Leaderboard

Popular Content

Showing content with the highest reputation on 04/30/22 in all areas

-

4 points

-

3 points

-

I took a look at your original thread, and saw that the needed replacements for are the rubbed in sort. Technically, this means that replacement of these jewels is going to be more difficult than the modern friction sort, which only require a Seitz type tool which presses the jewel out, and the replacement jewel pressed in. In jewels that are rubbed in to the mainplate, replacement of the jewels is quite time consuming. After removal of the damaged jewel by shattering it, the lip of metal that originally held it has to be opened. You then have to find a jewel with the right pivot hole, and right diameter, fit it in, then close the metal lip again. Do note that rubbed in jewels are not shaped like normal friction jewels, and are rounded at the edges, making purchasing them difficult. End shake adjustments of rubbed in jewels are also quite difficult to achieve. Even if you wanted to change the jewel type to friction fit, you would need a lathe to open the original hole to the right size. I am sorry to say, but I would expect that if you wanted to pay someone to do this, it would probably cost you $200 per movement, unless the person is doing this for his own practice/hobby. Even then, buying the replacement jewel might cost at least $50, if they can be found at all. I would suggest you save your money, and buy a working movement from somewhere else...3 points

-

3 points

-

3 points

-

Hi It looks ok If you are happy with the layout and lighting etc thats all that matters. If like me I have changed my workshop around three times and re floored it changed the lighting, I am happy they way things are , for now!.3 points

-

I've collected about 1/2 dozen extra cases, all 16s for pendant-set, open face movements. One or two I purchased separately simply because I liked them, the rest came with salvage movements that i doubt i can ever get working. Mark makes everything look so easy I must admit if i was certain i could find the proper replacement jewels (which I haven't even tried), i might be interested in investing in the tools and make this a project for next year as my confidence builds.2 points

-

Hi Would you have a go yourself? There are a few tutorials on YouTube, I’ve changed a couple of jewels over using peg wood. Obviously it’s better using jeweling tools but extremely expensive to buy. This is the tutorial I used2 points

-

2 points

-

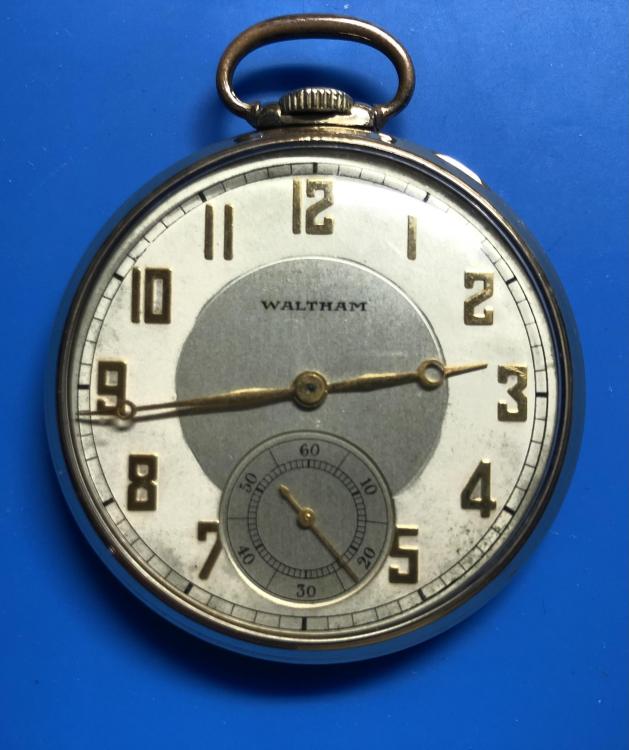

Hi Ross a picture of the movement will give us a clue. The names on the dials can be the finishers or the advertisers.2 points

-

A centenarian "H Samuel" branded Exactima - Most likely produced by H. Samuel / H. Williamson Ltd. Uhrwerke,; Büren, Schweiz; Some time between 1910 and 1920. This was in a lot with two other watches. A no name, ladies gunmetal pocket watch I would guess from around 1890 which probably has balance issues and a Services 5 jewels Art Deco wrist watch probably from some time between the 1930s and 1950s which the seller claims has a broken mainspring. The Exactima looks to be complete, and indeed was listed as "One Exactima H.Samuel 7 jewel pocket watch with broken mainspring but complete." - Time will tell whether that is an accurate description. Hopefully the seller can tell the difference between a mainspring and a balance. Mainsprings are a whole lot easier to come by than balances for these old watches. If I can get it running, I think it should look quite attractive, despite its modest origins. The nickel case should polish up nicely Needless to say these are prospective 404 club candidates since the ebay lot cost just under seven pounds.2 points

-

2 points

-

I am a long time watch enthousiast, but recently i began to watch Michael Bolton on youtube, and i said to myself why not give it a try? So i have a few watches with seiko 7s26 movement and started to dismantle and rebuild. My plans are to give my other watches also a good maintenance. I have also watches with the 7s36, 6309,4006 movents. I can say i really love the watchmaking because it give rest and peace to me .1 point

-

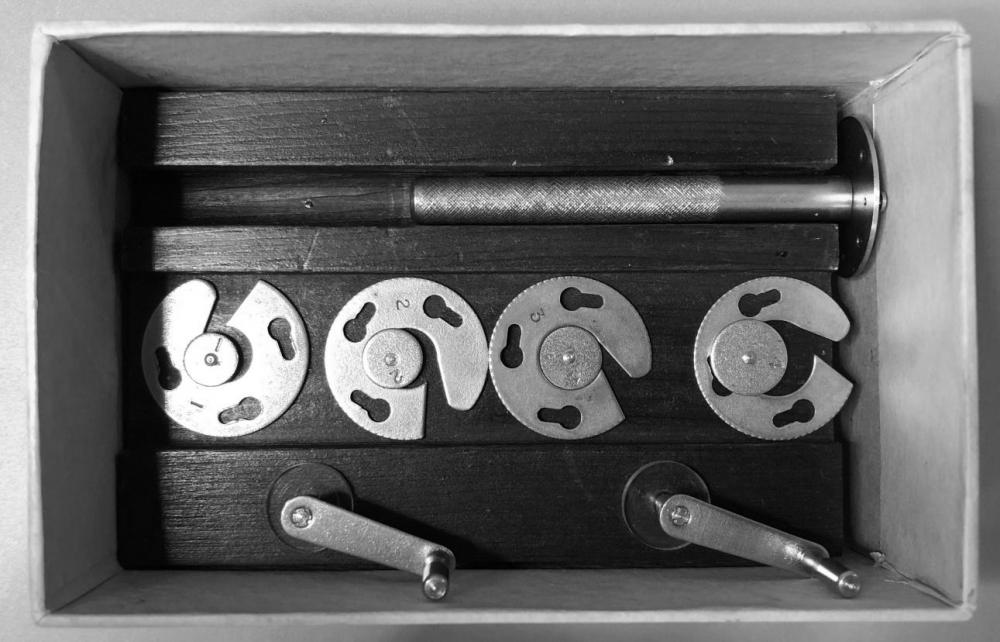

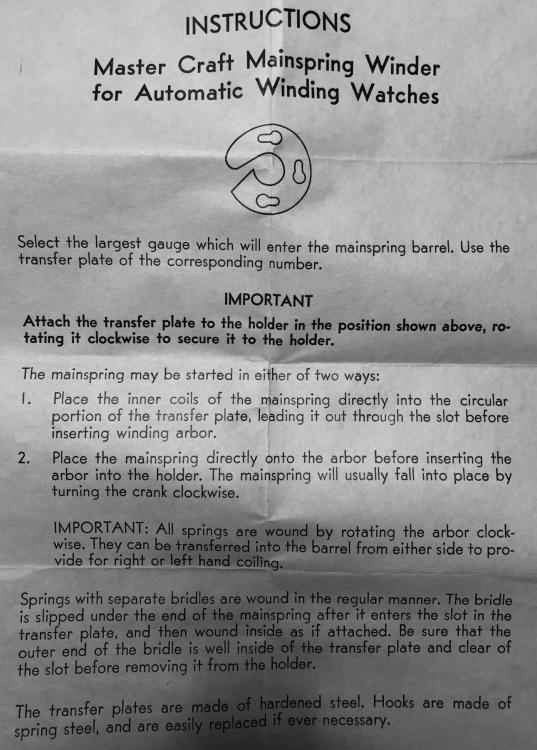

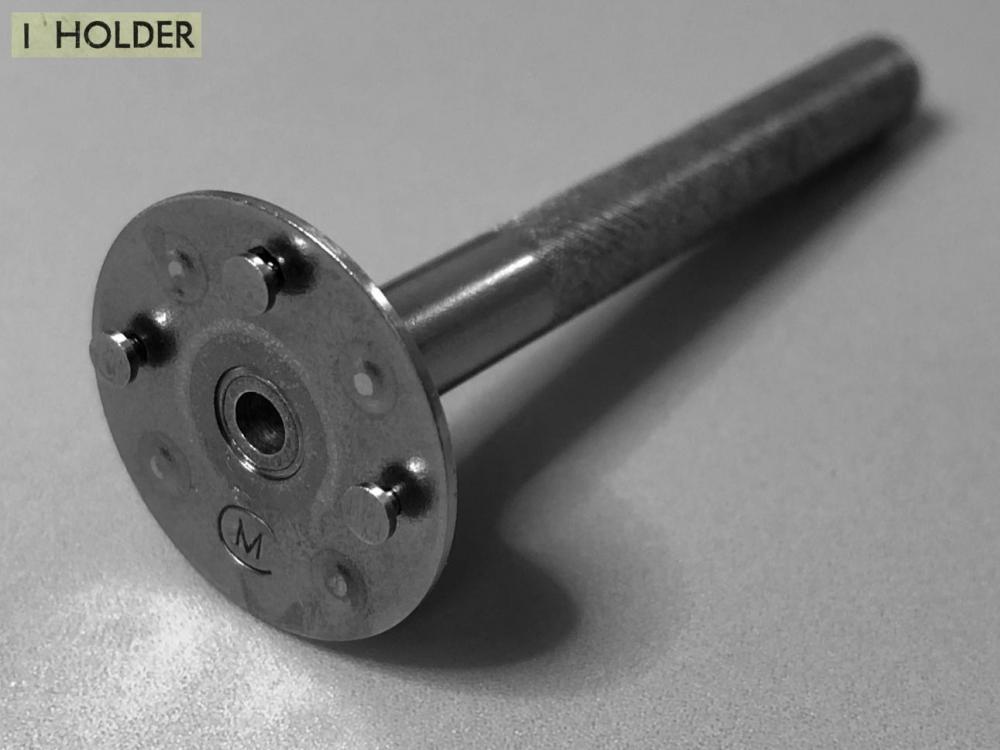

This Master Craft Mainspring Winder has been recommended and praised several times by @clockboy and I’m so happy that I, after several years of trying to acquire one, finally found a copy in very good condition on eBay. The Master Craft mainspring winder is surprisingly easy and convenient to use, and of the mainspring winder variants that I have tried so far, K&D 128, and Bergeon style winders, I must say that the Master Craft winder is the one that I now prefer with a good margin. Maybe a bit exaggerated, but I always dread and feel tense using my other mainspring winders, especially the K&D 128, but with the Master Craft I feel perfectly confident every time. It’s simply a joy to use and handle! There are several things with the Master Craft mainspring winder that I especially appreciate: The transparent discs of the winding arbors that make it so much easier to understand what is going on with the mainspring, both when you crank it in and especially when it’s to be detached from the winding arbor. The gauges that make it superfluous to measure the inside of the mainspring barrel. Instead, you can just try out which gauge best fits in the mainspring barrel and that’s it. That the mainspring can be transferred into the mainspring barrel from either side of the transfer plate to provide for right- or left-hand coiling. A nice feature too is that these transfer plates are coin edged making them easy to attach and detach from the holder. That the mainspring is so easy to crank into the transfer plate as the contact area between the mainspring and the transfer plate is so small. It almost feels as if the spring has lost 50 % of its tension. It also makes it quite easy to pull out the mainspring a bit from the transfer plate if you happen to crank it too far to get the bridle in. That it’s so easy to get the hook on the winding arbor to attach to the hole/eye in the inner coil of the mainspring. Using the suggested "method 1" in the user manual, I just push the winding arbor down in the inner coil of the mainspring while I crank it and the arbor hook automatically finds its way into the hole/eye in the mainspring. Conclusively, I must say that I’m super happy with this cleverly devised mainspring winder. It exceeded all that I was hoping for and was expecting! So much that I felt an obligation to write this post.1 point

-

No problem with my 130,190,260 and the others pushers on my chinese horia clone.1 point

-

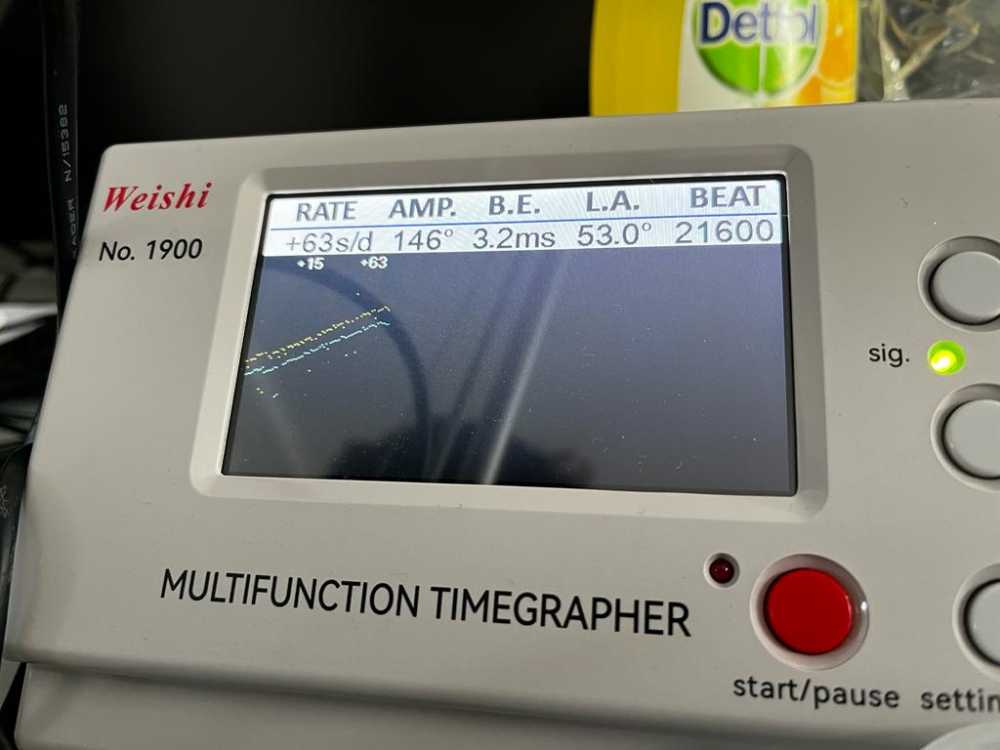

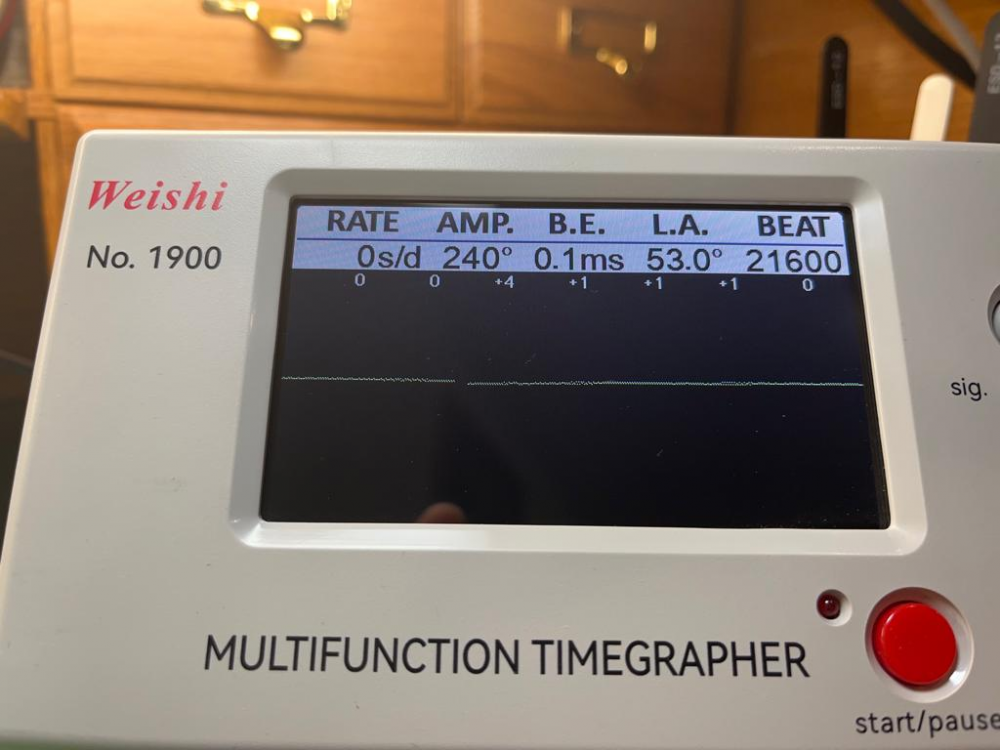

i want to give a quick update, thamks for the tips, i rewinded the barrel and it gave juice to the train. And after a few dismantlings of the barrel bridge, i found what was wrong, the pallet fork pin was crushed (i think my fault) and i broke 2 balance springs (happy i had reserve). After the cleaning and oiling i checked it on the timegrapher: and this is it now after all the work and adjustment:1 point

-

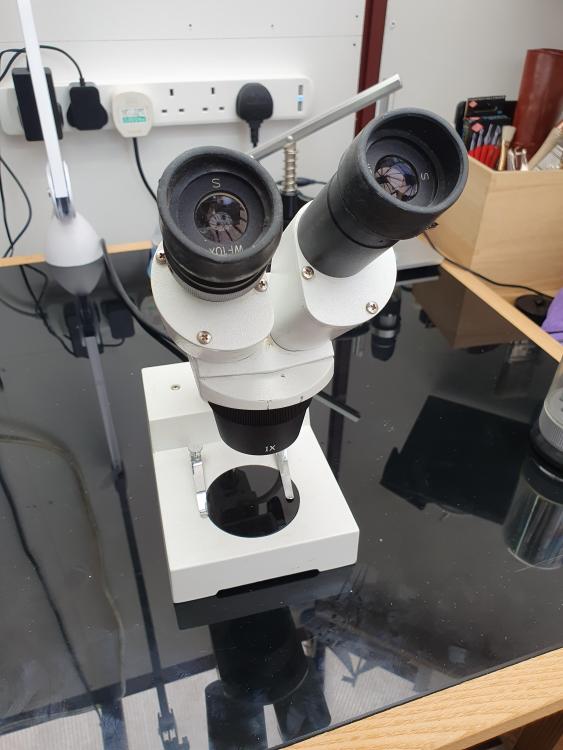

You may find the right microscope makes a taller work surface unnecessary. You're definitely leagues ahead of most of us amateurs!1 point

-

1 point

-

I bought a load of ancient jewels from eBay that probably have been gathering dust for the last hundred years all in good shape though. Then spent the next few days sorting through them, certainly learned patients. I had the old jewel to use for measurements. I would love a jewel press though, next time I’ll get one1 point

-

I also had a similar issue with the clone tool that some of the pushers were a little oversize. I should actually check and compare if it’s the same ones you had an issue with. That being said, I’ve already used it twice to replace jewels and it worked a charm. Someone should do a video on using this type (hint, hint @VWatchie), it took me a while to figure out exactly how to use it.1 point

-

For some reason the barrel I hate the most is the one I do most often. Big ups for having the guts to do it manually, they are real thin and a total pain1 point

-

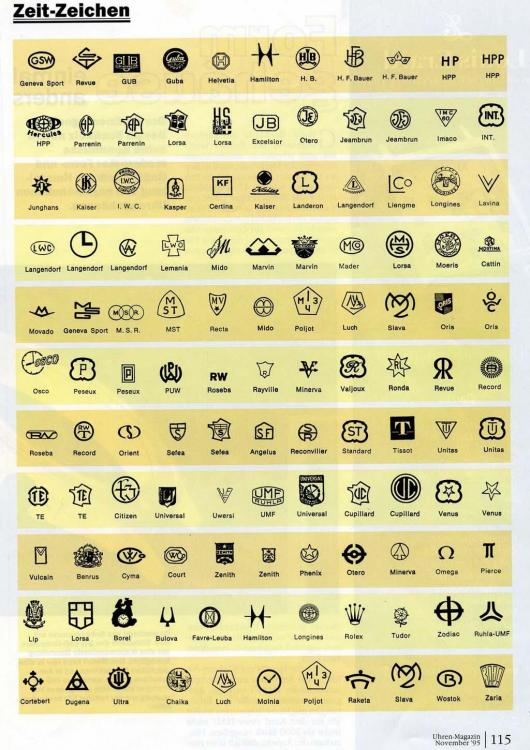

Hi Ross Indeed they do, you find Hattori movements, Miyota's movements Ronda movements in quite a number of cases with different names on the dial. It was the same years ago when the Eubauches manufactured several brands and did exactly the same (badge technology) The ones within a sheild P =Peseux and ST all eubauches movements. The one in side yours could be any of the quartz ones mentioned. To illustrate the problem I have attached a sheet of watch makers marks. So in effect you could order a watch and have any movement you choose and your name on the dial, doesn't mean you made it. Thats why we go with the movement mark and caliber number (the people who made the watch movement). Ordering an escape wheel for a Tissot means nothing It may be using an eta 2428-2 movement or Sellitia.1 point

-

I've seen where people will put the modern jewel in the burnished in setting the problem is it's not the right size shape and can have issues. The best is to modify a modern jewel which can be done if you have access to diamond lap sexy quite simple but still you have to modify the jewel to fit the original burnished in setting. according the book you don't need a lathe. The only minor problem with the pictures below is that to open up the hole big enough for friction jewel oftentimes they become really big.1 point

-

Oh my god, what a mistake. i'll try to reverse it, thanks for the solution and answers everyone.1 point

-

You're right! I think doing close hand work is relaxing for me too! Welcome to the forum.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Who is Michael Bolton?1 point

-

Its a case of any pin will do who cares what it looks like.1 point

-

1 point

-

Hi If the upper picture is the original and the lower one is the new spring it is indeed wound in the wrong direction1 point

-

1 point

-

Remove the arbor, tilt it into the inner spring loop. Fiddle with as you get the loop to surround the arbor and fit into the hole on the bottom of the barrel.1 point

-

Apologies for my late response, just didn't notice your post. I hope we get a good advice from those who know. Regds1 point

-

I, also, should track down a good book that covers more of the engineering that A.L. Breguet devised. The man was an horological genius, and practically lived and breathed timepieces. The concepts of modern mechanical timekeeping probably owe more to him that to any other single person before or since. I'm thinking the Daniels book would be a great one to have.1 point

-

yes i thought of that although it is the correct movement. I have had a look at rranft and all the data sheets on cousins, but no matter what the variant they all show jewelled movements. I am just wondering why this one is not. I think i have solved the riddle , my bridge appears to be from a 2572PC which was unjewelled.1 point

-

If you get yourself the same Horia clone that I bought and it works as well as mine, you will be satisfied. However, just do not expect that everything will be 100 % perfect but more like 95 % perfect. Anyway, when you can save approx. £1750 compared to the original Horia tool it's basically a no-brainer. At least if you are not a professional.1 point

-

This concept with the „transfer plate“ and the use of a spring as a hook is ideal for a self made winder imho1 point

-

Looks interesting. Hope some Chinese manufacturer picks up on it. I'm sure the patents have expired.1 point

-

1 point

-

At the moment I'm using a generic ultrasonic cleaner that I picked up on Amazon along with an ultrasonic concentrate that mixes with water. So far I have only run one set of old Elgin grade 313 parts through this. I'm likely going switch to something more watch-specific for a clean/rinse pairing. While I was careful to dry everything, I have noticed some tinges of rust here and there. I may clean again using lighter fluid with a rinse of Security Brand® Hairspring Dip. I'm not anxious to spend $100+ on 2 gallons of L&R product at this point. I do have lighter fluid and 99.9% IPA on hand.1 point

-

I broke down and purchased an Elma basket stack that has three stainless baskets about 2.5" DIA x 0.5" HIGH as well as a tiny basket that fits inside one of the other three. These stack inside the blue plastic attachment for an Elma machine. This will allow me to do a whole movement at one go rather than breaking everything out into the little tiny baskets that I had originally purchased.1 point

-

Anyway, it doesn't have to be a perfect fit. As long as the length of the mainspring can fit inside the transfer plate I don't think it matters much if the diameter of the transfer plate is too small to fit perfectly inside the barrel. (I'll see if I can replace this image of the gauges in my first post) There's a "hook" on the spring wrapped around the winding arbor, it just doesn't show in the picture. The below excellent post by @clockboy illustrates it well!1 point

-

1 point

-

1 point

-

Could be the Automatic winding weight is from another watch?1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point