Leaderboard

Popular Content

Showing content with the highest reputation on 08/02/22 in all areas

-

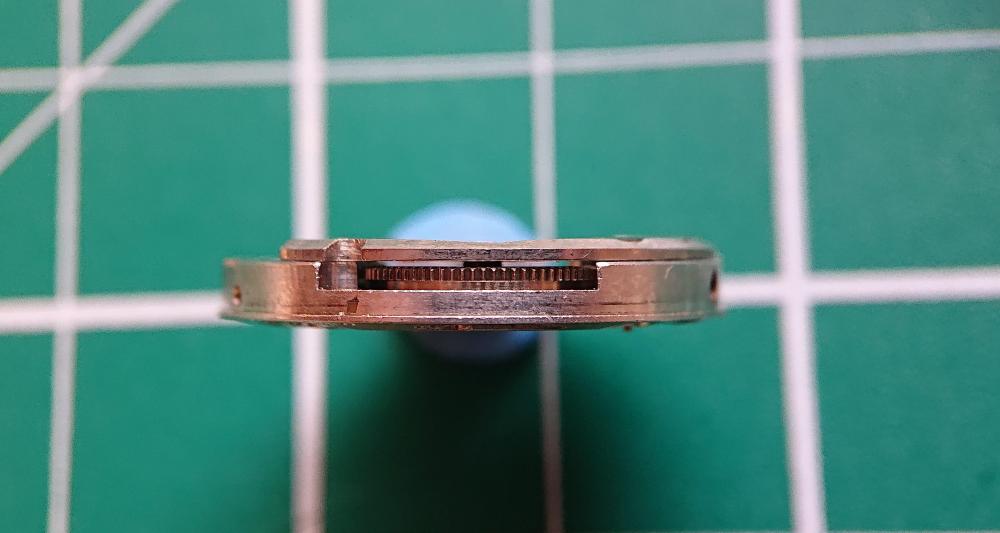

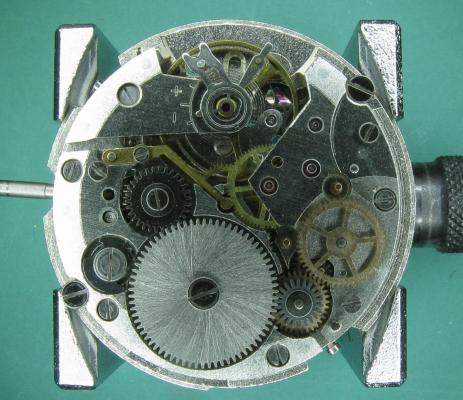

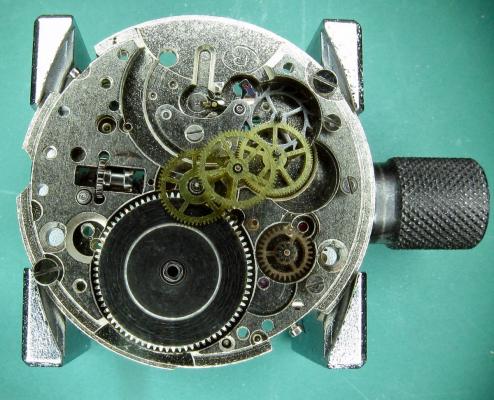

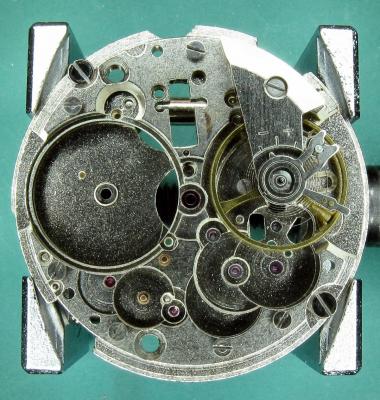

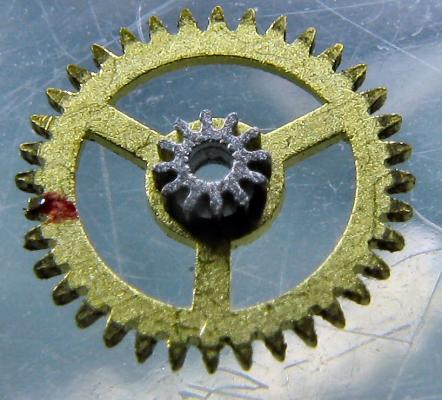

I've taken possession of an Eterna wristwatch belonging to a family member, in need of a service. It's in a sorry state externally. It barely runs and has terrible variation in between positions. It has been serviced in the past. There are four servicing marks in the case back and scratches on all of the bridges. It definitely requires deep cleaning. On examination, I found two significant challenges requiring attention, which are damage to the barrel bridge and the setting lever spring. Spares are no readily available for this movement and donors rarely come on the market. Plus it's time for me to move on from fault finding and parts replacement on to greater challenges. 1: The mainspring barrel bridge pivot hole is ovalised. The barrel arbor is no longer orthogonal to the plate and bridge. There is obvious wear to the upper side of the bridge from the ratchet wheel. I've resolved this issue by fitting a bushing to the bridge. I practiced the technique, refining each time on a couple of old citizen movements before working on the eterna: Having mounted the movement on a wax chuck I centred it on the lower barrel pivot using a wiggle stick, ensuring the movement was fully flat on the chuck: I then fitted the barrel bridge, and bored it out to about 2.7mm to regain the centring. I then bored the hole to 2.99mm using a seitz reamer. Following Perplexr's instructions on youtube, adapted to the tools I have available I turned a brass bushing 3.00mm in diameter and 0.44mm in thickness, pressed it in to place and broached it to size ready for a test fitting. If the fit is good I'l deburr it and re-plate the bridge. Happily the barrel now sits square, rotates freely without side play and with correct end play I then finished the bore with a burnishing broach, deburred and replated the bridge. Regrettably I scratched the surface of the bridge when boring the hole. You can see the scratch running up from the chamfered circle where the bushing meets the original material of the bridge. Oh well, it's only one more of many. It niggles me as I managed not to to do this on the practice pieces. Part 2 of the challenge (the setting lever spring) is rather daunting and I'm struggling to find the materials. I'll post it as a question in the other forum.4 points

-

Just a quick post on another lathe maintenance item. I have a Boley 8mm watch makers lathe which has a foot pedal control to adjust the speed of the lathe. As I pressed the pedal down the speed was not consistently increasing. I had just serviced the lathe motor and lathe body, so the only thing left to look at was the pedal. Cleaning the pedal switch improved the quality of the speed control, but it was surprising to see the switch construction. Outside is pretty boring, but functional. Back plate took a bit of convincing to slide it off. There are grooves either side of it and you have to sort of pry the end of the plate over the edge of the pedal body to get past the two indented stops. The switch is much larger than expected, held in place by one screw in the middle. When you press down on the body, it causes the lever to draw in the pair of thin metal pieces which gradually make firmer contact with the contact at the bottom. It gradually squeezes the end and in so doing somehow decreases resistance causing more more current to flow. Needed to unhook the thin metal blade from the lever arm. And the surprise for me was when I took the top end of the off, all these very thin carbon wafers spilled out, along with the end piece at the bottom of the picture. The resistance went down because more pressure caused better surface contact across all of these wafers! You can see they are varying shades going from gray to black. The blacker they are the more carbon build up from current. The carbon build up reduced the flow of current. So the solution was to clean both sides of all these wafers with Electrical Contact cleaner very carefully. Too much pressure on a slightly uneven surface would cause the wafers to snap into pieces. I broke two wafers in the cleaning process so did pretty good. But in order to keep the same overall thickness of the switch I had to replace the broken wafers with a couple of washers that were the same diameter. I sanded the end contacts and the thin metal strip that touches the contact at the bottom. I dropped the bottom contact down the hole first, then carefully coaxed the wafers in after it until I filled up the gap to the other contact assembly and attached the two screws. After assembly the speed control was smooth again.4 points

-

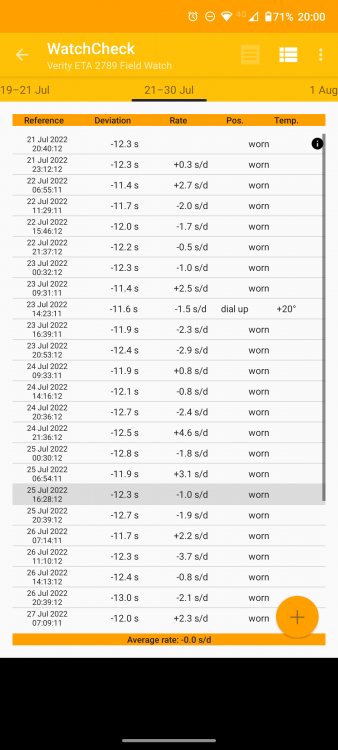

Hi All, just wanted to share that I added a hacking lever to an ETA 2789 movement. I used the same lever as specified for ETA 2824-2. All worked fine except the watch hacked on the date set position of the crown. I had to put a very slight bend in the lever so that there was a small gap between the lever and the balance rim in that position (as shown in photo). It was a fine adjustment as too much bend caused the lever to touch the barrel teeth in the crown pushed in position. All very doable without too much pain. Well worth it for £1.68 from Cousins. Steve.3 points

-

2 points

-

Thats the cleaner that i use now ammoniated. Tbh I'm not that impressed with it, it does make watch parts very shiney due to the ammonia but it is leaving a residue that i need to remove and evaporates quite slowly. So this is the reason why, i had read the label but wouldnt have understood what it meant until now. Thanks for confirming this Kalanag, we now know what specifically to look for in a cleaner. Your choice of using hexane is a good one Gert, but from what i think i understand is that it is as much a cleaner as it is a rinse. The fact that it is labled as a rinse maybe because it evaporates so quickly. You may very well get the same results from just using the hexane on its own. Although the cleaner you use may actually clean better that the hexane. So in actuality you are deep cleaning and then second cleaning with great evaporation. . The ipa is only a better choice when a waterbased cleaner is used because of its water dispersion. The rabbit hole is now dug by a very clever rabbit that has learned to remotely operate a JCB.2 points

-

Synta Visco Lube is 9020, Synta Lube is 9010.2 points

-

Good idea which appears feasible to me! Whateve you do you should start with a soft carbon steel followed by a heat treatment imho.2 points

-

Haven't done this myself, but I've seen other folks use super glue to fix the old part to new material, and then drill and saw out the new part. Super glue dissolves in acetone, much easier to remove than solder. Usually a jewelers piercing saw is used for cutting, the very thin blade allows you to follow the template and make tight turns. The final shaping would be done with a file. Then polishing, especially on areas that contact and slide on other parts. Good Luck!2 points

-

2 points

-

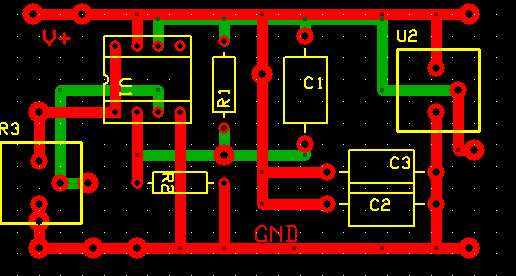

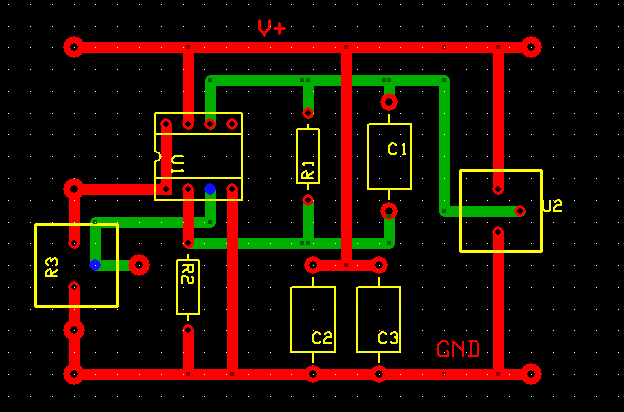

Here is my power supply. I use a 9V battery inside the box. The circuit in this box is different than the one posted above. The box is a stock box, but the front plate was 3D printed. I had the 10-turn pot in my box-o-parts, so I used it, but it could be a standard pot. Here is a tighter layout...just because... The dots are 0.1 inch spacing.2 points

-

2 points

-

Not sure if it's an optical illusion but does your guard pin look a little off center?2 points

-

I revisited this as the crown action wasn't right (too stiff to select the time setting position). Basically the lever was pushing too hard against the balance rim. I suspect that in time some damage could easily be caused to the balance pivots. I shortened the lever as shown filing away the wider bit at the end and then rounding it smooth (like a lolly stick). Lever is shown in the crown pushed in position. So much better now and the crown action is back to how it was. I can only conclude that ETA 2789 balance diameter is a bit larger than that of the ETA 2824-2. I don't have one to check but it sounds feasible due to the higher beat rate of ETA 2824-2. Steve.2 points

-

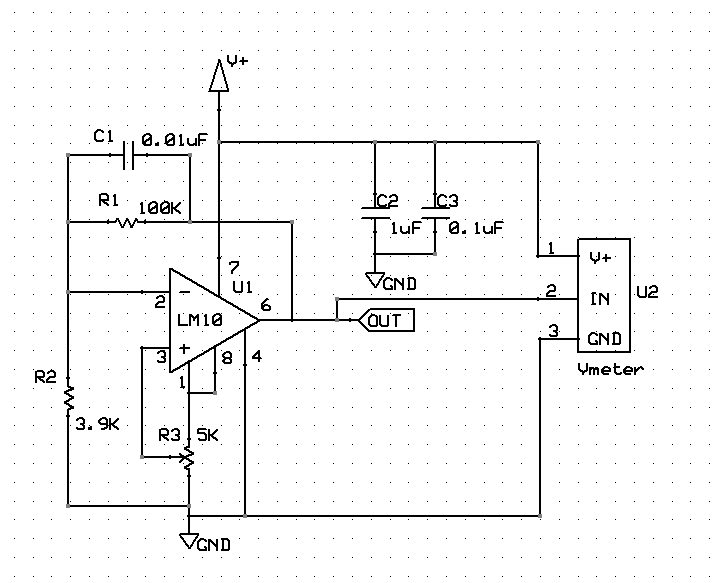

Use this for your volt meter. Shown here is a schematic and a layout. I did not try to make this compact so it is laid out very loose. Check my work...cranked out pretty fast. You can download the software used to generate these and order them online. You get three boards for about $60. US made and very high quality. In this layout, the Meter and pot are not intended to be placed on the PCB but shown this way for checking purposes. The bypass caps are overkill. If you want to build this, I can PM you the files and a link to the fab.2 points

-

Here's a PowerPoint of removing a refitting the so called 'fixed' centre seconds wheel, which should be removed, cleaned and properly lubricated. Enjoy Lesson 21. Baumgartner 866 Removing centre second wheel and oiling movement.pptx1 point

-

I would check that if the steel is any kind of spring or high carbon content steel i wouldnt think will cut with any manual saw blade. Even bimetallic hacksaw blades will barely cut hardened wood screws. The part would need to be mild steel unless grinding. Good idea about feeler gauges i bought a few sets of these a while back to do just that. Also consider the sprung steel from a hardpoint throw away handsaw. This stuff is bloody hard and retains its shape very well. In 40 years I've only ever managed to damage the tempered teeth part of the blade and even then very rarely. Thickness of around 2mm so it does depend on the part to be made unless you want to spend time grinding it to thickness required. Definitely no hand cutting will work, it will need to be fully ground to size and shape. Actually an old tenon saw blade will be considerably thinner. It is quite an intricate part, i would be tempted to try silver soldering first. I remember watching a guy making small figures from 2" mild steel nails a few years ago using silver solder. I had a go using some lead free solder and my plumber's blow torch. Curious to test the joints it would not break instead the nails just bent. Last week i repaired a broken setting lever with soft rosin core solder. Different scenario as it was a locating pin and did solder fill the the complete joint. But maybe worth a try, a pull and a tweak to test your joint should tell you if it will hold.1 point

-

Certainly not advisable to mess with it in any manner. There is practically no grease inside.1 point

-

Marc has a video on YouTube where he make a similar part using the old one as a template.1 point

-

Right! And the number of linked carbon atoms in the molecule defines the flash point which indicates how quickly the solvent evaporates. So you can find out whether the solvent you use is light, intermediate or heavy naphta by just observing the evaporation speed. The „Benzinum“ = „petroleum ether 40/60“ I use is a light naphta from mainly hexane (C6) with a flash point between 40 and 60°C and evaporates very quickly (much faster than IPA). No matter which naphta you use it has to be very clean to be useful for watch cleaning. „ELMA WF Pro“ is 90% naphta C9-C12 according to their data sheet.1 point

-

Looks very similar to an AS 969 but without a cap jewel on the escape wheel. I am not an expert at identifying these, but I was pretty sure it was an AS and just opened up all the images on 17jewels to find the similar image. https://17jewels.info/movements/a/as/as-969/ If you search for "AS" on https://ranfft.de and just click through all the movements of the right size (there are a lot of them) you will probably find the exact one.1 point

-

Hi well done indeed , setting lever springs have been fabricated from feeler gauge material by members in the past, maybe give that a try.1 point

-

1 point

-

Thats how it apears to me too, as if the hole jewel is domed and wrong side face the balance. Have you checked the side shake on fork arbour?1 point

-

Hi Accordint to the manual the 105 is based on the 104 with the calendar parts, therefore I assume that the plates are different / modified to carry to accomodate the extra parts. So based on that information one would assume the M25 is totaly different in its plates. Our Timex Guru Jersey Mo might be able to confirm.1 point

-

Having recently got into watches and repairing and I got an update on the Cousins v Swatch from Cousins today. I didn't even realise it was an issue until today. I suppose its inevitable that you will bump up against the politics once you are closer to an area of interest. I was looking to get a Omega watch as a present to myself - and now that will be scrapped and an alternative found. I do concur with the previous post and my thoughts here - there are people who would shop differently if informed by the issue, I suppose the question is how? In terms of impact - can anyone help me understand - if I want my quartz Longines serviced I got an online quote of GBP 165 (I was shocked by this) or GBP 180 from Longines - what would it typically be from an independent? i.e. what is the impact to the consumer?1 point

-

You probably have, at least several people here quite intrigued. I know that, I can be included amongst them. I am looking forward to a time where you are comfortable enough to share your tragic story with the rest of us. I would comfortably bet that everyone here has looked down at their bench and thought, "Oh (exploitive of choice)! What just happened?". We have all have been there and will be there again, soon enough. Shane1 point

-

1 point

-

I‘m very impressed by your professional escapement analysis. I bookmarked your thread!1 point

-

Now that you mention it, it looks like it in some of the pictures!?1 point

-

Others may be able to answer this question from their at hand knowledge but I may need to dig out a M25 and an M105 and see how feasible your inquiry is. From my memories, it's not just an M25 added onto the round date wheel plate. I think there are differences in the movements main plates and the diameters of the date rings are different. You may have better luck finding the correct movement or... Depending on what the "explosion" was, transplanting the wheels from one movement to the other might be an option. If it comes to that, we can look into it. Let me know if you want me to dig those movements out. Good luck. Shane1 point

-

Yes the problem of normal power supplies are not meant to do watch repair. They will not go typically low enough voltage sometimes a well. They typically go way too high and voltage. Plus they have way too much power out and if you short the leads together you'll have smoke and fire. None of which are nice to have on the watch bench.1 point

-

I'm gonna look into it. Looks like hexane is pretty available here if you order it online. thanks for the tip! This hadn't really come up anywhere else but when i look up hexane and watch cleaning it is a thing quite a few people recommend. And yeah i am really weary of ipa on things like balance assemblies and pallet forks as I've got some woodworking experience and know how quickly alcohol cuts through shellac.1 point

-

Great news G. The missus will need another restaurant evening out then . Having a little bit of surface friction where you grip screws and springs etc can help. Also look what happens at the end of your tweezers when you squeeze them. The very tip opens up, this can shoot a screw across the room and embed it in the wall. ( lol ok slight exaggeration there but you see my point ).1 point

-

If you flip the cock with a controlled sidewards movement letting the wheel be supported by your bench the wheel will follow without too much stress for the hairspring. I‘ve seen this in videos too.1 point

-

Lots of very interesting information to digest Daunting, but very interesting ! The good thing with this Omega is that I'm in no hurry and each time I discover that there is so much more to learn ....... comes back to my slogan on the bottom of each of my post: “The more I read & learn, the more I realize how little I know. And even what I think I know, I start to doubt" ! Thank you very much indeed !!1 point

-

The entry lock does look quite strong. From the pic the exit stone looks a little light too, but could be just fine. The thing is with the escapement you have to check everything- total lock is just one aspect. Briefly, to check (mind you in school some weeks are spent on this): All checks done with balance in, some power on train rotate balance slowly and observe drop lock, it should be minimal and equal on both sides at the moment of drop, manipulate the fork to check for freedom, this is "corner clearance". There should be freedom, and the escapement shouldn't unlock move the balance further a few degrees, check the fork freedom again, this is horn clearance to roller jewel face, should be small enough the escapement doesn't unlock continue moving the balance, now you will be checking guard pin clearance. Should be smaller than the horn clearance, and if so it will also be safe The above checks are checking the function of the pallet jewels relative to the roller jewel and safety roller. Observe how much lock is left with the fork horn against roller jewel- this is an indicator of how much adjustment you have as far as moving the stones in. The lock must remain safe with horn in contact with the roller jewel. All checks done on both stones of course, and in theory over the course of a whole escape wheel revolution. Next, moving balance slowly, at the moment of drop lock, observe the travel of the fork to its banking (looking at the escape tooth/pallet stone, not the banking). This is the "run to the banking". It is essential, but can be very small, bearing in mind that there are sideshakes that can eat up some of the clearance between fork and roller table in vertical positions. Run to the banking plus drop lock = total lock. So to boil it down as simply as possible for practical use, you can check the fork horn clearance, observe the lock remaining, and that amount "minus a little" is about the max you can move the stone in. *** If the total lock is large, and there is a lot of run to the banking, you can also close the banking. Easier said than done on many movements, as this might entail forging the banking with a punch in numerous cases. ***One very important thing to keep in mind with drop lock: moving one stone affects the drop lock for both itself and the other stone. If you move the entry stone into the fork, you reduce drop lock on the entry stone, but the escape tooth will also be released sooner on that stone, reducing the drop lock on the exit stone as well. And vice versa. After moving a stone, you must recheck for safe drop lock and safe fork horn clearance. Moving a stone affects drop lock similarly on both stones, and total lock on that stone. Moving a banking affects total lock for that stone, and run to the banking for that stone. No effect on the other stone. Can't really see much regarding the barrel holes in the bridges, but that could be some wear there in the upper one.1 point

-

Good lighter fluid is clean. I use medicinal grade Benzinum, which is mainly the same. Put a drop on a well cleaned hand mirror and let it evaporate. It should not leave a visible trace to be good for watch cleaning incl. hairsprings.1 point

-

Hello again. This is a really interesting and engrossing hobby. I'm able to disassemble, assemble and get a watch running. Using a smartphone time checker. Good fun. However, my cleaning needs advice. At present I use an Ultrasonic machine. I place the parts in containers and cover them with lighter fluid. I place the container, sealed into the ultrasonic and agitate for 10 minutes. I remove the container and then remove the parts, placing them onto paper to lose some of the liquid. I allow them to dry for 24 hours. I then begin my rebuild. Does some grease residue remain on the parts? Should I wash the parts again? I can purchase some IPA. If I use this, is it just a soak, or can I place all in a container as before and use the Ultrasonic machine? I know enough not the put the pallet fork and the balance complete into the IPA. Hope I've explained myself lucidly and that you can assist me. Thank you Ross1 point

-

I don't recall where you're located Ross but you can get it in the States from http://www.julesborel.com/1 point

-

How powerful is your ultrasonic? 10 mins is probably more than enough. I use 5 mins for cleaning, and 3 for rinsing. Yes, lighter fluid does leave a residue, you should use IPA for rinsing. When I used IPA I did 3 mins in the ultrasonic, and just 1 min for pallet and balance. Do NOT worry about dissolving old shellac ! After years of using refined Naphtha, IPA, I switched this year to proper cleaners - Elma WF Pro cleaner and Elma Suprol Pro rinse. I got the Elma as you can buy it in 2.5L size, so not too expensive, and it will last me years. (For each watch I use about 40ml of fluid in a glass beaker sat in the ultrasonic. So the total cost of cleaning+rinsing is about £1 per watch) The WF Pro cleans much better than naphtha, and leaves parts shining. And with the rinse there's no need to worry about dissolving shellac.1 point

-

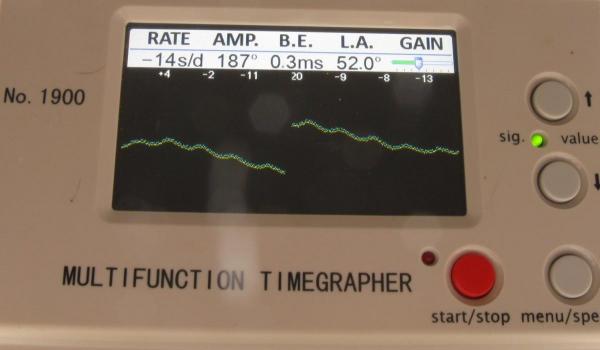

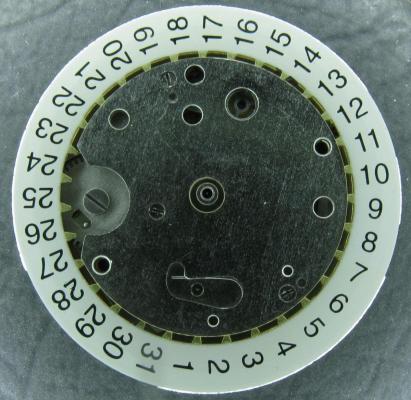

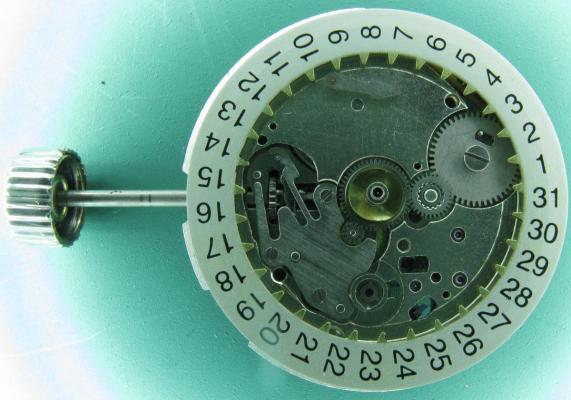

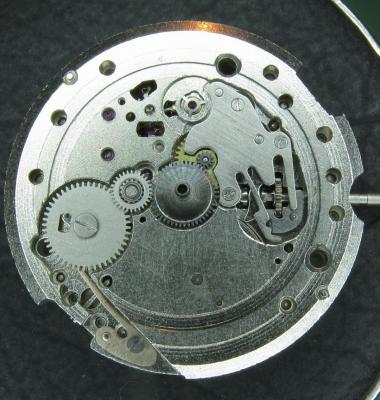

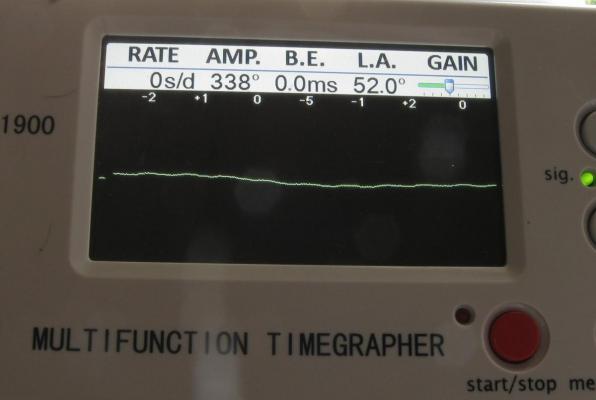

This is a bit of a departure for me as I usually like to play with stuff a little more vintage and a little more Swiss. That being said I have done a few vintage Russians in the past and this is a watch that I had been curious about for some time. I picked this one up at a car boot sale last summer for just £3 in a less than wonderful state. As you can see, the seconds hand was off and it was described a not running. It turned out that it did run, just not too well and the hour and minute hands didn't move. Canon pinion anyone? First impression with the back off is pretty encouraging. Still looking good with the rotor off. This is a 31 jewel movement, 10 of the jewels are inside those reverser wheels. Somewhat minimalist under the dial. With the calendar wheel retaining plate off you can access the motion works, the calendar works, and the keyless works. Flipped back over and with the auto-wind bridge out of the way. This is an indirect driven centre seconds hand which has a tension spring to hold the seconds hand pinion in place. This has to be supported when installing the seconds hand otherwise the hand simply pushes the pinion against the spring and won't install. Balance cock removed with the shim that the soviets are so fond of for adjusting end shake. Hair spring is in good shape. With the train and barrel bridges out of the way the going train is revealed in all its glory. Flipped over again to strip out the bottom plate and a problem comes to light. There is some damage to the minute wheel (marked in red ink). Maybe the canon pinion isn't the problem after all? In close up you can see the damaged minute wheel tooth. This I didn't think would be a problem, just replace it..... I thought. Not so easy as it turned out as I couldn't find anyone that could supply a new wheel, and a donor movement proved elusive unless I wanted to spend a fortune on a complete, working watch, which I didn't, so I had to wait for eBay to come up with a spares or repair victim at the right price, which it eventually did. The stripped out main plate with the balance and cock, minus jewels, ready for the cleaning machine. The bottom plate back together again after a good wash cycle in the Elma. At this point I did check the canon pinion anyway and it was as well that I did. There was virtually no transfer of power through to the hands at all so a suitable adjustment was made and a tighter fit achieved. Back in the case and ticking like a champ. The rotor and massive case back gasket back in place. And a much improved trace on the timer. This is with the original mainspring which turned out to be in very good shape requiring just a clean and relube. The trace isn't perfect by any means, but compared with other Russian watches that I have played with (and with it's starting trace), it's pretty good. There is still a hint of a periodic variation that I may investigate at some point but for now I shall just wear it and enjoy it. And here it is on the wrist after a bit of a cosmetic brush up. These are available with many different dial designs, apparently this one is referred to as a "SCUBA Dude". I have worn it for two days now and it has gained about 5 seconds a day so there is a little fine tuning to do to get it right "on the wrist". All in all I'm very pleased with this one. I had been curious about the Amphibia for some time having read a couple of articles detailing its history and design. It also has quite a large following of avid enthusiasts who rate it for both value and robustness. On the value front I can't complain with this one as the total cost to me was just £11 (including the donor). As for ruggedness only time will tell, but the performance so far is very impressive.1 point

-

Rolex looks nice. I quite like the Seiko as well. Have never seen one of them before.1 point

-

That definitely is a beautiful classic Rolex. Good that you sent it in to an authorized Rolex place to have it serviced. Well worth the cost in my book to have that done, especially it being handed down from you dad.1 point

-

Both very nice watches, with the seiko it's really about what you like, you were drawn to it and you wear it. I also love the backstory to your Rolex an heirloom watch with personal history is pretty special. I am working with my grandson to build his appreciation for watches, he has a couple of vintage seiko's that are older than his dad. He's pretty proud of them1 point

-

Baumgartner 866 Barrel friction fitted wheel .pdf Here is the last instalment of the BFG 866 lessons I wrote. This lesson shows how to remove the friction fitted minute wheel from the barrel cover, clean, lubricate and adjust the friction setting, so when in 'hand-setting' mode, the hands set correctly without being too sloppy or too tight when turning the crown. Some overlook removing this friction fitted wheel, but as you will see, there is a lot of old grease that doesn't help when left to congeal. Enjoy...1 point