Leaderboard

Popular Content

Showing content with the highest reputation on 05/04/22 in all areas

-

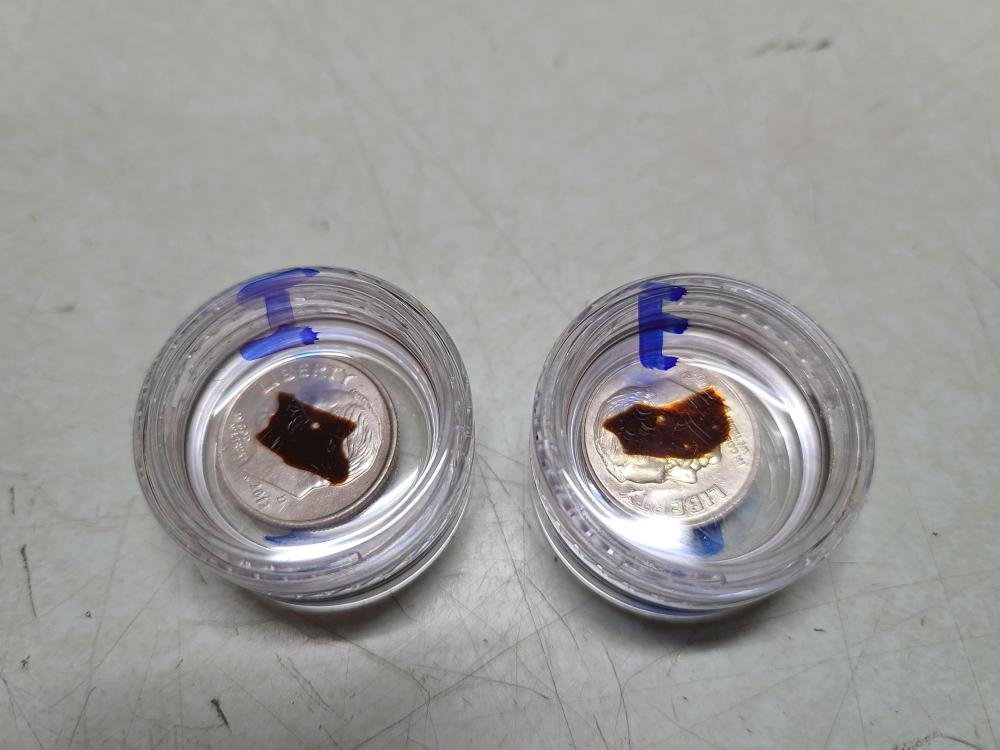

The experiment begins. Both dimes were heated to about 300c and then had a flake of garnet shellac laid on top. And then heated some more. 99% isopropyl on the left, denatured ethanol (containing up to 50% methanol) on the right. The ethanol may have some percent of water because i have had the gallon can of it for i think a couple years now. I use it to fuel alcohol lamps because it burns clean, unlike iso. The quantities of alcohol may be a little different but they are both immersed. These are 10g polystyrene lip balm containers i bought on ebay to hold small parts. They are reasonably air-tight when tightly closed but can then become hard to open. For acetone or limonene i would need to use some other container but i could do naphtha and odorless mineral spirits in these. I think we're all agreed that odorless mineral spirit aka stoddard solvent doesn't do anything to shellac, though. These photos seem to show up in reverse order, but as expected inside a half hour the ethanol side is completely dissolved. The isopropyl side is partially dissolved but largely intact. i'd say isopropyl is probably not going to harm an impulse jewel setting or pallet stone in a brief rinse. An extended, agitated rinse, is probably not a great idea. Maybe next I'll see what happens in isopropyl in ultrasonic?5 points

-

I thought I would remind everyone of something here? Just in case you're new to pocket watches. This watch uses lever setting so if you pull really hard on the crown thinking going to set the watch you're not. If you pull hard enough you're going to break something. In order to get the watch to go in the setting mode the lever which I circled in the picture attached has to be pulled out a little bit. I have a link below that shows the various setting methods and I think could've done a better job of describing things. The reason lever setting exists is it's the evolution of going from key set watches do something different. Later they understand how to make pendant setting watches. But in between we have lever setting. If it's a watch without a hunting case in other words it doesn't have a protective led the reference to removing the bezel means that you would just unscrew the bezel. In other words you wouldn't have to pry it off it would just unscrew the bezel with the crystal. Then more than likely the watch is not running because it hasn't been serviced in a very long time. The organic oils have a good characteristic of getting sticky hardening up and that keeps the watch from running which in reality is a good thing. It's good because that means you don't continue to run the watch forever with no oil at all wearing things out. Providing it hasn't been dropped breaking the balance staff or damaging it it probably just needs a cleaning and a new mainspring. then while the recommendation is to start with a pocket watch this is not the pocket watch to start on. First off it's a small size pocket watch. Second it's a vintage pocket watch that looks like it's a really nice condition. People often times brand-new to watch repair have a habit of well mysteriously things will happen in the watch might get damaged. Usually best to start on something inexpensive I usually recommend the Chinese clone of the 6497 it's a running watch if you taken apart and put it back together and it's not running well it does make it easier to figure out who's problem that is versus starting with a nonrunning pocket watch and just assuming it's the watch fault that it's still not running. Besides a watch like this the parts are going to be difficult to get. https://pocketwatchdatabase.com/reference/setting-types#Lever4 points

-

4 points

-

Yes, sometimes the balance and all its components don't come perfectly clean even in a current standard cleaning machine with fresh high end solutions. Watches can get really manky. The smallest bit of contamination on a roller jewel or fork slot can rob 30, 50 degrees of amplitude. I regularly rub down these parts with freshly cut pegwood (clean razor) and see benefits. 1/2 century old oil, dried up, can be very tenacious. Peg jewels, pith pinions, it all helps. Best is to do this pre-cleaning machine, with benzine and a brush. Twirl a flat ended pegwood down on pivots. It all helps. And a microscope is the only way you really see it.3 points

-

For a banking pin tool, I turn small brass rod (2mm or so?) into what looks like a small hollow staking punch. So, it tapers toward the end, and you drill it hollow so it’s just large enough to slip over the pin. Really handy for checking uprightedness - sometimes the pins will be bent in all directions and this makes it much easier to see.3 points

-

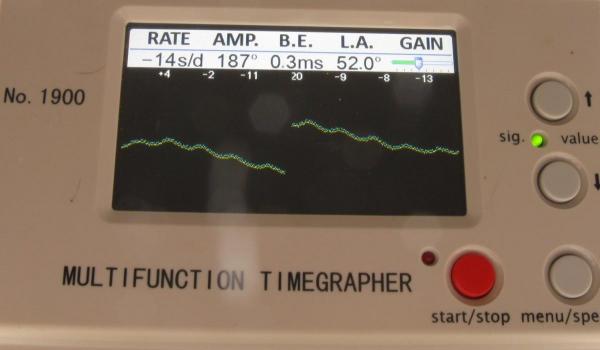

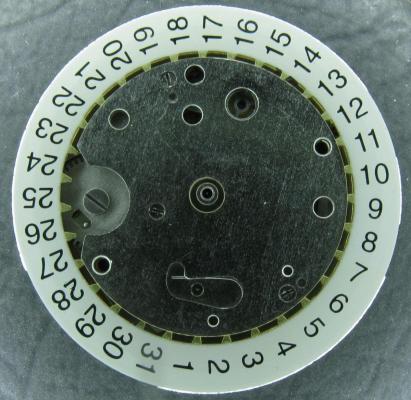

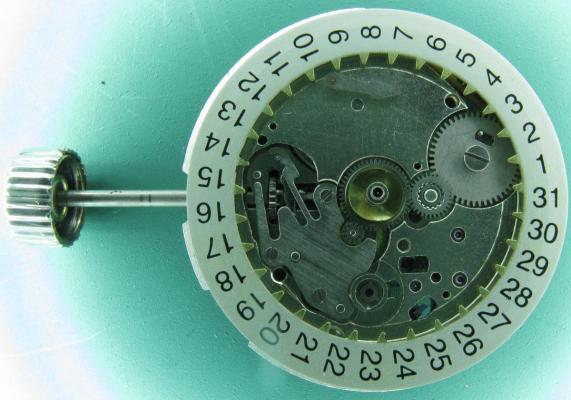

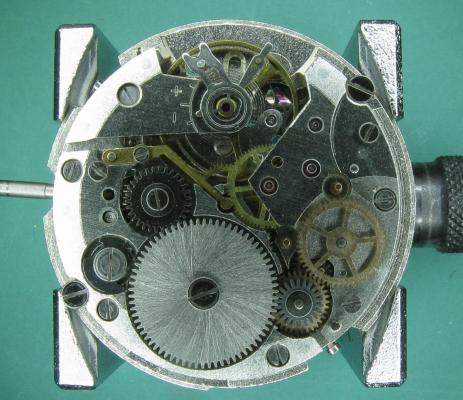

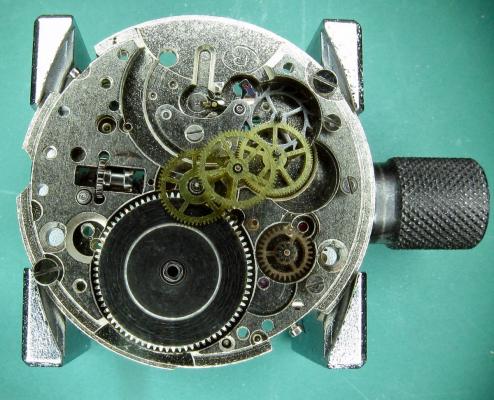

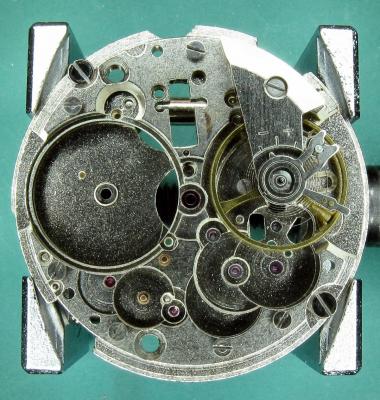

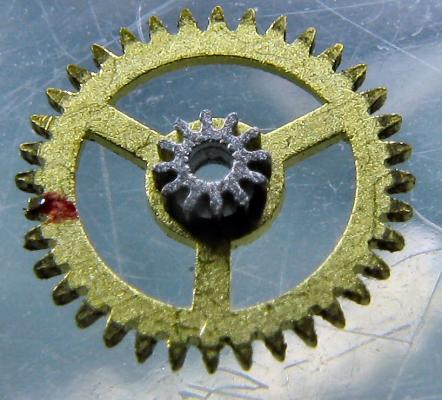

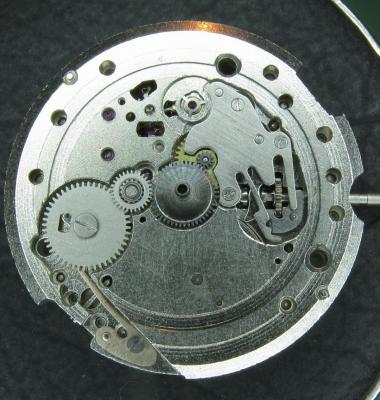

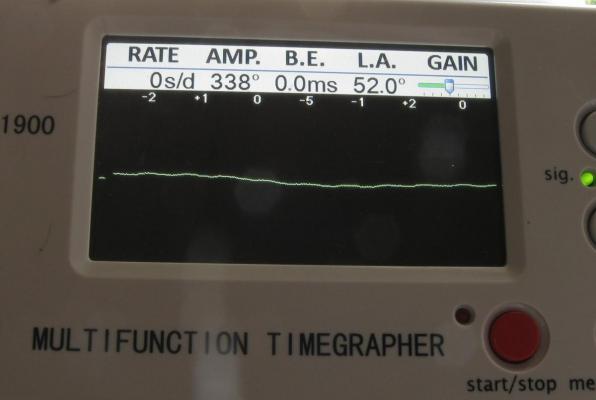

This is a bit of a departure for me as I usually like to play with stuff a little more vintage and a little more Swiss. That being said I have done a few vintage Russians in the past and this is a watch that I had been curious about for some time. I picked this one up at a car boot sale last summer for just £3 in a less than wonderful state. As you can see, the seconds hand was off and it was described a not running. It turned out that it did run, just not too well and the hour and minute hands didn't move. Canon pinion anyone? First impression with the back off is pretty encouraging. Still looking good with the rotor off. This is a 31 jewel movement, 10 of the jewels are inside those reverser wheels. Somewhat minimalist under the dial. With the calendar wheel retaining plate off you can access the motion works, the calendar works, and the keyless works. Flipped back over and with the auto-wind bridge out of the way. This is an indirect driven centre seconds hand which has a tension spring to hold the seconds hand pinion in place. This has to be supported when installing the seconds hand otherwise the hand simply pushes the pinion against the spring and won't install. Balance cock removed with the shim that the soviets are so fond of for adjusting end shake. Hair spring is in good shape. With the train and barrel bridges out of the way the going train is revealed in all its glory. Flipped over again to strip out the bottom plate and a problem comes to light. There is some damage to the minute wheel (marked in red ink). Maybe the canon pinion isn't the problem after all? In close up you can see the damaged minute wheel tooth. This I didn't think would be a problem, just replace it..... I thought. Not so easy as it turned out as I couldn't find anyone that could supply a new wheel, and a donor movement proved elusive unless I wanted to spend a fortune on a complete, working watch, which I didn't, so I had to wait for eBay to come up with a spares or repair victim at the right price, which it eventually did. The stripped out main plate with the balance and cock, minus jewels, ready for the cleaning machine. The bottom plate back together again after a good wash cycle in the Elma. At this point I did check the canon pinion anyway and it was as well that I did. There was virtually no transfer of power through to the hands at all so a suitable adjustment was made and a tighter fit achieved. Back in the case and ticking like a champ. The rotor and massive case back gasket back in place. And a much improved trace on the timer. This is with the original mainspring which turned out to be in very good shape requiring just a clean and relube. The trace isn't perfect by any means, but compared with other Russian watches that I have played with (and with it's starting trace), it's pretty good. There is still a hint of a periodic variation that I may investigate at some point but for now I shall just wear it and enjoy it. And here it is on the wrist after a bit of a cosmetic brush up. These are available with many different dial designs, apparently this one is referred to as a "SCUBA Dude". I have worn it for two days now and it has gained about 5 seconds a day so there is a little fine tuning to do to get it right "on the wrist". All in all I'm very pleased with this one. I had been curious about the Amphibia for some time having read a couple of articles detailing its history and design. It also has quite a large following of avid enthusiasts who rate it for both value and robustness. On the value front I can't complain with this one as the total cost to me was just £11 (including the donor). As for ruggedness only time will tell, but the performance so far is very impressive.3 points

-

WF Pro and Suprol Pro are both waterless (hydrocarbon based) cleaning solutions, so no, you would not follow either of those with water. You would only use a distilled water 1st rinse if you had used a water-based cleaner. WF Pro is a wash solution and Suprol Pro is a rinse solution. So, wash in WF Pro, 1st rinse in Suprol Pro, 2nd rinse in Suprol Pro or maybe IPA if that has been specified by the manufacturer or that just works better for you. The theoretical downside of using the same jug for 1st and 2nd rinse is that you use it faster, but conversely i think it is probably reasonable to replace the contents of the 1st rinse jar with the contents of the 2nd rinse jar when it is time for new rinse solution. It appears that shellac dissolves very slowly in IPA so a quick rinse for the balance and pallet in IPA is probably just fine particularly if you have heated drying, but if you have essence of renata or some other substance specifically recommended for rinsing hairsprings (one-dip, perhaps hexane, allegedly acetone but i should do the science), then why risk it? I'm unsure about temperatures for heated drying. I have a lot of hobbies and one of them is electronic repair, so i have frequently used my temperature-controlled hot air wand set to 100c which is its lowest setting, and it doesn't seem to cause problems. I could imagine arguments for keeping it below 80c, and i could imagine arguments that 120c wouldn't hurt either. *shrug* The pros seem to use an appliance that looks like someone shoved a hotplate burner in a box with a fan under it? Surely some form of temperature control though. Oh, just to be clear. Having a microscope allowed me to see that sometimes the balance really does need a lot more than a quick dip in a hairspring cleaner. So i have taken to re-installing the balance complete in the main plate for washing, and the pallet fork goes into a small parts basket along with the train wheels. This does mean that you will have to put extra effort into cleaning the top and bottom balance jewels and potentially the balance pivots as well. Even a cheap usb microscope can help you determine if these parts are clean enough.2 points

-

2 points

-

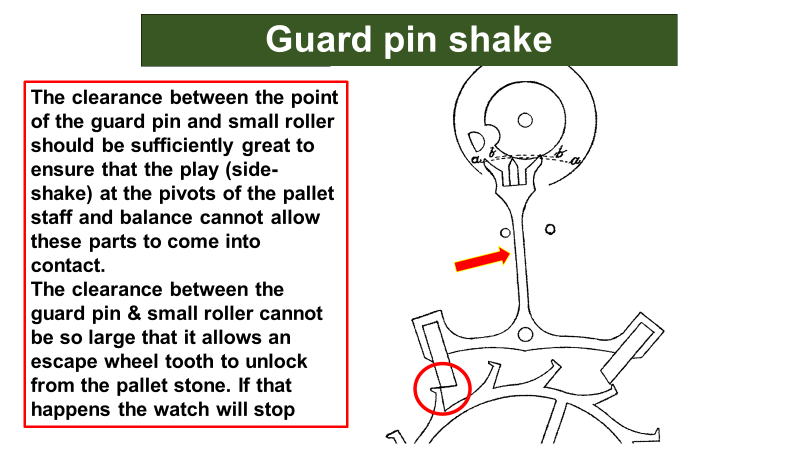

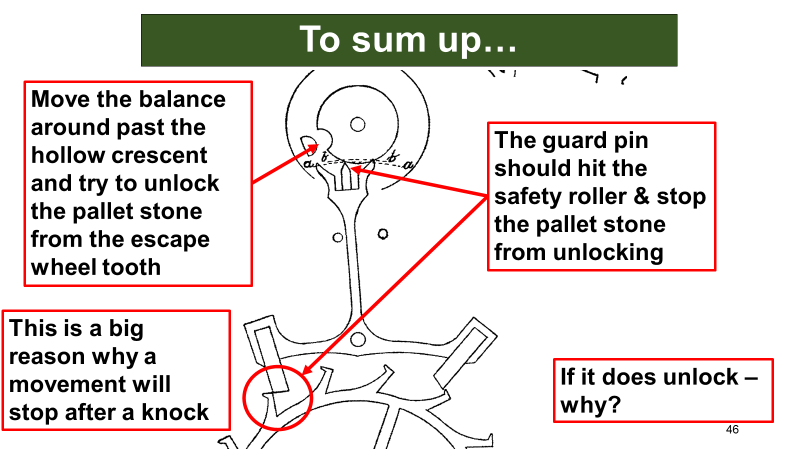

Moving the banking will only increase the total lock, it won't make the escapement unsafe. Moving a stone in can possibly cause an unsafe escapement that can unlock accidentally, if it's moved in enough that the guard pin shake allows it, and can also reduce the drop lock enough that that is unsafe as well.2 points

-

I've only used a shim if one was already there, and it's a really low grade piece, and if it works, and the solution would require something extensive like a new staff etc. I don't seek out low grade pieces, but I will work on them, old pin lever pocket watches or whatever, but usually the price occludes them making it to the bench.2 points

-

usually best if we determine why the problem exists then we can figure out how to fix the problem? like for instance was the watch running before servicing and now it's not kind of thing? Or did you start changing components? The most likely scenario for something like this is changing the balance staff. Or even changing the balance complete. a bigger problem with older watches because they're not actually made to exacting specifications. If you watch the vintage videos on making watches you'll see that the watch parts tend to be hand fit even if there were made on the assembly line. So if you start swapping balance components you can end up with issues.2 points

-

Hi RC. I would say you first need to find out the value of it working and non working and also attain a cost to have it repaired professionally. A 14 carat gold watch is going to be quite valuable sentimental or not and more so working. Unless you intend to turn this into a full time hobby anyway the cost of some decent tools to repair it will offset its value. But you are in the right place to start learning and get help and you almost have the right project to start with. A cheap pocket watch to practice on first would be your best option and unless this one just needs a service you may need one or two of those anyway to provide some parts.2 points

-

2 points

-

Neverenoughwatches hit the nail on the head. I have only worked on a mere handful of genuine Rolexes. But they're perfect. Even under magnification. They have to be, for the price they charge. I also saw that blob of lume on top of "Swiss" and thought to myself "Heck no, Rolex wouldn't do that." You look at a watch dial very often; some of us - every day. There would come a time when the owner would notice things like that and be displeased. And!...even if it is NOT fake, as expensive as Rolex parts can be, there's no way I'd pay even a moderate price for an imperfect part that my customer might bring back to me and complain about. With the high-end watches, it is safest that any replacement parts be genuine and flawless.2 points

-

As others have said, given that this if genuine would be on a 10 grand plus watch I would expect perfection, the lume pips are all over the place in both size and position, they just look like they have been done by hand, the Rolex pips would be added mechanically so would all be even in size and position relating to the hour markers. One common ply I have seen is someone has a bag of old junkers and throws in a fake Rolex, but never mentions it in the description so some poor fool thinks the seller has missed it so bids accordingly, the trouble is poor fools rearly act alone and they seem to congregate around the same auctions thus push the price of the bag of junk up to silly levels, which encourages the seller to do it again. Seen it happen in the Pen world as well, in one case 10 Chines pens which cost a couple of pounds each are bundled with a fake Montblanc and the description says I know nothing about these pens, I found them when clearing a dead relatives house. They then sit back and watch £20 worth of low quality pens sell for a couple of hundred to one of the affor mentioned poor fools.2 points

-

Hiya Rich . There are a lot of fake watches on ebay. I found a tag dial that was really badly done. Examine very closely. Any thing that doesn't indicate quality then it's a fake. The lettering does look a little off level and a bit pants . The calender 13 doesn't look quality at all, and look a the lume pip at 9. And the indices at 6 the lume pip is covering the Swiss lettering. These standout to my untrained eye. This would be from what a ten grand watch? I would expect much more for my money tbh. I nearly bought myself a Tudor this weekend that was reduced to 2 grand, it looked near perfect. Sorry mate there are loads of them. Its a trick that the seller uses, discreetly hiding something that looks valuable to bump up the bidding. Crafty barstuards2 points

-

1 point

-

Yeah potentially, you could glue some standoff feet of some sort to the back side of something like this and put your parts basket on top of the grill: https://www.amazon.com/AmazonBasics-500-Watt-Ceramic-Personal-Heater/dp/B074MX8VN5/ Some of these have a switch on the bottom to assure that they don't operate when they aren't standing upright, which you could permanently close with a bit of tape. Some of them may have an internal switch that opens when they aren't upright, but many of them depend on a mechanical switch with a bimetallic contact that opens when it heats over a certain point to assure that they don't start a fire. I have a few "personal space heaters" that i bought for heating enclosures for 3d printers (for plastics that print better in a warm environment)1 point

-

1 point

-

Here is a good video of the 2824-2 which is mainly the same:1 point

-

The picture is not very clear Rich. But just apply the same principles, your gut feeling should tell you. They do occasionally mate, you will quickly develop an eye to spot some good stuff. I have lots of fun taking the pee out of sellers that try the cleverly half hidden fake tricks. " Really ? You think I'm going to fall for that one, BTW dikhead Rolex's Freud branch now have your ebay details." Then sit back and watch how quickly they remove that listing . Its Really funny.1 point

-

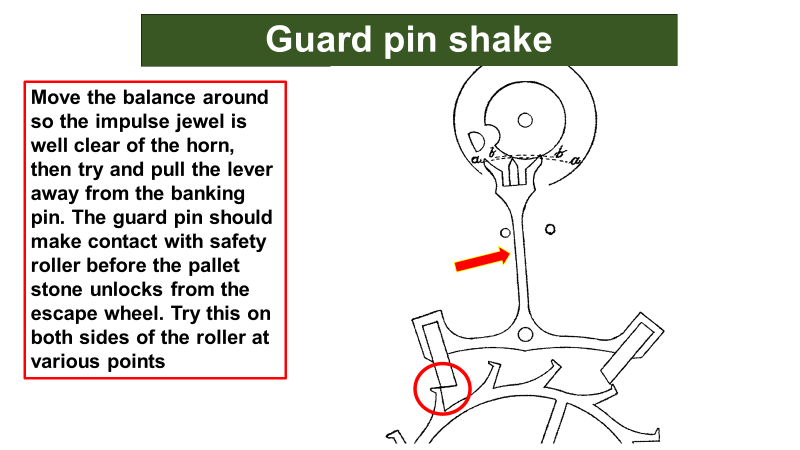

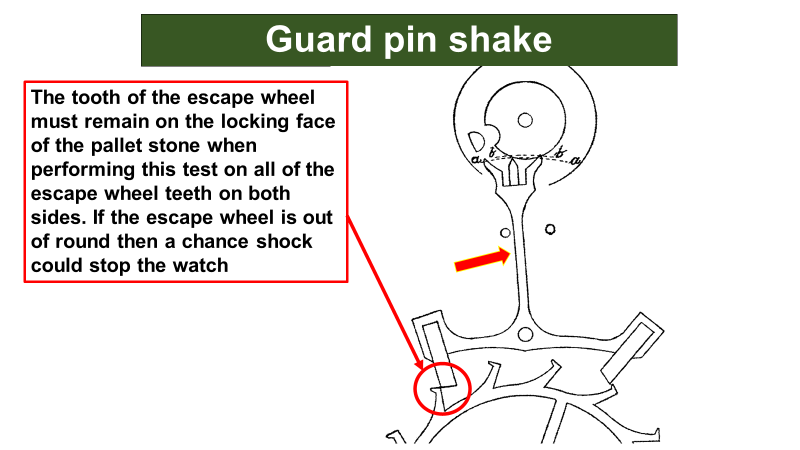

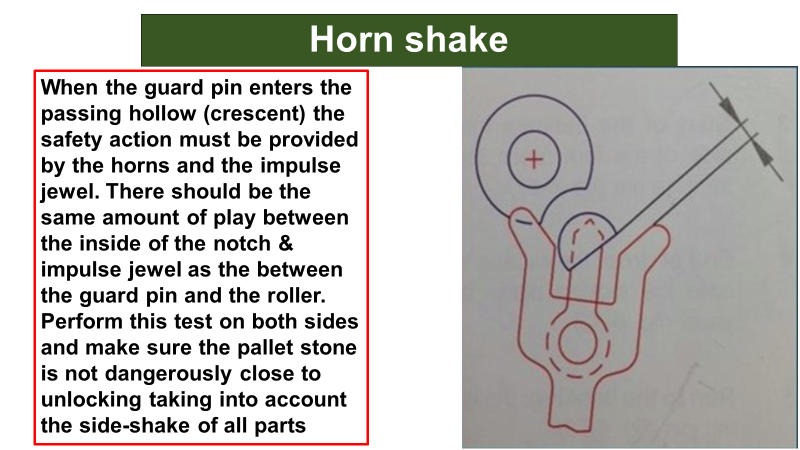

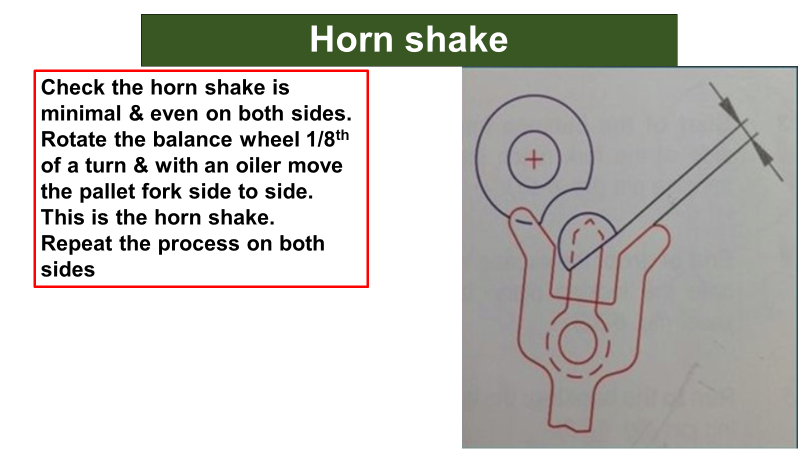

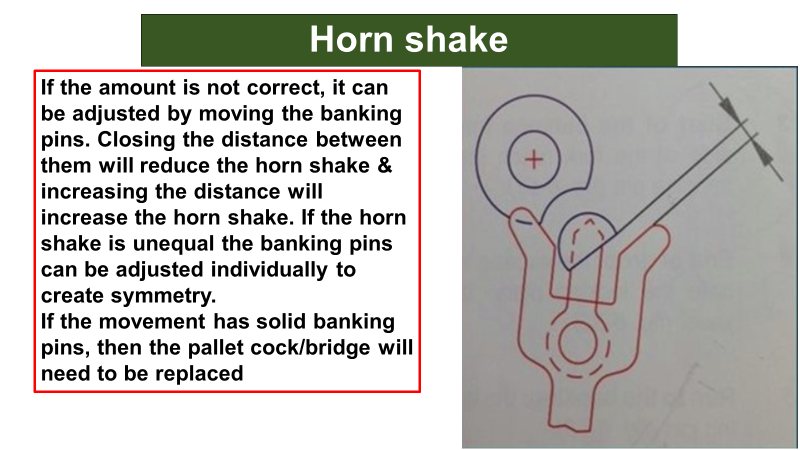

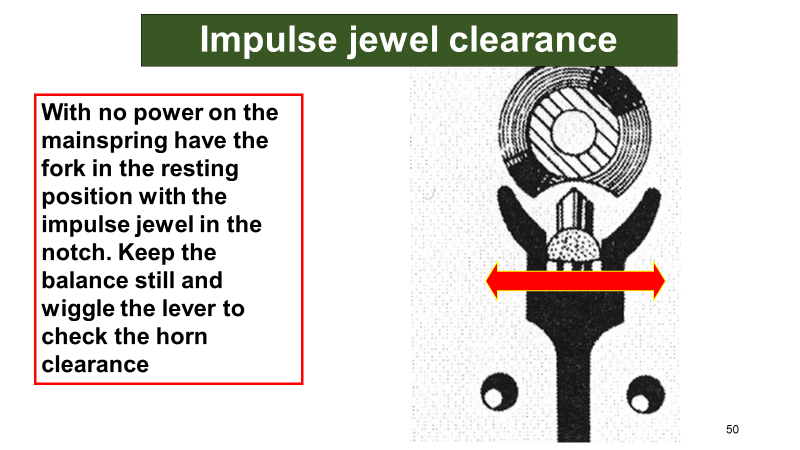

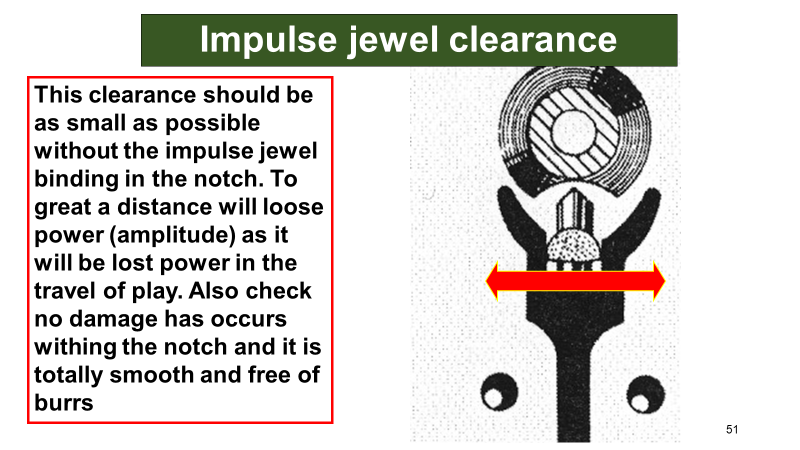

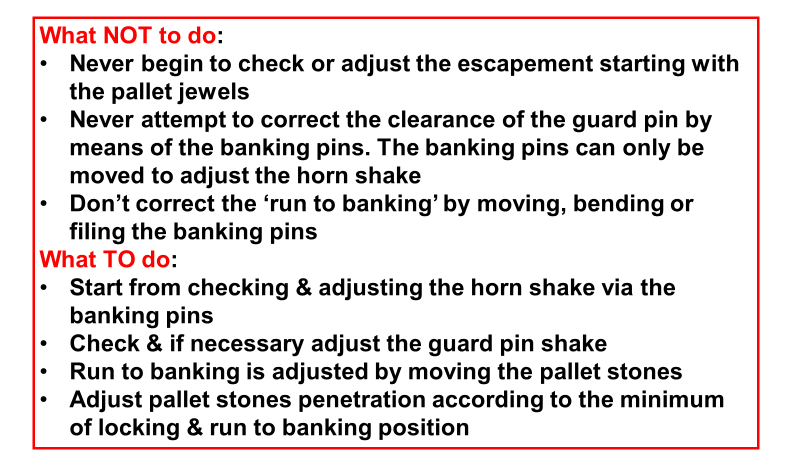

I would be very cautious of moving a banking pin to alleviate the problem, as this is going to increase the guard pin shake and horn shake, which could unlock the escapement if it receives a shock, so if you are going to move one or both banking pins, do it slowly and check with the balance in place that when the balance is turned in both directions, that when you try to pull the pallet away from the banking pin, the pallet stone doesn't unlock and the guard pin touches the safety roller before that happens, otherwise you could have the escapement mislocking or totally unlocking. These slides will help understand the principles as well as what you would check and adjust. Hope it helps. I have got a lesson on making a pallet stone warmer and spirit lamp as well as how to set pallet stones using shellac, but it has a lot of videos in and the server won't take it ]1 point

-

1 point

-

1 point

-

Thanks for this (now 7 year old) walk-through! I’m not sure it was mentioned in the thread so I’ll mention it now. The lift angle of these Vostok 24xx movements is 42 degrees. I noticed the near “re-banking” amplitude on your timing machine!1 point

-

oh? That's probably a servicing issue but just a reminder for pocket watches? something that people forget about is different frequencies of pocket watches can run at? I don't have an exact time frame the indication is the 1880s in the US. we end up with the terms quick train and slow train? for instance at the link up above that someone has the pocket watch database for this watch you go down the list and the get to the word train the lacrosse and you'll see the word quick so this Elgin is a quick train. the definition is quick train is 18,000 beats per hour probably the most common frequency of watches ever made. But slowly train is 16,200 beats per hour. That presents a confusion to someone trying to time a vintage typically clean a key while American pocket watch because it won't auto range to the proper range on your timing machine. If you grasp the problem you can manually set the machine to 16,200 and hopefully time your watch. The reference to hopefully is that a lot of people of played with your watch since it was made and well timing issues can occur. then if we go back in time farther key winding typically then you can end up with a variety of frequencies as there may not a been any kind of the standard because nobody had timing machines. There are standards in that you restricted by size and how much power you had in a watch. As the makers were buying components they would be standard components but they don't necessarily have to have a standard frequency. Which explains wife you look at the timing machine in your manual setting mode there is a heck of a lot of frequencies that you didn't know existed. Now if we were talking clocks then that's why they have books that list all the different frequencies because they could be just about anything. It's also why clockmakers timing machines typically measure beats per hour as opposed to how fast or slow it is in seconds per day.1 point

-

as a reminder you can take baby steps here? In other words when you put the gear train in you can push on the gear train and see that it spins. When you put the mainspring in the push on barrel gently and make sure the gear train still spins. When you get the keyless mechanism in and with your bench key you can start the wind the watch without the pallet fork in and make sure the gear train spins. one of these you do want to be careful about as you start swapping components around you do need to make sure that they actually work in your watch. There tends to be some variations amongst the various batches of components as always possible you can find things that might not actually work unless the serial numbers are really close together.1 point

-

Good call John, similar thoughts to mine and very well explained . And thank you for the mention of the setting lever, I'm thinking I want to learn more about pocket watches after my recent acquisition. The fusee are amazing to watch inside . The one I have has slowed down to one oscillation every 2 or 3 seconds. I want to strip down and service but a little concerned about dealing with the fusee . Looks like I will have to man up. RC have it looked at first mate just so you know what you are dealing with, like John says as an absolute beginner it's very very easy to bugger things up that goes without question. And honestly mate you really don't want to do that to such a beautiful watch.1 point

-

1 point

-

Going just on the heat proof wires, TOC and the spiral design with center plastic tube, it's a heating device out of something1 point

-

you forgot to include the picture of the movement? I suspect a lot of people probably don't understand what kind of watch this is so I have a link just in case and it has a picture the movement. in other words this isn't your normal mechanical watch. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA-ESA_91581 point

-

I'm sure you are right Nucejoe. It's just that initial hope of "ohhh I've found something valuable". When that calms down and you look more closely the hope turns to " oh shit its a piece of shit ". We've all had buyer's remorse, looking positively though Rich you know how to recognize fake dials and your next good find will be so much sweeter.1 point

-

1 point

-

1 point

-

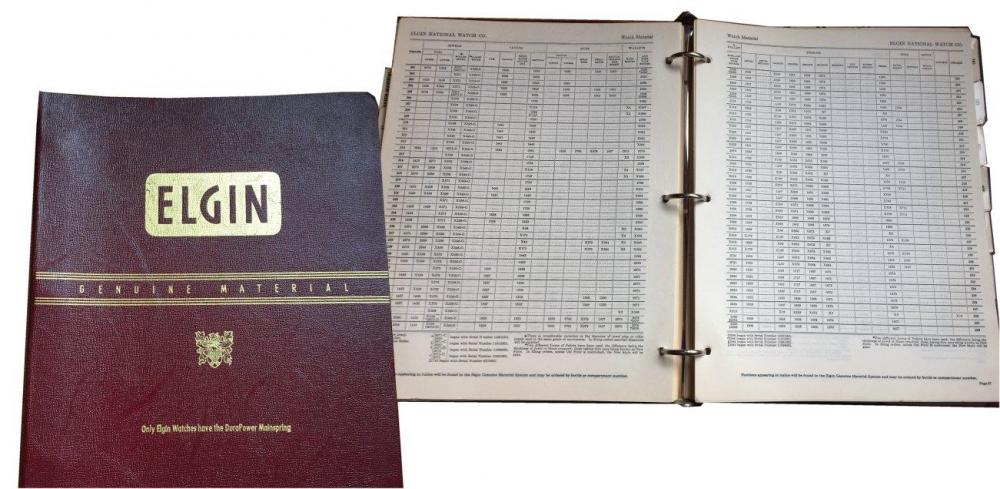

If I have read the s/n correctly (3273079) that Elgin was made in 1889. Some additional data here. They always suggest that you start your journey to watch repair with a pocket watch and that sure is a pretty pocket watch. Certainly the gold in the case is worth something. If the watch has sentimental value you might want to have it appraised and have somebody give you an idea what it might cost to repair. It's possible that the mainspring is broken.1 point

-

1 point

-

1 point

-

To remove the bezel, I suggest using a safety razor blade. It will get under the bezel and you can work your way around.1 point

-

1 point

-

Thanks Marc I appreciate your input and confirmation. Im stuck on the initials on the movement though next to the serial number.1 point

-

I would say the hands are certainly original, I wouldn’t be surprised if they are made of ivory, if they are thick then it would be yes. The plates are cast brass and not of the rubbish that you see in modern cuckoo clock movements. Another thing it has a count wheel strike, also a sign of the old type of movement, modern types have rack striking. The wood is from the lime tree which is favored in Germany. Not only is the movement German but the case also. A very basic shape of pendulum which is original. It is 30 hour duration. Dates from around the 1890.1 point

-

I just asked a friend who does work for AP, he's not in the shop and can't remember exactly but around 3 minutes he said. He checks the forks anyway and puts new shellac if/as needed. With my old Greiner machine that distilled, the manual recommends 30 seconds for the balance and fork in freshly distilled (and very warm) alcohol, then the rest of the parts go in and get rinsed for 10-15 seconds in the same alco bath, the bath gets dumped, and once it refills after about 6 minutes, that's it. The only time I ever had an issue with shellac dissolving in the Greiner was if I left the fork in for quite some time. Depends on the age of the shellac too; a fork I had freshly re-shellacced would lose its shellac much more quickly than a lot of older ones, but really old forks might lose it as fast as freshly applied. One thing that simply hasn't been an issue over 25 years of doing this is pallet stones just falling out after the shellac is removed (intentionally or accidentally). In fact, if I really have to dig in to an escapement adjustment the first thing I do is remove all shellac, make my adjustments, including running the watch, then re-apply when I'm happy with it. I understand there are some forks out there that are loose on the stones, but I haven't seen one.1 point

-

For years, in the ultrasonic, I used Naphtha (Hydrotreated light SBP3) bought from ebay, for cleaning, and 99.9% pure IPA for rinsing. As Nickelsilver says, it is not good for removing oil and grease. I switched to Elma WF Pro. Ok it stinks a bit, but cleans better than naphtha, and leaves a nice shine. I have continued to use IPA for final rinse - it does remove any residue from the WF Pro. I'm about to order some Elma Suprol Rinse. It's not cheap, but 2.5L will last me ages (I only service my own watches). It's designed for the job, and there's no worry about shellac.1 point

-

Are you planning to use IPA as your only cleaner? It's not a very good cleaner for grease and oil, at all. It's a very good absorber of water, if using water based cleaners, and must have a generally good effect as a rinse as multiple Swiss manufacturers spec it as the final rinse in machines running petroleum based cleaners. But it, on its own, for cleaning, isn't very good.1 point

-

Hi sorry to jump in on this. I do have a little mistake experience on this and I don't want to hear of any newbies make the same one because it can be costly in the sense of ruining a new expensive tool. Most of what I say is pretty obvious but often overlooked in a haste to get something done, never a good start in the world of watch repair to place time ahead of sensible thinking. Most of my tools are second hand ebay purchases, I can't justify paying a lot of money on expensive tools when I can get by with well chosen secondhand gear. Besides if the hobby interest fades for whatever reason I will have wasted a boat load of cash. So this post mostly relates to similar ilk as myself. Mistake coming up shortly. The mainspring winders I have are a generic set of 7 and 3, so 10 in total, so I thought this should cover most bases, I was wrong. They often don't fit and I frequently reinstall the mainspring by hand with a little gadget I devised, nothing clever because I'M not particularly, but it works ok. Now when i say my winders dont fit a barrel I mean it doesn't fit the barrel well, because its quite important that it does. Mistake coming up very soon. I was sizing up a winder to fit a barrel I was working on, only by eye i might add as I find skeg of E works for me on stuff like this. Mistake coming up now. "Not that one, not that one, ah that's not a bad fit a slight gap around the edge of the winder but it should work". Oopsey. A slight gap by eye is a big bloody gap under a microscope or 10 x loupe. So I'm winding the spring in, it felt a little tight towards the end but I got it in. I looked inside to check it was ok, "oh crap it looks a bit bloody snug in there". Would it pop into the barrel ? Would it f---. Mistake arrival. The winder hook was well and truly jammed in the mainspring eye with no room for any release to ease it back out. 15 minutes of tugging pulling and cursing, left me with a minature version of a slinky that looked like it had just finished coming down the people crowded steps of the Eiffiel Tower and a broken hook winder embedded workshop wall. So the moral of this lengthy detailed story ( apologies I'm very recently early semi retired and have far too much time on my hands ) is to make sure the winder you are going to use, fits the barrel in a positive undestructive, stress limiting and good resulting way. Thanks, I hope this helps at least one person that is in any kind of rush and thinks that they can get away with a - that pretty much fits attitude.1 point

-

In reference to your comments about remembering were all the bits go, you could do what I do, I use plastic 24 compartment boxes sold for bead storage in my local hobby store, then as I dismantle the watch each part and it's associated screws and springs go into each section of the box, once stripped I take a photo of the box so that after cleaning all the parts are sorted back to the correct section, then when rebuilding the watch I just work in the reverse order from the box. I also work under a stereo microscope that has a high definition camera fitted so I also video the whole strip down and take individual still shots of every single step, including showing every single screw next to the hole it came from to aid correct reassembly. It seems to work well for me1 point

-

I have used both the K&D and Watchcraft styles. In my opinion they both are unnecessarily finicky. In addition to this it isn’t unusual to find that these kits have hooks that are almost unusable. They are almost useless for automatic and modern mainsprings. They have caused me a lot of frustration. If I could give any advice I’d say buy a complete and new Bergeon set if you can afford it. They are beautiful to work with and make the process seamless. Wish I bought mine much earlier. Cheers1 point

-

Mark mentioned in one of his videos that this pops up from time to time - specifically with Seiko. I think maybe the Swiss are still mad at Seiko for the whole quartz crisis thing. Lol. But in all seriousness, Mark indicated that sometimes he'll mix and match an arbor from one winder-body with another but that doing so is less than ideal because the shaft diameter won't be right and the operation will be sub-optimal at best. If I found this to be the case I would probably either turn a custom winder-body out of a chunk of brass bar, or, depending upon the variance, use something to shim the arbor so it fit the body better. Depending upon the application it's amazing how good of an action you can get using polyimide tape to shim a rod so it fits a bore better. I have a Chinese hand setting press. It's actually made pretty well but the one part that was sloppier than I'd like was the fit of the pusher to the bore it slides in. I used a bit of polyimide tape on the rod and now it fits the bore great, but still slides smoothly (and now stays nice and straight through the bore).1 point

-

1 point

-

1 point