Leaderboard

Popular Content

Showing content with the highest reputation on 05/01/22 in Posts

-

4 points

-

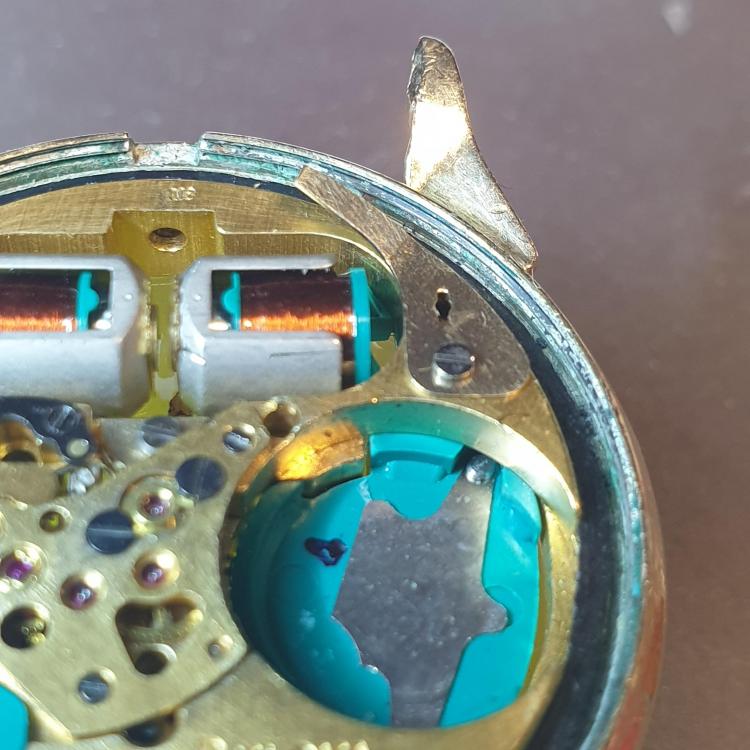

The watch I was working on when I posted "Do Not Open, Bulova Sealed" is, once again, alive and well. (I still need a gasket for it) This one tested my patience and I needed to step away at multiple times. Both balance jewels and their clips needed to be dug out of their respective pockets. The hairspring needed to be slowly soaked and delaminated coil by coil. Once the oil was desolved, just about every part needed to be brushed to remove some hardend deposits of polomerized crud. An arduous two weeks of not knowing exactly when the expletives would start. At the end I should have stepped away at least one more time. I rushed installing the hands and put the minute hand on several minutes fast. I pulled the hands back off and slipped putting them on the second time, scratching the dial. The scratch (at 10:30) is small and unnoticeable with my naked eyes but is there and will haunt me every time I wear it. I hope this will help everyone myself including take your time and breathe.3 points

-

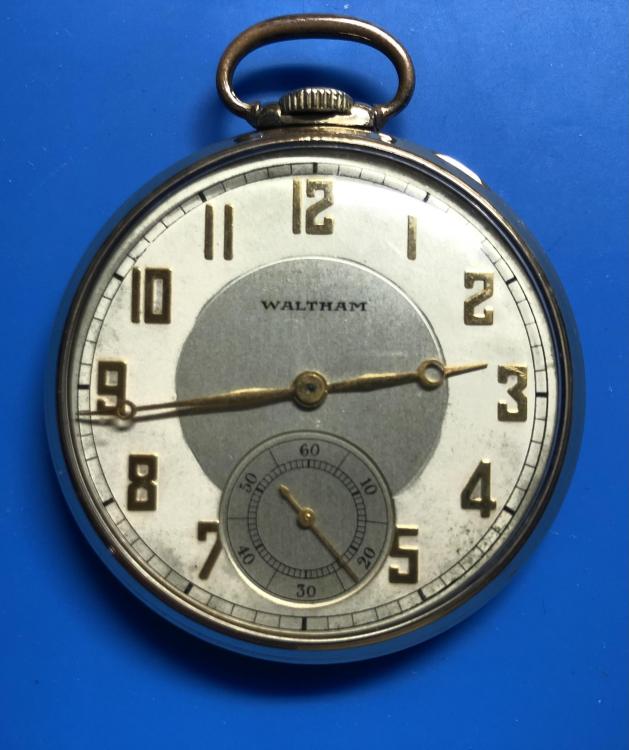

Driving home from my College Station, we stopped in Lockhart--if you are not familiar with these places...you should be We stopped at Blacks BBQ and then to an antique store. I picked up this Waltham Crescent St 21J watch. Very nice. 10K gold filled case. All for a hundred bucks (not including the BBQ)!!3 points

-

I just wanted to share this technique that gave me a great result and is very quick. Using the tip of a cocktail stick with a small divot in the end made with a 1mm dia drill. Dip the stick in a bit of Molykote 111 and then push the pointed end of the stick into the o ring. Using brass tweezers push the o ring half way along the stick. Pick up the pusher between finger and thumb of left hand and hold the stick against the end of the pusher ( with end of pusher in the 1mm divot). Slide the o ring along the stick with the tweezers and it just goes into place very easily. Hope this makes sense. How do you guys do this? Is there a specific tool that you should use? Steve.3 points

-

2 points

-

2 points

-

That is a Hattori VD57B movement. https://www.esslinger.com/hattori-japan-chrono-6-hand-quartz-watch-movement-vd57-date-at-3-00-overall-height-6-8mm/2 points

-

Hi attached is the parts sheet should you require and parts. Eterna 1411.pdf2 points

-

2 points

-

The acetic acid in vinegar is more aggressive than citric acid. I'm not keen on the high water content in vinegar though. I thought I'd do a quick scale of what to use so far to remove rust for future ref, and would love any additions or feedback on them. Some things I have tried and some I have not . But I will definitely be experimenting when a situation arises.. No 1. safest option naptha and any alcohol based product. Generally little effect. No 2. Lemon juice, citric acid. Some reasonable effects. No 3. Vinegar, 5 -10 % acetic acid 90 % water. Good rust removing ability, be aware high water content. No 4. Coca Cola . Contains very small amounts of phosphoric acid, high water content and sugar Also good rust removing ability. Four easily obtainable household items. Each can have heat (naptha and solvent with caution), ultrasonic, mechanical and prolonged soaking to increase their rust removing potential. Lastly specific manufactured products. Evapo rust, wd40 rust remover. I have only tried Rustins, this stuff is lethal and will literally dissolve small watchparts overnight.2 points

-

Welcome to our forum! Wait until you meet JerseyMo! He's one of our Timex experts. We have a few. I specialize in the antiques, primarily pocket watches, and even I have gained a measure of respect for old pin-lever Timex watches. I have an old Marlin and an Electric. They may not be a Vacheron Constantin, but they have a certain vintage charm to them. And once you get used to expecting certain unique idiosyncrasies, they're actually not that hard to service. There's even a degree of parts-interchangeability between some models. A couple years ago, I'd never expect to be singing any praises about them, but for something rugged, reliable, affordable, and accurate enough to get workers to their job on time, they're a hard act to follow. Have fun here! Share stories! Post pictures! Spend time!2 points

-

I'll see if I find the time to measure them tomorrow. That's a good idea! Unfortunately, producing videos is extremely time consuming if you strive for decent pedagogic quality. Anyway, there are several videos on YT that demonstrates the Bergeon type of mainspring winders and they use the same principle.2 points

-

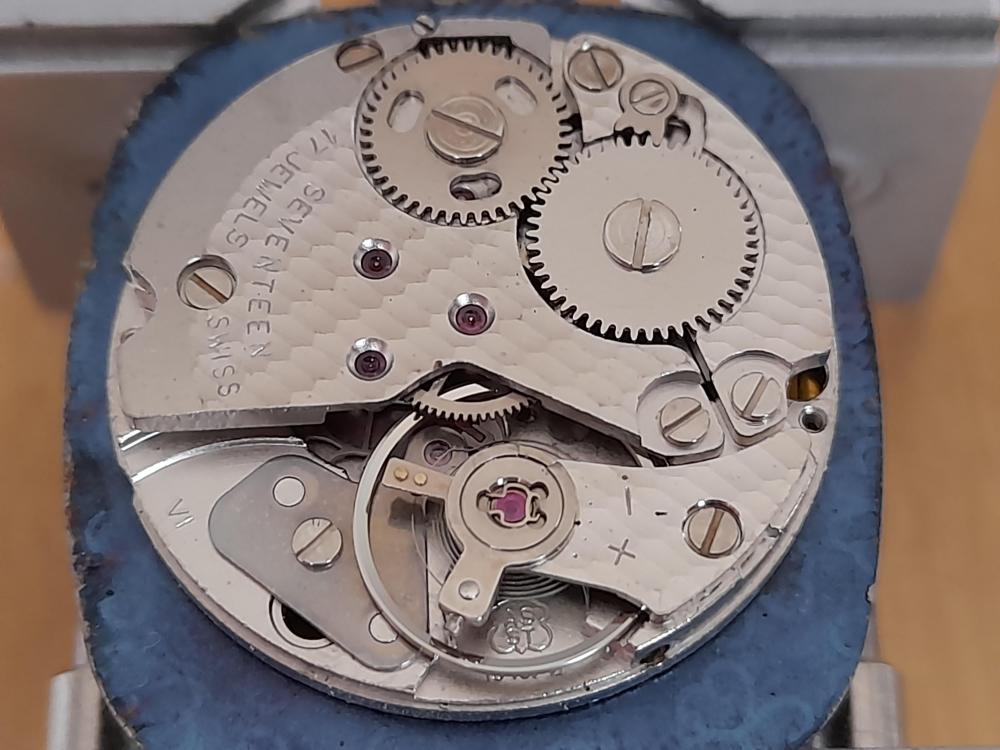

Not so much what's coming but what's arrived. I feel very lucky to win these two. Especially the Timex 100, lovely blue face. I didn't know Timex used a swiss movement back in 1975. Was it a short lived thing, or was this a more expensive Timex back then? Sadly it's not running very well, looking forward to finding out why. Couldn't wait to have a peek inside so posted a couple pictures too.2 points

-

1 point

-

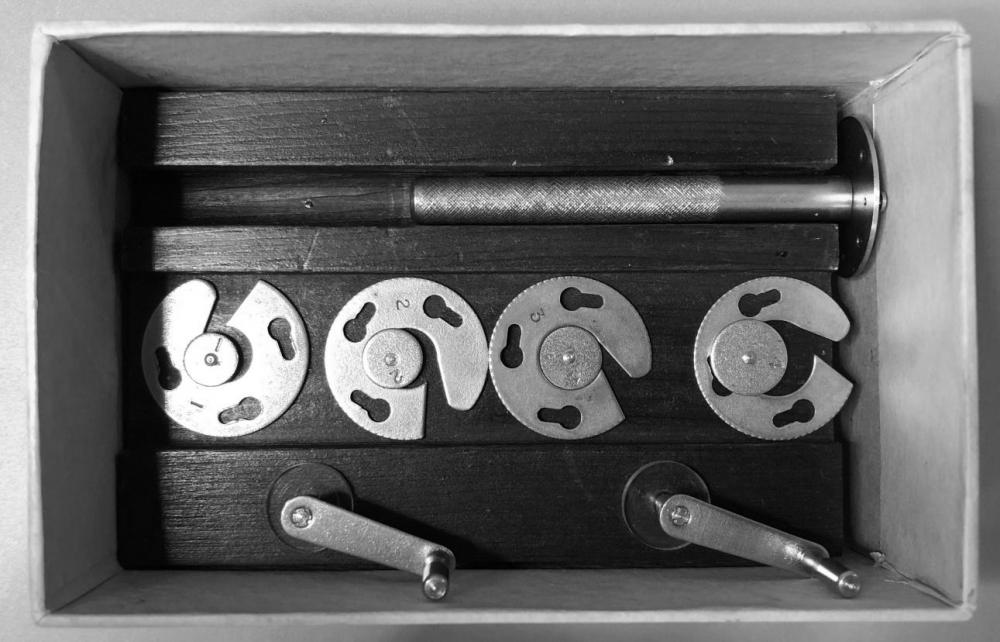

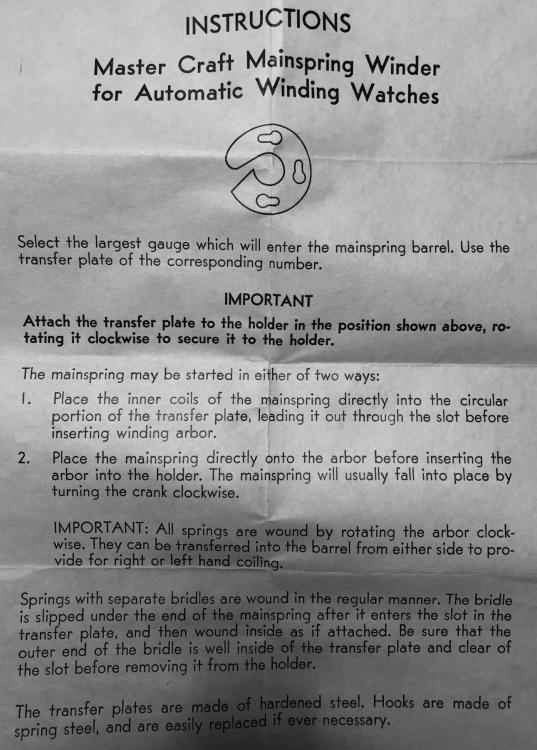

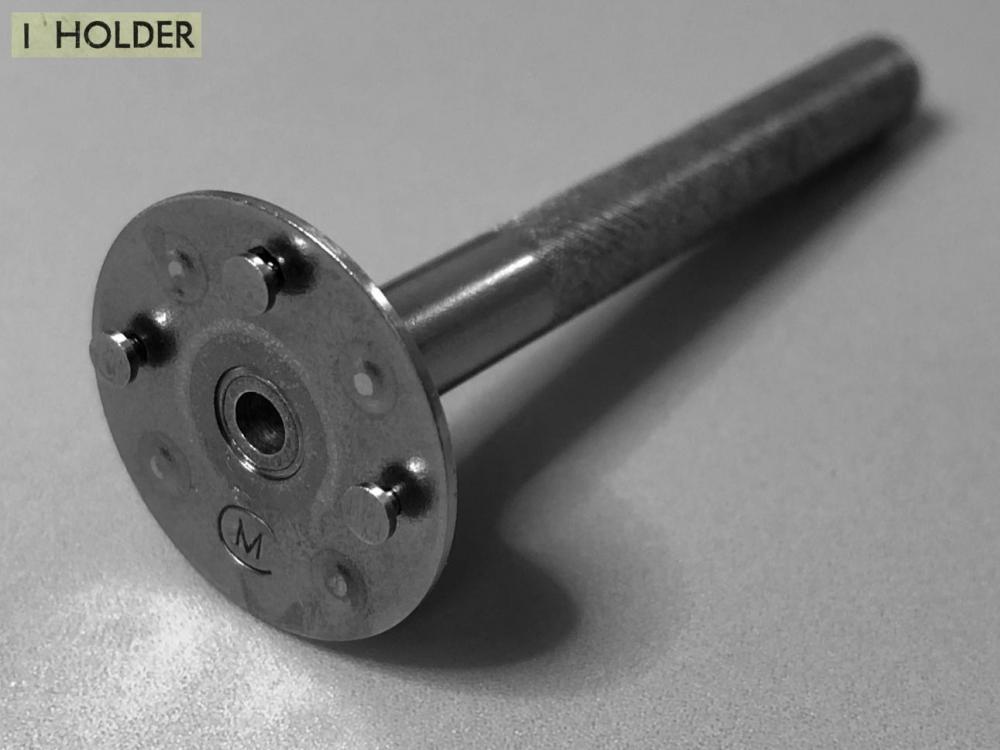

This Master Craft Mainspring Winder has been recommended and praised several times by @clockboy and I’m so happy that I, after several years of trying to acquire one, finally found a copy in very good condition on eBay. The Master Craft mainspring winder is surprisingly easy and convenient to use, and of the mainspring winder variants that I have tried so far, K&D 128, and Bergeon style winders, I must say that the Master Craft winder is the one that I now prefer with a good margin. Maybe a bit exaggerated, but I always dread and feel tense using my other mainspring winders, especially the K&D 128, but with the Master Craft I feel perfectly confident every time. It’s simply a joy to use and handle! There are several things with the Master Craft mainspring winder that I especially appreciate: The transparent discs of the winding arbors that make it so much easier to understand what is going on with the mainspring, both when you crank it in and especially when it’s to be detached from the winding arbor. The gauges that make it superfluous to measure the inside of the mainspring barrel. Instead, you can just try out which gauge best fits in the mainspring barrel and that’s it. That the mainspring can be transferred into the mainspring barrel from either side of the transfer plate to provide for right- or left-hand coiling. A nice feature too is that these transfer plates are coin edged making them easy to attach and detach from the holder. That the mainspring is so easy to crank into the transfer plate as the contact area between the mainspring and the transfer plate is so small. It almost feels as if the spring has lost 50 % of its tension. It also makes it quite easy to pull out the mainspring a bit from the transfer plate if you happen to crank it too far to get the bridle in. That it’s so easy to get the hook on the winding arbor to attach to the hole/eye in the inner coil of the mainspring. Using the suggested "method 1" in the user manual, I just push the winding arbor down in the inner coil of the mainspring while I crank it and the arbor hook automatically finds its way into the hole/eye in the mainspring. Conclusively, I must say that I’m super happy with this cleverly devised mainspring winder. It exceeded all that I was hoping for and was expecting! So much that I felt an obligation to write this post.1 point

-

The arbor diameters are 2.4mm and 2.7mm. If you can DIY one, it would likely draw a lot of interest! Let me know if I can provide any other info about this Master Craft mainspring winder and I'll see what I can do.1 point

-

Yes it fusee ww. It was up at 68.00 and had a trade price of 60. I thought it was ok for 60.00. Needs a good service though. , I'm only getting 4 winds on the key about 3 hours. Yes randy. Its very similar1 point

-

Hi like everything in watchmaking there is a tool but not as cheap and effective as yours, thanks for the post it may save a frw members headaches.1 point

-

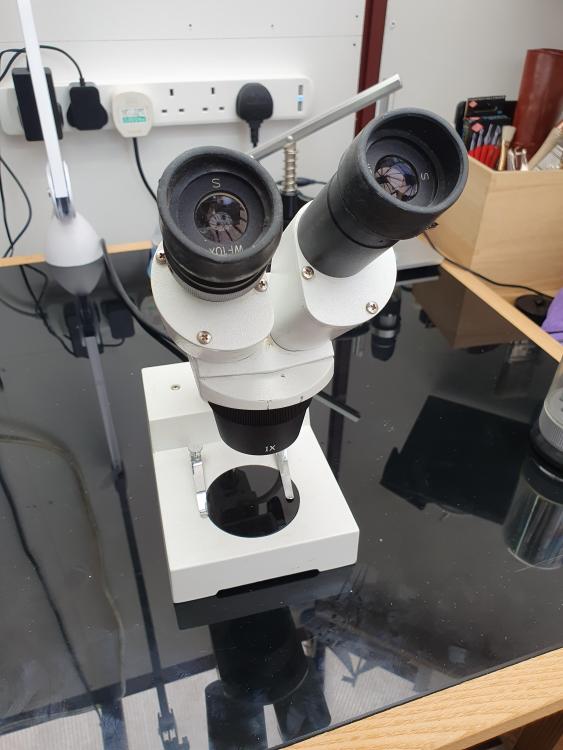

I meant the scope gets your working head height at a comfortable position relative to a normal bench height, rather than needing to bring the work surface up high enough to not cause neck injury. I went the opposite direction in my shop by cutting the legs off an already short stool to bring my head down to bench height rather than the other way around. It's not as comfortable for my legs, but was an inexpensive trial of the work height adjustment, and my toddler will get plenty of use out of it if I don't. Since I got my scope, I haven't used the stool for anything more than a foot rest.1 point

-

Hi Definitley english is it a fusee with a chain?. Harrogate £80 not too bad, everything costs more in Harrogte its posh there. Have a shufty at the pocketwatchdatabase.com and see what the number brings up.1 point

-

Hi Ross Hector is spot on Hattori VD57B I have attached the techincal docs for you. some of these guys require you to jump start them by shorting out the ac (clear) spot and the cover plate , it will all be in the docs if so. cheers 3007_Hattori VD57B pg 1-5 (4).pdf 3008_Hattori VD57B pg 6-10 (2).pdf Hi Ross Apologies for the garbage pressed wrong key (senior moment)1 point

-

1 point

-

1 point

-

I wouldn't be surprised if Brooks & Bentley was bought by Japs, the movement looks a generic Japan made one. Compared to mechanical movements, Chronograph complications on quartz movements are somewhat less complex to work on, nevertheless, you are likely to get advised to replace the movement if this one needed a full tear down. Good luck pal.1 point

-

A good thing about Timex is that one can't get it to run worse. Welcome to WRT forum pal.1 point

-

A mild but effective rust remover, used since centuries, is tea. I recommend to try it before sugared drinks or chemicals made for marine engines and the like. Even if isn't a mandate, there is a certain satisfaction is getting results by using old methods and tools in restoration work.1 point

-

For reference the GR mainspring for the 72 is 3357, 1.30 x 0.14 x 360 11.5 This caliber is a particularly good runner, but if you were getting enough amplitude to rebank you probably did have the wrong spring. I have gotten springs from old suppliers where the spring was in a hand marked envelope, no size or ref other than "Val 72" and they've been way too strong. Don't remember the measured thickness but they were too strong. This caliber, with 270 horizontal, should drop around 40 degrees to 240 give or take. If it's dropping to 190 there are other issues. If the escapement is set up with heavy locks, either from opening the bankings or pulling the stones out, that can have a more noticeable affect on the verticals than horizontals. If the balance pivots are rough, same. Too much endshake on balance, same. I am thinking you got it with the strong mainspring; perhaps a previous repairer tried increasing the lock to drop the amplitude. When you're back at the bench, some close up picks of the escapement locked on both sides, and if possible, some video, would help. Yes, you can adjust an escapement without the expensive tools, but it can be a lot of back-and-forth trial to hit the sweet spot.1 point

-

So it‘s an Eterna 1411U caliber. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Eterna_1411U_0&1 point

-

Is the positional variation not good enough at 270 degrees? I wouldn’t worry about the chronograph running amplitude too much I wouldn’t recommend altering the escapement action - if you increase the lock then this is effectively making your lever escapement less “detached”. I would have a look at alternative mainsprings.1 point

-

A type of rust remover is needed. I hate the stuff but WD40 would do.1 point

-

It belongs to the Eterna 1411 to 1415 caliber family. If you measure the diameter of your movement you will know exactly. It’s very unlikely that you’ll find this two-part stem anywhere in stock. One-piece stems should be still available.1 point

-

Soak the plate in Coca-Cola for 48hrs. Naphta isn't as effective.1 point

-

Its an ETA, the caliber No is stamped under or near the balance on the mainplate.1 point

-

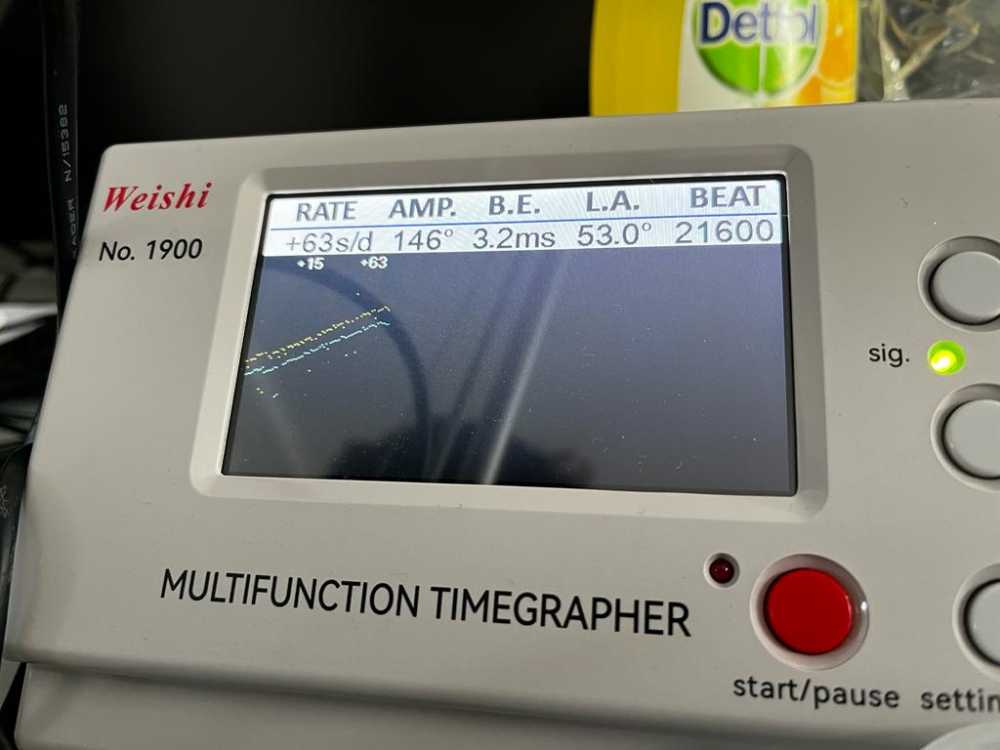

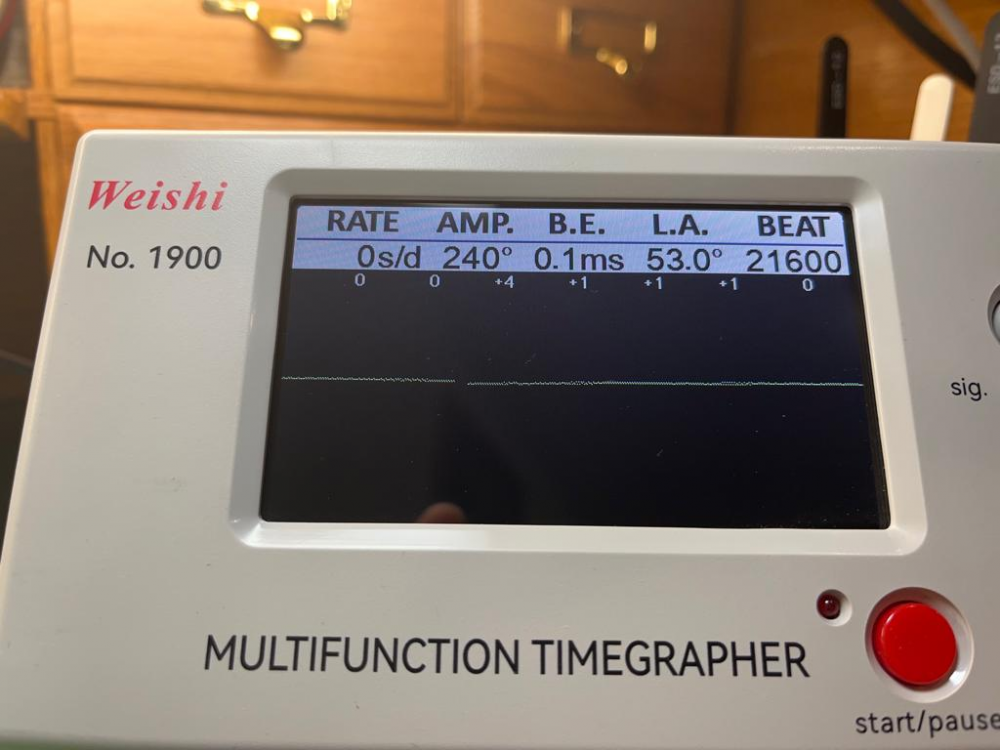

i want to give a quick update, thamks for the tips, i rewinded the barrel and it gave juice to the train. And after a few dismantlings of the barrel bridge, i found what was wrong, the pallet fork pin was crushed (i think my fault) and i broke 2 balance springs (happy i had reserve). After the cleaning and oiling i checked it on the timegrapher: and this is it now after all the work and adjustment:1 point

-

Hi Ross the whole idea of a forum such as this . the dissemination of information. I find it dificult to comprehend when that is not so . as there is no purpose in being on the forum if you are not able to share knowledge and information to those just starting out. ask all the questions you want its a major way of learning all the best.1 point

-

When you let Google search after this brand logo (double B with crown) it will return nothing. So this brand is most likely „unknown“.1 point

-

You may find the right microscope makes a taller work surface unnecessary. You're definitely leagues ahead of most of us amateurs!1 point

-

1 point

-

I don't suppose you could give us a picture of the timing machine results? It also is nice to see the watch in another position other than dial down a dial up whichever you're currently using. In other words crown down to be really nice.1 point

-

1 point

-

1 point

-

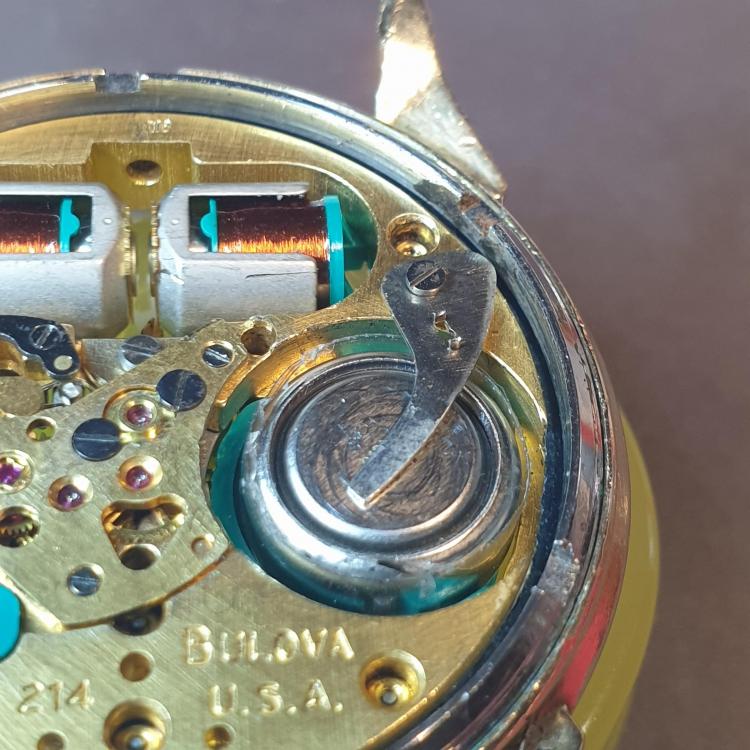

I've been servicing Accutrons for some time now. But yesterday I just had an AHA! moment. When phasing the 214, I had been using the power from my Accutron 700 test meter to supply voltage to the watch. I would clip one lead to the ground strap and used one hand to press the positive lead to the battery terminal. This leaves only one hand to adjust the pawl finger. I was thinking of a way to make a battery clip hold the battery in place to make this procedure easier. Then it hit me.... All I needed to do was to flip the ground strap upside-down and use it as a battery clip!1 point

-

I had a concave pusher in my set that was big enough to do an hour hand. It is almost the same profile as the hand closing pusher. I'm sure the correct tool would have been better but it worked.1 point

-

I imagine your zinc isn't the issue. What grit is the diamond powder? What type of oil are you using? The mixture should be thick, like twice as thick as peanut butter. Natural plant oil is better than mineral oil. The plate should have a textured surface, like from a very coarse file. It does have to be clean of course, and it's good to keep a file that is only used to dress the plate. When polishing you want the paste to dry out. If it's wet the grains can ball up and give you scratches. It will get to a sort of "magic" state where it's just dry enough but not too dry. Some guys will use one part of the plate with wetter paste and have a dry patch for the final bit. Generally you'll flatten the part on self adhesive precision graded abrasive paper stuck to glass, 12 microns is a good general grit, and you can go straight to polishing. Clean the part extremely well to not transfer grit to the plate. Something like your set bridge you'd want to glue or shellac to a subplate and hold that in your tripod. I use round plates about 80-10mm diameter. When I dress them I make a line down the middle of the plate and keep the feet of the tripod on one side, part on the other. If the polishing is going well but it get just a bit too dry and you don't want to mess things up reapplying paste, just breathing on the plate can help. Most folks I know use tin rather than zinc, but both work. I prefer tin. Swedish and Finnish watchmakers like to add about 0.5% of silver; but when I asked several how they add the silver they said they just add a little piece to the melted tin- which is nowhere near the melting point of silver and just proves how much superstition surrounds polishing. As for abrasives, as Hector said diamond isn't necessary. I used to use aluminum oxide from Linde, 0.3micron, which was great. Around here everyone uses Biodiamant, which is a prepared diamond paste in like a giant chapstick tube, so I use that now. Both work fine.1 point