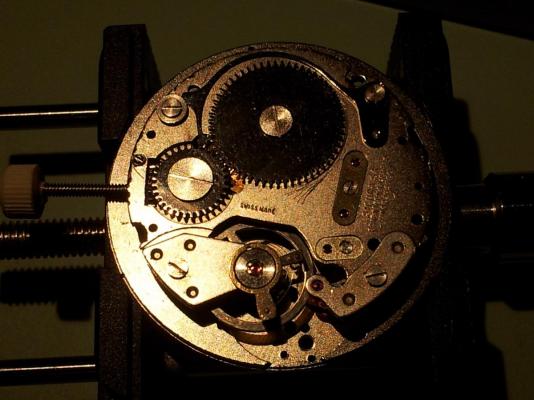

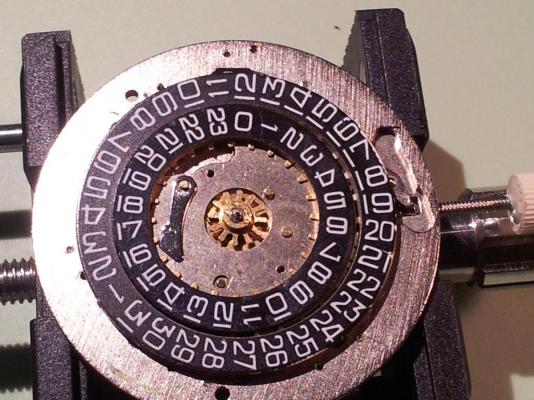

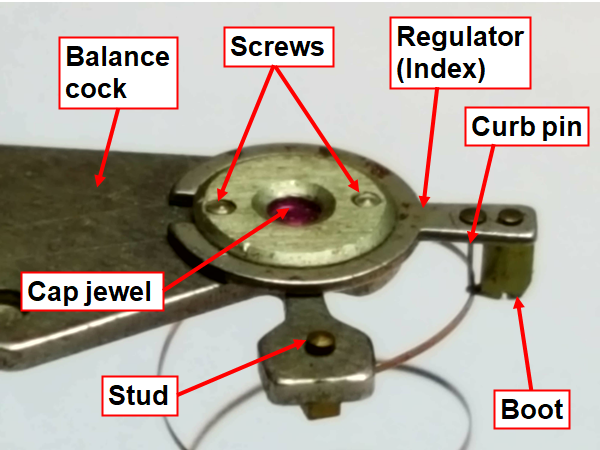

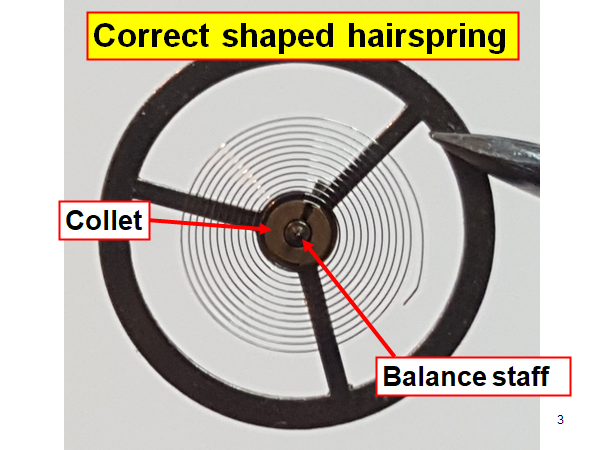

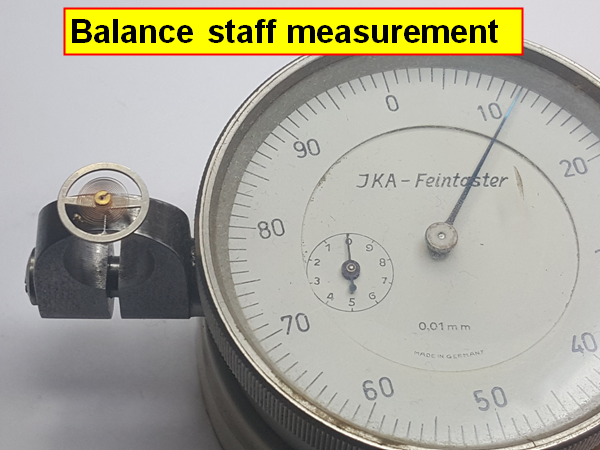

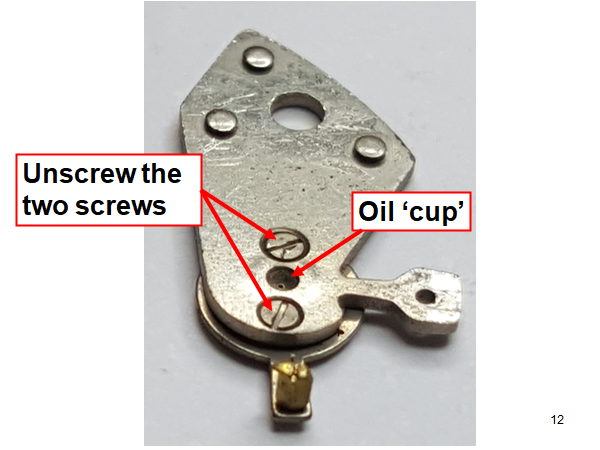

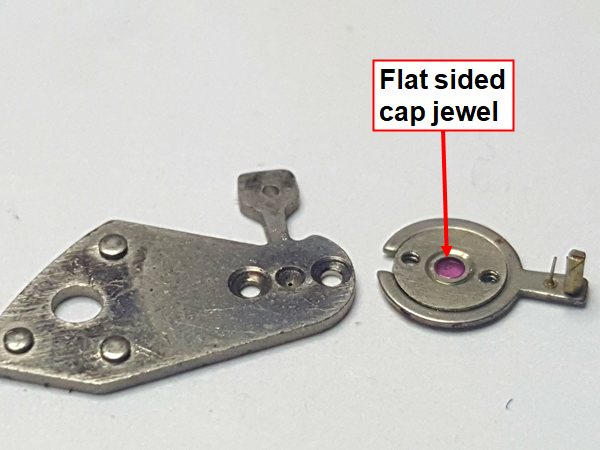

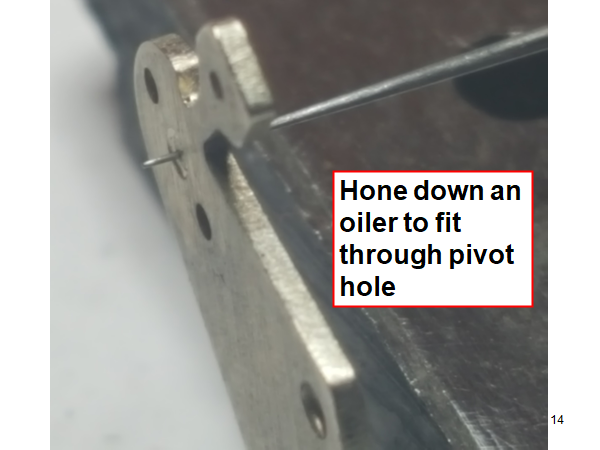

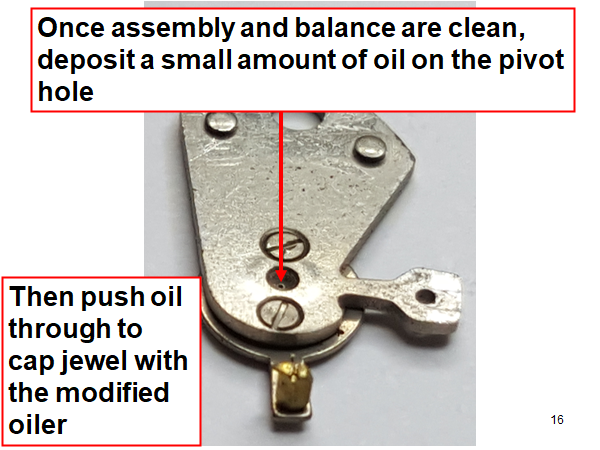

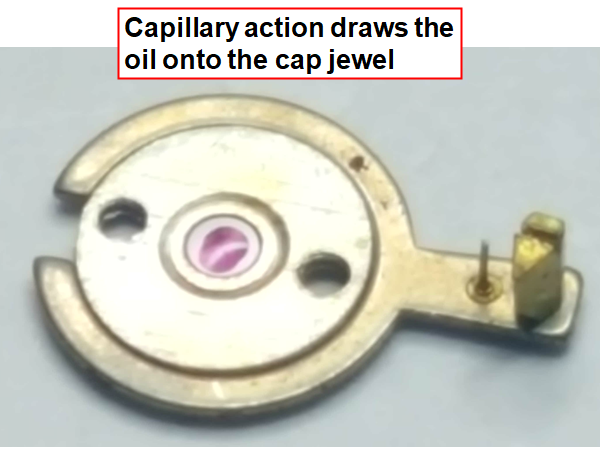

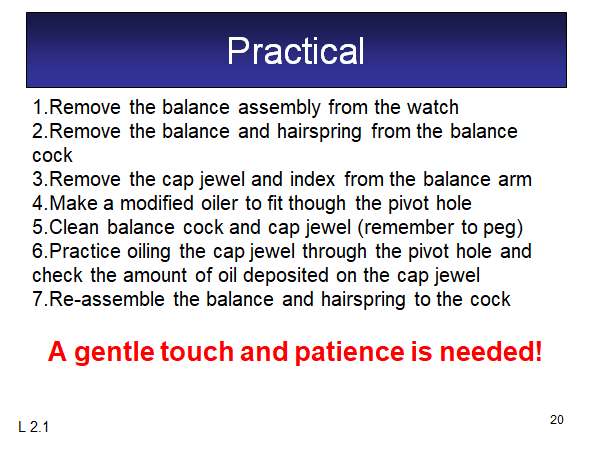

Hi All, I posted a while ago a walk through of the Baumgartner BFG 866 and wanted to add to it, especially as there is little out there to explain how to oil the cap jewels of a non shock proof watch. This is the balance cock of the BFG 866 and as you can see it has a cap jewel held in place with two screws, screwed from underneath. Some pull the hairspring out of the way to oil through the oil sink, but I find it safer to remove the hairspring, but also it is good practice to do so. If the balance and hairspring is removed the shape of the hairspring is seen a lot easier and any manipulation can be done. The hairspring may have to be taken off the balance if it isn't a simple tweak. Removing the balance from the cock is quite simple Measure the balance staff to find out how big it is, so when we make a tool to push the oil through to the cap jewel, we will know the correct size to make We need to unscrew the cap jewel to clean it Now we are going to hone an old oiler to fit through the hole in the oil sink that the balance staff pivot passes through Be careful not to damage the pivot hole Once the balance cock and setting has been cleaned thoroughly, we can then oil the cap jewel through the oil sink with Moebius 9010 If you are not sure you have oiled it enough, or your technique is correct, remove the cap jewel and have a look. Obviously before screwing back the cap jewel it will have to be cleaned properly again This is a safer way than oiling whilst the hairspring is attached to the balance cock. It may take a while longer, but it is a lot safer! It is also good practice in removing the balance and hairspring from the cock, but also checks the state of the hairspring, especially the uniformity of all the coils and how the hairspring is studded onto the collet The other cap jewel in the mainplate would be oiled in exactly the same fashion. Trying to oil the cap jewels and then fixing them onto the setting isn't a good way to oil them, as the oil will probably be smeared when re-fitting them. This is the way I teach my students to oil their non shockproof cap jewels I Hope this helps someone else in the future. More BFG 866 practicals to follow....1 point

-l1600.thumb.jpg.f6db738dabded7ab5213f881b67dceb7.jpg)

-l1600.thumb.jpg.718f957522bf4ce2513d10d11e0c47c4.jpg)

-l1600.thumb.jpg.76426bbc5d7adf426b3a642a1a1d0b61.jpg)