Leaderboard

Popular Content

Showing content with the highest reputation on 04/22/22 in all areas

-

Hello all. Actually thought I registered for this site back when I took the watch repair course but guess I was wrong. My name is Chris. I am retired military and have been working on clocks for around 8 years. My dad owns a clock shop and taught me everything I know on clocks. I recently just graduated watchmaking at Gem City College in Quincy, IL. Will be moving to Arkansas in a couple months and going to help dad at his store. Guess that's all I have for now. Looking forward to helping and gaining knowledge from fellow horologists.3 points

-

200 degrees is the lower limit after 24 hours in a vertical position for vintage pieces by some Swiss makers. 200 horizontal at full wind is far from decent amplitude. Not much use looking at the timing discrepancy after a day of running until you get the amplitude up to a healthy level. At 120 degrees of amplitude every little fault in the escapement gets amplified, no surprise if it sounds strange. Almost impossible to troubleshoot the amplitude problem without more information, but the timing difference could be something as simple as the regulator pins too open. -how was it cleaned, how was it oiled? - was there train freedom and recoil of the escape wheel after a couple of clicks of wind, dry movement, fork out? -does the fork snap back and forth cleanly with a slight nudge with just a few click of wind? -does the balance oscillate freely with the fork out? with the fork in, no power?3 points

-

I've yet to service a watch having the impulse pin fixed with shellac. I believe it's basically just "very old" watches having the impulse pin fixed with shellac. So, all the watches I've serviced so far (not that many) have had their impulse pin friction fitted.3 points

-

2 points

-

I have vibrated springs using a stopwatch when I didn't have the correct master balance for the Luthy tool (those wonderful LeCoultres with 20,222 or 20,944 beats per hour haha). Just count every other beat and do the math over 30 seconds and you will be close. The pain is how to hold the spring if you don't have the tool. Just holding it in your tweezers will get you in the ballpark, even though the micro movements of your hand will have an influence. You will probably be close enough to do as Joe says above, get it in the watch with some extra spring out the stud and adjust from there.2 points

-

As @nickelsilver says - "does the balance oscillate freely with the fork out?". But was is 'freely'? One test I do straight after cleaning, is put the balance and cock on to the mainplate, then give the balance a good blast from a dust blower. For a balance like that, I want to see the balance still moving well after 30 seconds. If it's barely moving, or stopped, after 30 seconds, something's wrong. You can also have a good look at the mainspring from the side, and check endshake.2 points

-

2 points

-

I quite like the look of that tool and may get one to modify. I’m still surprised at the number of people who are paranoid about deforming hairsprings by suspending the balance wheel by the spring. In my experience, there are few balances which are heavy enough to cause damage if you handle them carefully.2 points

-

1 point

-

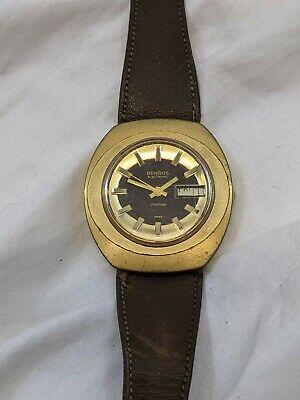

Hi all! I just picked up this little watch - not running, super dirty inside, but looked too interesting to pass! doesn’t have any markings on it (aside from “Swiss made on one of the corners of the movement).. any thoughts on where I can find more details on it? I don’t have any tools yet so perhaps I could look behind the dial once I can get it off!1 point

-

Hi Khang. Ww. Might be right. My raketa manual wind has a similar thin plate that fits onto the mainplate. I'm not sure if I recognise anything else though but I could have a look it's in pieces at the moment.1 point

-

Are you talking about brand-new Raw hairspring or matching an existing hairspring to a different balance wheel? The reason I ask is the procedures are different I hope you have deep pockets? Standard watch timing machines have limits like the Chinese machines will only go to 999 seconds which seems like a lot until your vibrating hairspring. Witschi has additional features at about 10 times the cost of the Chinese machine. For instance frequency mode will tell you exactly how many beats per hour your watches running. So if you had your new balance wheel hairspring combination running watch the witschi machine would tell you how far you are away from whatever frequency are aiming for. Otherwise you go with the clock timing machine they typically measure beats per hour. Then there's another option which is the Microset timing machine as it has a hairspring attachment for vibrating hairsprings. https://www.bmumford.com/mset/ Then if you're only doing one hairspring this would be the easiest procedure to follow1 point

-

Replacing a pocket watch mainspring is the same as a wristwatch mainspring. If you can identify who made the watch you can look up and see what supposed to be used. Otherwise you just measure the dimensions and find another spring. The only complications you run into typically with pocket watch springs are specific types of ends. Like T type and there's a variety of other ones very common on American pocket watches. It would be nice to have a picture looking straight down on the barrel so we can see the entire spring in the barrel. Can't quite see where the end is as you seem to trim that often all the pictures? But it looks like a standard tongue type in spring. Also looks like it fills the barrel up nicely it's not too short I would just pull it out and measure it and get another one. If you give us the dimensions we can look at our mainspring books and see what probably is. Typical mainspring measurements are based on the width – thickness and length. Sometimes there's a fourth dimension which is the diameter the inside of the barrel in other words if you expect to build this shove the mainspring and without a Winder. These are more common on wristwatches.1 point

-

So I've been stripping down the case today and removed the dial. The wife looked at the case and said your not buying second hand anymore. I think it needs a over night bath. When I removed the dial I noticed I break in the mounting ring (think that what it's called) would you glue it or replace it. I would like to replace the hands as they all bent from the bubble wrap and the fact that the glass was missing. I am going to replace the bracelet as it's all bent and most of the links are damaged Glass should arrive in June. But I may still order the original shape, I'm not sure yet1 point

-

I've got a lathe, but neither the skill nor the cutters to do anything as yet. Have you got the original?1 point

-

I was able to find the exact part number for my Elgin grade 313 by going to: pocketwatchdatabase.com however I know the model and serial number of my movement. As @praezis says, you might not need a new spring. Does the arbor engage with the end of the spring? Optionally, if you know the height of the spring, the thickness of the spring and the length of the spring you can go to: https://www.cousinsuk.com/category/filter/mainsprings-by-size-watch-pocket and by matching the end hole patterns they will make an effort to suggest a spring. Let us know how it turns out.1 point

-

These guys (Horologica) have some info on the bellows etc. https://r.search.yahoo.com/_ylt=AwrIQhK8.2JiKYkA0yR3Bwx.;_ylu=Y29sbwMEcG9zAzQEdnRpZAMEc2VjA3Ny/RV=2/RE=1650682940/RO=10/RU=https%3a%2f%2fhorologica.co.uk%2fC_services%2fAtmosBellows.html/RK=2/RS=KAbR03yS7ZKjtQRvQMz19ga3Eik-1 point

-

Whoop whoop. Oh yeah I'm a winner Cheers Khang. You're a mate XXX. I need to go thank Rich.1 point

-

1 point

-

Haha you read my mind. I was just commenting on it when you asked freaky1 point

-

Its is possible to calculate the length difference from ratio of is-swing period to wanted-swing period and total length of the spring (with factor 1/2 or was it x2?). Observing the Caspari effect would be very useful, but using a hairspring w/ collet, you have to accept what you will get. Frank1 point

-

Another possibility if they are pooly finished parts is that it is of Russian origin. If possible assemble the keyless works alone with the setting lever spring and re post a pic some one may recognise the layout and be able to pinpoint the maker. cheers1 point

-

That looks like an uphill task, what colour are the screw heads, If blue could be a chinese clone if so no documentation available and next to nothing in the way of parts either1 point

-

1 point

-

For years, in the ultrasonic, I used Naphtha (Hydrotreated light SBP3) bought from ebay, for cleaning, and 99.9% pure IPA for rinsing. As Nickelsilver says, it is not good for removing oil and grease. I switched to Elma WF Pro. Ok it stinks a bit, but cleans better than naphtha, and leaves a nice shine. I have continued to use IPA for final rinse - it does remove any residue from the WF Pro. I'm about to order some Elma Suprol Rinse. It's not cheap, but 2.5L will last me ages (I only service my own watches). It's designed for the job, and there's no worry about shellac.1 point

-

Are you planning to use IPA as your only cleaner? It's not a very good cleaner for grease and oil, at all. It's a very good absorber of water, if using water based cleaners, and must have a generally good effect as a rinse as multiple Swiss manufacturers spec it as the final rinse in machines running petroleum based cleaners. But it, on its own, for cleaning, isn't very good.1 point

-

1 point

-

Providing a compatible and long enough hairspring, attach the stud and build your balance complete, instal in the watch and try regulating on TG, you will face one of the following cases. 1- Oscilator runs fast with regulator arm closest to beat adjustor. Weigth needs to be added to the balance, which is impossible on anular balance. 2- Oscilator is regulable. proceed with regulating. 3-Oscilator runs slow with regulator arm farthest from the beat adjustor. Spring's length is to be shortened so you free to make an educated guess as to whereabouts to repin the springs stud, check the rate on tg to decide which direction you shoild inch towards to the right pining point. Do not cut the spring until you find the pining point. Mention was once made of the caspari effect by member praezis, which I do near the collet. Your further questions are welcomed.1 point

-

Thanks for that matey. I'm having a work day today. I'll catch you later I'll check that out, I do have some 1940s. Vintage. But i can check from now on if the balance can take a strong solvent.My gallon arrived today, I need to have a play now. I was planning on just using ipa from now on. Except the pallet of course.1 point

-

That is the unfortunate problem of any watch that sealed up what exactly is inside the case? Here's of for instance it's an electric watch similar but different. Obviously somebody had a bad watch repair day and you getting a lot of Miscellaneous bits and pieces unknown if you could assemble a running watch or not. I'm probably guessing not because if you could wouldn't be here in bits and pieces https://www.ebay.co.uk/itm/324769998473 Then of course there's the search of somebody who has a heck of a lot of movements it's in pieces etc. etc. These were very very popular movements at one time. https://www.ebay.co.uk/sch/i.html?_dmd=2&_dkr=1&iconV2Request=true&_ssn=vintagewatchpart&store_cat=0&store_name=vintagewatchpart&_oac=1&_nkw=esa1 point

-

1 point

-

Most probably it is a Camy brand name, but there are a number of "Tivoli" brands in the mikrolisk.de database https://www.mikrolisk.de/show.php?site=280&suchwort=tivoli More on Camy here -> https://chronopedia.club/Camy1 point

-

Yup I keep looking at yours HectorLooi, definitely Rado-esk. You've done it now, this old astromer wants something space age looking. I blame you as well1 point

-

I'm fancying something electric now. Omega made some, not for me though. I think I'd want something more low end at the moment, but I have seen some timex on ebay a month or so ago . I'm also going to blame ms60 for starting an electric watch craze.1 point

-

1 point

-

really should be better instructions out there and maybe they are I'm just not finding them. What makes the system interesting is there's lots of various adjustments more than a regular system. The regulator pins can be opened. Then you center with the stud so they hairspring is in the center. Then you close but not super tight need to be closed but not tight the needs to be a little breathing room. So that means you can open up the pins and have horrible isochronism because the pins are too far apart. Then don't worry about letting the power off just wait until watch runs down to around 200° hundred and 80 would be nice about their. Just had to expand the search in the computer found a PDF that will be helpful. seiko etachron.pdf1 point

-

1 point

-

1 point

-

1 point

-

I know I'm terrible at quoting paragraphs. I also reply to myself, I'm getting there slowly, very slowly lol. Stop picking on me , I'm not the only one that does it. And I also have a small phone and big fingers it's not my fault. Excuses excuses.1 point

-

Thanks for the intro @escabena welcome to the WRT forum! I'm also relatively new and I'm in the middle of my first service of an Elgin Grade 313 movement which has been stalled for a while as I was waiting for oil and a mainspring winder. Well, my oil arrived today and luckily I picked up an identical 2nd movement so as I disassemble that one it will help me remember how to re-assemble the first one! I've posted some shots of my watches here.1 point

-

I like the logo but also the red sweep second hand against the dark blue face and stainless hands. Classy!1 point

-

This curious little ladies pendant watch was manufactured long before transparent Swatches arrived on the scent. I'm going to guess this is from the late 1950s or early 1960s, but it is difficult to tell, as the caliber looks older, perhaps 1940s. There is quite a lot of wear on the acrylic and the plating, and since it is not shock protected, there is a pretty high chance the balance pivots may be damaged, but even if it proves unrepairable it is still quite an interesting piece.1 point

-

1 point

-

Thank you Just sharpening my screw driver which sounds strange when you say it out loud1 point

-

Electric watches have unique problems. First there is the electrical or electronic components. With a mechanical watch you look at things and see if they look good that doesn't necessarily mean they are good. But the electrical stuff you can't tell the condition that things are in. This basically ideally means you have to have test equipment. There's specific tests on quartz watches and I know that the Hamilton watches have tests that should be made to make sure things are right. Then all of the electric watches with gear trains have another problem. All of the gear trains have to be super free to rotate. Mechanical watch can plow right through a lot of dirt poor lubrication sticky lubrication at least up to a point. But a quartz watch for instance the wrong oil can action cause the watch to stop and definitely give you problems. The balance wheel electric watch that balance wheel doesn't have a lot of power if this watch is never been serviced the old sticky lubricant would be enough to cause you issues. More than likely your watch needs to be serviced. At least it runs for 10 seconds it's better than not running at all slats a good sign that's what's pointing at it probably just needs to serviced.1 point

-

1 point

-

I can understand what you say, but why are you using Spanish in an English forum?1 point

-

Hi djmcd, I use lighter fluid and a soft brush to clean the parts, and then 2 quick rinses in 99% alcohol, then air dry on a paper towel (the alcohol evaporates really quickly, leaving no residue behind). If needed, I soak the parts in lighter fluid for some time, but never in the alcohol (it will dissolve the shellac used on some parts). I need to get an ultrasonic cleaner too...1 point