Leaderboard

Popular Content

Showing content with the highest reputation on 08/10/22 in all areas

-

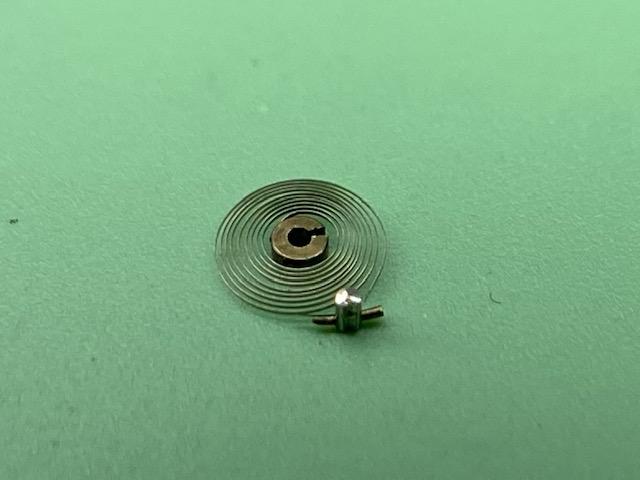

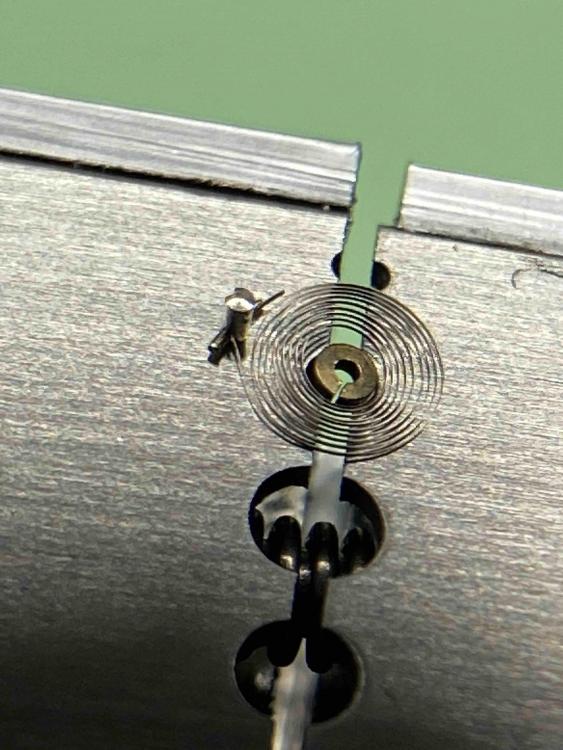

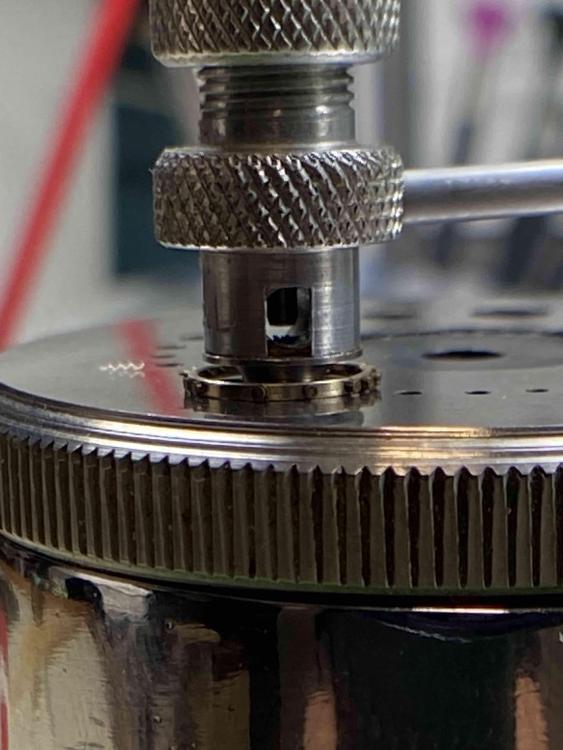

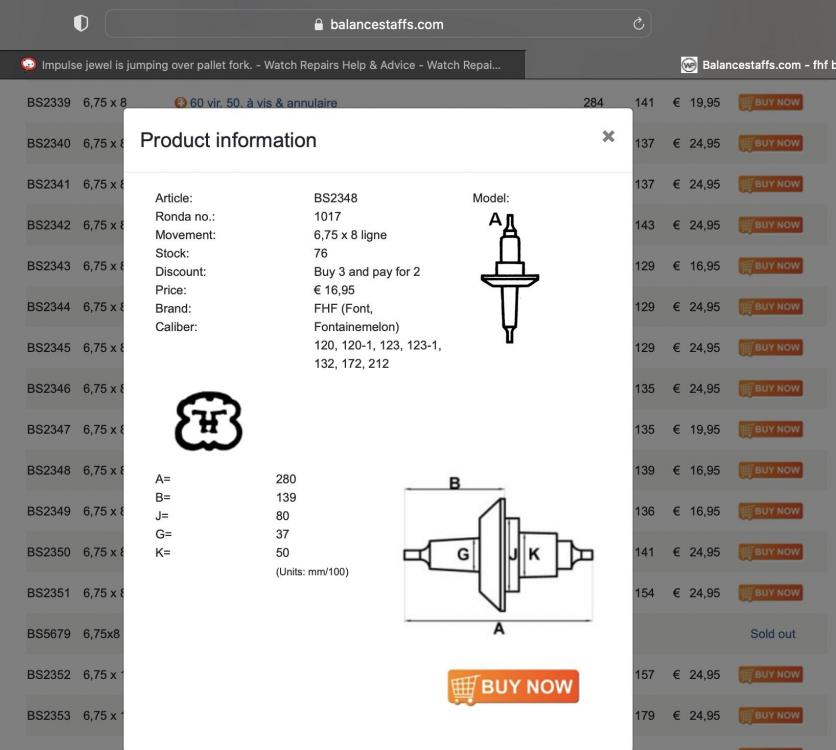

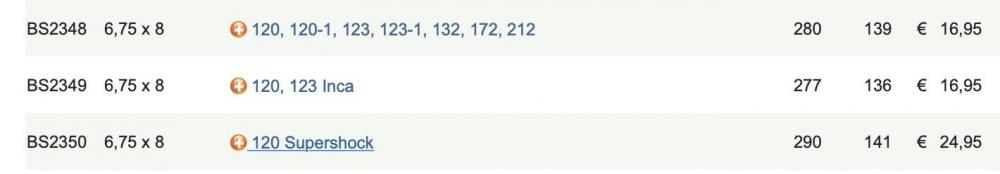

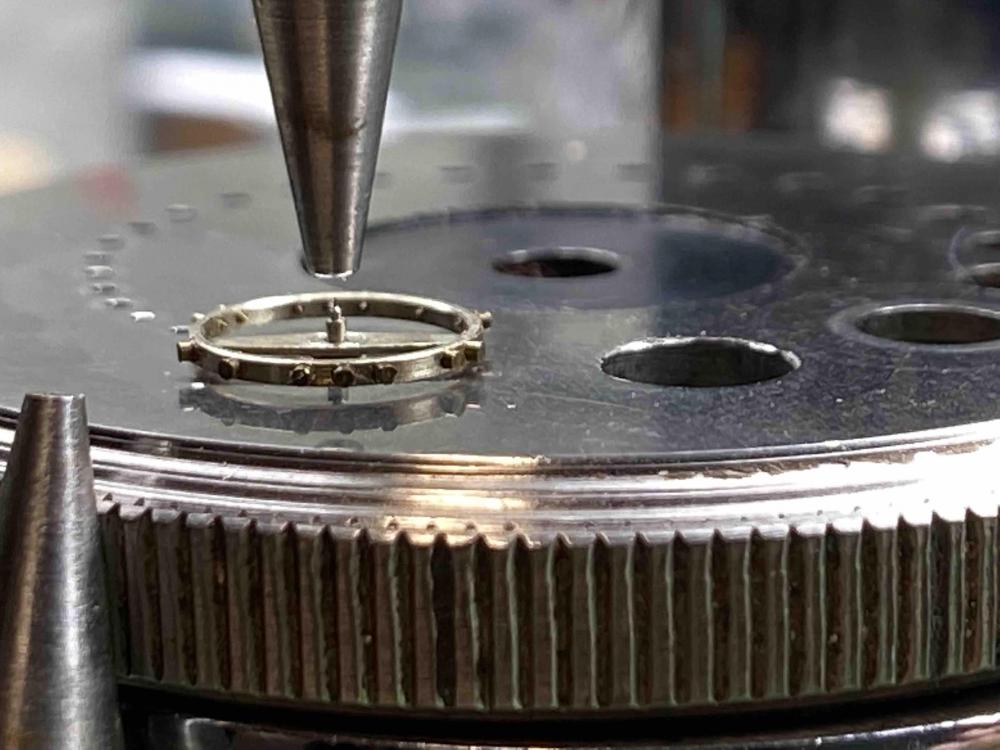

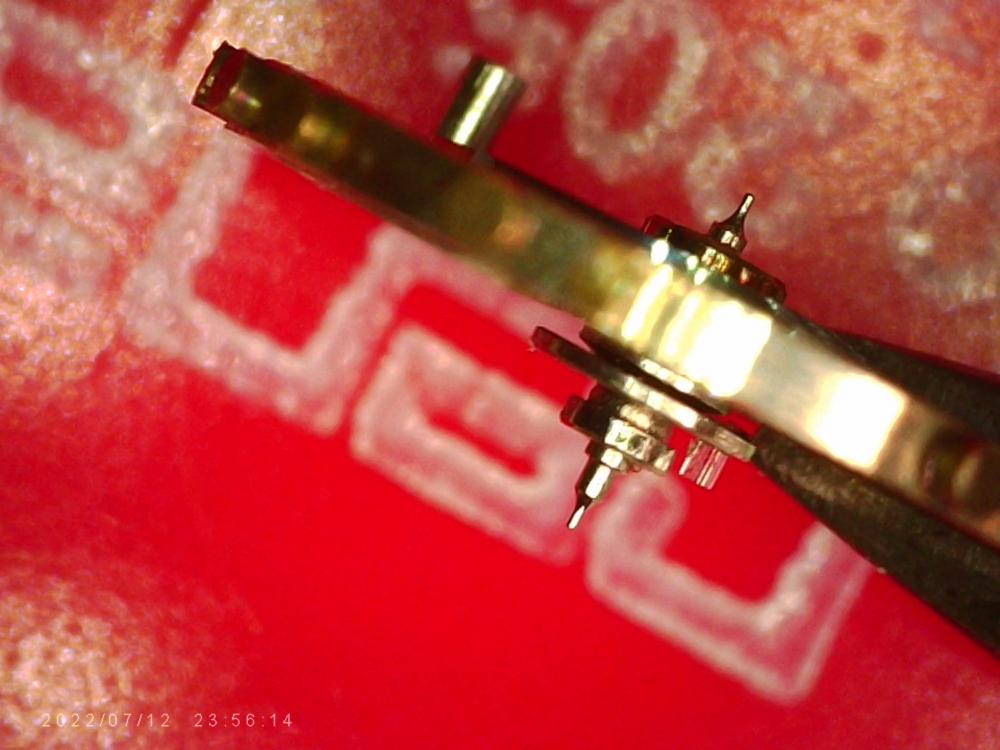

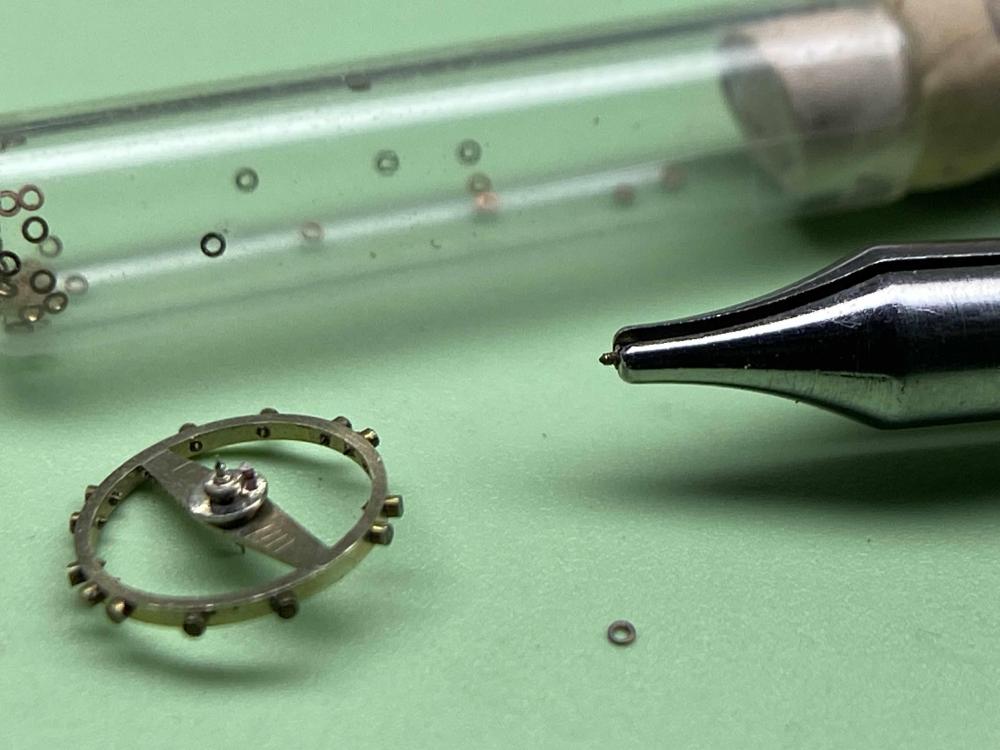

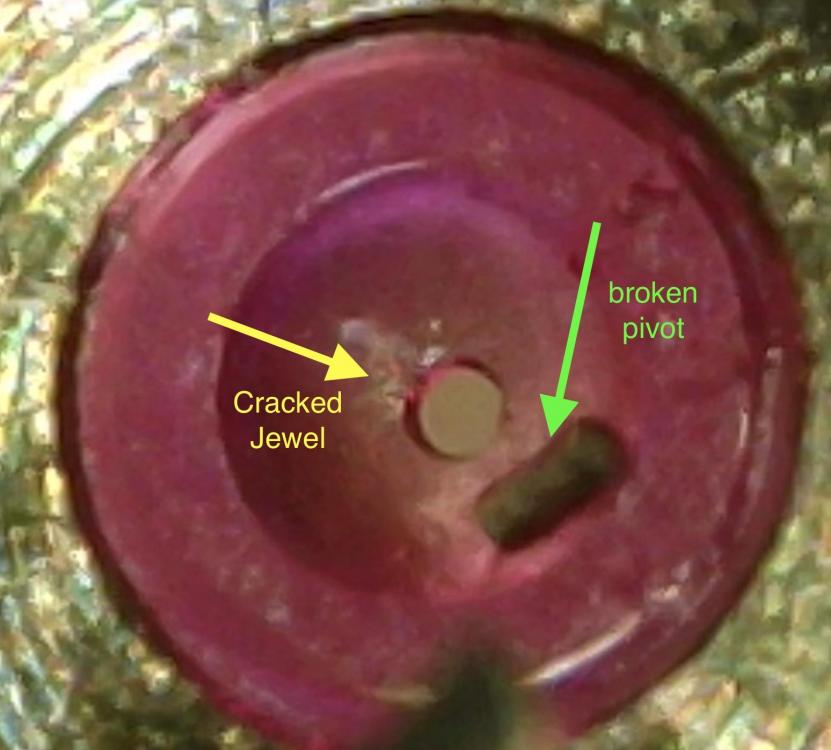

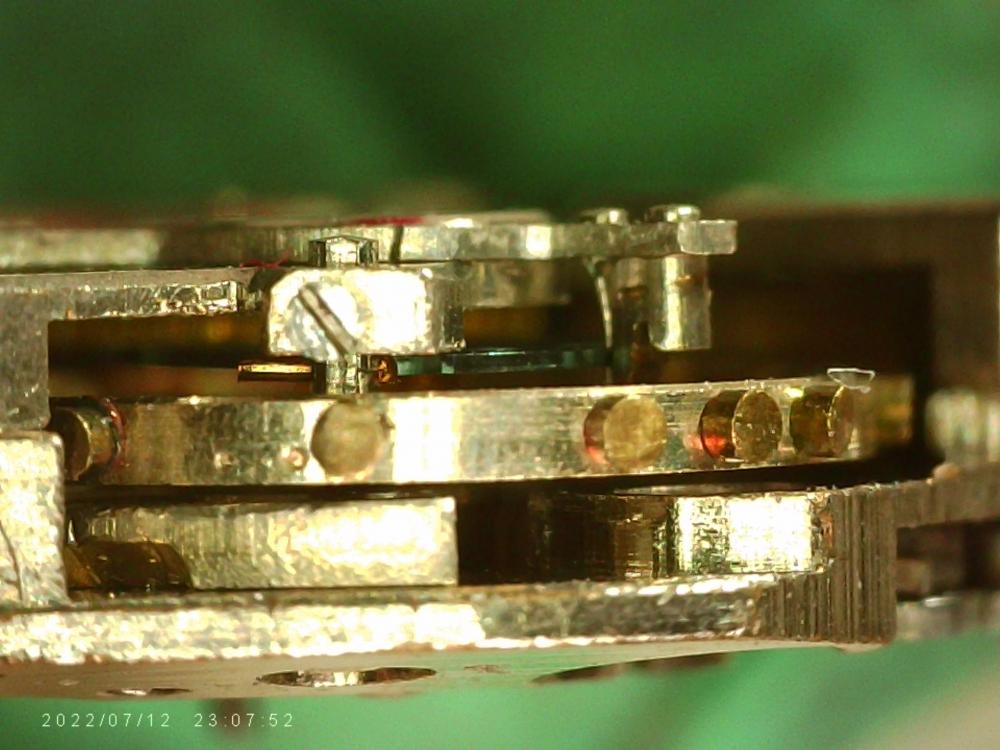

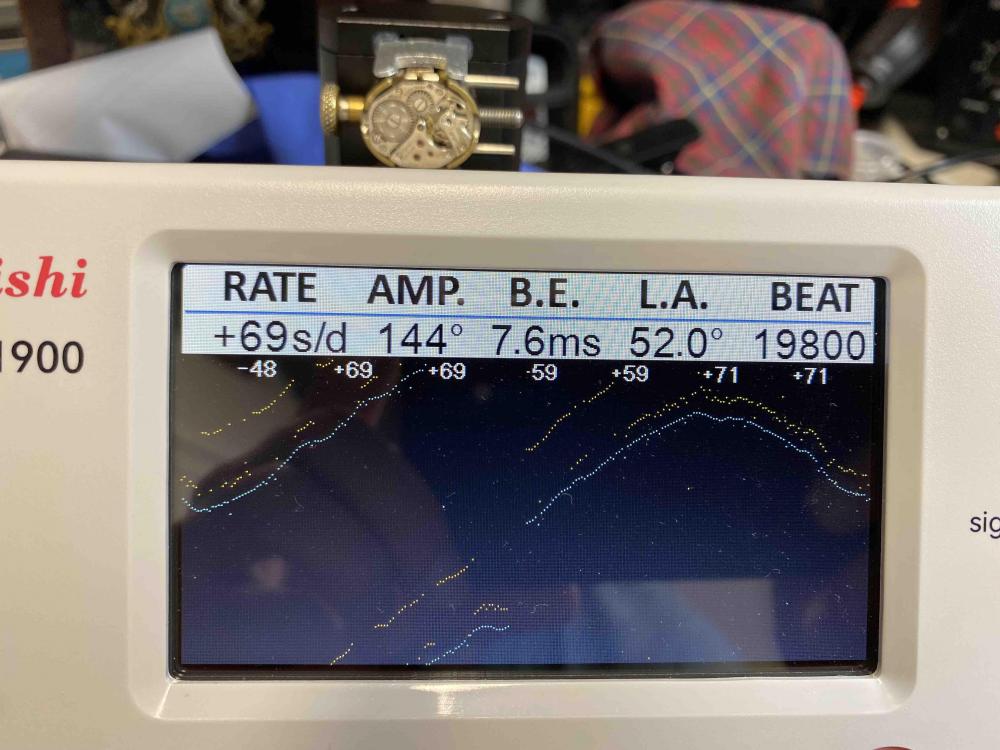

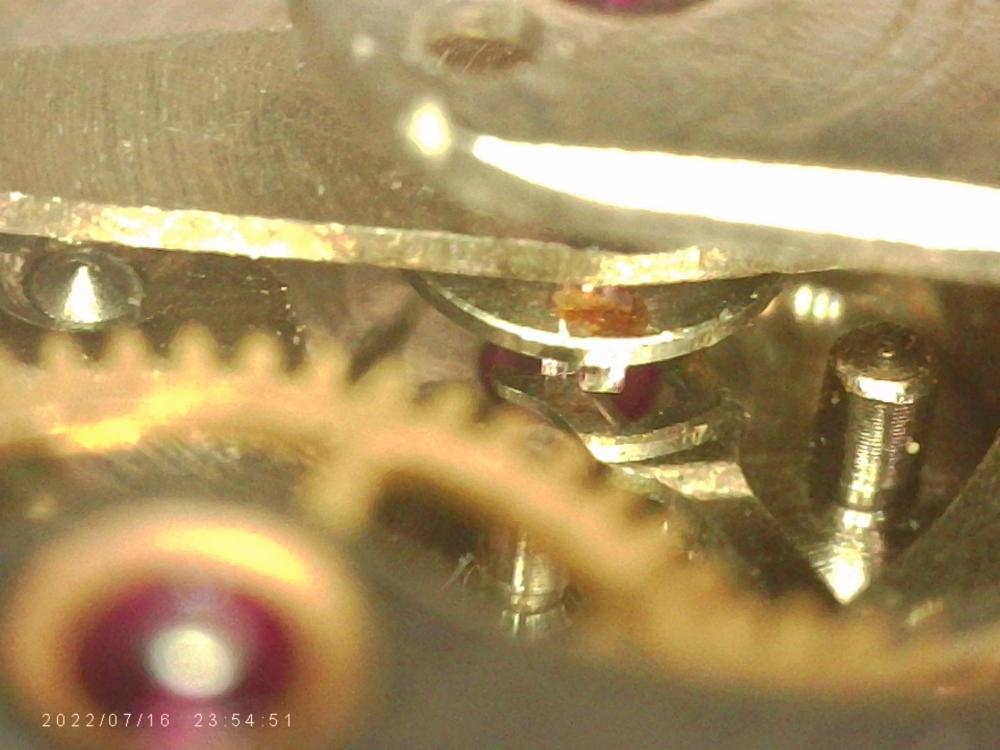

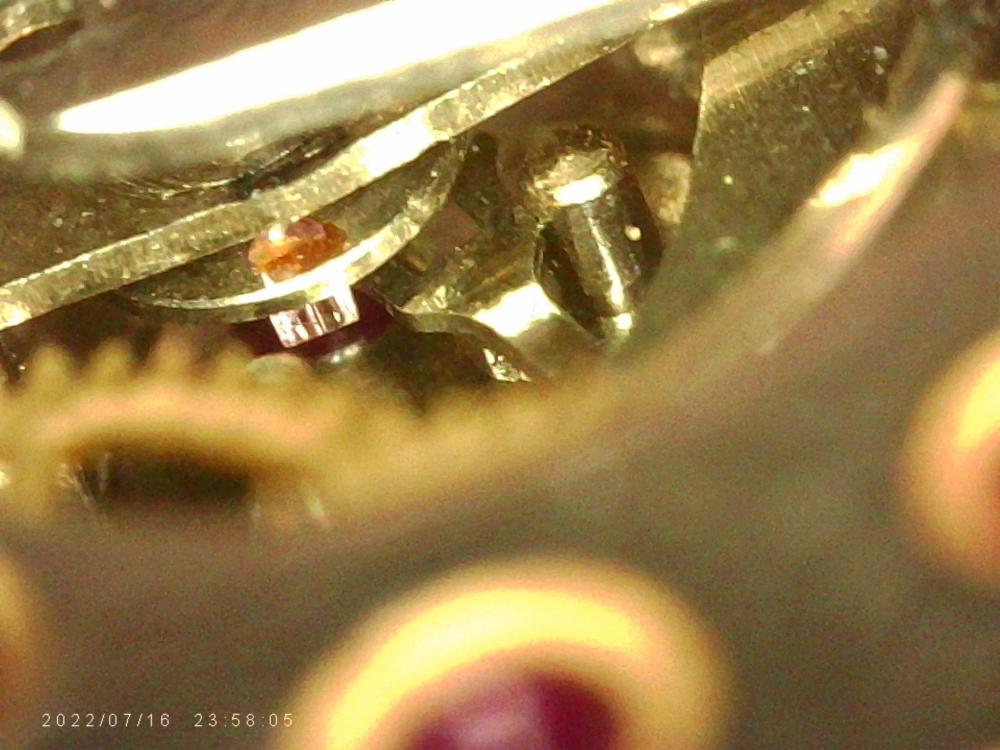

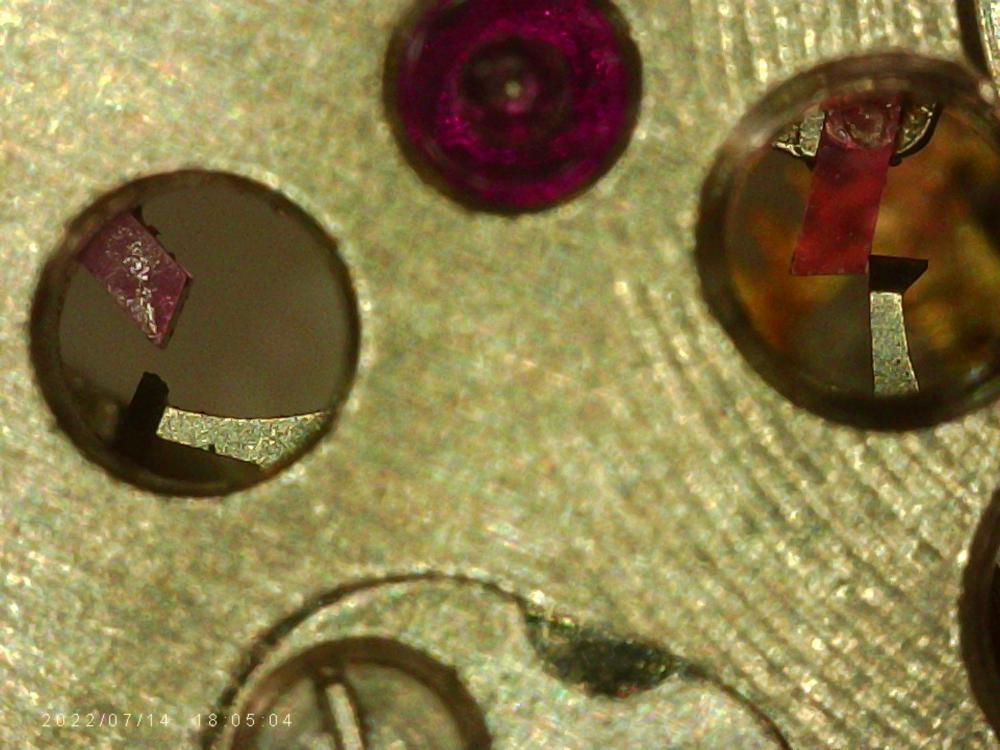

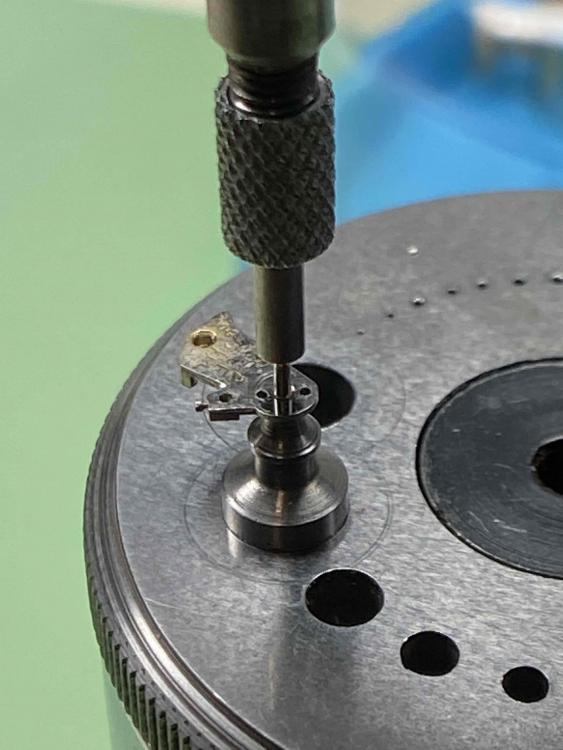

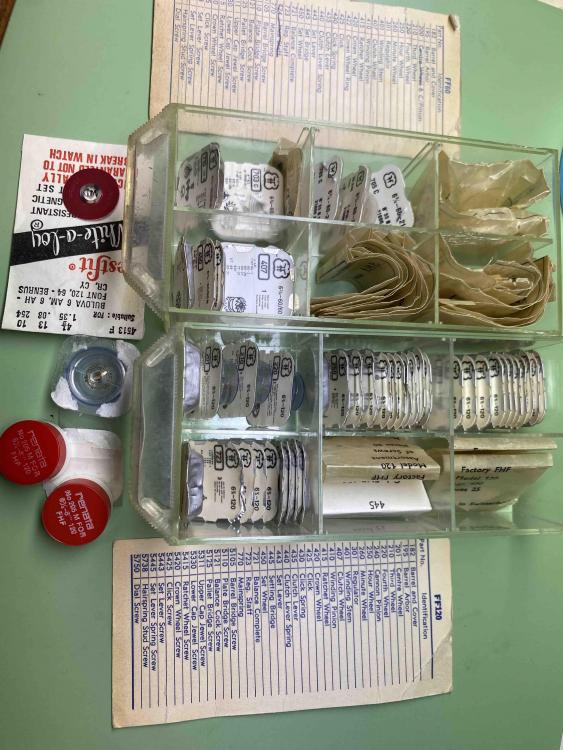

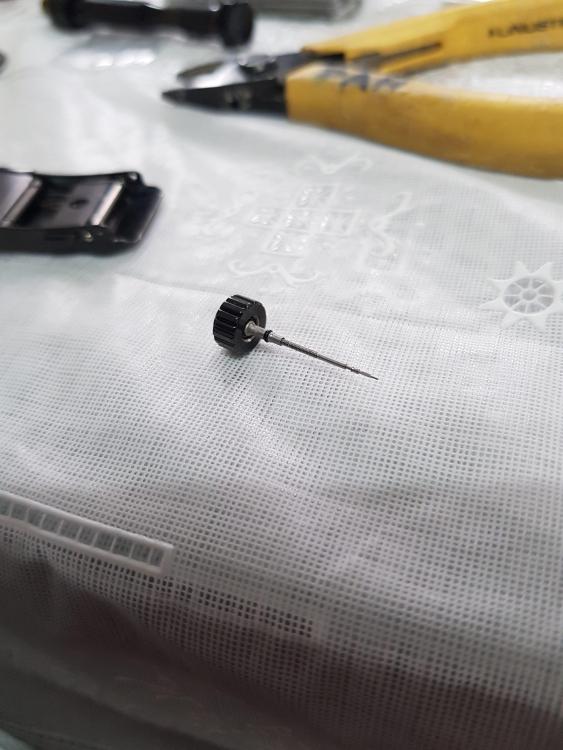

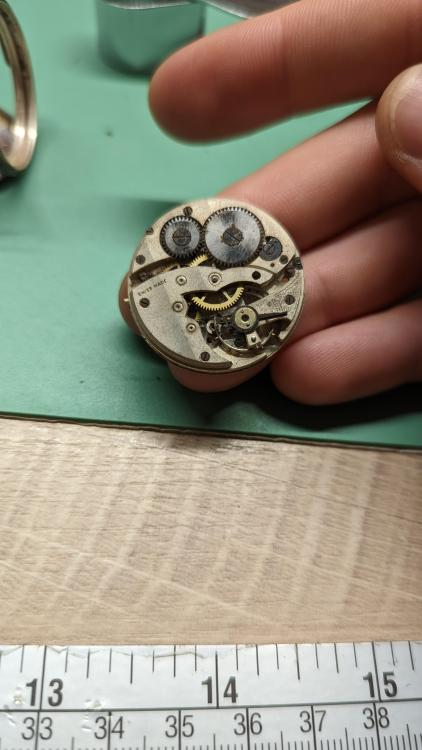

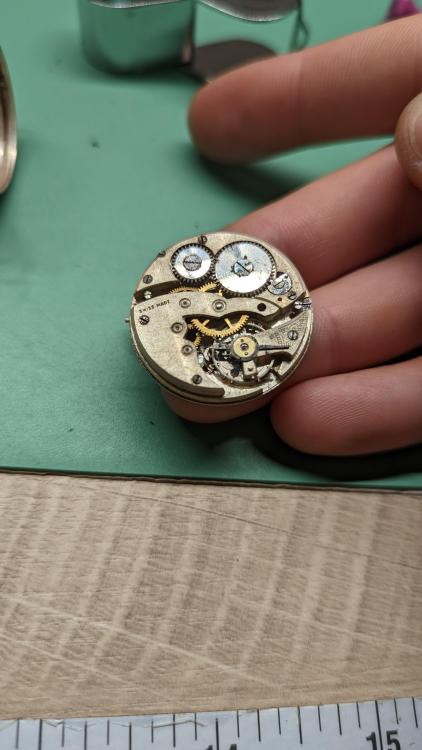

I was given a small ladies watch to repair that was not working, not even cased. No clues as to what the issue was, but as long as I could get it going again without sinking a bunch of money on parts it would be considered a success. I took the challenge. Man what was I thinking? Movement: FHF (FONT) 120, 17 Jewel Fontainemelon SA Type: Ladies, manual wind. Rate: 18,000 bph. plate size: 6.75 x 8 ligne Findings: Motion Works. Able to change time smoothly, hands have good clearance. Switching between winding and time setting is not clean. Setting Lever arm was broken off and wedged in wheel train. Prevented smooth flow of wheels so no power was coming form mainspring to escape wheel. No Case or crystal. Dial is scratched and dirty (will not be able to restore dial to original shape). Movement is scratched as well and has fibers and dirt throughout. Watch was very dirty and oil had solidified causing it to become abrasive. Mainspring holds power, but is old and may not be able to sustain same level of power and there is no power compensating bend. Arbor looks ok, scraping on barrel case, but due to prior repairs (not movement fault). Teeth look ok. Very old grease dried inside barrel, needed to be scrubbed to remove (not just placed in cleaning machine). Mainspring is old style (no reverse bend to allow for sustained power). Wheel Train: No power on escape wheel when pallet fork removed, even after winding a few turns. Loosened the train bridge and wheels started to turn again. Found the culprit under the watch movement as the end of the setting lever arm had been lodged in amoungst the wheels. Re attached bridge and good movement observed from wheel train when wound. End shake minimal (might want to adjust jewel depth on a couple wheels if performance issues experienced). Teeth all intact, pinions ok, and pivots not bent. Jewels pivot holes in wheel train appear good. Pallett Fork: guard pin and pallet jewels looks good. Banking pins not bent (part of plate). Does not spring fully to opposite banking pin when tapped on end. This turned out due to no power being transferred up wheel train. Fair amount of end shake, and good drop depth on entry and exit. Balance Complete: Balance wheel is old school with timing screws (inconsistent material removed on opposite sides of wheel may lend to poising issue) No Incabloc protection. Balance rotates for about 5 -10 seconds before it stops. Timing information: Unable to obtain accurate timing until endshake problem resolved. Amplitude low in some positions (new mainspring would help, and fixing jewel problem as well). Cracked lower balance jewel provides problems. Also showing signs that either one of the pallet fork jewels or impulse jewel needs to be adjusted. Repairs: Setting Lever Spring broken - replaced Mainspring - needs new spring for better amplitude Balance staff pivot broken - replaced Balance spring twisted and bent - fixed Balance spring collet to wide - need to be closed more for better fit Timing washer required to poise balance Double roller table - replaced Lower Balance jewel chipped - needs to be replaced jewels need to be adjusted to reduce end shake. All the parts disassembled prior to cleaning. The mainspring should be replaced as it is retaining its compressed shape so has lost power and does not have the reverse curve for sustained power. Mainspring cover was scratched, and had grease in the barrel that was one of the worst I have seen. Cleaned the barrel and cover manually before placing them in the ultrasonic. Broken setting lever spring and replacement. Ultrasonic cleaning machine. 5 minutes cleaning solution, spin off cleaner, then 4 minutes in rinse #1 and #2 (spinning off liquid between each jar). Followed by 5 minutes in the drying chamber. Pegged out the jewels in the main plate and bridges. Did the balance separately since it had issues (normally would screw it in place on the plate for cleaning). Ready to start addressing the problem parts and reassemble. Straightened bent hairspring. Removed stud, ran an oiler from the collet (center) to the stud location on the edge to remove the tangle. Made several bends to straighten the balance spring so flat, and so it had the right terminal curve, even gaps all around. Balance staff pivot was broken as well. Luckily had one in stock, so you can see the replacement staff in the background. Balance spring stud is in pin vise, and stud pin is sitting next to balance spring in preparation for re-attachement. Threaded the spring through the stud, then passed the very small tapered pin next to lock the stud to the balance spring. Still had to work on a the remaining bends after this picture was taken for the terminal curve and the slight bend before the stud. Lastly had to reduce collet opening since it would not firmly attach to the balance staff. Another problem found and resolved. Removing the double roller table using the 18R inverto staking tools. Positioned staking tool roller table remover and pivot punch. Placed the roller remover arm in the hole in the center of the staking tool base. Turning the knurled knob to gradually tighten the two blades of the remover so they were wedged between the bottom of the roller table and the balance arms. One VERY gentle tap and the double roller table removed, impulse jewel intact. Setting up the balance staff remover on the staking tool base, with the tip of the associated staff staking tool loaded and visible inside gap in tool. (dark square floating above the broken pivot head). The staff remover was tightened securely to prevent damage to the balance wheel. A couple more light taps and the balance staff passed through the balance wheel. Surface of wheel arms in good shape. There are three possible balance staffs to pick from that vary only in overall length A and distance B. The balance staff I used was 2.77 mm in length. (Could possibly try the 2.80 for less endshake) Attaching the new balance staff. Using the rounded tip staking tool with hole just large enough for pivot to enter in order to create the rivet ridge first. Then used the flot staking tool (seen to the left leaning against the base) to smooth over the ridged material created in the first step which secures the staff to the balance wheel. Not the slickest job, but this balance has a few miles on it. The staff is firmly attached (does not twist in setting) and the balance arms were not warped because of the operation. Truing the wheel in calipers after staking. It had a bit of a wobble, but after cinching up caliper ends over the pivots to protect them, and performing a few extremely gentle bends using my thumb, got the balance wheel true. It is a solid wheel and the round was not affected but verified was true in the round as well. Doesn't show up well in this picture, but there is an adjustable arm protruding out of the calipers next to the bottom right of the balance wheel. This arm has a parallel surface you are aligning with the edge of the balance wheel to indicate if the wheel is running truly flat for the whole circumference as you rotate the balance and check for level. Reattached double roller table using staking tool. Placed roller table over a hole in the die base that was big enough for the pivot, placed the balance staff (wheel attached) through the base of the roller table and tapped the roller table onto the staff. Appears to be level and pivots look perfect now. However, all is not well! When I reattached the roller table, either I did not notice it had a problem before, or I was guilty of tapping one time too many to get it seated in place. The top of the impulse jewel is below the safety roller table surface, which I did not immediately notice and which shows up later to be a problem for me. Next was poising the wheel. Gently pushed the balance wheel with a feather to get it to start rolling on the two ruby rails of the poising tool. It had a heavy spot on one side as it always stopped at the same spot when spinning it gently on the leveled ruby poising tool. Added a timing washer under the timing screw on the opposite side. Timing screw end is visible in the timing screw adjusting tool. After that the wheel seemed to stop at random spots from that point on, so I was lucky not to have a long session. Re-attached hairspring collet (pressed on using flat tips of tweezers). Found the old broken pivot wedged in the balance jewel oil well and removed it. The lower blalance jewel is chipped and needs to be replaced. The end cap (not shown) looked ok, no pitting. Balance wheel sits well dial down. Can see the new timing washer on the left most timing screw (it is clear of touching anything) and the screw head is not protruding far enough to touch the plate. Balance spring is sitting flat and in the regulator. There is a bit too much endshake in the balance though. I believe the balance jewels on the main plate may need to be moved in a bit. Fork end looks fine, along with the guard pin. Banking pins seem straight, not sure how to tell if they are 90 degrees perpendicular, but nothing obvious showing. (can still see the broken pivot in the jewel in the background) Wow is this timing ugly! Attempting to adjust timing is futile until the jewels are replaced and adjusted. Also believed there was an overbanking problem or with either the impulse jewel or one of the pallet fork jewels due to the staggered second timing line? Watch runs ok in dial down and vertical positions. As soon as it moves towards dial up the balance stops. The impulse jewel ends up on the wrong side of the pallet fork instead of being inside it. Somehow the impulse jewel is jumping over the guard forks. Initially I thought it was due to excessive endshake. Here is an example of when the impulse jewel is jumping out of the pallet fork horn and sitting on the pallet horn . When it finishes it’s movement, the impulse jewel pushes off on the horn sending it back to the other banking pin and the watch stops running since it is now overbanked. That is when NickelSilver informed me that the roller table appeared to be crushed (see the red background picture earlier), which explained the impulse jewel jumping over the pallet. So I needed to replace the roller table. Instead of tapping it in, I decided to use the jewel lever attachment to press it in gently. Watched closely to make sure not to press any further once the gap between the roller table and the balance wheel was closed. Once this was done, the overbanking issue was resolved and the watch would run in all positions. The pallet jewels appear to have a proper drop on either side of the pallet. The jewels appear to have decent surfaces, and I later removed the pallet and cleaned the excess moebius 9145 off the rather greasy looking pallet stones. So the very last step prior to demagnetizing the watch again and adjusting the beat and rate, will be to replace the cracked balance jewel. To replace the jeweI I will be using the K&D staking tool set with a hollow ended jewel pusher and stump. Just checking that the size of the pusher is ever so slighly smaller than the jewel, and the hole in the hollow stump is larger than the jewel. After the jewel is out, I will double check it’s diameter by using a jewel reamer to test the hole size (the new jewel will be a fraction larger than that reamer size). And take a depth reading off the micrometer on the staking tool prior to removing the old jewel so I can replace it at the same depth it was inserted to previously. (Note: These two example pictures had the balance bridge posing for me instead of the main plate to just illustrate the process I will do. When working on the plate I need to push the jewel in from the inside of the watch plate for the balance jewel. That wraps it up for this fix. It was satisfying to have all the little victories making it past each challenge presented and was a good experience. I still have to spend time adjusting the beat and rate and possibly the end shake, but the major work is complete. Cheers. Terry7 points

-

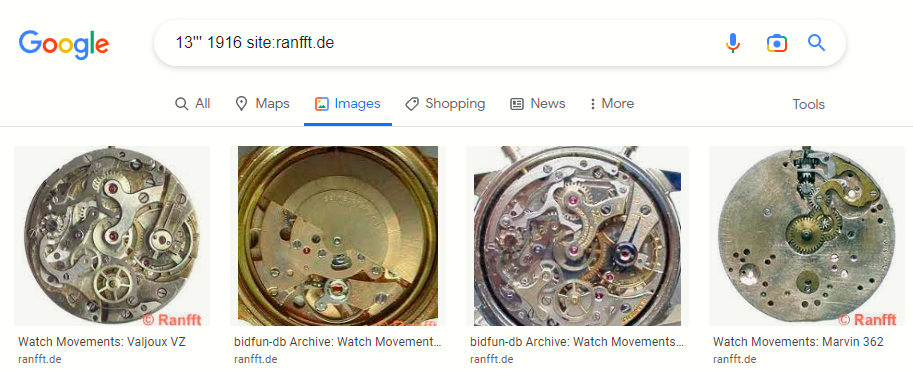

Hi @Neverenoughwatches Thank you for those kind words. Whilst I've mentioned Marvin, anything from that MSR group of companies is worth a look. I have a couple of Revue's, a Vertex and a Vulcain. All nice watches. As you say though the fashion for when these were popular was of the smaller size compared to what people prefer today. But fashions come and go and, probably like me, you like what you like and wear what you like. You've mentioned Longines and as a bit of trivia their 490 movement is the same as the Marvin 700 (but you'll pay a premium for the former). Now coming back to your question... ... there was actually a way that someone with no (Marvin in this case) knowledge and trying to find a needle in a haystack could have tracked this down. There was some very good information provided by the OP and having just sanity checked the method I'll explain below could have allowed the pinpoint. Let me try and explain! Those two pieces of information were 1914 and 13''' (in fact I think it should be a forum mandate that anyone wanting help identifying a movement has to include such size information and preferably a pic of the keyless works! ). You'll probably have noticed from any use of the ranfft.de site that it is good at providing the ligne size and usually an example of date of manufacture against movement details. So try this search in your browser bar... 13''' 1914 site:ranfft.de Note the three single quotes after the number for ligne size - this format needed for a match to how ranfft provides a size. This tells the browser to just search the site ranfft.de for any pages with those, in this example, two search terms. Clearly if there were other or different search terms these could be used. Now look at images returned (I'm using google and sometimes have to select the "see more anyway" option at the bottom of the page if there are more images returned than the paltry default google pulls back). In this case no matches. But don't despair as we know we should be looking at a reasonable year range for when the movement might have been used and thus be in the ranfft example. So change 1914 to 1915 and repeat. Mmm ... still nothing. But now change 1915 to 1916. Bingo!!! There's the fella - fourth image on the top row. Yippee!!! Hope the above makes sense! It can be a good way (watch movements or not) if trying to track or narrow something down you think is likely to be against a specific website.4 points

-

Hi clockboy, thank you for that very valid grounding comment, and I would normally agree with it. However, I have trays of spare FHF120 /60 parts on hand that may never be used so there were no out of pocket expenses in this instance. However, time was spent for the cost of experience. This was the first time I had done many of these repairs. I had to get into the frame of mind to analyze what was causing the problems and the logical steps of what to check first, and putting theory into practice. Next time I get a job that requires any of these tasks it will hopefully take me less time, and I will have a better understanding of what I should be charging for the repair. Thank you kindly for your feedback , I appreciate all comments.3 points

-

3 points

-

I have no idea what Omega is saying from above (I'm here!); does sound like they're suggesting oiling the fork pivots though. Not how I'd do it. As one source is saying 0.10, and OP is at 0.115, and getting rebanking there at full wind, I'd say the spring is too strong. Increases in thickness is like cubed regarding power increase- just going from 0.10 to 0.105 can give rebanking in a really top condition watch. But on a different track- some U.S. makers used flat tipped balance pivots. This brought the amplitudes of flat closer to vertical positions.* Gruen was made in Switzerland but assembled and hairspring counted in Cincinnati... I think they used "normal" rounded balance pivots but hoping John will jump in with more info. *and was an issue when using Swiss made aftermarket staffs with rounded pivot- they rebanked-- especially if coupled with the new "Whitalloy" or whatever mainspring. Which is another possible contributor- some modern springs have up to 15% more power for a given cross section compared to blue steel springs.3 points

-

My boards arrive today. I have the parts already. Maybe later today, I will post the assembled unit...stay tuned!!2 points

-

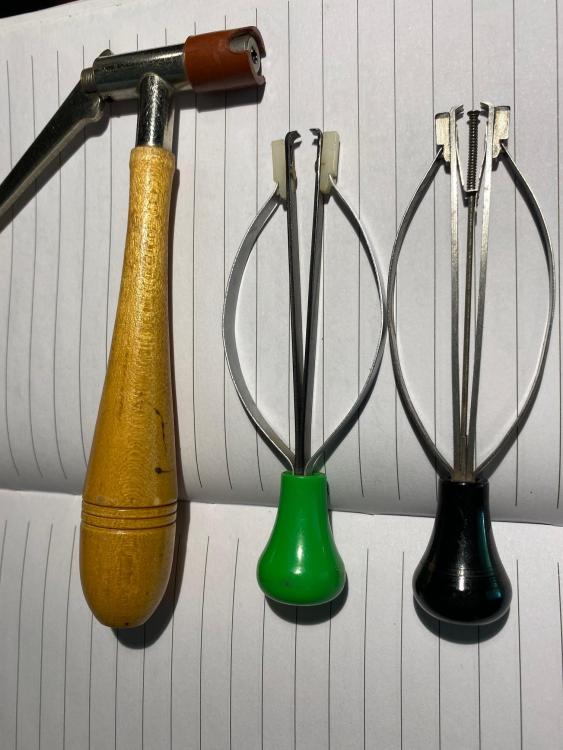

I use a vintage canon pin remover on the left first (usually works), but if not I switch to the presto which will do the trick otherwise. I am surprised, but at the same time not surprised that they appear to be out of stock everywhere. I am having trouble getting a proper clock mainspring winder. Vintage puller (left), presto puller (center), and presto hand puller ( far right). Interestingly the presto hand remover seems identical to the presto cannon pinion remover except for the plunger, but it is in stock. You could maybe buy one and try using it. If the spring plunger gets in the way, pull it off. If the gap in the pulling edge needs a bigger hole, use a file to make it a fraction bigger. As a final touch, paint the handle green2 points

-

I recently purchased a watch off eBay with broken stem I have cleaned and then dissolved stem in alum powder and replaced with new stem movement is e168 so stem not to hard to find hope you enjoy the pics Watch back with broken stem dissolving stem in alum powder mixed with water put this jam jar in pan of boiling water on cooker ring and 10 hours later over 2 days you get a crown minus stem if crown is stainless steel. Old stem and new stem next to nice clean crown and clean crown crown with new stem cut to length and tested the loctite thread seal used and seals put back . case back cleaned and seal lubed. The watch was cleaned in ultrasonic bath before reassembly. watch all back together happy happy hope you enjoyed1 point

-

Correct, dressing would remove the gold. In fact, using them removes the gold. I have replated them once or twice...just for fun. Polished? I guess. They are nice tips, but not sharp. Half of the cost for these was for the name...maybe more.1 point

-

5021.D is the caliber No, search the interweb for pdf and exploded view etc to see how all three stems are to be removed. Good luck1 point

-

Thanks Terry for your well illustrated sequence. One question: How long have you been working on watches? It appears that you're a pro.1 point

-

Can't recommend them yet, but I have a pair of Dumont 1AM brass tweezers on my wishlist. I have a pair of Erem AM brass, but the tip is a little too blunt for me, but I still use them quite a bit. My other goto tweezers are a pair of Asco P5 bronze tweezers, the tips work well but being a bit harder than brass they can scratch.1 point

-

I'm looking for help identifying the movement in this watch. Date letter (London) seems to date this case to 1914, sponsored by Stockwell & Co. I love these types of watches despite the value not being exceptionally high and would love to repair this. The issue is that the balance and hairspring are kaput along with at least the dial side of the balance jewel/cap jewel, as well as there being at least one screw missing (I know in photos that the hour wheel is missing, I took it off so as not to lose it). I figure the best way to go about it is to buy a replacement movement in better condition (and ideally a higher jewel count) and either swap it or scavenge the necessary parts from it. Issue is that I can't seem to identify the movement at all. I tried using my old Bestfit catalogs to try and identify the setting lever etc but can't match it up. It seems to be a 13L but that's as far as I've gotten. Any help would be greatly appreciated!1 point

-

Graham, looks like you have a leg up on a lot of us here if these are your only worries about watchmaking: But I worry a bit about the following: A) The cost of equipment B) The space requirements C) My fading visual acuity D) My fading mechanical ability E) My failing memory1 point

-

Thanks for all of the replys. First, I should point out that I'm a hobbyist with less then 1 year experience. For the first 4 months I worked on Elgin Grade 291 pocket watches to learn the basics and figure out what I needed to build a decent workshop. These past 3 months I've focused solely on 1950s vintage manual wind Bulovas, Gruens and a couple of odd Hamiltons, Wittnauers and Benrus thrown in for good measure. All of these movements (some with cases, most without) were in pretty rough shape and cost on average $25 or less on eBay. I got a couple to run pretty well, a couple that don't run so well (mostly low amplitude) and a bunch that have been put in to my "salvage for parts" drawer (usually I've fouled the hairspring or lost a microscopic part somewhere). No matter--I figure this will take me, along with on-line coursework, at least 2 years to get decent at. I look at each movement as a learning platform..the exercise with the Gruen 452ss has forced me to really focus on and understand mainsprings in a way that I had not up until now and to get a better understanding in practice seeing overbanking. Anyhow back to the Gruen 452ss...... I did try lubricating the pallet jewels with D5 (the only thick oil I have). Unfortunately it didn't help and if anything, caused the timing to worsen (actually the beat error went up some too). So I'm going to strip the movement again, reclean it, and have purchased a weaker mainspring. I'll report back later if/when I get it all put back together and re-timed (this time with pictures and in multiple positions). Again, thanks Levine981 point

-

That is really helpful watchmaker, similar to me you put time and effort into helping people, i spoil some of mine though with barmy banter sometimes . I will be spending the next few days testing myself with that information. I'm now waiting to bid on the Marvin skeleton watch i like. Coincedence that you mentioned you have Vertex, one of the WW2 Brithish army spec watches, another that i want to seek out. In fact any of the 12 DD brand i will look out for. If its a good enough maker for the British army to choose for their soldiers then they must be worth having.1 point

-

A good job done for sure. But the amount of time spent and parts spend makes it economically not viable..1 point

-

1 point

-

1 point

-

1 point

-

Cousins is out of stock at the moment. Supposed to get new batch in October.1 point

-

1 point

-

I think I may need to disagree about this being a cylinder escapement. 1) it has a roller "pin" (rather than a jewel) - cylinders do not have those. 2) the staff does not appear to be hollow, but simply has a cutaway portion. I think this is a pin lever with a bent staff, and the conical pivots are not great but could still be serviceable if burnished correctly. I'd be happy to be wrong about it, but I don't think it is a cylinder.1 point

-

Thank you VWatchie much appreciated sir I am sure I will need to refer to it. I have seen you on WUS in the past along with Roland. Best regards to you and have a great day, James.1 point

-

Those movements are very interesting, fun, and educational to get started with. Good luck! BTW, you might find this service walkthrough useful.1 point

-

Can we have pictures of the timing machine. Plus timing and more than one position like dial-up and dial down and then crown down as it's a wristwatch. Also when you wind it up wait about 15 minutes before you take the pictures. Also when the watches wound up what does it sound like? Then here's the mainspring information I found for the watch MS-610K MAINSPRING 1.50-.11-300 9 GR 41491 point

-

Something a little different today. An early quartz alarm ESA 926311 based "Claude Helier Paris" with a white enamel dial. I can't quite make my mind up about the case. It may be gold, as it has a stamp next to the crown, and the metal where scratched doesn't appear to be plated. I'm in two minds about this one, and I'm going to presume for the time being that it probably isn't gold, unless of course someone can prove otherwise. I didn't take the mechanism out of the case as it is fairly pristine, other than the scratches on the case from previous battery changes (not made by me I hasten to add). It came with a suede leather case, embossed with "Claude Hellier" and an apparently little worn, or unworn "genuine crocodile" strap.1 point

-

1 point

-

Hi watchmaker, i had an idea that you were familiar with Marvin to identify it so quickly. I do enjoy your knowledgeable help, you always give that bit more to learn from. You now have me looking at my next purchase, either a Hermetic or a lovely art deco skeleton . i love that styling of the 40s and 50s with great quality watches like Longines, Movado, Doxa, though the small cases can make you feel like you are wearing a ladies watch, sometimes luck throws up an oversize. From the ones I've been looking at i have noticed a company connection with Revue. Great history thank you watchmaker.1 point

-

1 point

-

I agree, the higher the Dennison number, the thinner the spring. Ranfft does give the spring thickness for the base movement 455SS as 0.10 mm, but there can be errors. I'm more inclined to believe the GR Database for mainsprings, and BestFit agrees with the thickness of 0.11 mm1 point

-

Hi @Neverenoughwatches I must admit to having a soft spot for Marvins and have several in my personal collection. Their movements have always appeared to be good quality ... and even a little quirky / original thinking like the 580 if you ever get a chance to work on one. Okay their absorption into Manufactures d'Horlogerie Suisses Réunies (MSR) meant they moved away from their own in-house movements but they have still always seemed good quality and using movements from the likes of ETA. Although clearly an older watch the stand-out here was that rather unusual setting lever spring (did I say "quirky"? ) .1 point

-

They thickness (strength) does a make difference for sure. However .5 is not a massive amount. It certainly seems it’s over banking. I presume there is no wear with the barrel or barrel bridge. My GR ref book shows a strength of .11 for the 452ss. By any chance have you the original spring if so measure the strength1 point

-

No one (apart from Seiko) suggests oiling pallet jewels, but it is an easy way to reduce amplitude. A bit of HP 1300 on one or both jewels. The Omega Workshop manual suggests : In most cases, knocking is detected in horizontal positions when the movement is completely wound, and when the amplitude is over the maximum amplitude tolerance levels: - 310° for self-winding watches - 325° for hand-winding watches How to eliminate knocking: If the knocking continues: Replace the lubrication on the bridle facing the dial (or the movement if the dial is already installed) with colourless Moebius SYNT-HP-1300 oil. This will reduce the amplitude by approximately 10-15°. If this operation is not sufficient, the bridle on the other side may be lubricated with colourless Moebius SYNT-HP-1300 oil. I'm not sure what is meant by "bridle", I guess the pallet jewels ? (unless it means the balance? - I've never tried HP1300 on the balance) (We need one of the "pro's" to help - if I mention @nickelsilver x3 he magically appears !)1 point

-

Almost - I hold it in my right hand, lower it on to the cannon pinion, then hold the collar with my left hand, and twist the barrel until it's tight. Then pull straight up, but I do that by resting my hand on the table and just using my fingers to pull up. On pocket watches I usually use heavy brass tweezers, and just hold the movement and try to lift straight up. I fit my thumb under the tweezers and and try to lift that way, rather than levering, which could bend things. Hard to describe, and probably not the best technique, but so far so good. I'm sure I'll end up with a Presto #2, but my tool budget is stretched a bit at the moment buying collets for my lathe. Darned expensive, even for used ones.1 point

-

Lol...coming up on my two~year mark...$15k investment! Crazy, no? By next year I will be ready to fix my Valjoux 726. not counting Summers working for my Dad.1 point

-

1 point

-

Watchmaker, how on earth did you find this ?1 point

-

Marvin 362 http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&a&2uswk&Marvin_3621 point

-

Very interesting article. I'll revise my cleaning procedure to include pegging the pallet fork and roller jewel. Thanks!1 point

-

Hi Graham look forward to the results and the site. I am sure a single source /one stop shop will be well received by all.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Great to hear you're still positive on the endeavor! I wonder that myself. Like you, I'm pretty good at taking them apart and cleaning... I was sure the Pobeda was going to be my first actual watch that I was going to successfully "service" in as much as it was working when I got it and it had a case and crystal (as opposed to just a movement). During re-assembly I noticed that I lost the screw that fastened the pallet bridge and tried to replace it with a scavenged screw from the job lot pile. Unfortunately the one I selected didn't quite work as it sits in the counter bore but also sits proud so it interferes with the balance. This has been pretty discouraging and I've let things sit for the last week. Another good question, Is my goal to scrounge around eBay looking for wondrous finds in the hopes of putting them back into running order? I rarely wear a watch these days. I was hoping to get the Pobeda purring, put a new strap on it and proudly wear the first of my labors. Now I'm not sure. I have a bunch of pieces that are worth working on and may proceed. I may also continue my search for a screw to replace the one that would properly hold the pallet bridge in place. But I may not. So, as the Magic 8 Ball says:1 point